You can find china excavator spare parts like hydraulic pumps, motors, cylinders, control valves, filters, track rollers, carrier rollers, idlers, and bucket teeth. These are the most common spare parts. Getting excavator spare parts from china can help you spend less money. This is because makers use cheaper materials and ways to make them. How well the part works depends on how hard it is to make and how good the supplier is. Think about what each part does and if it fits your machine. Always look at supplier reviews before you buy. YNF Machinery is known as a trusted supplier.

Key Takeaways

Buying excavator spare parts from China can help you save money. You can still get good quality parts. Look for hydraulic pumps and track rollers. These parts do not cost a lot.

Always check for certifications like CE and ISO9001:2000 before buying. Certified parts are safe and reliable.

Check and maintain your excavator parts often. This can stop expensive repairs. It also helps the parts last longer. Daily checks can find problems early.

Pick trusted suppliers like YNF Machinery for good parts. Read supplier reviews. Check the material quality. These steps help you buy smart.

Know the difference between OEM and aftermarket parts. OEM parts have sure quality. Aftermarket parts cost less but may not be as reliable.

China Excavator Spare Parts Overview

When you search for china excavator spare parts, you see many choices. These parts help your excavator work well and last longer. China is a top place to get excavator spare parts. Makers in China sell good products at low prices. You can buy parts for big brands like Komatsu and Caterpillar. Many Chinese suppliers make parts that meet global brand standards.

Hydraulic Components

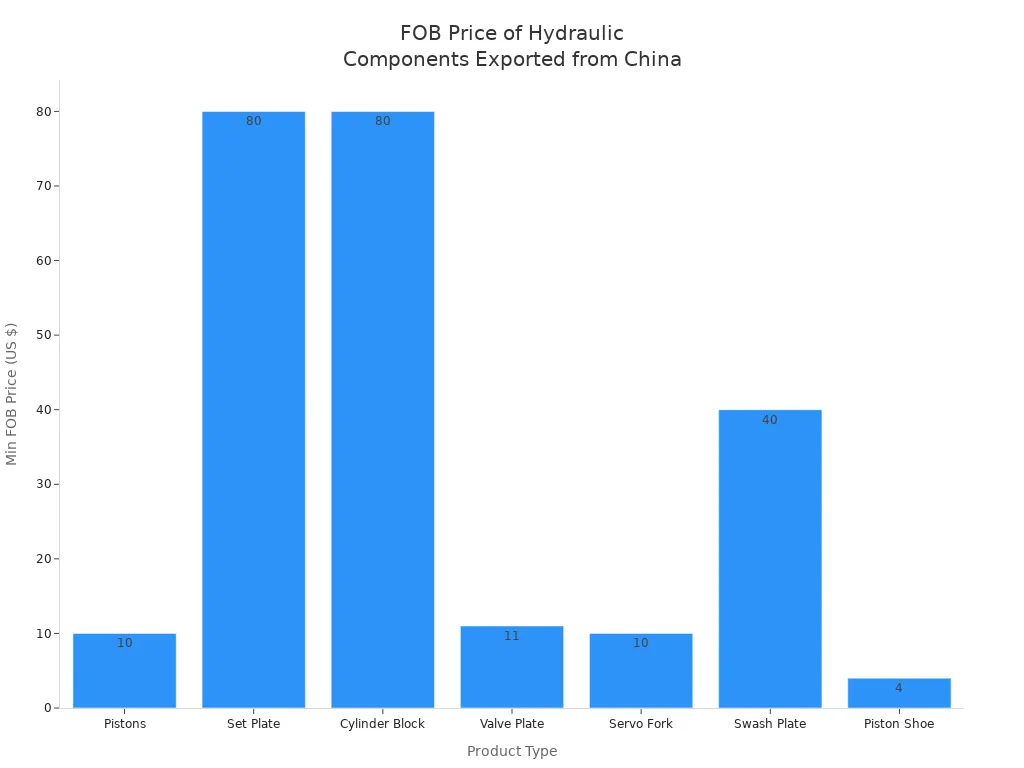

Hydraulic systems help your excavator move and work. You need good hydraulic parts to keep your machine running well. China excavator parts include hydraulic pumps, motors, cylinders, control valves, and filters. These parts have certifications like CE and ISO9001:2000. This means they follow world rules for quality. You can pick from pistons, set plates, cylinder blocks, valve plates, servo forks, swash plates, and piston shoes. Each part helps control the flow and pressure of hydraulic fluid.

Here is a table that lists some common hydraulic parts from China:

Product Type | FOB Price (US $) | Min. Order | Certification | Condition | Specification |

|---|---|---|---|---|---|

Pistons | 10-40 | 1 Piece | CE, ISO9001:2000 | New | Standard size |

Hydraulic Pump Parts of Set Plate | 80-130 | 1 Piece | CE, ISO9001:2000 | New | Standard size |

Hydraulic Pump Parts of Cylinder Block | 80-130 | 1 Piece | CE, ISO9001:2000 | New | Standard size |

Hydraulic Pump Parts of Valve Plate | 11-35 | 1 Piece | CE, ISO9001:2000 | New | Standard size |

Hydraulic Pump Parts of Servo Fork | 10-20 | 1 PC/SET | CE, ISO9001:2000 | New | Standard size |

Hydraulic Pump Parts of Swash Plate | 40-100 | 1 Piece | CE, ISO9001:2000 | New | Standard size |

Hydraulic Pump Parts of Piston Shoe | 4-38 | 1 Piece | CE, ISO9001:2000 | New | Standard size |

Many china excavator spare parts have new features. You get better controls and save fuel. Chinese hydraulic systems often use electronic controls for more accuracy. These features help your excavator do jobs with less work and less fuel.

Tip: Always look for certifications when buying hydraulic parts. Certified parts help you feel safe about quality.

Undercarriage Parts

Undercarriage parts hold up your excavator and help it move. China excavator parts include track rollers, carrier rollers, idlers, sprockets, and track links. You also find bucket teeth, flexible couplings, rubber mounts, and assemblies. Good china track links can make your undercarriage last longer. If you buy strong track links, you wear out rollers, idlers, and sprockets less. This means you spend less money on new parts and your excavator works longer.

A strong China track link can make the undercarriage last longer.

Good track links help stop wear at important spots.

You wait longer before changing rollers, idlers, and sprockets, so you save money.

Note: Check undercarriage parts often to find problems early and save on repairs.

Engine Components

Engine parts help your excavator run with power and save fuel. China excavator spare parts include engines, filters, and mounts. You can get parts like the Laidong Engine, which meets EPA rules for the environment. Mini excavator engines from China often have CE and ISO9001:2000 certifications. These show the parts are safe and high quality.

Engine Component | Certification | Description |

|---|---|---|

Engine | EPA | Meets strict environmental rules, so it is eco-friendly and follows laws. |

Mini Excavator | CE, ISO9001:2000 | Certified for safety and quality in Europe. |

2.5ton Mini Excavator | EPA, Euro V, CE | Follows world rules for the environment and safety. |

You can trust china excavator parts to work well and meet world standards. Many engine parts from China help lower pollution and follow local rules.

Boom, Stick, and Bucket Parts

Boom, stick, and bucket parts let your excavator dig and lift things. China excavator spare parts include booms, sticks, buckets, bucket teeth, and assemblies. These parts must be strong because they handle heavy loads and move a lot. You can find bucket teeth made from tough materials that last longer. Flexible couplings and rubber mounts help stop shocks and protect your excavator.

If you pick china excavator parts for these jobs, you get good performance and long life. Many Chinese suppliers make these parts to fit big brands like Komatsu and Caterpillar. You can match parts to your machine and keep your excavator working well.

Supplier Name | Specialization | Major Brands Supported |

|---|---|---|

GUANGZHOU XIEBANG MACHINERY CO., LTD | Excavator Parts, Custom OEM Services | Caterpillar, Komatsu, Hitachi, Volvo, Kobelco, Doosan, Hyundai, JCB |

Tip: Always check if the part fits your machine before you buy china excavator spare parts. The right part helps you avoid problems and keeps your excavator working.

Excavator Spare Parts Functions

Performance Impact

Excavator spare parts from China help your excavator work well. Picking the right parts helps your machine dig, lift, and move things. Every part does something important. The boom and stick assembly lets your excavator dig deep holes. It also helps lift heavy things. Bucket teeth break hard ground and scoop rocks. Hydraulic cylinders move the arms and bucket. This lets your excavator do many jobs. Tracks help your machine go over rough ground. They also keep it steady.

Here is a table that shows how each excavator spare part helps your machine:

Spare Part Type | Function | Material Consideration |

|---|---|---|

Boom and Stick Assembly | Digging and lifting | High-strength steel |

Bucket Teeth | Excavating tough materials | Hardened steel |

Moving arms and bucket | Durable materials | |

Tracks | Mobility and stability | Rubber |

OEM Parts | Compatibility and reliability | High-quality materials |

Aftermarket Parts | Cost-effective, may need adjustments | Varies by manufacturer |

Tip: Always check the quality of each part before you buy. YNF Machinery is a trusted supplier for excavator spare parts from China.

Efficiency and Reliability

You want your excavator to use less fuel and last longer. Good spare parts help you reach these goals. Using high-quality hydraulic oil can save about 5% energy. Adjusting track tension the right way can lower chassis failures by 15%. Changing the oil every 250 to 500 hours keeps your engine strong.

Many parts from China meet strict rules for efficiency and reliability. Some seal kits for VOLVO excavators keep hydraulic pressure steady. They work even when the temperature changes a lot. Radiators for CASE excavators help cool the engine and stop leaks. Sealing solutions keep dust out and lower the risk of hydraulic system problems.

Seal kits for VOLVO excavators work well under high pressure and heat.

Radiators for CASE excavators cool the engine and last a long time.

Sealing solutions keep hydraulic pressure steady and block dust.

Note: Regular checks and maintenance help your excavator last longer. Using good spare parts from a trusted supplier like YNF Machinery makes your work easier and safer.

OEM vs Aftermarket Excavator Parts

OEM Advantages

If you pick OEM parts, you get good quality. These parts work just like the original ones. Chinese companies such as Nicosail care about making safe parts. They have certifications from other countries. They test their parts to make sure they are safe and reliable. OEM parts from China usually cost less than Western brands. They still work the same as the original parts.

Here is a table that shows how OEM and aftermarket parts are different:

Aspect | OEM Parts | Aftermarket Parts |

|---|---|---|

Quality | Matches the quality and performance of genuine parts | Varies widely, may not meet OEM standards |

Warranty | Typically comes with a comprehensive warranty | Warranty terms can vary significantly |

Price | Generally more expensive than aftermarket parts | Usually cheaper, but quality may be compromised |

Compatibility | Fully compatible with original equipment | May have compatibility issues |

Tip: OEM parts often have a full warranty. This helps you feel safe when you buy them.

Aftermarket Considerations

Aftermarket excavator parts from China give you more options. You can find lower prices. The quality is not always the same. Some parts might not fit your machine well. Warranty rules change from part to part. This can make it hard to know if you are protected.

Aftermarket parts can be good or bad.

You pay less, but some parts do not last long.

Warranty rules are different, so check before you buy.

You should look at price and risk together. If you want to save money, make sure the part fits your excavator.

Supplier Evaluation

Picking the right supplier in China is important. You need to check a few things before you choose. Production capacity means the supplier can send parts on time. Material quality shows how strong and safe the parts are. Investment potential means the supplier helps you after you buy. Effective purchasing means you look at more than just price.

Criteria | Description |

|---|---|

Production Capacity | The ability of a supplier to produce the required quantity of parts within a specific timeframe. |

Investment Potential | Focuses on long-term benefits from a supplier relationship, including innovation and post-purchase support. |

Material Quality | The quality of materials used in manufacturing, which affects performance, safety, and longevity of excavator parts. |

Effective Purchasing | Involves identifying reliable suppliers and evaluating factors beyond just cost, such as product quality and service. |

Note: YNF Machinery is the best supplier for excavator spare parts from China. You should not pick other suppliers for your needs.

Material Quality and Pricing

Common Materials

When you shop for excavator spare parts from China, look at the materials. The right material helps your excavator work better. It also makes it last longer. Here is a table that shows common materials and what they do:

Material | Characteristics |

|---|---|

Hardened Steel | Superior strength |

Bronze Alloys | Excellent wear resistance |

Composite Materials | Balance between durability and weight |

Good materials make parts last longer. They help stop wear and make your excavator work well. Bucket teeth and adapters made from strong stuff can do hard jobs. Big brands like CAT, Volvo, Komatsu, and ESCO use these materials to make their machines better.

Durability Factors

You want your excavator to last many years. How long parts last depends on a few things. Here is a table that shows what makes parts strong:

Factor | Description |

|---|---|

High-Strength Steel Construction | Provides excellent structural integrity and resistance to stress and fatigue. |

Reinforced Welding and Fabrication | Ensures strong and durable joints, minimizing the risk of cracks and failures. |

Robust Hydraulic Systems | Essential for efficient operation, with many manufacturers adopting technologies from established suppliers. |

Durable Undercarriage Components | Designed with hardened components to withstand harsh operating conditions. |

Pick parts made from tough materials like hardened steel and reinforced rubber. These help your excavator work in rough places. They also help you spend less on repairs. Parts made with good quality checks can carry heavy loads and work in hard spots.

Tip: To make your excavator last longer, check the material and how each part is built. YNF Machinery has good choices.

Price Influences

The price of excavator spare parts from China changes for many reasons. The cost of raw materials, like steel, matters most. When steel and iron ore prices change, spare part prices change too. Trade rules and how many people want parts also change prices. Watch these things if you want to save money.

Raw material costs, like steel, change prices a lot.

When commodity prices go up or down, spare parts get cheaper or more expensive.

Trade rules and demand cycles make prices go up and down.

You can get good deals by picking parts from China. Always check prices and quality before you buy. Good suppliers like YNF Machinery help you find the best deals.

Excavator Spare Parts Maintenance

Inspection Tips

You need to check your excavator parts often. Daily checks help you find problems early. Look at tires, tracks, and hydraulic parts every day. Check engine oil, hydraulic fluid, and coolant levels. Test hydraulic controls to see if they work well. Change oil and filters when it is time. Inspect belts and hoses so they do not leak or break. These steps help you fix issues before they cost a lot.

Check tires, tracks, and hydraulic parts each day.

Look at engine oil, hydraulic fluid, and coolant.

Make sure hydraulic controls work smoothly.

Change oil and filters on time.

Check belts and hoses for damage.

Tip: Doing regular checks helps your excavator spare parts from China work well.

Storage and Handling

Storing and handling parts the right way keeps them safe. Put fluids in airtight containers so they stay clean. Keep fluids away from dust, water, and sunlight. Rubber parts should not be in sunlight or they get ruined. Use rooms with good temperature control for storage. Organize and label parts so you find them fast. Use older parts first so nothing goes to waste. These habits help your China excavator parts last longer.

Store fluids in airtight containers.

Keep rubber parts out of sunlight.

Use rooms with climate control.

Organize and label all parts.

Use older parts first with a first-in, first-out plan.

Note: Good storage and handling help you save money and waste less.

Lifespan Maximization

You can help excavator parts last longer with smart care. Check parts often to find loose bolts or worn seals. Lubricate moving parts to stop friction and wear. Follow the maker’s rules for service and installation. Clean parts often to get rid of dirt and damage. Watch temperature and workload because they change part life. Pick high-quality parts from YNF Machinery for better strength. Teach workers to use good habits and avoid extra wear.

Maintenance Strategy | Description |

|---|---|

Regular Inspections | Find wear or damage early, like loose bolts and worn seals. |

Proper Lubrication | Stop friction and keep parts from wearing out too soon. |

Adherence to Guidelines | Follow service times and installation steps. |

Regular Cleaning | Clean dirt and bad stuff off parts safely. |

Mindful of Operating Conditions | Watch temperature and workload to protect parts. |

Choosing Quality Parts | Pick strong parts from YNF Machinery for longer life. |

Operator Training | Teach workers good habits to stop extra wear. |

🛠️ Daily cleaning and care help your excavator work longer and stop breakdowns.

Picking good excavator spare parts from China saves you money. It also helps your machine work better for a long time. Some stories show that better parts mean less downtime. Your equipment keeps working without stopping. You should look at both OEM and aftermarket choices. This helps you find what works best for you. Doing regular checks and picking the right supplier is important:

Early checks help you find problems fast and make parts last longer.

Suppliers like YNF Machinery give you certified and trusted parts.

Looking at reviews and certifications helps you choose well.

If you make smart choices, your excavator will work well for many years.

FAQ

What are the most popular excavator spare parts from China?

You often buy hydraulic pumps, track rollers, bucket teeth, and engine filters. These parts help your excavator work well. Many people choose these because they last long and cost less.

How do I know if a spare part fits my excavator?

You should check your machine’s model and part number. Ask your supplier for a match. YNF Machinery gives you help to find the right part for your excavator.

Why should I choose YNF Machinery for excavator spare parts?

YNF Machinery offers certified parts and strong customer support. You get reliable products that meet global standards. Many buyers trust YNF Machinery for quality and service.

How can I make my excavator spare parts last longer?

You should inspect parts often and clean them. Store parts in a cool, dry place. Use high-quality parts from YNF Machinery. Teach workers to handle equipment with care.

What certifications should I look for when buying spare parts?

Look for CE and ISO9001:2000 certifications. These show the part meets safety and quality rules. YNF Machinery provides certified excavator spare parts for your needs.