When it comes to maintaining your Bobcat mini excavator, choosing the right bobcat mini excavator parts for sale can make a significant difference in performance and reliability. OEM parts deliver unmatched quality and durability because they are crafted by the original manufacturer to meet exact specifications. On the other hand, aftermarket parts offer affordability and flexibility, often catering to a wider range of models. Your decision depends on what matters most—whether it’s long-term reliability or immediate cost savings. Understanding these options ensures you get the best value for your investment.

Key Takeaways

Understand the difference: OEM parts are made by the original manufacturer, ensuring precise fit and reliability, while aftermarket parts offer affordability and broader compatibility.

Consider your priorities: If long-term reliability and warranty compliance are crucial, opt for OEM parts. For budget constraints and flexibility, aftermarket options may be more suitable.

Research reputable brands: Not all aftermarket parts are equal; choose trusted suppliers like YNF Machinery to ensure quality and performance.

Verify compatibility: Always check that the parts you purchase match your specific Bobcat mini excavator model to avoid installation issues.

Be cautious of counterfeit parts: Purchase from reliable sources and inspect product details to avoid low-quality components that can harm your equipment.

Evaluate availability: Aftermarket parts are often easier to find, especially for older models, reducing downtime and ensuring quick repairs.

Balance cost and quality: While OEM parts may be more expensive, their durability can save you money in the long run by minimizing replacements and repairs.

What Are OEM and Aftermarket Parts?

When you need replacement parts for your Bobcat mini excavator, understanding the difference between OEM and aftermarket options is essential. Each type has unique characteristics that can influence your decision.

Definition of OEM Parts

OEM stands for Original Equipment Manufacturer. These parts are made by the same company that produced the original components for your Bobcat mini excavator. They are designed to match the exact specifications of your equipment, ensuring a perfect fit and reliable performance. For example, if your excavator originally came with a specific hydraulic pump, an OEM replacement will be identical in design and quality. You can often purchase these parts directly from the manufacturer or authorized dealers, which guarantees their authenticity and compatibility.

“OEM parts are like the name-brand models of the machinery world. They come with the assurance of quality and precision because they are crafted by the original supplier.”

Definition of Aftermarket Parts

Aftermarket parts, on the other hand, are produced by third-party manufacturers. These companies design parts to be compatible with a range of equipment models, including Bobcat mini excavators. While they are not made by the original equipment manufacturer, many aftermarket parts meet or exceed OEM standards. They offer a broader selection, catering to diverse needs and budgets. For instance, you might find an aftermarket hydraulic pump that fits multiple excavator brands, giving you more flexibility in sourcing.

“Aftermarket parts provide a cost-effective alternative, often offering comparable quality and performance for less money.”

Key Differences Between OEM and Aftermarket Parts

Understanding the distinctions between OEM and aftermarket parts helps you make an informed choice:

Branding: OEM parts carry the branding of the original manufacturer, while aftermarket parts do not. This difference often influences perceived quality and trust.

Fit and Compatibility: OEM parts guarantee a precise fit because they are made specifically for your equipment. Aftermarket parts may require additional adjustments, as they are designed for broader compatibility.

Quality Assurance: OEM parts undergo rigorous testing to meet the manufacturer’s standards. Aftermarket parts vary in quality, depending on the manufacturer. Some may use high-grade materials, while others might cut corners to reduce costs.

Availability: Aftermarket parts are widely available and often easier to source, especially for older Bobcat models. OEM parts may have limited availability, particularly for discontinued equipment.

Cost: OEM parts tend to be more expensive due to their guaranteed quality and brand reputation. Aftermarket parts are usually more affordable, making them a popular choice for budget-conscious buyers.

Choosing between OEM and aftermarket parts depends on your priorities. If you value precision and long-term reliability, OEM parts are the way to go. If affordability and flexibility matter more, aftermarket options might suit your needs better.

Advantages of OEM Parts

When you invest in OEM parts for your Bobcat mini excavator, you gain access to a range of benefits that enhance the performance and longevity of your equipment. These parts are specifically designed to meet the highest standards, ensuring your machine operates at its best.

Guaranteed Compatibility with Bobcat Mini Excavators

OEM parts offer guaranteed compatibility with your Bobcat mini excavator. Each component is crafted with precise design to match the exact specifications of your equipment. This ensures a seamless fit and eliminates the guesswork often associated with aftermarket alternatives. You can install these parts with confidence, knowing they will integrate perfectly with your machine’s existing systems.

“With OEM parts, you avoid the risk of mismatched components and ensure your excavator performs as intended.”

This level of equipment compatibility reduces downtime and prevents costly errors during installation. Whether you need a hydraulic pump or an engine part, OEM options provide a hassle-free solution tailored to your machine.

Superior Quality and Durability

OEM parts stand out for their superior quality assurance. Manufacturers subject these components to rigorous testing to meet strict performance standards. This ensures you receive quality parts that deliver consistent results under demanding conditions. The precise design of OEM components also contributes to their exceptional durability, allowing them to withstand wear and tear over time.

Unlike some aftermarket parts, which may vary in quality, OEM parts maintain a high level of reliability. Their robust construction minimizes the risk of premature failure, reducing the need for frequent replacements. By choosing OEM, you invest in component durability that keeps your excavator running smoothly for years.

Warranty Compliance

Using OEM parts helps you maintain warranty compliance for your Bobcat mini excavator. Many manufacturers require the use of original components to honor warranty agreements. Installing non-OEM parts could void your warranty, leaving you responsible for repair costs.

“OEM parts protect your investment by ensuring your warranty remains intact.”

This compliance provides peace of mind, knowing that any future issues with your equipment will be covered. It also reflects the overall benefits of choosing quality options that align with the manufacturer’s guidelines.

By selecting OEM parts, you prioritize reliability, precise design, and long-term value. These components not only enhance your excavator’s performance but also safeguard your investment, making them the preferred choice for discerning operators.

Long-Term Reliability

When it comes to ensuring the longevity of your Bobcat mini excavator, OEM parts stand out as the most reliable choice. These parts are engineered to meet the exact specifications of your equipment, which means they integrate seamlessly and perform consistently over time. Their durability reduces the likelihood of unexpected breakdowns, keeping your machine operational when you need it most.

“OEM parts are built to last, offering peace of mind for operators who prioritize long-term performance.”

Aftermarket parts, while often more affordable, can vary significantly in quality. Some may match OEM standards, but others might fall short due to the use of lower-grade materials or inconsistent manufacturing processes. This variability can lead to premature wear and tear, increasing the risk of frequent replacements and higher maintenance costs over time.

Why OEM Parts Excel in Reliability:

Precision Engineering: OEM parts are designed specifically for your Bobcat mini excavator. This precision ensures optimal performance and reduces stress on other components.

Consistent Quality: Manufacturers subject OEM parts to rigorous testing, guaranteeing they meet strict durability and performance standards.

Reduced Downtime: Reliable parts mean fewer unexpected failures, allowing you to maintain productivity without interruptions.

In contrast, aftermarket parts may save you money upfront, but their inconsistent quality can lead to hidden costs. A poorly made part might fail sooner, requiring additional repairs or replacements. Over time, these expenses can outweigh the initial savings.

The Cost of Reliability

While OEM parts often come with a higher price tag, they represent a long-term investment in your equipment. Their durability minimizes the need for frequent replacements, saving you money in the long run. Additionally, their reliability ensures your excavator operates efficiently, reducing downtime and maximizing productivity.

“Think of OEM parts as an investment in the future of your machine. They deliver consistent performance, helping you avoid costly setbacks.”

If you value dependable performance and want to extend the lifespan of your Bobcat mini excavator, OEM parts are the clear choice. By prioritizing quality and reliability, you ensure your equipment remains a valuable asset for years to come.

Drawbacks of OEM Parts

Higher Costs

OEM parts often come with a higher price tag. This premium cost reflects their precision engineering, rigorous testing, and guaranteed compatibility with your Bobcat mini excavator. While these factors ensure top-notch quality, they also make OEM parts less budget-friendly. If you’re managing tight finances or operating older equipment, the expense of OEM parts might feel overwhelming.

“Investing in OEM parts means paying for peace of mind, but it can strain your budget in the short term.”

For many, the upfront cost of OEM parts becomes a barrier, especially when aftermarket alternatives offer similar functionality at a fraction of the price. However, it’s essential to weigh the long-term benefits of reliability against the immediate financial impact.

Limited Availability for Older Bobcat Models

Finding OEM parts for older Bobcat mini excavators can be challenging. Manufacturers often focus on producing components for newer models, leaving limited stock for discontinued equipment. This scarcity can lead to delays in repairs, as you may need to wait for special orders or search extensively for the required parts.

“When your equipment is older, sourcing OEM parts can feel like searching for a needle in a haystack.”

This limitation can disrupt your operations, especially if your excavator plays a critical role in daily tasks. In such cases, aftermarket parts may become a more practical solution due to their broader availability.

Lack of Customization Options

OEM parts are designed to meet the exact specifications of your Bobcat mini excavator. While this ensures compatibility, it also limits customization. If you’re looking to enhance performance or adapt your machine for unique tasks, OEM parts may not provide the flexibility you need.

Aftermarket parts, on the other hand, often offer innovative designs and modifications that cater to specific requirements. For example, you might find an aftermarket hydraulic pump with improved efficiency or a seal kit tailored for extreme conditions. With OEM parts, you’re restricted to the original design, which may not always align with your evolving needs.

“OEM parts excel in precision but fall short when it comes to customization and innovation.”

This lack of adaptability can be a drawback for operators who want to optimize their equipment for specialized applications.

Advantages of Aftermarket Parts

When it comes to maintaining your Bobcat mini excavator, aftermarket parts offer a range of benefits that make them an attractive option for many operators. These advantages can help you save money, find parts more easily, and even achieve comparable performance to OEM components.

Affordability and Cost Savings

One of the most compelling reasons to choose aftermarket parts is their affordability. On average, aftermarket parts cost significantly less than OEM components—sometimes up to 60% less. This price difference can make a huge impact, especially if you’re managing a tight budget or maintaining older equipment. Lower costs allow you to allocate resources to other critical areas of your operation without compromising on essential repairs.

“Aftermarket parts provide a cost-effective solution for keeping your Bobcat mini excavator in top condition without breaking the bank.”

The savings you gain from choosing aftermarket parts can add up over time. Whether you’re replacing a hydraulic pump, engine component, or seal kit, the reduced upfront expense makes aftermarket options a practical choice for budget-conscious buyers.

Wide Availability for Bobcat Mini Excavator Parts for Sale

Aftermarket parts are widely available, making it easier for you to find the components you need when you need them. Unlike OEM parts, which may be harder to source for older Bobcat models, aftermarket options cater to a broader range of equipment. This accessibility ensures that you can quickly address repairs and minimize downtime.

Many suppliers stock aftermarket parts for Bobcat mini excavators, offering a variety of options to suit different needs. Whether you’re searching for engine parts, couplings, or hydraulic cylinder seal kits, you’ll likely find multiple choices readily available. This convenience allows you to keep your equipment running smoothly without long delays.

“With aftermarket parts, you can avoid the frustration of waiting weeks for a specific component to arrive.”

The extensive availability of aftermarket parts also means you have more flexibility in sourcing. You can compare prices, brands, and features to find the best fit for your machine and budget.

Potential for Comparable Quality

While OEM parts are known for their precision and durability, many aftermarket parts deliver comparable quality at a fraction of the cost. Reputable manufacturers produce high-quality aftermarket parts that meet or even exceed OEM standards. These components undergo rigorous testing to ensure they perform reliably under demanding conditions.

“Not all aftermarket parts are created equal, but quality aftermarket parts can rival OEM components in performance and longevity.”

For example, aftermarket hydraulic pumps or engine parts designed for Bobcat mini excavators often match the specifications of their OEM counterparts. By choosing parts from trusted suppliers, you can enjoy the benefits of durability and efficiency without paying a premium price.

To ensure you’re getting the best value, look for aftermarket parts from well-known brands like YNF Machinery. Their commitment to quality and reliability makes them a trusted choice for excavator owners worldwide.

Flexibility in Sourcing

When it comes to sourcing parts for your Bobcat mini excavator, aftermarket options provide unmatched flexibility. This flexibility allows you to explore a wide range of suppliers, brands, and price points, ensuring you find the right part for your needs without unnecessary delays.

Aftermarket parts are available from numerous manufacturers, giving you access to a diverse selection. Unlike OEM parts, which are often limited to authorized dealers or the original manufacturer, aftermarket components can be purchased from various sources, including online marketplaces, local distributors, and specialized retailers. This broad availability makes it easier to locate parts, even for older or less common Bobcat models.

“With aftermarket parts, you gain the freedom to shop around and compare options, empowering you to make the best choice for your equipment.”

This sourcing flexibility also means you can evaluate multiple brands to find the perfect balance between cost and quality. Some aftermarket manufacturers, like YNF Machinery, produce high-quality parts that meet or exceed OEM standards. By choosing a reputable supplier, you can enjoy reliable performance without paying the premium price associated with OEM components.

Additionally, aftermarket parts often cater to specific needs that OEM parts may not address. For example, you might find a hydraulic pump designed for enhanced efficiency or a seal kit built for extreme working conditions. These tailored solutions allow you to optimize your excavator’s performance based on your unique requirements.

Here’s how aftermarket flexibility benefits you:

Broader Availability: Easily find parts for both new and older Bobcat models.

Competitive Pricing: Compare prices across multiple suppliers to secure the best deal.

Custom Options: Access innovative designs and specialized features not offered by OEM parts.

Convenient Sourcing: Purchase parts online or locally, reducing downtime and simplifying logistics.

By leveraging the flexibility of aftermarket sourcing, you can maintain your Bobcat mini excavator efficiently and cost-effectively. This approach ensures you have the right parts when you need them, keeping your operations running smoothly.

Drawbacks of Aftermarket Parts

While aftermarket parts offer affordability and flexibility, they come with certain risks that you should carefully consider before making a purchase. Understanding these drawbacks will help you make an informed decision for your Bobcat mini excavator.

Inconsistent Quality

One of the biggest challenges with aftermarket parts is the inconsistency in quality. Unlike OEM parts, which undergo strict testing and adhere to precise manufacturing standards, aftermarket components vary widely depending on the manufacturer. Some aftermarket parts meet or even exceed OEM standards, but others may fall short due to the use of inferior materials or less rigorous production processes.

“Not all aftermarket parts are created equal. While some deliver excellent performance, others can lead to premature wear and tear.”

This variability means you need to be cautious when selecting aftermarket parts. A poorly made part can compromise your excavator’s performance, leading to frequent breakdowns and higher maintenance costs. To avoid this, always research the manufacturer and choose reputable brands like YNF Machinery, which prioritize quality and reliability.

Warranty Issues

Using aftermarket parts can sometimes void your equipment’s warranty. Many manufacturers require the use of OEM components to maintain warranty compliance. If you install an aftermarket part and it causes damage to your Bobcat mini excavator, you may have to cover the repair costs out of pocket.

“Choosing aftermarket parts might save you money upfront, but it could cost you more in the long run if your warranty becomes invalid.”

Before opting for aftermarket parts, check your equipment’s warranty terms. If maintaining warranty coverage is important to you, OEM parts may be the safer choice. However, if your warranty has already expired, aftermarket options could still provide a cost-effective solution.

Risks of Counterfeit Parts

The aftermarket industry is vast, and not all suppliers operate with integrity. Counterfeit parts are a growing concern, especially in online marketplaces. These fake components often mimic the appearance of genuine aftermarket parts but lack the durability and performance needed for heavy-duty equipment like Bobcat mini excavators.

“Counterfeit parts may look like a bargain, but they can lead to costly repairs and even safety hazards.”

To protect yourself from counterfeit parts, purchase from trusted suppliers with a proven track record. Look for clear product descriptions, customer reviews, and guarantees of authenticity. Brands like YNF Machinery ensure that their aftermarket parts meet high standards, giving you peace of mind and reliable performance.

By understanding these potential drawbacks, you can weigh the risks and benefits of aftermarket parts more effectively. While they offer significant cost savings and availability, careful selection is crucial to avoid issues like inconsistent quality, warranty complications, and counterfeit products. Always prioritize trusted suppliers to ensure your Bobcat mini excavator operates efficiently and safely.

Key Factors to Consider When Choosing Between Aftermarket vs OEM

When deciding between aftermarket and OEM parts for your Bobcat mini excavator, several factors play a crucial role in making the right choice. Each consideration helps you align your decision with your equipment’s needs, budget, and long-term goals.

Equipment Age and Model

The age and model of your Bobcat mini excavator significantly influence your decision. For newer models, OEM parts often provide the best fit and performance. These parts are specifically designed to match the exact specifications of your machine, ensuring seamless integration and reliability. If your equipment is still under warranty, using OEM parts also helps maintain compliance, protecting your investment.

For older models, aftermarket parts may become a more practical option. Manufacturers often discontinue OEM parts for outdated equipment, making them harder to find. Aftermarket suppliers, however, cater to a broader range of models, including those no longer supported by the original manufacturer. This availability ensures you can keep your older excavator operational without unnecessary delays.

“If your excavator is aging, aftermarket parts might be your only option to avoid downtime and keep it running efficiently.”

Budget Constraints

Your budget is one of the most critical factors when choosing between aftermarket and OEM parts. OEM parts typically come with a higher price tag due to their precision engineering and brand reputation. While this cost reflects their quality and reliability, it may not always align with your financial constraints.

Aftermarket parts, on the other hand, offer a cost-effective alternative. They are often priced significantly lower than OEM components, allowing you to save money upfront. This affordability makes aftermarket parts an attractive choice for those managing tight budgets or maintaining multiple machines.

“Aftermarket parts deliver value by offering reliable performance at a fraction of the cost, helping you stretch your budget further.”

However, it’s essential to balance cost savings with quality. Opting for low-cost aftermarket parts from unreliable sources can lead to frequent replacements and higher long-term expenses. Always prioritize reputable suppliers like YNF Machinery to ensure you get the best value for your money.

Performance and Reliability Needs

The performance and reliability of your Bobcat mini excavator depend heavily on the quality of the parts you choose. If you prioritize long-term reliability and consistent performance, OEM parts are often the safer bet. These components undergo rigorous testing to meet strict standards, ensuring they perform optimally under demanding conditions.

Aftermarket parts, while more affordable, can vary in quality. Some manufacturers produce parts that meet or exceed OEM standards, offering comparable performance and durability. Others may cut corners, resulting in inconsistent quality and reduced reliability. To avoid these risks, research the brand and verify the part’s compatibility with your equipment.

“For critical components where reliability is non-negotiable, OEM parts provide peace of mind. For less demanding applications, high-quality aftermarket parts can offer a practical solution.”

Ultimately, your choice depends on how you balance performance needs with cost considerations. If your excavator operates in harsh environments or handles heavy workloads, investing in OEM parts may save you from costly breakdowns. For less intensive use, aftermarket parts from trusted suppliers can deliver excellent performance without exceeding your budget.

Part Availability and Lead Times

When maintaining your Bobcat mini excavator, the availability of parts and the time it takes to receive them can significantly impact your operations. Whether you choose OEM or aftermarket parts, understanding how these factors affect your decision is crucial.

Faster Access with Aftermarket Parts

Aftermarket parts often shine when it comes to availability. Multiple manufacturers produce these components, creating a broader inventory that’s easier to access. Unlike OEM parts, which are typically limited to production by the original manufacturer, aftermarket options come from various suppliers. This diversity ensures you can find the parts you need without unnecessary delays.

“Aftermarket parts are easier to find. OEM parts will take a lot longer to arrive if you order a part from a dealer.”

For example, if you’re searching for a hydraulic pump or seal kit, aftermarket vendors often have these items in stock and ready to ship. Many aftermarket suppliers also offer expedited shipping options, allowing you to receive your parts as quickly as the next day. This speed can be a game-changer when you’re facing tight deadlines or unexpected equipment breakdowns.

Challenges with OEM Lead Times

OEM parts, while dependable, can take longer to arrive. Manufacturers often centralize their inventory in specific warehouses, meaning dealers must place orders on your behalf. This process can lead to extended lead times, especially if the part you need is out of stock or discontinued. For older Bobcat models, sourcing OEM parts becomes even more challenging, as manufacturers may have stopped producing components for outdated equipment.

“Sometimes, aftermarket parts are the only option for buyers. Many manufacturers cut back on or stop producing OEM products as their equipment ages.”

This delay can disrupt your workflow, causing downtime that impacts productivity and profitability. If your excavator plays a critical role in daily operations, waiting weeks for an OEM part may not be a viable option.

Why Aftermarket Parts Save Time

Aftermarket parts not only offer faster availability but also provide flexibility in sourcing. You can purchase them from online marketplaces, local distributors, or specialized retailers. This accessibility reduces the time spent searching for components, ensuring your excavator gets back to work sooner.

Here’s how aftermarket parts help you save time:

Wider Inventory: Multiple manufacturers produce aftermarket parts, increasing the likelihood of finding what you need quickly.

Expedited Shipping: Many suppliers prioritize fast delivery, minimizing downtime.

Local Availability: Unlike OEM parts, which often require special orders, aftermarket options are frequently stocked by local retailers.

“Imagine looking for OEM parts and discovering that the dealership doesn’t offer fast shipping, whereas the aftermarket vendor can get you its parts by tomorrow.”

Making the Right Choice

When considering part availability and lead times, think about your equipment’s role in your operations. If minimizing downtime is your top priority, aftermarket parts provide a practical solution. Their widespread availability and faster shipping options ensure you can address repairs promptly. However, if you’re working with newer equipment and prefer the precision of OEM parts, plan ahead to account for potential delays.

By weighing these factors, you can make an informed decision that keeps your Bobcat mini excavator running efficiently and your projects on schedule.

Tips for Buying High-Quality Aftermarket Parts

When you’re in the market for aftermarket parts, making informed decisions ensures your Bobcat mini excavator operates efficiently and safely. Follow these tips to avoid common pitfalls and maximize the value of your investment.

Verify Compatibility with Your Bobcat Mini Excavator

Before purchasing any part, confirm it’s compatible with your specific Bobcat mini excavator model. Manufacturers design aftermarket parts to fit a range of equipment, but not all will align perfectly with your machine. Using an incompatible part can lead to performance issues, increased wear, or even damage to other components.

To verify compatibility:

Check your equipment manual: Look for part numbers or specifications that match the replacement part.

Consult the supplier: Reputable sellers often provide detailed compatibility information. Don’t hesitate to ask questions.

Inspect the part dimensions: Ensure the size, shape, and connection points align with your excavator’s requirements.

“Installing the wrong part can cost you time and money. Always double-check compatibility to avoid unnecessary headaches.”

Taking these steps minimizes the risk of downtime and ensures the part integrates seamlessly with your machine.

Research Reputable Aftermarket Brands like YNF Machinery

Not all aftermarket parts are created equal. Quality varies significantly between manufacturers, so choosing a trusted brand is essential. Reputable companies like YNF Machinery prioritize durability, performance, and safety, ensuring their parts meet or exceed industry standards.

When researching brands:

Look for customer reviews: Positive feedback from other buyers indicates reliability and satisfaction.

Evaluate the company’s experience: Established brands with years of expertise, like YNF Machinery, are more likely to deliver consistent quality.

Check for certifications: Reliable manufacturers often adhere to international quality standards, which guarantees better performance and longevity.

“A trusted brand ensures you’re not gambling with your equipment’s performance. YNF Machinery, for example, has built a reputation for delivering high-quality aftermarket parts.”

By selecting a reputable supplier, you reduce the risk of receiving counterfeit or substandard components, which can compromise your excavator’s safety and efficiency.

Check for Warranties and Return Policies

A warranty provides peace of mind when buying high-quality aftermarket parts. It shows the manufacturer’s confidence in their product and protects you from unexpected defects. Similarly, a clear return policy ensures you can exchange or refund parts that don’t meet your expectations.

When evaluating warranties and return policies:

Review the warranty terms: Look for coverage on defects, performance issues, and material quality.

Understand the return process: Ensure the supplier offers hassle-free returns if the part doesn’t fit or fails prematurely.

Ask about support: Some companies, like YNF Machinery, provide technical assistance to help you resolve installation or performance concerns.

“A strong warranty and return policy reflect the manufacturer’s commitment to quality and customer satisfaction.”

Prioritizing these factors ensures you’re protected against potential risks, giving you confidence in your purchase.

By following these tips, you can navigate the aftermarket market with ease and confidence. Verifying compatibility, choosing reputable brands, and checking warranties help you avoid common pitfalls and ensure your Bobcat mini excavator performs at its best. When buying high-quality aftermarket parts, diligence pays off, saving you time, money, and frustration.

Avoid Counterfeit or Substandard Parts

Counterfeit or substandard parts can jeopardize the performance and safety of your Bobcat mini excavator. These parts often mimic genuine components but fail to meet the necessary quality and safety standards. Using them may lead to premature failures, costly repairs, or even hazardous conditions.

Recognize the Risks of Counterfeit Parts

Counterfeit parts are a growing concern in the aftermarket industry. They are designed to look like authentic components but are made with inferior materials and poor craftsmanship. These parts can:

Compromise Safety: Substandard materials may not withstand the stress and demands of heavy machinery, increasing the risk of accidents.

Reduce Equipment Lifespan: Poor-quality parts wear out faster, leading to frequent replacements and higher maintenance costs.

Cause Unexpected Failures: Counterfeit parts often fail under pressure, resulting in downtime and lost productivity.

“Counterfeit parts may save you money upfront, but they can cost you much more in the long run through repairs, downtime, and safety risks.”

Tips to Avoid Counterfeit or Low-Quality Parts

Protecting your investment starts with sourcing reliable parts. Follow these tips to ensure you avoid counterfeit or substandard components:

Buy from Trusted Suppliers

Always purchase parts from reputable suppliers like YNF Machinery. Established brands prioritize quality and reliability, ensuring their products meet or exceed industry standards. Trusted suppliers also provide clear product descriptions and guarantees of authenticity.Inspect Product Details

Pay attention to the packaging, branding, and part numbers. Genuine parts often have consistent markings, high-quality packaging, and detailed specifications. Counterfeit parts may show signs of poor printing, misspelled labels, or mismatched part numbers.Check for Certifications

Look for certifications or quality seals that indicate the part meets international standards. Reliable manufacturers often include these marks to demonstrate their commitment to safety and performance.Avoid Deals That Seem Too Good to Be True

Extremely low prices can be a red flag for counterfeit or low-quality parts. While affordability is a benefit of aftermarket options, prices that are significantly below market value may indicate compromised quality.Read Customer Reviews

Reviews from other buyers can provide valuable insights into the quality and performance of a part. Positive feedback often signals a trustworthy product, while repeated complaints about durability or fitment should raise concerns.

Why Quality Matters

Using high-quality parts ensures your Bobcat mini excavator operates efficiently and safely. Genuine or well-made aftermarket components reduce the risk of breakdowns, extend the lifespan of your equipment, and maintain optimal performance. By avoiding counterfeit or substandard parts, you protect both your machine and your bottom line.

“Investing in quality parts is an investment in the reliability and safety of your equipment. Don’t let counterfeit components undermine your operations.”

Take the time to verify the authenticity and quality of every part you purchase. This diligence will save you from unnecessary expenses and ensure your excavator continues to perform at its best.

How YNF Machinery Supports Your Needs for Bobcat Mini Excavator Parts

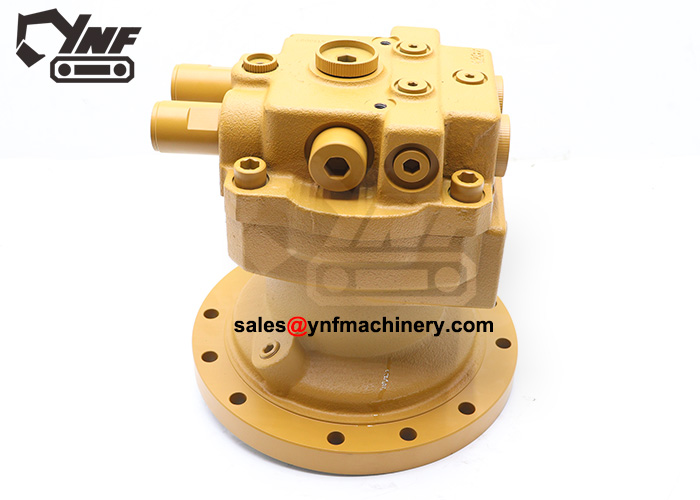

When it comes to maintaining your Bobcat mini excavator, YNF Machinery stands out as a trusted partner. With over 35 years of experience, YNF Machinery delivers high-quality parts that ensure your equipment operates at peak performance. Whether you need engine components, couplings, or seal kits, YNF Machinery provides reliable solutions tailored to your needs.

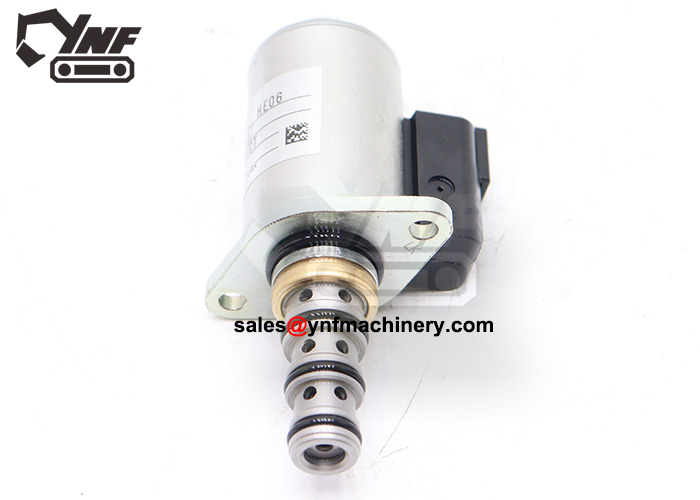

High-Quality Excavator Engine Parts for Optimal Performance

Your excavator’s engine is its powerhouse, and keeping it in top condition is essential. YNF Machinery offers a comprehensive range of engine parts designed to enhance performance and durability. These parts include pistons, crankshafts, gaskets, and fuel pumps, all crafted to meet or exceed OEM standards.

By choosing YNF Machinery’s engine parts, you ensure compatibility with your Bobcat mini excavator. Each component undergoes rigorous testing to guarantee reliability under demanding conditions. This precision reduces the risk of breakdowns, saving you time and money on repairs. Unlike some aftermarket hydraulic cylinders, which may compromise performance, YNF Machinery’s engine parts deliver consistent results, ensuring your equipment runs smoothly.

“Investing in high-quality engine parts minimizes downtime and extends the lifespan of your excavator.”

YNF Machinery also offers both OEM hydraulic cylinders and aftermarket options, giving you flexibility based on your budget and equipment needs. Their engine parts not only improve efficiency but also reduce maintenance expenses over time, making them a cost-effective choice.

Durable Excavator Couplings for Reliable Power Transmission

Efficient power transmission is critical for your excavator’s performance. YNF Machinery’s excavator couplings are engineered to provide durability and reliability. These couplings connect the engine to the hydraulic pump, ensuring smooth and consistent power flow.

YNF Machinery offers a variety of coupling types, including Centaflex and Bowex models, designed to handle the stress of heavy-duty operations. These couplings compensate for misalignment and absorb vibrations, protecting your equipment from unnecessary wear and tear. Unlike some aftermarket hydraulic cylinders that may lack precision, YNF Machinery’s couplings are built to exact specifications, ensuring a perfect fit.

“Reliable couplings reduce the risk of mechanical failure, keeping your excavator operational when you need it most.”

With YNF Machinery, you gain access to both OEM hydraulic cylinders and aftermarket options, allowing you to choose the best solution for your specific requirements. Their couplings not only enhance performance but also contribute to the overall longevity of your equipment.

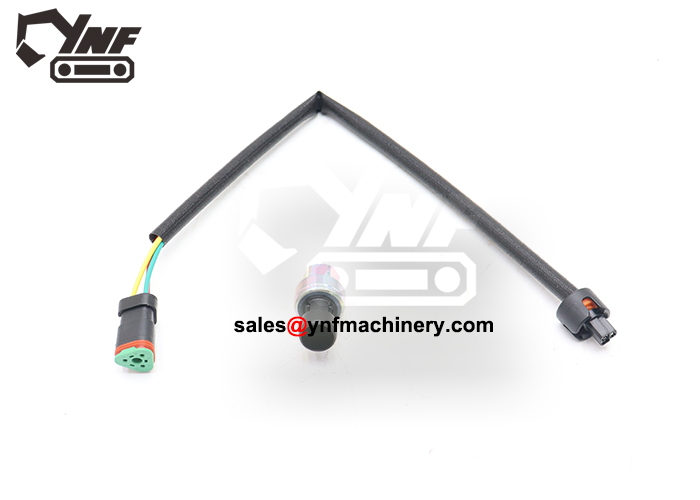

Hydraulic Cylinder Seal Kits to Prevent Oil Leaks and Ensure Efficiency

Oil leaks can disrupt your excavator’s performance and lead to costly repairs. YNF Machinery’s hydraulic cylinder seal kits provide an effective solution to this problem. These kits are designed to prevent leaks and maintain the efficiency of your excavator’s hydraulic system.

Each seal kit is made from high-grade materials, ensuring durability and flexibility. YNF Machinery offers kits compatible with a wide range of Bobcat mini excavator models, making it easy to find the right fit. Unlike some aftermarket hydraulic cylinders that may require frequent replacements, YNF Machinery’s seal kits deliver long-lasting performance.

“Preventing oil leaks not only protects your equipment but also reduces maintenance costs and downtime.”

YNF Machinery’s seal kits work seamlessly with both OEM hydraulic cylinders and aftermarket options, giving you the freedom to choose based on your budget and operational needs. By investing in these high-quality kits, you ensure your excavator operates efficiently, even in challenging conditions.

YNF Machinery combines quality, reliability, and affordability to meet your Bobcat mini excavator’s needs. Whether you prioritize OEM hydraulic cylinders for their precision or aftermarket hydraulic cylinders for their cost-effectiveness, YNF Machinery provides solutions that keep your equipment running at its best.

Choosing between OEM and aftermarket parts for your Bobcat mini excavator depends on your priorities. If you value precision, compatibility, and long-term reliability, OEM parts are the ideal choice. They ensure your equipment performs as intended and maintain warranty compliance. However, aftermarket parts offer a cost-effective solution, especially for older models or when availability is a concern. Brands like YNF Machinery provide high-quality aftermarket options that balance affordability and performance. Evaluate your needs carefully, research thoroughly, and select parts that align with your operational goals.

FAQ

What are the main differences between OEM and aftermarket parts?

OEM parts come directly from the original manufacturer of your Bobcat mini excavator. They guarantee a precise fit and meet strict quality standards. Aftermarket parts, made by third-party manufacturers, offer more variety and affordability. While OEM parts ensure compatibility, aftermarket options provide flexibility and cost savings. Your choice depends on your priorities—precision or budget.

“OEM parts deliver unmatched reliability, while aftermarket parts cater to diverse needs and budgets.”

Are aftermarket parts as reliable as OEM parts?

The reliability of aftermarket parts depends on the manufacturer. Reputable brands like YNF Machinery produce aftermarket parts that meet or exceed OEM standards. These parts undergo rigorous testing to ensure durability and performance. However, poorly made aftermarket parts can compromise your excavator’s efficiency. Always choose trusted suppliers to ensure reliability.

How do I know if a part is compatible with my Bobcat mini excavator?

To confirm compatibility, check your equipment manual for part numbers or specifications. You can also consult the supplier for detailed information. Trusted brands like YNF Machinery provide clear compatibility details for their products. Verifying dimensions and connection points ensures the part fits seamlessly with your machine.

“Double-checking compatibility saves you time, money, and potential headaches.”

Why are OEM parts more expensive than aftermarket parts?

OEM parts cost more because they are designed specifically for your equipment. They undergo extensive testing and meet strict quality standards. The higher price reflects their precision and guaranteed performance. Aftermarket parts, produced by third-party manufacturers, often use cost-effective methods, making them more affordable.

Can using aftermarket parts void my equipment’s warranty?

Yes, using aftermarket parts can sometimes void your warranty. Many manufacturers require OEM components to maintain warranty compliance. If your warranty is still active, check its terms before installing aftermarket parts. For expired warranties, aftermarket options become a cost-effective alternative.

How can I avoid counterfeit aftermarket parts?

To avoid counterfeit parts, purchase from reputable suppliers like YNF Machinery. Inspect product details, including packaging and part numbers, for consistency. Look for certifications or quality seals that indicate authenticity. Avoid deals that seem too good to be true, as they often signal counterfeit or substandard products.

“Investing in genuine parts protects your equipment and ensures long-term performance.”

Are aftermarket parts available for older Bobcat models?

Yes, aftermarket parts are often easier to find for older Bobcat models. OEM parts for discontinued equipment may be limited or unavailable. Aftermarket manufacturers cater to a broader range of models, ensuring you can maintain your older excavator without delays.

What should I look for when buying aftermarket parts?

When purchasing aftermarket parts, prioritize compatibility, quality, and supplier reputation. Verify the part fits your Bobcat mini excavator. Choose trusted brands like YNF Machinery that meet industry standards. Check for warranties and return policies to protect your investment.

Do aftermarket parts come with warranties?

Many reputable aftermarket manufacturers, including YNF Machinery, offer warranties on their products. These warranties cover defects and performance issues, providing peace of mind. Always review the warranty terms before purchasing to understand what is covered.

Why should I consider YNF Machinery for my Bobcat mini excavator parts?

YNF Machinery offers high-quality aftermarket parts designed for durability and performance. With over 35 years of experience, they provide reliable solutions for Bobcat mini excavators. Their parts meet or exceed OEM standards, ensuring compatibility and efficiency. YNF Machinery also offers excellent customer support, fast shipping, and competitive pricing.

“Choosing YNF Machinery means investing in quality, reliability, and exceptional service.”