Selecting the right bobcat excavator quick connect bucket parts means you must check if they fit. You should know your attachment and coupler choices. Think about what your job needs and how much money you have. If you use parts that do not fit, your bucket may wobble. Your equipment can wear out faster. If things do not line up, the bucket’s dump and curl angles change. This makes it harder to attach the bucket. It also lowers how well you work.

Accuracy is important. Always look at the manufacturer’s information before picking parts.

Mistake | Why It Matters |

|---|---|

Not picking the right size equipment | Costs go up and work slows down |

Not knowing about all attachments | You cannot work as well |

Thinking bucket weight means it is strong | The material matters more |

Using a general bucket for hard stuff | Work does not go well |

Not thinking about the teeth type | The bucket may not work right |

Not matching bucket width to trench | You dig too much or too little |

Forgetting to care for equipment | You pay more over time |

Follow these steps to work safely and well.

Key Takeaways

Always look at your Bobcat excavator’s model and serial number before you buy parts. This helps you get the right part and stops expensive mistakes.

Use your operator’s manual and check compatibility charts to find part numbers. This helps you match parts correctly and saves you time.

Think about what kind of quick coupler you need. Hydraulic couplers let you change tools fast from inside the cab. Manual couplers make you get out of the cab to change tools.

Look at the quality of the parts. OEM parts fit well and work better. Aftermarket parts can be different in quality. Pick carefully to keep your machine safe.

Check and take care of your equipment often. Good care stops damage and saves you money over time.

Identify Your Bobcat Excavator

Find Model and Serial Number

You must know your bobcat excavator’s model and serial number. These numbers help you pick the right quick connect bucket parts. They stop you from making mistakes. You can find these numbers in a few ways.

Look for the product identification plate. It is near the boom swing or under the left lift arm.

Check the front of the machine below the operator’s cab. The serial number is on the right or left side.

Open your user manual. The reference section lists the serial number.

Ask your Bobcat dealer. Dealers keep records and can help you check your numbers.

Tip: If you lost your manual, you can get a new one from Bobcat or your dealer. Manuals have diagrams and tips for taking care of your machine.

Always check your model and serial number before you order parts. The Bobcat website has parts catalogs. You can look up diagrams with your model or serial number. Dealers and service centers also give updated diagrams and help with matching parts.

Importance of Accurate Identification

Getting the right model and serial number is very important. If you use the wrong numbers, you might buy parts that do not fit. This can waste money and time. You may need to return parts or stop work while you wait for new ones.

Not all parts fit every bobcat excavator. Even machines that look alike can use different parts.

The serial number and date made help you find the exact parts.

If you get your machine wrong, you can waste resources and face delays.

Always double-check your numbers before you buy quick connect bucket parts. Getting the right numbers keeps your equipment working well and helps you avoid mistakes that cost money.

Check Compatibility

Use Manuals and Compatibility Charts

You must check if parts fit before you buy them. Start by reading your operator’s manual. The manual gives you the right part numbers. It also has pictures that show how parts fit. Match the part number in your manual to the part you want. This helps you not make mistakes.

Compatibility charts are also very helpful. These charts show which buckets and attachments fit your machine. You can find them on the Bobcat website, in catalogs, or from your dealer. Some guides tell you which buckets fit different excavators. They also talk about which buckets work with many machines. The Bobcat X-Change collection helps you see which attachments work with quick connect systems.

Tip: Use both the manual and compatibility charts. This makes checking easier and more correct.

Here are steps to check if parts fit:

Find your bobcat excavator’s model and serial number.

Look in the attachments catalog for your model.

Use charts to see if the attachment fits.

Check if your system is pin-on or quick attach.

Measure the mounting plate and pin size.

Make sure the bucket size matches your lift capacity.

Spread the weight to protect your hydraulic system.

Make sure the attachment follows the maker’s rules.

Ask a bobcat expert if you have questions.

Check all details before you put on new attachments.

Match Part Numbers

Matching part numbers is very important. Your manual lists the right part numbers for your machine. When you find a part online or at a store, compare its number to the one in your manual. If the numbers match, the part should fit.

You also need to check the size, pressure, and flow rate. These things affect how the part works with your hydraulic system. Make sure the part fits your model and serial number. If you use the wrong part, your machine can break or slow down.

Note: If you are not sure about a part, ask your dealer or a bobcat expert. They can help you check and stop mistakes.

Avoid Common Mistakes

Many people make mistakes when checking if parts fit. You can avoid these problems by following some simple rules.

Mistake | How to Avoid |

|---|---|

Using the wrong part number | Always match numbers from your manual |

Ignoring compatibility charts | Check charts before you buy |

Not measuring mounting plates | Measure carefully every time |

Forgetting about hydraulic limits | Check pressure and flow rate |

Skipping expert advice | Ask for help if you are unsure |

Always check charts and manuals twice. Never guess if a part will fit your machine. Checking saves you time and money. It keeps your equipment safe and working well.

Tip: Make checking if parts fit a habit every time you buy new bucket parts or attachments.

Good places to find charts are:

Bobcat website

Parts catalogs from dealers

Bobcat X-Change bucket and attachment guides

You can trust these places to help you check if parts fit and find the right ones for your bobcat excavator.

Bobcat Excavator Quick Connect Bucket Parts

Types of Quick Couplers

You have several choices when you look for bobcat excavator quick connect bucket parts. The type of quick coupler you pick affects how fast you can change a bucket or attachment. You want to make sure the parts fit your bobcat excavator and work for your job.

Hydraulic quick couplers let you switch a bucket or attachment without leaving the cab. You save time and work safer.

Manual quick couplers need you to get out of the cab to lock the bucket or attachment. They work faster than old pin-on methods.

Dedicated quick connect style mounts are made for certain bobcat models. These mounts help you use attachments across machines that fit the same system.

S Type couplers work with tiltrotators. They help you manage the height of your bucket and attachment.

Fully hydraulic coupler systems let you connect hydraulic attachments without hooking up hoses by hand. You work faster and avoid leaks.

When you choose bobcat excavator bucket parts, think about how often you change a bucket or attachment. If you switch parts many times each day, a hydraulic quick coupler helps you work faster. If you use the same bucket or attachment most of the time, a manual coupler may fit your needs and budget.

Tip: Always check that the quick coupler and bucket parts fit your bobcat excavator before you buy. Look at the mounting plate, pin size, and system type.

Hydraulic Pin-Grabber Coupler

A hydraulic pin-grabber coupler is a popular choice for bobcat excavator quick connect bucket parts. This coupler grabs the bucket by its pins and locks it in place using hydraulic power. You control the coupler from the cab, so you do not need to leave your seat.

Here is a table that shows the advantages and disadvantages of hydraulic pin-grabber couplers:

Advantages | Disadvantages |

|---|---|

Easily change attachments from the cab | More expensive than manual couplers |

Significantly reduces downtime between changes | Paying for a luxury if attachments are not changed often |

Increases versatility by enabling multiple attachments | Added complexity may require more maintenance |

Reduces risk of injury during manual changes |

Hydraulic couplers help you finish jobs faster. You do not waste time changing a bucket or attachment by hand. You lower the risk of injury because you stay in the cab. The hydraulic system makes switching attachments smooth and quick. You boost your productivity and keep your bobcat excavator working longer.

If you use many different attachments, a hydraulic pin-grabber coupler fits your needs. You can use buckets, grapples, and other parts without stopping work. If you only use one bucket or attachment, you may not need a hydraulic coupler.

Attachment and Bucket Requirements

The right bobcat excavator quick connect bucket parts depend on your job and the attachments you use. You want to make sure every part fits your bobcat excavator and matches your work needs.

Quick couplers make it easy to change a bucket or attachment. You work faster and do not waste time.

Manual couplers need exact pin sizes and mounting plates. You must check that the bucket and attachment fit your machine.

Hydraulic couplers can fit a range of pin sizes. You get more choices for bucket and attachment parts.

The space between attachment ears matters less with hydraulic couplers. You can use more types of buckets and attachments.

Standard pin diameters and stick widths help you pick the right parts. You spend less time searching and get the right fit.

Your job affects which bobcat excavator bucket parts you need. If you dig trenches, you want a bucket that fits the trench width. If you move rocks, you need a strong bucket and attachment. Each attachment has a weight rating. You must check that the bucket and attachment do not go over your machine’s limits. If you use the wrong parts, your bobcat excavator may break or work poorly.

Note: Always match the attachment and bucket to your bobcat excavator’s weight class and hydraulic flow. Using the wrong parts can damage your machine and slow your work.

When you pick bobcat excavator quick connect bucket parts, look at your job needs, the type of attachment, and the fit. You want every part to work together. This keeps your bobcat excavator safe and helps you finish your work on time.

Compare Bobcat Excavator Bucket Parts

Bucket Types and Dimensions

You have many choices when you look at bobcat excavator bucket parts. Each bucket type works best for a certain job. You need to know the size and shape of each bucket before you pick one. The right bucket size matches your job and helps your bobcat excavator work better.

Here is a table that shows some popular bucket types and their dimensions:

Bucket Type | Overall Width | Inside Width | Inside Depth | Inside Height | Weight Capacity |

|---|---|---|---|---|---|

30″ Tooth Trench | 30 Inches | 28.75 Inches | 23 Inches | 18 Inches | 10,000 – 14,000 lb |

42″ Smooth Ditching | 42 Inches | – | – | – | 6,000 – 10,000 lb |

36″ Smooth Ditching | 36 Inches | – | – | – | 6,000 – 10,000 lb |

You should always check if the bucket size matches your job. A trenching bucket works well for digging narrow spaces. A ditching bucket is better for moving soft soil or cleaning ditches. Picking the right bucket helps you finish your work faster.

Attachment Points and Weight Limits

Attachment points are where you connect the bucket to your bobcat excavator. You must make sure these points fit your machine. Quick couplers let you change attachments fast. Manual couplers need you to match the pin size and shape to your bobcat. Hydraulic quick couplers can fit many pin sizes, so you get more choices for attachments.

Quick couplers make it easy to switch attachments.

Manual couplers need exact pin sizes for a safe fit.

Hydraulic couplers work with many pin centers and diameters.

Universal pin standards help you use more attachments safely.

You must check the weight limit for each bucket and attachment. If you use a bucket that is too heavy, you can damage your bobcat excavator. Always make sure the bucket size matches your machine’s lift capacity.

Ease of Use and Job Needs

When you choose bobcat excavator bucket parts, think about how easy they are to use. The right parts help you work faster and safer. Look at these factors:

Factor | Description |

|---|---|

Material Type | Hardened steel is strong for tough jobs. Wear-resistant alloys last longer and weigh less. |

Compatibility | Make sure all parts fit your bobcat excavator to avoid problems. |

Application-Specific Needs | Pick sharp teeth for digging. Use narrow buckets for trenching. |

Maintenance Costs | High-quality parts cost more but save money over time. |

You should always match the bucket and attachment to your job. If you dig hard soil, use a strong bucket. If you clean ditches, use a wide, smooth bucket. The right bobcat excavator bucket parts help you finish your work with less effort.

Tip: Always check if the parts fit your bobcat before you buy. The right fit keeps your machine safe and helps you avoid costly repairs.

Evaluate Sellers and Budget

OEM vs Aftermarket

When you pick quick connect bucket parts for your bobcat, you have two choices. You can buy OEM parts or aftermarket parts. OEM stands for “Original Equipment Manufacturer.” These parts come from bobcat. They always fit your machine. Aftermarket parts come from other companies. They may not fit every bobcat. Their quality can be different.

Here is a table that shows the main differences:

Feature | Genuine Bobcat Parts | Aftermarket Bobcat Parts |

|---|---|---|

Manufacturer | Bobcat | Other companies |

Compatibility | Always fits | Might not fit |

Quality | Always good | Can vary |

Cost | More expensive | Less expensive |

Availability | Harder to find sometimes | Easier to find |

Genuine bobcat parts are reliable. They help keep your warranty safe. Aftermarket parts cost less money. You need to check their quality before you buy. Some aftermarket parts work well. Others wear out fast or break your machine. If you use the official parts catalog, you can find the right part for your bobcat. This helps you avoid mistakes.

Tip: Always look at your official parts catalog before you buy. This helps you match the part to your bobcat.

Seller Reputation

You should buy parts from sellers you trust. Look for companies with many years of experience. Good sellers have high ratings. They test their parts and give warranties. You can check supplier ratings and buyer records. This shows how well they treat customers.

Note: Always check the seller’s reputation before you buy. Pick companies with good ratings and lots of experience. This helps you avoid bad parts.

Budget Considerations

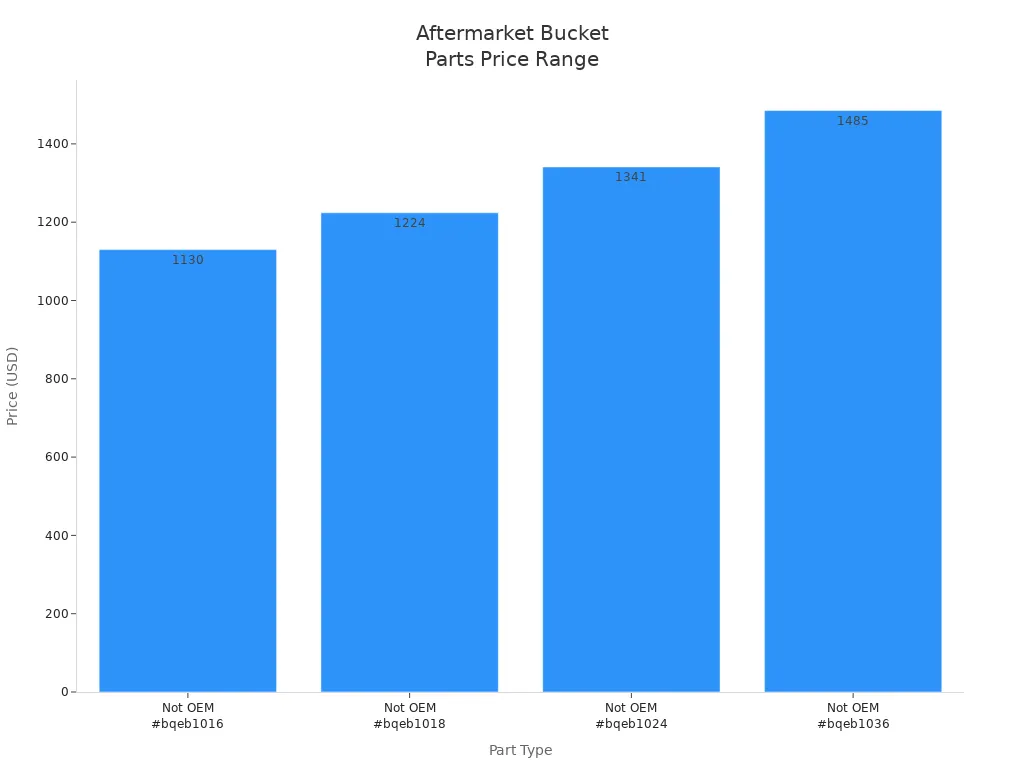

You need to think about both quality and cost when you buy bobcat quick connect bucket parts. OEM parts cost more money. They last longer and protect your machine. Aftermarket parts cost less. Their quality can change. Some aftermarket parts work well. Others wear out fast and break down.

Here are some prices for aftermarket parts:

Part Type | Price |

|---|---|

Compatible, Not OEM #bqeb1016 | $1130 |

Compatible, Not OEM #bqeb1018 | $1224 |

Compatible, Not OEM #bqeb1024 | $1341 |

Compatible, Not OEM #bqeb1036 | $1485 |

OEM parts for bobcat quick couplers cost between $1,150 and $1,448. Aftermarket parts cost less. You must check their quality and make sure they fit your bobcat.

Callout: Aftermarket parts save money now. Poor quality can mean more repairs and higher costs later. OEM parts protect your machine and often have a warranty.

To avoid fake or bad parts, follow these steps:

Find the right part using your bobcat model and serial number.

Check if the seller is trustworthy. Pick companies instead of single sellers.

Buy new parts for better reliability. If you buy used, ask for a warranty and testing.

Tip: Always use your official parts catalog and check all details before you buy. This keeps your bobcat safe and helps you avoid expensive mistakes.

You can pick the right quick connect bucket parts by doing these things: First, check your Bobcat’s model and serial numbers. Next, look in your manual or catalog for part numbers. Then, match the part numbers to your machine’s details. You should ask trusted suppliers to make sure the parts are right. Picking carefully helps your equipment stay safe and work well. Here is how the right bucket fits your needs:

Feature | Details |

|---|---|

Product Type | 13″ tooth trench bucket for Bobcat mini excavator |

Compatibility | Fits E Series and Quick X Change models |

Weight Capacity | For machines weighing 6,000 – 10,000 pounds |

Always use manufacturer resources and check every detail before you buy.

FAQ

What is a quick connect bucket part?

A quick connect bucket part lets you attach or remove a bucket from your Bobcat excavator fast. You do not need special tools. This part saves you time and helps you switch between jobs easily.

How do I know if a bucket part fits my Bobcat excavator?

You should check your model and serial number. Use your operator’s manual and compatibility charts. Always match part numbers before you buy. If you feel unsure, ask your dealer for help.

Can I use aftermarket parts instead of OEM parts?

Yes, you can use aftermarket parts. You must check their quality and fit. OEM parts always fit and protect your warranty. Aftermarket parts may cost less, but you should buy from trusted sellers.

Why does bucket weight capacity matter?

Bucket weight capacity tells you how much your excavator can lift safely. If you use a bucket that is too heavy, you can damage your machine. Always check the weight rating before you buy or use a bucket.

What should I do if I am not sure about compatibility?

Tip: Contact your Bobcat dealer or a trusted supplier. They can help you check part numbers and fit. Never guess. Double-checking keeps your equipment safe and working well.