Choosing the right excavator undercarriage parts manufacturers plays a vital role in maintaining your equipment’s performance. High-quality parts ensure efficiency, durability, and cost savings over time. A trusted undercarriage parts supplier helps you avoid frequent breakdowns and costly repairs. However, finding reliable manufacturers can be challenging. You must evaluate product quality, brand reputation, and compatibility with your equipment. Understanding your working environment and consulting professionals can simplify this process. Researching supplier reputation and conducting a cost-effectiveness analysis also ensures you make informed decisions.

Key Takeaways

Pick manufacturers that use strong, good-quality materials. This makes parts last longer and avoids frequent changes.

Check your excavator’s undercarriage parts often. Finding damage early saves money and helps your machine last longer.

Make sure the parts fit your excavator model. Right parts work better and keep the machine steady.

Choose suppliers with warranties and helpful customer service. This keeps your money safe and gives help when needed.

Read online reviews about the manufacturer. Good reviews mean their products are reliable and well-made.

Understanding Excavator Undercarriage Parts

What Are Excavator Undercarriage Parts?

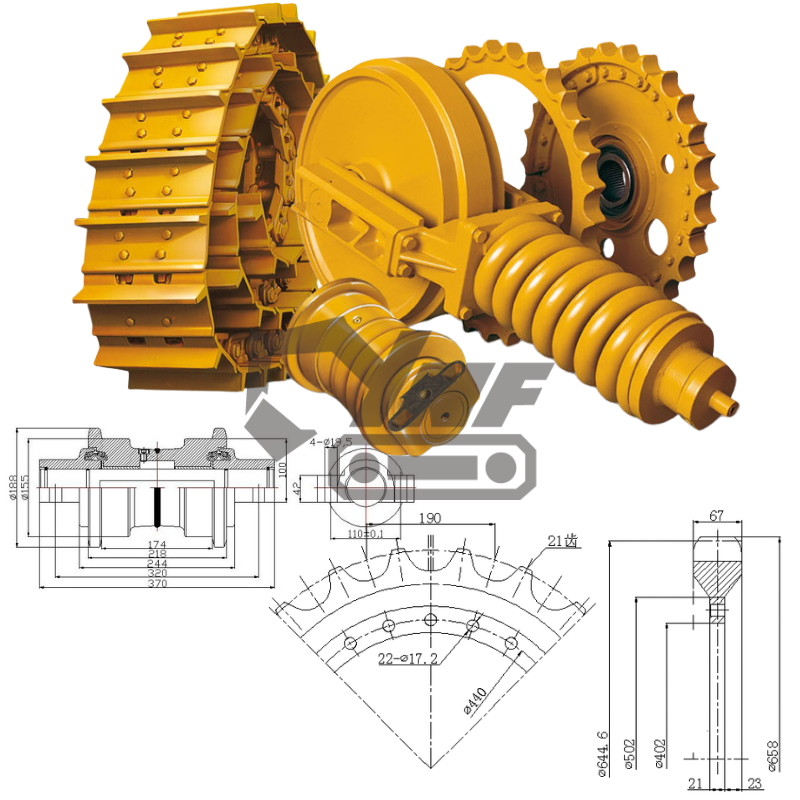

Excavator undercarriage parts form the foundation of your machine. These components include tracks, rollers, idlers, sprockets, and other essential elements that support the excavator’s movement and stability. They work together to ensure the machine operates efficiently on various terrains. Whether your excavator uses steel tracks for rugged environments or rubber tracks for delicate surfaces, the undercarriage plays a critical role in maintaining balance and traction.

Why Are Undercarriage Parts Essential for Excavator Performance?

The undercarriage directly impacts your excavator’s performance and lifespan. It provides stability, mobility, and support during operations. Well-maintained undercarriage parts prevent breakdowns, reduce wear and tear, and improve overall efficiency. For example, track shoes distribute the machine’s weight evenly, while rollers keep the tracks aligned. Proper tensioning mechanisms ensure smooth movement, avoiding derailments. Neglecting these parts can lead to misalignment, increased wear, and costly repairs.

Tip: Regular inspections and timely replacements of undercarriage parts can extend your excavator’s lifespan and save you money in the long run.

Common Types of Excavator Undercarriage Parts

Excavator undercarriage parts come in various types, each serving a specific function. Here are some of the most common ones:

Tracks: Provide traction and stability. Steel tracks are ideal for heavy-duty tasks, while rubber tracks suit sensitive surfaces.

Track Chains: Hold the tracks together and transmit power from the drive sprockets.

Rollers: Support the machine’s weight and keep the tracks aligned.

Idlers: Guide the tracks and maintain proper tension.

Drive Sprockets: Engage with the track chains to propel the excavator.

Track Shoes: Distribute weight and provide grip on different terrains.

Tensioning Mechanism: Prevent derailment by maintaining track tension.

Each part contributes to the excavator’s overall functionality, ensuring smooth and efficient operations. Understanding these components helps you make informed decisions when selecting or replacing essential undercarriage parts.

Signs of Wear and When to Replace Undercarriage Parts

Recognizing the signs of wear in your excavator’s undercarriage parts is essential for maintaining optimal performance. Routine inspections help you identify issues early, preventing costly repairs and downtime. Here are some key indicators to watch for during your checks:

Tracks showing uneven wear or visible damage.

Rollers and idlers with cracks or oil leaks.

Sprockets with worn or broken teeth.

Track chains with elongation or missing links.

You can also use specific measurements to determine when parts need replacement:

Sprocket teeth lose more than 30% of their tip thickness.

Carrier roller rims fall below the standard thickness of 8mm.

Track rollers develop dents deeper than 5mm.

Track shoes exhibit penetrating cracks.

Idler wheels wear more on the inner side than the outer side.

Delaying the replacement of worn-out components can lead to several problems. A neglected undercarriage increases fuel consumption and reduces machine efficiency. Worn parts compromise stability, raising the risk of accidents. Operating with damaged components also results in higher maintenance costs and frequent breakdowns. These issues not only affect your machine’s power and handling but also increase downtime, impacting your productivity.

Tip: Regularly inspect your undercarriage and replace worn parts promptly. This practice ensures your excavator operates efficiently and safely, saving you money in the long run.

By staying proactive, you can avoid the negative consequences of neglect and keep your equipment in top condition. Always prioritize timely replacement to maintain the reliability and performance of your excavator.

Key Indicators of Reliable Excavator Undercarriage Parts Manufacturers

Use of High-Quality Materials and Advanced Manufacturing Techniques

Reliable manufacturers prioritize the use of premium materials and cutting-edge manufacturing methods to produce durable undercarriage parts. High-strength alloy steel is a popular choice due to its resistance to bending, torsion, and impact. Composite materials also enhance durability and stability, making them ideal for demanding applications. For instance, wear-resistant alloy steel is essential for heavy-duty operations like mining or rough terrain work. These materials extend the service life of your excavator undercarriage parts, reducing the frequency of replacements.

Modern manufacturing techniques further ensure the quality of these components. Forging, a superior method for creating durable parts, is widely used. Some manufacturers employ a 5-station automatic forging line for in-house production, maintaining strict quality control. Heat treatment processes, with carefully monitored parameters, enhance the strength and reliability of parts. Automated assembly using advanced robotics ensures precision and consistency, resulting in high-quality products that perform well under extreme conditions.

Adherence to Industry Standards and Certifications

Trustworthy excavator undercarriage parts manufacturers comply with industry standards and hold relevant certifications. These standards ensure that the parts meet safety, performance, and durability requirements. Manufacturers who adhere to international benchmarks demonstrate their commitment to quality and reliability. Certifications also provide you with confidence that the products are tested and approved for use in various applications. When evaluating manufacturers, always check for compliance with recognized standards to ensure you receive dependable undercarriage parts.

Availability of Warranties and Comprehensive After-Sales Support

Warranties and after-sales support are critical indicators of reliable suppliers. A warranty reflects the manufacturer’s confidence in their product’s quality. It also protects your investment by covering potential defects or issues. Comprehensive after-sales support ensures you have access to replacement parts that match original factory standards. This consistency restores your equipment’s performance and stability.

Timely replacement of worn parts minimizes downtime and reduces maintenance costs. Some manufacturers offer customized preventative maintenance plans to help you maintain warranty coverage and extend the lifespan of your equipment. Regular service intervals, often required by OEM warranties, ensure compliance and protect your investment. Choosing a manufacturer with robust after-sales support guarantees a smoother ownership experience and long-term reliability.

Transparent Pricing and Detailed Product Information

Transparent pricing and detailed product information play a crucial role when selecting an excavator undercarriage parts manufacturer. These factors not only simplify your decision-making process but also build trust between you and the supplier. A reliable manufacturer ensures you understand the costs upfront, eliminating the risk of unexpected charges later.

When manufacturers provide clear pricing models, you can plan your budget more effectively. This transparency fosters trust and reassures you that there are no hidden fees. It also promotes a partnership approach, where both parties work together to achieve mutual success. You feel more confident knowing exactly what you are paying for and why.

Detailed product information is equally important. Manufacturers who offer comprehensive descriptions of their products help you make informed decisions. For example, specifications such as material type, dimensions, and compatibility with specific excavator models allow you to verify if the part meets your requirements. This clarity reduces the chances of purchasing incompatible or substandard components.

Why It Matters:

Transparent pricing and detailed product information save you time and money. They also reduce stress by ensuring you know what to expect from your purchase.

Here are some benefits of these practices:

You avoid unexpected charges and hidden fees.

You gain a clear understanding of pricing models, easing concerns.

You feel more confident in the supplier’s reliability.

By choosing a manufacturer that prioritizes transparency and clarity, you ensure a smoother purchasing experience. This approach not only enhances your trust in the supplier but also ensures your excavator operates efficiently with the right parts.

Ensuring Compatibility with Your Excavator Model

Importance of Choosing Model-Specific Excavator Undercarriage Parts

Selecting undercarriage parts tailored to your excavator model ensures optimal performance and longevity. Each excavator has unique specifications, including weight, size, and operational requirements. Using generic parts can lead to poor fitment, reduced efficiency, and faster wear. Model-specific parts align perfectly with your machine’s design, maintaining balance and stability during operations. They also reduce the risk of mechanical failures, which can disrupt your projects and increase costs.

Tip: Always refer to your excavator’s manual or consult the manufacturer to identify the correct undercarriage parts for your model.

How to Verify Compatibility Before Purchase

Verifying compatibility before purchasing undercarriage parts saves you time and money. Start by gathering essential details about your excavator, such as the make, model, and serial number. Use this information to cross-check part specifications provided by the manufacturer or supplier. Many reliable manufacturers offer detailed product descriptions, including dimensions and material types, to help you confirm compatibility.

You can also reach out to the supplier’s customer support team for assistance. They can guide you in selecting parts that match your excavator’s requirements. Some suppliers even provide compatibility tools on their websites, allowing you to input your machine’s details and find suitable components. Ensuring compatibility with different makes of excavators is crucial, especially if you manage a fleet with diverse brands.

Note: Double-checking compatibility prevents costly mistakes and ensures your excavator operates efficiently.

Customization Options for Unique Equipment Needs

Modern projects often demand specialized solutions, making customized undercarriage parts essential. Customization allows you to adapt your excavator to unique working conditions, enhancing its performance and reliability. For example:

Some manufacturers design high-performance undercarriages for specific applications, such as large mining excavators or compact construction machines.

Others collaborate with clients to create tailor-made solutions, from design to production, ensuring the parts meet exact requirements.

These services not only improve your equipment’s efficiency but also give you a competitive edge in challenging environments. Custom undercarriages handle diverse tasks with precision, whether you’re working on rough terrains or delicate surfaces.

Tip: Discuss your project needs with the manufacturer to explore customization options that suit your equipment.

Evaluating the Reputation of Excavator Undercarriage Parts Manufacturers

Checking Online Reviews and Testimonials

Online reviews and testimonials provide valuable insights into a manufacturer’s reputation. They reflect the experiences of other customers, helping you gauge the quality of products and services. Positive reviews often highlight high-quality parts and excellent customer service. On the other hand, negative reviews can reveal areas where the manufacturer may fall short.

Monitoring reviews regularly allows you to identify trends in customer feedback. For example, consistent praise for durability or performance indicates reliability. Conversely, repeated complaints about delivery delays or product defects may signal potential issues. Many manufacturers also use review management services to gain deeper insights into customer perceptions. These tools help them address concerns and improve their offerings.

Tip: Look for reviews on multiple platforms to get a balanced view. This approach ensures you make an informed decision based on diverse opinions.

Researching Industry Experience and Track Record

A manufacturer’s industry experience and track record speak volumes about their reliability. Companies with years of experience often have a deep understanding of excavator undercarriage parts and their applications. Their expertise enables them to produce parts that meet high standards and perform well under various conditions.

Researching a manufacturer’s history can also reveal their commitment to quality and innovation. Long-standing companies often invest in advanced technologies and materials to stay competitive. Additionally, a proven track record of satisfied customers indicates consistent performance. You can find this information on the manufacturer’s website or through industry publications.

Note: Prioritize manufacturers with extensive experience and a solid reputation. Their expertise ensures you receive dependable products.

Seeking Recommendations from Industry Professionals

Assessing Customer Service and Responsiveness

Customer service and responsiveness play a vital role in your experience with an excavator undercarriage parts manufacturer. A company that values its customers ensures smooth communication and prompt assistance, which can save you time and reduce stress.

Start by evaluating how quickly the manufacturer responds to your inquiries. A reliable supplier answers questions about product specifications, pricing, and compatibility without delay. Quick responses show that the company prioritizes your needs and values your time. You can test this by contacting their customer support team through email, phone, or live chat. Pay attention to how long it takes to receive a reply and whether the information provided is clear and helpful.

Tip: Look for manufacturers that offer multiple communication channels, such as email, phone, and instant messaging apps like WhatsApp. This flexibility makes it easier for you to reach them when needed.

The quality of customer service also reflects the manufacturer’s commitment to your satisfaction. A good supplier listens to your concerns and provides practical solutions. For example, if you face issues with a part, they should guide you through troubleshooting or offer a replacement if necessary. Companies that go the extra mile to resolve problems demonstrate their reliability and professionalism.

You should also consider how the manufacturer handles after-sales support. Do they assist with installation or provide maintenance tips? Do they follow up to ensure you are satisfied with your purchase? These actions show that the company values long-term relationships with its customers.

Why It Matters: Excellent customer service ensures a hassle-free purchasing experience. It also builds trust, giving you confidence in the manufacturer’s ability to meet your needs.

By choosing a manufacturer with responsive and supportive customer service, you can avoid unnecessary delays and ensure your excavator operates efficiently.

Why YNF Machinery Is the Right Excavator Undercarriage Parts Supplier

Over 35 Years of Experience in the Excavator Parts Industry

When choosing the right excavator undercarriage parts supplier, experience matters. YNF Machinery has been in the excavator parts industry for over 35 years. This extensive experience allows the company to understand your needs and deliver reliable solutions. Their deep knowledge ensures that you receive parts designed to perform well in various conditions. Whether you operate in construction, mining, or infrastructure development, YNF Machinery has the expertise to support your operations.

Did You Know? A supplier with decades of experience often provides better insights into product performance and durability.

High-Quality Products Backed by Rigorous Quality Inspections

YNF Machinery prioritizes quality in every product. Each excavator part undergoes rigorous inspections to meet high standards. These inspections ensure that the parts perform reliably and last longer. For example, their undercarriage components are made from durable materials like high-strength alloy steel. This focus on quality reduces the risk of breakdowns and minimizes maintenance costs. By choosing YNF Machinery, you can trust that your excavator will operate efficiently with dependable parts.

Competitive Pricing and Low Minimum Order Quantities

Affordability is another reason why YNF Machinery stands out as the right excavator undercarriage parts supplier. The company offers competitive pricing without compromising on quality. This approach helps you manage costs effectively, especially for large projects. Additionally, YNF Machinery provides low minimum order quantities, making it easier for you to stock up on essential parts. Whether you need a single component or bulk orders, their pricing structure ensures value for your investment.

Tip: Look for suppliers who balance quality and affordability to maximize your budget.

YNF Machinery combines experience, quality, and affordability, making it the right excavator undercarriage parts supplier for your needs. Their commitment to excellence ensures that your equipment performs at its best.

Comprehensive Support and Logistics Assistance

Reliable excavator undercarriage parts manufacturers offer more than just quality products. They provide comprehensive support and logistics assistance to ensure a seamless purchasing experience. This support helps you save time, reduce stress, and keep your operations running smoothly.

Manufacturers with strong logistics capabilities ensure timely delivery of parts. They use efficient shipping networks to minimize delays, even for international orders. For example, a supplier might partner with global carriers to deliver parts to remote locations. This reliability ensures you receive the components you need without disrupting your projects.

Tip: Always confirm the shipping options and estimated delivery times before placing an order. This step helps you plan your maintenance schedule effectively.

Comprehensive support also includes clear documentation and guidance. Manufacturers often provide detailed installation manuals, maintenance tips, and troubleshooting guides. These resources help you install and maintain parts correctly, reducing the risk of errors. Some suppliers even offer video tutorials or virtual consultations to assist you further.

Customer-focused manufacturers also handle customs clearance and paperwork for international shipments. This service simplifies the process for you, ensuring compliance with regulations. Additionally, they track shipments and provide updates, so you always know the status of your order.

Here are some key benefits of choosing a manufacturer with robust support and logistics:

Timely Deliveries: Avoid project delays with reliable shipping.

Expert Guidance: Access resources to install and maintain parts.

Hassle-Free Imports: Let the supplier manage customs and documentation.

Real-Time Updates: Stay informed about your shipment’s progress.

By selecting a manufacturer that prioritizes support and logistics, you ensure a smooth and efficient experience. This approach not only saves you time but also enhances your confidence in the supplier’s reliability.

Benefits of Building Long-Term Partnerships with Reliable Manufacturers

Consistent Quality and Reliable Supply Chain

Partnering with reliable suppliers ensures you receive consistent quality in your undercarriage parts. This consistency reduces the risk of equipment failure and keeps your excavator running efficiently. A dependable manufacturer also strengthens your supply chain. They deliver parts on time, even during global disruptions, ensuring your projects stay on schedule. Reliable suppliers often adopt sustainable practices, which not only reduce environmental impact but also enhance your brand reputation. By building a long-term relationship, you gain access to tailored solutions that meet your specific needs, adding unique value to your operations.

Tip: A strong partnership with a reliable supplier helps you maintain operational stability and avoid costly delays.

Cost Savings Through Bulk Orders and Loyalty Programs

Long-term partnerships often come with financial benefits. Reliable suppliers offer discounts on bulk orders, allowing you to save money while stocking up on essential undercarriage parts. Loyalty programs provide additional value, such as exclusive deals or priority services. These savings can significantly reduce your operational costs over time. By working closely with a trusted manufacturer, you also minimize the risk of purchasing substandard parts, which can lead to expensive repairs or replacements.

Why It Matters: Bulk orders and loyalty rewards not only save you money but also ensure a steady supply of high-quality parts for your excavator.

Access to Expert Advice and Technical Support

Reliable manufacturers provide expert advice and technical support to help you maintain your equipment. Their expertise minimizes downtime by resolving issues quickly and efficiently. Prompt maintenance services prevent minor problems from escalating into major disruptions. Many manufacturers also offer customized maintenance programs tailored to your specific needs. These programs enhance the efficiency of your undercarriage and extend the lifespan of your excavator. By leveraging their technical support, you ensure your equipment operates at peak performance.

Note: Expert guidance from a trusted supplier adds significant value to your operations, keeping your equipment reliable and productive.

Strengthening Business Relationships for Future Needs

Building strong relationships with reliable manufacturers benefits your business in the long run. These partnerships ensure consistent access to high-quality undercarriage parts, which keeps your equipment running smoothly. A trusted supplier becomes more than just a vendor. They become a valuable partner who understands your needs and helps you achieve your goals.

Long-term relationships often lead to better communication. When you work closely with a manufacturer, they learn about your specific requirements. This understanding allows them to provide tailored solutions, such as customized undercarriage parts or faster delivery times. You also gain access to exclusive benefits, like priority service or early access to new products.

Collaborating with a dependable supplier strengthens your supply chain. Reliable manufacturers ensure timely delivery of undercarriage components, even during unexpected challenges. This reliability reduces downtime and keeps your projects on schedule. A strong partnership also gives you peace of mind, knowing that your supplier will support you in urgent situations.

Investing in these relationships can also save you money. Many manufacturers offer loyalty programs or discounts for repeat customers. These savings add up over time, especially if you frequently purchase undercarriage parts. Additionally, a trusted supplier helps you avoid the costs associated with poor-quality components, such as frequent replacements or equipment damage.

Tip: Regular communication with your supplier strengthens your partnership. Share feedback about their products and services to help them meet your expectations.

By fostering strong business relationships, you create a foundation for future success. These partnerships ensure you always have access to the undercarriage parts you need, helping your business grow and thrive.

Choosing the right excavator undercarriage parts manufacturers is essential for maintaining your equipment’s performance and reducing costs. Start by understanding your working environment and equipment needs. Focus on product quality and brand reputation to ensure durability and reliability. Regular inspections and professional consultations help you maintain efficiency. Perform a cost-effectiveness analysis to balance initial costs with long-term savings.

YNF Machinery stands out as a trusted partner with over 35 years of experience. Their high-quality products, competitive pricing, and excellent support make them a reliable choice. Take informed steps to select the best manufacturer and keep your operations running smoothly.

FAQ

What should you look for in a reliable excavator undercarriage parts manufacturer?

Focus on manufacturers that use high-quality materials, follow industry standards, and offer warranties. Check for transparent pricing, detailed product information, and strong customer support. Research their reputation through reviews and testimonials to ensure reliability.

Tip: Always prioritize manufacturers with a proven track record and positive customer feedback.

How often should you inspect your excavator’s undercarriage parts?

Inspect your excavator’s undercarriage parts every 100-200 operating hours or after working in harsh conditions. Regular checks help you identify wear and tear early, preventing costly repairs and downtime.

Why It Matters: Routine inspections extend your equipment’s lifespan and maintain its efficiency.

Can you use generic undercarriage parts for your excavator?

Using generic parts may compromise your excavator’s performance and durability. Model-specific parts ensure proper fitment, balance, and stability. They also reduce the risk of mechanical failures and frequent replacements.

Note: Always verify compatibility with your excavator model before purchasing parts.

How can you ensure compatibility when buying undercarriage parts?

Gather your excavator’s make, model, and serial number. Use this information to cross-check part specifications with the manufacturer. Many suppliers provide compatibility tools or customer support to help you choose the right parts.

Tip: Double-check compatibility to avoid costly mistakes and ensure smooth operations.

Why is YNF Machinery a trusted supplier for excavator undercarriage parts?

YNF Machinery offers over 35 years of expertise, high-quality products, and competitive pricing. Their rigorous quality inspections and excellent customer support make them a reliable choice. They also provide low minimum order quantities and logistics assistance for a seamless purchasing experience.

Did You Know? YNF Machinery serves clients worldwide, ensuring reliable parts for over 26 excavator brands.