A ball guide excavator uses special balls to help it turn. These balls are made very carefully. The ball guide is in the middle of the swing system. It helps the top part of the excavator move smoothly. The balls lower friction between the moving parts. This lets the excavator turn without problems. The ball guide also holds up heavy weights. It keeps the machine steady while it works. The hydraulic system gives power to the swing motor. The swing motor moves the ball guide. Each time the hydraulics push, the swing moves. The ball guide helps control these moves exactly. It keeps the top and bottom parts lined up. This works even when the pressure is very high. Operators use this system to turn safely and lift things. If the ball guide was weak, the swing would not work well. The ball guide makes sure every move is smooth and steady. Hydraulic circuits, motors, and pumps need the ball guide to work their best. In every excavator with hydraulics, the ball guide is very important. It helps the machine stay stable, turn well, and carry heavy loads.

Key Takeaways

The ball guide helps the excavator turn easily. It lowers friction and keeps the top and bottom parts lined up. It holds heavy loads and keeps the machine steady when digging or lifting. Checking and oiling the ball guide often stops wear, leaks, and damage. This keeps the machine safe and working well. A good ball guide helps the hydraulic system work better. It also saves fuel by lowering friction. If you ignore ball guide problems, the machine can get noisy and shaky. It can also need expensive repairs. Finding problems early is very important.

Ball Guide Excavator Basics

What Is a Ball Guide

A ball guide excavator uses a special bearing system. This system has small steel balls inside. These balls help the top part turn easily. The ball guide is a main part of the excavator. It lowers friction between moving parts. This makes turning easier for the machine. The ball guide is made from strong iron and steel. These materials help it last a long time. They also stop it from wearing out fast. The ball guide works well with little oil. It can even work in water. This makes it a strong part of the hydraulic system.

The ball guide assembly has many important parts. Each part helps the swing mechanism work smoothly.

Component Type | Description / Role |

|---|---|

Plates | Separator plates, friction plates, retainer plates, cam plate, port plate |

Balls | Ball bearings used within the assembly |

Springs | Various springs including brake springs |

Pistons | Pistons involved in the ball guide mechanism |

Pins | Pins for assembly and positioning |

Retainers | Retainer plates and other retaining components |

Shafts and Keys | Shafts and keys for mechanical connection |

Seals | Lip type seals to stop leaks |

Where It’s Located

The ball guide is inside the swing bearing. The swing bearing sits between the top and bottom of the excavator. It is just under the cab. The ball guide helps the top part turn over the bottom part. This spot is important for digging and lifting. The ball guide works with the hydraulic system. It lets the machine turn all the way around. Operators use it when digging or lifting things.

Role in Excavator Structure

The ball guide is important for the excavator’s structure. It connects the top and bottom parts. It keeps them lined up when working. The ball guide holds heavy loads. It helps the machine do hard jobs. It also lowers wear on other parts. This makes the hydraulic system work better. It helps the machine last longer. The ball guide works with attachments and other parts. It keeps the excavator safe and steady when digging. Many attachments need the ball guide to move smoothly.

Ball Guide Excavator Function

Swing Motion Control

The ball guide helps the excavator turn with great accuracy. It sits in the middle of the swing system. This lets the top part spin over the bottom part. The hydraulic system gives power to the swing motor. The swing motor moves the ball guide to control turning. Operators can turn the cab and arm exactly where needed. The ball guide lowers friction, so turning is fast and safe. This helps the operator put the bucket in the right spot. The ball guide keeps the swing steady, even with heavy loads. This control is important for safety and getting work done well.

Load-Bearing Capacity

The ball guide must hold up very heavy weights. It supports the top part, the boom, and anything being lifted. Its design lets it carry forces from many directions at once. This is important when digging or lifting. Ball guides in new excavators meet strict rules for strength. For example, the static load rating for ball bearings follows DIN ISO 76. This sets a pressure limit of about 4,200 N/mm². This limit stops the ball guide from getting damaged by heavy loads. Ball guides can last from 1,700 to 4,000 hours in slewing gears. Some last up to 5,000 hours. These numbers show how strong and tough the ball guide is.

Feature | Explanation |

|---|---|

360-degree joint support | Lets the ball guide hold up loads from many angles, which is needed for digging and lifting. |

Shaftless design | Gives more room for other parts and helps movement under heavy force. |

High load carrying capacity | Handles big weights and strong forces while working. |

Ideal stiffness | Stops the ball guide from bending or breaking under pressure. |

Low friction | Cuts down on wear and helps the hydraulic system work better. |

Extended service life | Lasts longer, even in hard jobs, which saves money and time. |

The ball guide can adjust itself if things are not lined up perfectly. Two rows of balls inside help lower friction and heat. The curved raceway takes in stress and keeps the ball guide working well. This is true even on rough ground or when lifting heavy things.

Stability and Maneuverability

The ball guide is important for keeping the excavator steady and easy to move. It connects the top and bottom parts and keeps them lined up. The ball guide keeps the machine steady when lifting or turning. This is very important on slopes or bumpy ground. The ball guide also helps the operator move the machine exactly where needed. It allows for smooth turns and stops. The hydraulic system and ball guide work together for quick responses. This teamwork gives the excavator its special abilities.

Operators trust the ball guide for safe lifting and digging. The ball guide lowers the chance of tipping or losing control. It also protects other parts by spreading out the forces. The ball guide makes sure the excavator can do hard jobs and stay safe.

Tip: Check the ball guide and hydraulic system often to keep the excavator steady and ready for heavy work.

Excavator Performance Impact

Efficiency and Reliability

Ball guides help the excavator work better and faster. They make the swing system move with less force. This lets the operator finish jobs more quickly. The ball guide keeps the top and bottom lined up. This helps the excavator stay steady during hard work. When the ball guide works right, the machine saves energy. The operator can use the excavator for many hours without trouble. Ball guides also help add extra hydraulics. These systems let the excavator use different tools for digging or lifting. Good ball guides make sure these tools work well every time.

Wear Reduction

The ball guide lowers rubbing between moving parts. This helps stop parts from wearing out too soon. When the excavator digs or lifts heavy things, the ball guide spreads out the force. This keeps the machine strong and safe. Less wear means the hydraulic system lasts longer. The operator does not need to fix or change parts as much. Ball guides also protect the swing bearing and other hydraulic parts. They help the machine keep working, even in hard digging jobs or with heavy tools.

Tip: Check the ball guide and hydraulic system often. This can stop early wear and keep the excavator ready for work.

Hydraulic System Support

Ball guides are important for the hydraulic system. They help the hydraulic pump work smoothly by lowering friction inside the pump. This lets oil flow the right way and keeps pressure steady. Good oil flow and pressure help the excavator dig and lift with power. Ball guides also spread out pressure in the pump. This protects the pump and other hydraulic parts from damage. When the ball guide works well, the hydraulic system stays strong, even with extra hydraulics for special tools. The ball guide helps the excavator handle tough digging and lifting jobs every day.

Ball guides help with:

Smooth running of hydraulics

Even pressure in the hydraulic pump

Reliable use of extra hydraulics and tools

The ball guide makes sure the excavator can use all its hydraulic power for digging, lifting, and using tools. This keeps the machine ready for any job.

Maintenance and Issues

Common Problems

Ball guides in an excavator can have many problems each day. Operators often notice these issues:

If there is not enough oil, parts wear out fast and get too hot. Too much oil can break seals and make leaks.

Rust happens when water or acid gets to the ball guide. This can hurt the surface and make it dirty.

When dust and dirt build up, the ball guide wears out faster.

If the ball guide is not lined up right, it gets damaged from uneven weight.

Using the ball guide for a long time makes it less steady and loose.

Not taking care of the ball guide, like skipping oil or cleaning, causes damage and stops it from working.

Tip: Check the ball guide often and use good oil to stop most problems.

Signs of Wear

Operators should look for signs that the ball guide needs fixing. Finding problems early can stop bigger repairs. Some signs are:

The excavator makes more noise or shakes when turning or digging.

The top and bottom parts feel loose or move too much.

Oil leaks show up near the swing bearing or hydraulic parts.

The swing moves unevenly or jerks, especially with extra tools.

You can see rust, dirt, or damage on the ball guide.

If you ignore these signs, the hydraulic system can break and the machine may stop working.

Maintenance Tips

Taking care of the ball guide helps it last longer and work well. Here are some easy tips:

Put the right oil on the ball guide often. Do not use too much oil so seals stay safe.

Keep the swing bearing area clean to stop dirt from getting in. This keeps the ball guide safe when digging.

Look at the seals and change them if they are worn or broken. Good seals keep out water and dust.

After hard digging or changing tools, check if the ball guide is lined up. Fix it if needed to stop uneven weight.

Only use the right hydraulic oil for the excavator and extra tools. This keeps all parts safe.

Check the ball guide often, especially after lots of digging or using extra tools.

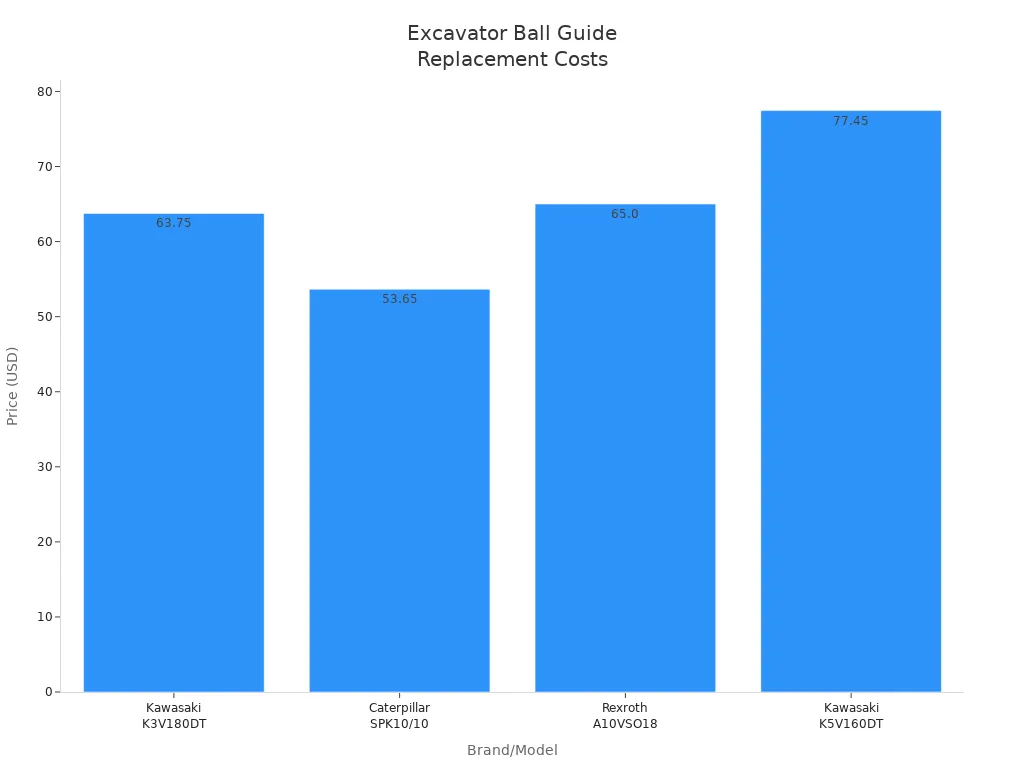

How much a new ball guide costs depends on the brand and model. The table below shows some prices:

Brand/Model | Price Range (USD) | Warranty | Delivery Time |

|---|---|---|---|

Kawasaki K3V180DT | $63.75 | 3-6 months | 1-10 days |

Caterpillar SPK10/10 | $53.65 | Not specified | Not specified |

Rexroth A10VSO18 | $65.00 | Not specified | Not specified |

Kawasaki K5V160DT | $77.45 | Not specified | Not specified |

Doosan DX340 113 | Negotiable | 3-6 months | 1-10 days (stock dependent) |

Note: These prices are just for the part. You will pay more for work and time lost during replacement.

A ball guide lets the excavator turn easily and stay steady. It holds up heavy things and helps the swing system work right. Checking and caring for the ball guide often stops damage and keeps the hydraulic system strong. Operators should do these things: 1. Look for cracks, leaks, or strange sounds. 2. Wipe off the ball guide after using the machine. 3. Add oil when the manual says to. If the ball guide breaks, the excavator might not work safely. Taking care of it keeps the machine safe and working well.

FAQ

What happens if a ball guide fails in an excavator?

A failed ball guide can cause the excavator to lose smooth swing motion. The machine may shake or make loud noises. Operators might see oil leaks or loose movement. Repairs should happen quickly to prevent more damage.

How often should operators check the ball guide?

Operators should check the ball guide before each work shift. Regular checks help find leaks, dirt, or wear early. Many experts suggest a full inspection every 250 hours of use.

Can a ball guide be repaired, or does it need replacement?

Some ball guides can be repaired if damage is minor. Most severe problems require a full replacement. Using damaged ball guides can harm other parts of the excavator.

Does the ball guide affect fuel use?

Yes, a well-working ball guide lowers friction. The excavator uses less power to turn. This can help save fuel and reduce operating costs.