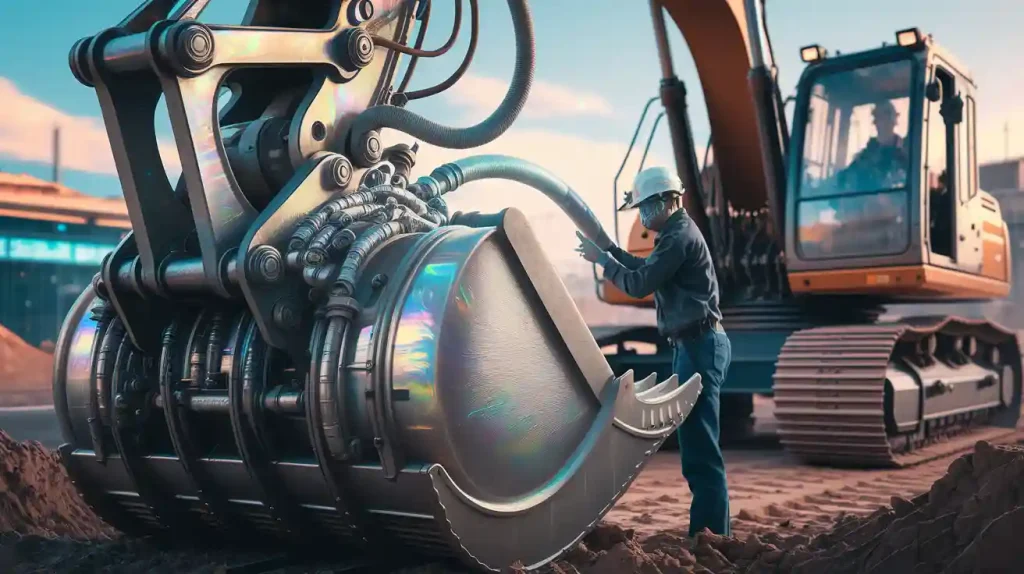

A blue excavator hydraulic pump helps you use heavy machines. It changes mechanical energy into hydraulic pressure. This pump gives power to different parts of your excavator. The hydraulic system needs the pump to work smoothly and reliably. There are different kinds of pumps you might see. These include gear, piston, axial piston, radial piston, and vane pumps. Each type moves pressurized fluid in its own way. Knowing if your pump uses fixed or variable displacement is important. This helps you keep your equipment working well.

Type of Pump | Description | Common Uses in Construction Equipment |

|---|---|---|

Gear Pumps | Simple and dependable, uses gears that fit together | Lubrication systems, chemical processing |

Piston Pumps | Very efficient, works at high pressure | Hydraulic presses, industrial machines |

Axial Piston Pumps | Has many pistons, gives strong pressure | High-performance hydraulics for excavators |

Radial Piston Pumps | Pistons are in a circle, very efficient | Mining equipment, industrial automation |

Vane Pumps | Has vanes on a spinning part, can change volume | Used in construction machines like excavators |

Key Takeaways

A blue excavator hydraulic pump changes engine power into hydraulic pressure. This helps the machine dig, lift, and turn well.

There are different hydraulic pumps like gear, piston, and vane pumps. Each type does a special job and fits certain tasks in construction.

It is important to take care of the hydraulic pump. You should change the oil and manage the filters often. This helps the pump last longer and work better.

You can pick fixed or variable displacement pumps. This choice can give you better control and save energy for different jobs.

Using eco-friendly fluids and quieter pumps is good for the environment. These choices also help your excavator work better.

Blue Excavator Hydraulic Pump Overview

Definition

A blue excavator hydraulic pump is a device that helps the excavator work. It turns engine power into hydraulic pressure. The pump sits in the middle of the hydraulic system. It pushes fluid through hoses and valves. This lets the machine dig, lift, and turn. The pump takes energy from the engine and makes pressure energy. This helps hydraulic fluid move to different parts of the excavator.

The hydraulic pump is like the heart of your excavator. Without it, the engine would just make noise and heat. Nothing would move without the pump.

The usual pressure for a blue excavator hydraulic pump is 20 to 200 PSI. The exact pressure depends on the number of valves and hoses in the system.

The pump is powered by the engine.

It changes engine energy into pressure and movement in the fluid.

The pump sends pressurized fluid to actuators. These move the boom, bucket, and other parts.

Main Function

You need the blue excavator hydraulic pump for every movement. The pump makes sure fluid flows with enough force for tough jobs. Here are the main things it does:

The pump turns engine energy into hydraulic energy.

It makes the pressure needed to move fluid in the system.

The pump lets you dig, lift, and turn with strong force.

The hydraulic system helps you lift heavy loads and dig deep.

How well your pump works affects your excavator’s performance. If you use a pump with new technology, you can save fuel and money. Operators can choose to work faster or save fuel. New pumps, like variable displacement piston pumps, are quieter and more accurate. Features like independent metering valves and creep mode give smoother control and more comfort.

Feature | Benefit |

|---|---|

Variable Displacement Design | Quieter operation |

Independent Metering Valves | Smoother control |

Closed-Center Valve System | Lower fuel use |

Digital Controls | Custom functions |

You should think about the environment when using hydraulic pumps. Eco-friendly fluids help protect soil and water. Quieter pumps make less noise. Better designs lower carbon emissions.

If you want a good blue excavator hydraulic pump, you can contact YNF Machinery. They have pumps that fit your needs and help your excavator work better.

Excavator Hydraulic Pump System

Types of Hydraulic Pumps

Excavators use different kinds of hydraulic pumps. Each pump works in its own way. Some pumps are better for certain jobs. You need to know how each pump works. This helps you pick the best one for your machine.

Gear pumps are simple. They are good for easy jobs. They do not make a lot of pressure or flow.

Vane pumps work harder than gear pumps. They can handle bigger jobs. They make more pressure.

Piston pumps are the strongest. They are best for heavy work. They give the most pressure and flow.

You should learn about fixed displacement and variable displacement pumps. The table below shows how they are different:

Pump Type | Advantages | Disadvantages |

|---|---|---|

Variable Displacement | Saves energy by changing flow when needed. | Harder to fix because of moving parts. |

Can change flow for different jobs. | ||

Lasts longer because it uses less energy. | ||

Fixed Displacement | Simple design makes it easy to fix. | Not as good when jobs change. |

Costs less to buy at first. | ||

Always gives the same flow, good for steady work. |

Tip: Pick a variable displacement pump for more control and saving energy. Pick a fixed displacement pump for easy care and steady work.

Working Principle

It is important to know how the blue excavator hydraulic pump works. The pump uses engine power to make hydraulic pressure. This pressure moves oil through the system. It helps the excavator do its job.

The pump works in steps:

Stage | Description |

|---|---|

Energy input | The engine gives power to the pump. The pump starts to turn. |

Suction stage | The pump pulls oil from the tank. The oil goes into the pump. |

Compression stage | The pump squeezes the oil. The oil gets high pressure. |

Liquid discharge | The pump pushes the oil out. The oil moves through the system. |

Circulation process | The pump keeps repeating these steps. This keeps the pressure steady. |

You see this every time you use your excavator. The pump sends pressurized oil to the cylinders. The boom, stick, and bucket move because of the hydraulic system. You can make many parts move at once. This helps you dig, lift, and turn easily.

The pump gives power to the cylinders. You can move the arms and tools.

The system lets you stretch and pull the boom, stick, and bucket.

You can control many movements at the same time. The system makes everything work smoothly.

To keep your excavator working well, take care of the pump and system. YNF Machinery has pumps that fit your needs. Their pumps help your excavator work better and last longer.

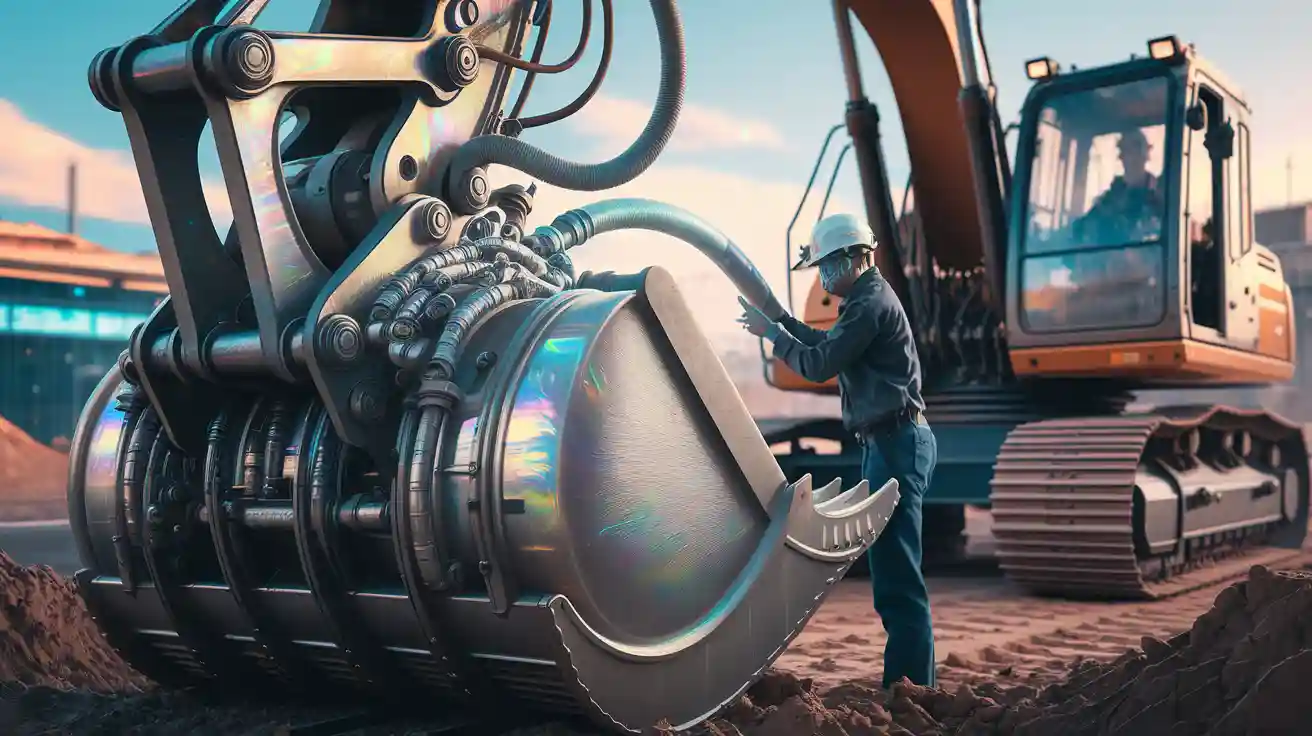

Hydraulic Pump Excavator Parts

Key Components

It is important to know the main hydraulic pump excavator parts. Each part does a special job in the system. The table below lists the most important parts and what they do:

Component | Function |

|---|---|

Hydraulic Pump | Moves hydraulic fluid from the oil tank to the hydraulic system. |

Gear Pump | Works with lower pressure and is good for simple jobs. |

Piston Pump | Handles higher pressure and speed, making the machine run smoother. |

Other hydraulic pump excavator parts are hoses, actuators, boom, dipper, and bucket. Hydraulic hoses carry fluid between the pump, valves, and actuators. Hydraulic cylinders turn hydraulic energy into movement. The boom, dipper, and bucket use this movement to dig, lift, and carry things.

The table below shows how these hydraulic pump excavator parts work together:

Component | Role in Hydraulic System | Interaction with Other Parts |

|---|---|---|

Hydraulic Hoses | Carry fluid through the hydraulic system. | Link the pump, valves, and actuators for smooth fluid movement. |

Hydraulic Cylinders | Change hydraulic energy into straight movement and force. | Push the piston to move the boom, arm, and bucket when fluid goes in. |

Tip: Check hoses and cylinders often. Broken hydraulic pump excavator parts can cause leaks or weak movement.

Fluid Delivery Process

The blue excavator hydraulic pump sends pressurized fluid to the actuators. This happens in three main steps:

Oil suction stage: The pump pulls hydraulic oil from the tank by making low pressure.

Pressurization stage: The pump squeezes the fluid to make it high pressure.

Delivery stage: The pump sends high-pressure oil to the actuators, which moves the boom, dipper, and bucket.

Hydraulic pumps make flow and control pressure. Pressure depends on how much the oil is blocked in the system. Flow rate changes with pump size, speed, fluid thickness, and temperature. You need to balance flow and pressure for strong digging and lifting.

Hydraulic pumps make flow and handle pressure.

Pressure comes from blocking oil flow in the system.

Flow rate depends on pump size, speed, fluid type, and temperature.

If you want strong hydraulic pump excavator parts, you can contact YNF Machinery. Their products help your excavator work well and last longer.

Maintenance and Common Issues

Routine Care

You must keep hydraulic pump excavator parts clean and in good shape. Taking care of them often helps the hydraulic pump last longer. It also helps the pump work well every day. You should follow the rules used by the industry. The table below lists important ways to take care of your pump:

Maintenance Practice | Details |

|---|---|

Filter Management | Change filters every 1,000 hours. For heavy use, change them after 500 hours. |

Oil Replacement | Replace hydraulic oil every 1,000-2,000 hours or once a year. Use oil that meets ISO 11158. |

Oil Sample Monitoring | Test oil samples every 500 hours for water and dirt. |

Bolt Torque Verification | Tighten bolts to the right level and check them often. |

Cleaning and Lubrication | Clean parts with special alcohol and use the right grease. |

Vibration and Temperature Monitoring | Check vibration and temperature every 500 hours to stop overheating. |

On-site Emergency Response | Keep a repair kit and spare parts ready for quick fixes. |

Tip: Doing regular checks helps you find small problems early. You can fix them before they get worse. This saves you time and money.

Troubleshooting

Sometimes, you may have problems with hydraulic pump excavator parts. Knowing how to spot and fix these problems is important. It helps your hydraulic pump keep working well. Here are some common problems and how to fix them:

Issue | Causes | Fixes |

|---|---|---|

Overheating | Not enough oil, dirty oil, blocked cooling, heavy work | Add oil, clean and change oil, clean cooling parts, avoid heavy work |

Noisy Hydraulic Pump | Not enough oil, dirty filters, leaking hoses, wrong oil | Add oil, change filters, check hoses, use the right oil |

Low Hydraulic Pressure | Worn parts, leaks, dirty filters, air in the system | Change parts, fix leaks, change filters, remove air |

To fix problems with hydraulic pump excavator parts, follow these steps: First, check the fluid level and look for blockages in the suction strainer. Next, test the pump and relief valve for noise, pressure, and heat. If you still have problems, open the pump and check the rotors, bearings, and seals.

Note: Always use the right hydraulic oil and filters. This helps stop common problems with hydraulic pump systems.

Longevity Tips

You can help your hydraulic pump and parts last longer by following these tips: Watch the fluid temperature and keep it under 180°F. Look at the fluid color and thickness. Check for leaks near cylinders and motors. Test the system pressure and how fast it works. Change hydraulic filters every 250 hours. Test the fluid for dirt every 500 hours. Change all the hydraulic fluid every 1,000 hours. Use air breathers and filters to keep the fluid clean. Clean and check parts often. Fix small problems fast so they do not get worse.

Taking care of your pump and fixing problems quickly helps it work better and last longer. Good pumps give strong flow and pressure. Pumps that are not cared for lose power and can break.

If you want strong hydraulic pump excavator parts, you can contact YNF Machinery. Their products help your excavator stay strong and work well.

The blue excavator hydraulic pump makes your machine move. It helps you lift heavy things and dig carefully. The pump changes engine power into hydraulic force. This is why the pump is important:

Key Aspect | Description |

|---|---|

Hydraulic Power | Lets you do hard work with strong force. |

Variable Displacement | Helps you control how much fluid and power you use. |

Long Lifespan | Can last up to 15,000 hours if you take care of it. |

You can help your pump last longer by doing these things:

Use good hydraulic oil and change it often.

Look for leaks and broken hoses every day.

Do not make your excavator work too hard or get too hot.

Follow the care steps in your manual.

Taking care of your pump saves money and helps your excavator work well. If you need strong hydraulic pumps and parts, pick YNF Machinery.

FAQ

What does a hydraulic pump do in an excavator?

You use a hydraulic pump to move fluid through the excavator’s system. This pump helps you lift, dig, and turn with strong force. It changes engine power into pressure so your machine can work.

How often should you check hydraulic pump parts?

You should check pump parts every week. Look for leaks, worn hoses, and dirty filters. Regular checks help you find problems early and keep your excavator working well.

Why does my excavator lose power during operation?

Low power can happen if the fluid level drops, filters get dirty, or hoses leak. You should inspect these parts and replace them if needed. Clean oil and tight hoses help your machine stay strong.

Where can you buy reliable hydraulic pump parts?

You can buy strong and reliable hydraulic pump parts from YNF Machinery. They offer products that fit your excavator and help it last longer.

How do you know when to replace hydraulic oil?

You should replace hydraulic oil every 1,000 to 2,000 hours or once a year. Check the oil color and thickness. If the oil looks dirty or thin, change it sooner.