Choosing the right parts for your excavator is crucial for maintaining its efficiency and performance. When you select compatible and high-quality case excavator parts, you ensure that your machine operates smoothly and safely. Regular maintenance with the right components reduces downtime and enhances the longevity of your equipment. Case, a reputable brand in the construction industry, offers reliable parts that fit perfectly with your machinery. This selection not only improves safety but also leads to better savings and greener operations, making it an essential aspect of excavator maintenance.

Key Takeaways

Choosing the right Case excavator parts is essential for maintaining efficiency and performance, reducing downtime and repair costs.

Always identify your excavator’s model and serial number to ensure compatibility when ordering parts, preventing costly mistakes.

Regularly inspect common wear components like hydraulic systems and engine parts to catch issues early and maintain optimal performance.

Consider both OEM and aftermarket parts; OEM parts guarantee a perfect fit, while aftermarket options can offer cost savings without sacrificing quality.

Utilize compatibility charts and consult with experts to ensure you select the right parts for your specific excavator model.

Budget wisely by estimating costs and planning for future replacements, allowing for proactive maintenance and potential savings.

Purchase from reputable sources like authorized dealers or trusted suppliers like YNF Machinery to ensure quality and reliability in your excavator parts.

Understanding Your Excavator Model

When it comes to maintaining your excavator, understanding your specific model is crucial. Each model has unique features and specifications that require precise attention. Knowing these details ensures you choose the right parts, enhancing the performance and longevity of your machine.

Importance of Model and Serial Number

How to Locate Model and Serial Numbers

Finding the model and serial numbers on your excavator is the first step in identifying the correct parts. Typically, these numbers are located on a metal plate attached to the frame of the machine. You might find them near the cab or on the engine block. Always check your user manual for exact locations. Having these numbers at hand helps you avoid mistakes when ordering parts.

Why Accurate Identification Matters

Accurate identification of your excavator’s model and serial number is vital. It ensures that you purchase parts that fit perfectly and function correctly. Incorrect parts can lead to poor performance or even damage to your machine. By using the right components, you maintain the efficiency and safety of your excavator, reducing downtime and repair costs.

Case Brand Overview

History and Reputation of Case

Case Construction Equipment has a rich history of over a century in the industry. Known for their dedication to quality, Case has fine-tuned their machines to deliver high performance and productivity. Their commitment to improving productivity and simplifying maintenance has made them a trusted name worldwide. Case’s dealer network provides world-class equipment and support, ensuring that you receive genuine parts and excellent service.

Key Features of Case Excavators

Case excavators stand out due to their robust construction and advanced technology. Each new CASE E Series excavator comes with features like the CASE ProCare, which includes a three-year telematics subscription and a comprehensive warranty. These machines are engineered to withstand heavy work and harsh environments, ensuring reliability and durability. With a focus on reducing the total cost of ownership, Case excavators offer efficient operation and easy maintenance, making them a preferred choice for many operators.

Identifying the Needed Excavator Parts

Understanding which excavator parts require regular attention and potential replacement is vital for maintaining optimal performance. By focusing on common components and recognizing signs of wear, you can ensure your excavator operates efficiently and safely.

Common Parts Requiring Replacement

Excavators, like any heavy machinery, have parts that frequently need replacement due to wear and tear. Identifying these parts early can prevent unexpected breakdowns and costly repairs.

Hydraulic Components

Hydraulic systems are the lifeblood of your excavator, powering everything from the arm to the bucket. Over time, hydraulic components such as pumps, hoses, and seals can wear out. Regular inspection and timely replacement of these parts are crucial. Hydraulic oil, in particular, should be checked and replaced as needed to maintain system efficiency. Keeping a stock of hydraulic components ensures that you can address issues promptly, minimizing downtime.

Excavator Engine Parts

The engine is the heart of your excavator, and its components require regular maintenance. Common engine parts that may need replacement include filters, belts, and injectors. Ensuring these parts are in good condition helps maintain the engine’s performance and extends its lifespan. Investing in high-quality new parts or remanufactured parts can enhance reliability and reduce the risk of engine failure.

Signs of Wear and Tear

Recognizing the signs of wear and tear on your excavator parts can help you address issues before they escalate. Regular checks and maintenance are key to keeping your machine in top condition.

Visual Inspection Tips

Conducting a visual inspection of your excavator is a straightforward way to identify potential problems. Look for signs of leaks, cracks, or unusual wear on hydraulic hoses and seals. Check the condition of attachments and ensure they are securely fastened. Inspect the engine for any signs of oil leaks or worn belts. Regular visual inspections can help you catch issues early, allowing for timely replacement of worn parts.

Performance Indicators

Monitoring the performance of your excavator can also reveal when parts need attention. If you notice a decrease in hydraulic power or unusual noises from the engine, it may indicate that components require replacement. Pay attention to how the excavator attachments function; any sluggishness or difficulty in operation could signal a need for new parts. Keeping track of these performance indicators helps you maintain the efficiency and safety of your machine.

Compatibility and Specifications for Case Excavator Parts

Ensuring the right fit for your excavator parts is crucial for maintaining optimal performance. Understanding the specifications and compatibility of the parts you choose can make a significant difference in how well your machine operates.

Checking Part Specifications

When selecting case excavator parts, always check the specifications provided by the manufacturer. These guidelines help you understand the exact requirements for your machine.

Manufacturer Guidelines

Manufacturers provide detailed guidelines for each part. These guidelines include information about size, material, and function. By following these instructions, you ensure that the parts you select will work efficiently with your excavator. For example, if you need a hydraulic component, the manufacturer’s specifications will guide you in choosing the correct size and type, ensuring seamless integration with your machine’s system.

Cross-Referencing Part Numbers

Cross-referencing part numbers is another effective way to verify compatibility. Each part has a unique number that corresponds to specific models and functions. By matching these numbers with your excavator’s requirements, you can confidently select the right parts. This process reduces the risk of errors and ensures that the parts will fit and function as intended.

Ensuring Model Compatibility

Model compatibility is essential when choosing excavator parts. Different models have unique features and specifications, making it important to select parts that match your machine’s design.

Using Compatibility Charts

Compatibility charts are valuable tools for identifying the right parts for your excavator. These charts list various models and the corresponding parts that fit them. By consulting these charts, you can quickly determine which parts are suitable for your machine. For instance, the CASE E Series includes models like the CX260E, CX220E, and CX365E SR, each with different net horsepower and operating weight. Compatibility charts help you navigate these differences and make informed decisions.

Consulting with Experts

When in doubt, consulting with experts can provide additional assurance. Professionals with experience in excavator maintenance can offer insights into part selection and compatibility. They can help you understand the nuances of your machine’s design and recommend the best parts for your needs. This expert advice can be invaluable, especially when dealing with complex systems like hydraulic components.

By focusing on compatibility and specifications, you ensure that your excavator operates at peak performance. This careful selection process not only enhances efficiency but also extends the lifespan of your machine.

Quality and Brand Considerations

When selecting excavator parts, you must consider both quality and brand. These factors significantly impact the performance and longevity of your machinery. Understanding the differences between OEM parts and aftermarket parts can help you make informed decisions.

OEM vs. Aftermarket Excavator Parts

Choosing between OEM parts and aftermarket parts involves weighing their respective advantages. Each option offers unique benefits that cater to different needs and preferences.

Advantages of OEM Parts

OEM parts, or Original Equipment Manufacturer parts, are designed specifically for your excavator model. They ensure a perfect fit and optimal performance. These parts replicate the original components, allowing for seamless integration without any modifications. Various experts highlight that OEM parts provide cost-effectiveness through their durability and longevity. You can rely on their high-quality materials to keep your machinery operating as intended. Additionally, OEM parts often come with warranties, offering peace of mind and protection against defects.

“New OEM parts are cost-effective by way of their longevity. Their high-quality materials and build will ensure your machinery continues operating as intended.” – Various Experts

Benefits of Aftermarket Options

Aftermarket parts present a cost-effective alternative to OEM parts. They are typically sold at lower prices, providing significant savings without sacrificing much in quality. Some aftermarket parts undergo rigorous testing to meet or exceed OEM standards, ensuring reliable performance even under extreme conditions. These parts offer flexibility in availability, reducing downtime and enhancing efficiency. However, it’s crucial to purchase from reputable dealers to ensure compatibility and quality.

“Aftermarket excavator parts can indeed be a cost-effective solution for many equipment owners. These parts are typically sold at lower rates than original equipment manufacturer (OEM) parts, which translates into huge savings without sacrificing much in quality.” – Various Experts

Evaluating Part Quality

Assessing the quality of excavator parts is essential for maintaining your machine’s performance. Focus on material durability and the support offered by the supplier.

Material and Durability

The materials used in manufacturing excavator parts play a crucial role in their durability. High-quality materials ensure that parts withstand the rigors of heavy-duty use, such as hydraulic components. Durable parts reduce the frequency of replacements, saving you time and money in the long run. When evaluating new parts, consider their ability to endure harsh conditions and maintain performance over time.

Warranty and Support

A comprehensive warranty indicates the manufacturer’s confidence in their product’s quality. It provides assurance that you can rely on the parts for consistent performance. Additionally, consider the level of support offered by the supplier. Access to technical assistance can be invaluable during installation and maintenance. Reliable support ensures that you can address any issues promptly, minimizing downtime and maximizing efficiency.

By carefully considering quality and brand, you can select excavator parts that enhance your machine’s performance and longevity. Whether you choose OEM or aftermarket options, prioritize durability and support to ensure optimal results.

Cost and Budgeting for Excavator Parts

Managing costs effectively is crucial when purchasing excavator parts. By planning and budgeting wisely, you can ensure that your machine remains in top condition without overspending.

Budgeting for Excavator Parts

Estimating Costs

To start, you need to estimate the costs of the parts required for your excavator. Consider the frequency of replacements and the specific components that often need attention. For instance, hydraulic components and engine parts are common areas where wear occurs. By understanding these needs, you can allocate funds appropriately. Research prices from various suppliers to get a sense of the market rates. This approach helps you avoid unexpected expenses and ensures that you have the necessary resources for timely maintenance.

Planning for Future Replacements

Planning for future replacements is an essential part of budgeting. Create a schedule based on the expected lifespan of different parts. Regular maintenance checks will help you identify when parts are nearing the end of their service life. By anticipating these needs, you can set aside funds in advance. This proactive strategy minimizes downtime and keeps your excavator running smoothly. It also allows you to take advantage of bulk purchasing discounts, further reducing costs.

Finding Cost-Effective Solutions

Discounts and Promotions

Look for discounts and promotions when purchasing excavator parts. Many suppliers offer seasonal sales or bulk purchase discounts. These opportunities can significantly reduce your expenses. Keep an eye on supplier websites and sign up for newsletters to stay informed about upcoming deals. By taking advantage of these offers, you can maintain your excavator without breaking the bank.

Balancing Cost and Quality

While it’s important to save money, you must also consider the quality of the parts you purchase. Aftermarket parts can be a cost-effective solution for many equipment owners. They often provide similar performance to OEM parts at a lower price. However, you should ensure that these parts meet high-quality standards. Read reviews and consult with experts to verify their reliability. By balancing cost and quality, you can maintain your excavator’s performance and longevity without overspending.

“Aftermarket excavator parts can indeed be a cost-effective solution for many equipment owners. These parts are typically sold at lower rates than original equipment manufacturer (OEM) parts, which translates into huge savings without sacrificing much in quality.” – Various Experts

By carefully managing your budget and exploring cost-effective options, you can keep your excavator in excellent condition. This approach not only saves money but also ensures that your machine operates efficiently and reliably.

Where to Buy Case Excavator Parts

Finding the right source for your excavator parts ensures you get quality components that fit perfectly. You have several options when it comes to purchasing these parts, each with its own advantages.

Reputable Sources for Parts

Authorized Dealers

Authorized dealers provide a reliable option for purchasing excavator parts. They offer genuine parts that meet the manufacturer’s specifications. When you buy from an authorized dealer, you ensure that the parts are authentic and compatible with your machine. These dealers often provide excellent customer service and technical support, helping you make informed decisions about the parts you need.

Online Marketplaces

Online marketplaces offer a convenient way to shop for excavator parts. You can compare prices and read reviews from other customers. This helps you find the best deals and ensures you choose high-quality parts. However, it’s important to verify the credibility of the sellers. Look for those with positive ratings and a history of selling genuine parts. This approach minimizes the risk of purchasing counterfeit or substandard components.

Recommended Supplier: YNF Machinery

Overview of YNF Machinery

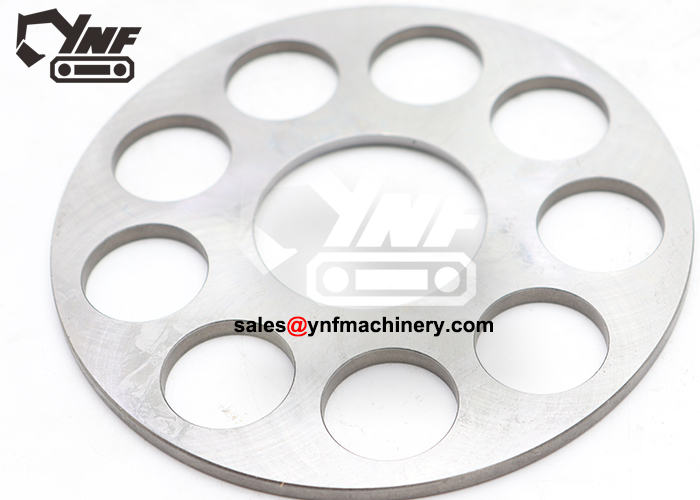

YNF Machinery stands out as a trusted supplier of excavator parts. With over 35 years of experience, they have built a reputation for providing high-quality components at competitive prices. YNF Machinery specializes in a wide range of parts, including rubber couplings, hydraulic components, and engine parts. Their commitment to quality ensures that you receive durable and reliable products.

Benefits of Purchasing from YNF

Purchasing from YNF Machinery offers several benefits. They provide a comprehensive selection of parts, ensuring you find exactly what you need for your excavator. Their products undergo rigorous quality inspections, guaranteeing performance and longevity. YNF Machinery also offers excellent customer support, assisting you with any questions or concerns. Additionally, their competitive pricing and fast shipping make them a cost-effective choice for maintaining your equipment.

By choosing reputable sources like authorized dealers and YNF Machinery, you ensure that your excavator operates efficiently and reliably. This careful selection of suppliers not only enhances the performance of your machine but also extends its lifespan.

Choosing the right case excavator parts is essential for maintaining your machine’s efficiency and performance. Prioritize quality and compatibility to ensure your excavator operates smoothly and reliably. High-quality parts reduce wear and tear, leading to lower maintenance costs and increased equipment longevity. Regular maintenance with the right components enhances efficiency and minimizes downtime. Consider YNF Machinery as a reliable supplier for your excavator needs. Their commitment to quality ensures you receive durable parts that fit perfectly, supporting your machine’s optimal performance.

FAQ

What are the most common excavator parts that need replacement?

Excavators, like any heavy machinery, have parts that frequently wear out. Common components include hydraulic hoses, seals, and engine parts such as filters and belts. Regular inspection helps you identify these parts early, preventing unexpected breakdowns.

How can I ensure I am purchasing the correct parts for my excavator?

To ensure compatibility, always check your excavator’s model and serial number. These details help you find the right parts. You can also consult compatibility charts or speak with experts to confirm your selection.

Are OEM parts better than aftermarket parts for excavators?

OEM parts offer a perfect fit and optimal performance because they are designed specifically for your excavator model. They often come with warranties, providing peace of mind. However, aftermarket parts can be a cost-effective alternative if they meet high-quality standards.

Where can I buy reliable excavator parts?

You have several options for purchasing reliable parts. Authorized dealers provide genuine components that meet manufacturer specifications. Online marketplaces offer convenience, but you should verify seller credibility. YNF Machinery is a recommended supplier known for high-quality parts and excellent customer support.

How do I know when to replace excavator parts?

Regular maintenance checks help you identify when parts need replacement. Look for signs of wear, such as leaks or unusual noises. Monitoring performance indicators, like reduced hydraulic power, can also signal the need for new parts.

Does YNF Machinery stock all types of excavator parts?

YNF Machinery offers a comprehensive selection of excavator parts, including hydraulic components and engine parts. Their extensive inventory ensures you find the parts you need for various models and specifications.

What should I consider when budgeting for excavator parts?

Estimate costs by considering the frequency of replacements and specific components that often need attention. Plan for future replacements by creating a schedule based on part lifespan. Look for discounts and promotions to reduce expenses.

Can I get technical support when purchasing excavator parts?

Yes, many suppliers, including YNF Machinery, offer technical support. This assistance can be invaluable during installation and maintenance, ensuring you address any issues promptly.