High-quality parts play a vital role in maintaining your excavator’s performance and minimizing downtime. Poor-quality track motor parts often lead to excessive wear on undercarriage components like tracks, rollers, and idlers. This wear increases maintenance costs and disrupts operations. Choosing compatible excavator track motor parts ensures your machine operates efficiently and avoids unnecessary repairs. When you prioritize quality and compatibility, you protect your investment and keep your heavy equipment running smoothly. Making informed decisions about excavator spare parts helps you avoid the risks associated with substandard components.

Key Takeaways

-

Pick track motor parts that fit your machine’s needs.

-

Buy strong materials like hardened steel for longer-lasting parts.

-

Check for warranties and support to protect your money.

-

Inspect often to find problems early and avoid big repairs.

-

Read reviews and check suppliers to avoid fake parts.

Key Factors to Consider When Choosing Excavator Track Motor Parts

Ensuring Compatibility with Your Excavator

Matching parts to your excavator’s model and specifications

Choosing the right excavator track motor parts starts with understanding your machine’s specifications. Factors like weight, size, and intended applications determine compatibility. For example, heavier excavators require track motors with higher torque output to handle demanding tasks. Additionally, the type of track motor—hydraulic or electric—affects performance and suitability for specific projects. Always consider the terrain and conditions where your excavator operates. Slopes, soil types, and other environmental factors influence the effectiveness of the parts you select.

Importance of manufacturer recommendations and part numbers

Manufacturer recommendations and part numbers simplify the process of finding compatible replacement parts. These details ensure that the parts align with your excavator’s design and performance requirements. Ignoring these recommendations can lead to mismatched components, reducing efficiency and increasing wear on other excavator parts. Always consult the excavator size guide or the equipment manual to confirm compatibility.

Evaluating Quality and Durability

How material quality impacts performance and longevity

High-quality parts are essential for maintaining your excavator’s durability and performance. Materials like hardened steel and heat-treated alloys enhance the strength and lifespan of components. For instance, bottom track rollers made from hardened steel reduce wear and tear, while forged sprockets extend track life. Using durable materials minimizes the need for frequent replacements, saving you time and money.

|

Component |

Material Used |

Benefits |

|---|---|---|

|

Bottom Track Rollers |

Hardened Steel |

Enhanced durability, reduced wear and tear |

|

Sprockets |

Forged and heat-treated |

Superior material strength, extended track life |

|

Ground Engaging Tools |

Tough materials |

Enhanced productivity, lower operating costs |

Certifications and reviews as indicators of high-quality parts

Certified excavator parts, such as those with ISO or CE certifications, guarantee reliability. These certifications indicate that the parts have undergone rigorous testing and meet industry standards. Customer reviews also provide valuable insights into the quality and compatibility of replacement parts. Look for suppliers with positive feedback to ensure you receive high-quality parts that perform well under various conditions.

Balancing Cost and Value

Finding affordable options without compromising quality

Balancing cost and value involves finding excavator spare parts that meet your budget without sacrificing quality. While aftermarket parts often cost less than OEM options, ensure they meet the same performance standards. Investing in high-quality parts reduces long-term expenses by minimizing repairs and downtime.

Accounting for hidden costs like shipping and installation

When comparing prices, consider hidden costs such as shipping fees and installation charges. Some suppliers offer competitive pricing but may have high shipping costs that affect the overall value. Additionally, complex installations may require professional assistance, adding to the expense. Evaluate these factors to make an informed decision when choosing the right excavator parts.

Warranty and Support Considerations

The value of warranty coverage for peace of mind

A warranty provides you with confidence when purchasing excavator track motor parts. It acts as a safety net, ensuring that you can replace or repair defective parts without additional costs. High-quality suppliers often offer warranties that cover a specific period or usage limit. This coverage protects your investment and reduces the risk of unexpected expenses.

When evaluating warranties, pay attention to the terms and conditions. Some warranties only cover manufacturing defects, while others may include wear and tear under normal usage. A comprehensive warranty reflects the supplier’s confidence in their product quality. For example, YNF Machinery offers reliable warranty options, giving you peace of mind when sourcing parts for your excavator.

Tip: Always keep a copy of your warranty documentation. It simplifies the claims process if you encounter issues with your parts.

Assessing customer support for technical assistance

Reliable customer support ensures you receive help when you need it most. Whether you have questions about part compatibility or installation, a responsive support team can save you time and frustration. Look for suppliers that provide multiple communication channels, such as email, phone, and live chat.

A good supplier will also assist you in selecting the right parts for your excavator. For instance, YNF Machinery offers expert guidance to help you match parts to your machine’s specifications. This level of support minimizes errors and ensures smooth operations.

Note: Test a supplier’s responsiveness by reaching out with a question before making a purchase. Quick and helpful replies indicate strong customer service.

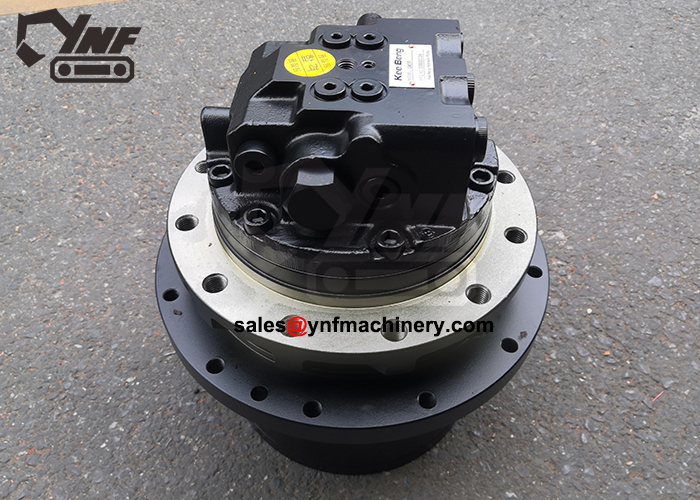

Exploring Types of Excavator Track Motor Parts

OEM vs. Aftermarket Excavator Parts

Key differences and benefits of OEM parts

OEM parts, or Original Equipment Manufacturer parts, are produced by the same company that built your excavator. These parts guarantee compatibility and seamless integration with your machine. They also come with comprehensive warranties, ensuring peace of mind. OEM parts maintain high standards of quality and durability, making them a reliable choice for heavy equipment parts. However, they are often more expensive due to their brand recognition and quality assurance.

Advantages and considerations for aftermarket parts

Aftermarket parts offer a cost-effective alternative to OEM parts. These replacement parts are manufactured by third-party companies and are generally less expensive. However, their quality can vary depending on the manufacturer. Researching the reputation of the supplier is essential to ensure performance and compatibility. While aftermarket parts may not always match the precision of OEM parts, they can still provide excellent value when sourced from trusted suppliers.

New vs. Remanufactured Parts

When to choose new parts for optimal performance

New excavator parts are ideal when you need maximum performance and reliability. They are free from wear and tear, ensuring optimal functionality. New parts are especially beneficial for critical components like track motors, where durability and efficiency are paramount. For demanding applications or when working in harsh conditions, new parts provide the best assurance of long-term performance.

Benefits of remanufactured parts for cost savings

Remanufactured parts offer significant cost savings compared to new ones. These parts are refurbished to meet original specifications, making them a sustainable and budget-friendly option. They also reduce environmental impact by reusing materials. For non-critical applications or when managing costs, remanufactured parts provide a practical solution without compromising quality.

|

Advantage |

Description |

|---|---|

|

Cost Reduction |

Remanufactured parts are significantly less expensive than new ones. |

|

Environmental Impact |

Remanufacturing uses fewer resources than producing new parts, promoting sustainability. |

Genuine vs. Counterfeit Heavy Equipment Parts

Identifying counterfeit parts and their risks

Counterfeit parts pose serious risks to your excavator. They often lack the precision and quality of genuine parts, leading to reduced performance and increased downtime. These parts can also compromise safety, causing accidents and long-term damage to your equipment. Identifying counterfeit parts involves examining packaging, inspecting workmanship, and verifying documentation. Always compare part numbers with the excavator size guide to ensure compatibility.

Ensuring authenticity through trusted suppliers like YNF Machinery

Purchasing from trusted suppliers like YNF Machinery ensures you receive genuine, high-quality parts. YNF Machinery provides proper documentation and certifications, guaranteeing authenticity. Their rigorous quality inspections and customer support make them a reliable choice for excavator spare parts. By choosing a reputable supplier, you protect your investment and maintain the efficiency of your equipment.

How to Evaluate Suppliers for Excavator Track Motor Parts

Reputation and Customer Reviews

Importance of supplier experience in the heavy equipment industry

A supplier’s reputation reflects their reliability and expertise in providing excavator parts. Experienced suppliers often have a strong market presence and a proven track record in delivering high-quality replacement parts. When evaluating a supplier, consider key indicators of their reputation:

|

Indicator |

Description |

|---|---|

|

Market Share |

Indicates reliability and popularity; larger market share often means robust operational capacities. |

|

Global Presence |

Ensures consistent service and equipment availability across regions, crucial for international projects. |

|

Safety Standards |

Compliance with local and international safety regulations is essential for protecting users and worksites. |

|

Sustainability Practices |

Commitment to eco-friendly solutions and lower emissions is vital in today’s market. |

|

Innovation Capabilities |

Investment in R&D to meet current and future demands, including automation and advanced materials. |

Suppliers with these attributes are more likely to provide durable and compatible excavator spare parts, ensuring optimal performance for your equipment.

Using online reviews and testimonials to assess reliability

Customer reviews offer valuable insights into a supplier’s reliability. Positive reviews often indicate consistent delivery of high-quality excavator parts and excellent service. Look for comments about delivery speed and part availability, as these factors directly impact your maintenance schedule. Be cautious of red flags like complaints about delayed shipments or poor-quality used parts. These issues can lead to increased downtime and higher costs.

Tip: Check multiple review platforms to get a well-rounded view of a supplier’s reputation.

Warranty and Return Policies

Key features of a trustworthy supplier’s warranty terms

A reliable warranty reflects a supplier’s confidence in their products. Look for warranties that cover manufacturing defects and normal wear under specified conditions. Comprehensive coverage ensures you can replace faulty parts without additional expenses. Suppliers offering warranties for both OEM parts and aftermarket parts demonstrate their commitment to quality and compatibility.

Flexible return policies as a sign of customer focus

Flexible return policies enhance your purchasing experience. They allow you to return items within a reasonable timeframe, accommodating your busy schedule. A customer-friendly return process boosts confidence and fosters long-term relationships.

-

A seamless return process reduces disputes.

-

Tailored policies show the supplier’s understanding of customer needs.

-

Flexible returns improve satisfaction and encourage repeat business.

Customer Service Excellence

Responsiveness and availability of technical support

Access to knowledgeable technical support is invaluable when dealing with complex machinery. A reliable supplier provides expert assistance to help you select the right replacement parts. This support ensures the parts function properly within your excavator, reducing the risk of errors.

Assistance with part selection and installation

Suppliers offering guidance during part selection simplify the purchasing process. For example, YNF Machinery provides expert advice to help you choose compatible excavator track motor parts. This level of support ensures smooth installation and optimal performance, saving you time and effort.

Note: Test a supplier’s responsiveness by contacting their support team before making a purchase. Quick replies indicate strong customer service.

Maintenance Tips for Extending the Life of Excavator Track Motor Parts

Regular Inspections and Preventive Maintenance

Identifying wear and tear before it leads to failure

Regular inspections are essential for catching problems early. They help you identify minor issues before they escalate into costly repairs. For example:

-

Routine checks can reveal worn-out components, allowing you to replace them before they fail.

-

Preventive maintenance ensures efficient operation, reducing breakdown risks and enhancing productivity.

-

Addressing small problems early can prevent complete component failures, saving you money.

By incorporating planned maintenance kits into your routine, you can streamline these inspections and ensure all necessary tools and replacement parts are readily available.

Tools and techniques for effective inspections

Effective inspections require the right tools and techniques. Start by maintaining proper track tension to prevent excessive wear. Regularly clean the undercarriage to remove dirt and debris. Use these tips:

-

Check rollers for debris and ensure they rotate smoothly.

-

Inspect all undercarriage components for signs of wear.

-

Clean soil, clay, and ice from parts to avoid damage.

Tip: “Track tension must be checked daily or when underfoot conditions change. Mud packing in sprocket segments can alter chain tension and accelerate wear.”

Proper Usage and Operation

Avoiding overloading and misuse of the excavator

Overloading your excavator beyond its design limits increases wear and tear. Misusing work modes, such as running in the highest mode unnecessarily, leads to higher fuel consumption and costs. Avoid these common mistakes:

-

Neglecting pre-operational safety checks.

-

Ignoring environmental conditions that affect operation.

-

Inadequate operator training, which results in improper use.

Proper usage minimizes stress on components and extends their lifespan.

Adhering to manufacturer guidelines for optimal performance

Manufacturer guidelines provide specifications that align with your excavator’s operational demands. Following these recommendations ensures compatibility and enhances performance. For example, adhering to these guidelines helps you select high-quality replacement parts and maintain the durability of your machine.

Cleaning and Lubrication Practices

Keeping parts clean to prevent damage and wear

Cleaning your excavator regularly prevents damage caused by dirt and debris. Start with a rinse to remove loose particles, then use gentle cleaning agents to avoid corrosion. Pay special attention to the undercarriage, as it accumulates the most debris.

-

Clean attachments separately for thorough maintenance.

-

Use soft brushes and cloths to avoid scratching surfaces.

-

Dry all parts thoroughly to prevent rust.

Daily cleaning and weekly washing ensure your machine operates smoothly without unexpected breakdowns.

Recommended products for lubrication and cleaning

Lubrication reduces friction and extends the life of moving parts. Regularly lubricate support wheels and rollers to minimize wear. Check the drive system oil and clean the filter to maintain smooth operation. Use these best practices:

-

Apply rust-preventive lubricant to exposed metal surfaces.

-

Use mild detergents or specialized cleaning products recommended by the manufacturer.

-

Pressure washers or hoses with jet nozzles work well for cleaning the undercarriage.

Incorporating these practices into your routine will maximize the lifespan of your excavator’s track motor parts.

Scheduled Replacements and Maintenance Logs

Knowing when to replace parts to avoid unexpected breakdowns

Timely replacement of worn-out components is essential for keeping your excavator in peak condition. Ignoring signs of wear can lead to unexpected breakdowns, which disrupt operations and increase repair costs. Pay attention to performance changes, such as reduced efficiency or unusual noises, as these often indicate the need for new replacement parts. For example, track motors showing signs of sluggish movement or overheating may require immediate attention.

Using planned maintenance kits simplifies the process of scheduling replacements. These kits include essential components and tools, ensuring you have everything needed for routine maintenance. By replacing parts before they fail, you minimize downtime and extend the life of your equipment. Regularly consulting your excavator’s manual helps you determine the recommended intervals for part replacements, ensuring optimal performance.

Tip: Keep a checklist of critical components, such as track motors and rollers, to monitor their condition during inspections.

Benefits of maintaining a detailed maintenance log

A detailed maintenance log serves as a valuable tool for managing your excavator’s upkeep. It helps you track the history of maintenance activities, making it easier to identify recurring issues. This record ensures compliance with warranty requirements, protecting you from unexpected repair costs.

-

Maintenance logs reveal patterns in equipment performance, helping you predict potential issues.

-

They aid in planning preventive maintenance tasks, reducing the risk of sudden failures.

-

Logs provide a clear timeline of part replacements, ensuring you stay on schedule.

Incorporating planned maintenance kits into your routine further enhances the effectiveness of your maintenance strategy. These kits streamline the replacement process, allowing you to address wear and tear promptly. By maintaining a log, you gain insights into your equipment’s needs, ensuring long-term reliability and efficiency.

Note: Digital maintenance logs offer added convenience, allowing you to access records quickly and set reminders for upcoming tasks.

Choosing the right excavator parts ensures your machine operates efficiently and avoids costly downtime. High-quality excavator track motor parts improve performance and extend the life of your equipment. Always prioritize compatibility by matching parts to your excavator’s specifications. Reliable suppliers like YNF Machinery simplify this process by offering genuine parts and excellent customer support. Regular maintenance and inspections, combined with informed purchasing decisions, keep your excavator running smoothly. Take time to research customer reviews and select parts that meet your needs. This approach protects your investment and ensures long-term reliability.

FAQ

What are the signs that my excavator track motor parts need replacement?

Look for reduced performance, unusual noises, or overheating. Sluggish movement and visible wear on components also indicate the need for replacement. Regular inspections help you catch these signs early.

Can I use aftermarket parts instead of OEM parts?

Yes, aftermarket parts can be a cost-effective alternative. Ensure they meet your excavator’s specifications and come from a trusted supplier like YNF Machinery. Research reviews and certifications to confirm quality.

How do I verify the authenticity of excavator parts?

Check for proper documentation, certifications, and part numbers. Inspect the packaging and workmanship. Purchasing from reputable suppliers like YNF Machinery ensures you receive genuine parts.

Are remanufactured parts reliable for heavy-duty applications?

Remanufactured parts can perform well if refurbished to original specifications. They offer cost savings and sustainability. Use them for non-critical applications or when managing budgets, but ensure they come from a trusted source.

How can I extend the life of my excavator track motor parts?

Follow a maintenance routine that includes regular inspections, cleaning, and lubrication. Avoid overloading your excavator and adhere to manufacturer guidelines. Keep a detailed maintenance log to track replacements and repairs.

Tip: Use planned maintenance kits to simplify upkeep and ensure you have the necessary tools and parts.