Understanding the parts of an excavator is essential for anyone involved in construction or heavy machinery operation. Each component plays a vital role in the machine’s functionality, ensuring tasks are completed efficiently and safely. By familiarizing yourself with the common parts of an excavator, you can enhance your operational skills and maintain the equipment effectively. Regular maintenance and inspection of these parts, especially the hydraulic systems and controls, are crucial for optimal performance. Investing in quality excavator parts not only extends the machine’s life but also boosts its efficiency and performance.

The Undercarriage of an Excavator

The undercarriage forms the foundation of an excavator, providing stability and mobility. Understanding the components of the undercarriage is crucial for maintaining the machine’s efficiency and longevity. Let’s explore the key parts of the excavator’s undercarriage.

Tracks

Excavator tracks are vital for movement and traction. They allow the machine to navigate various terrains with ease. There are different types of tracks, each designed for specific conditions.

Track Chains

Track chains connect the track pads and enable movement. These chains, often made from steel or other durable materials, reduce wear and tear on other undercarriage parts. By ensuring smooth operation, track chains play a crucial role in the overall performance of the excavator.

Track Shoes

Track shoes provide the necessary grip and stability for the excavator. They are attached to the track chains and come in various designs to suit different terrains. Choosing the right type of track shoes can enhance the machine’s efficiency and prevent slippage.

Rollers and Idlers

Rollers and idlers work together to guide the tracks along the undercarriage. They ensure smooth and reliable track movement, minimizing wear and optimizing performance.

Bottom Rollers

Bottom rollers support the weight of the entire machine. They maintain clearance height and reduce stress on other components like sprockets and front wheels. Proper maintenance of bottom rollers is essential for the longevity of the excavator.

Top Rollers

Top rollers brace the chains and provide crucial support for the tracks. They help in maintaining the tension and alignment of the tracks, ensuring efficient operation.

Drive Sprockets

Drive sprockets are responsible for moving the tracks. They engage with the track chains, propelling the excavator forward or backward. Regular inspection of drive sprockets is necessary to prevent wear and ensure smooth movement.

Understanding these parts of an excavator’s undercarriage helps you maintain the machine effectively. By focusing on these components, you can enhance the performance and lifespan of your excavator.

The Cab of the Excavator

The cab of an excavator serves as the command center for the operator. It houses all the essential controls and features that ensure efficient operation and comfort. Understanding the components within the cab can significantly enhance your ability to operate the machine effectively.

Operator’s Seat

The operator’s seat is a crucial element in the cab, designed with ergonomics in mind. A well-designed seat reduces fatigue and increases productivity during long hours of operation. Modern excavators often feature adjustable seats, allowing you to customize the position for optimal comfort. This adjustment capability ensures that you maintain a proper posture, which is vital for reducing strain on your body.

Expert Testimony: John Dotto, a Product Application and Training Specialist, emphasizes, “Operator comfort has a direct impact on productivity, and the more we utilize the basic principles of ergonomics specific to the type of equipment we build, the greater productivity we can provide our customers.”

Control Panel

The control panel is the heart of the excavator’s operation. It contains all the necessary excavator controls that allow you to maneuver the machine with precision. Familiarizing yourself with these controls is essential for efficient operation. The layout typically includes joysticks, pedals, and switches that manage the movement of the boom, arm, and bucket. Mastery of these controls ensures that you can perform tasks smoothly and safely.

Expert Testimony: Vince Porteous, a Product Manager at Komatsu Europe, notes, “We already provide our customers with highly productive and efficient machines. With the new operator cab, we’ve taken a significant step forward by increasing operator comfort and ergonomics.”

Visibility Features

Visibility is a key factor in safe and efficient excavator operation. The cab is equipped with features that enhance your ability to see the work area clearly.

Windows

Windows in the cab provide a clear view of the surroundings. They are strategically placed to minimize blind spots and maximize visibility. Clean and well-maintained windows are essential for ensuring that you can monitor the worksite effectively.

Mirrors

Mirrors complement the windows by offering additional perspectives. They help you keep an eye on areas that are not directly visible through the windows. Properly adjusted mirrors are crucial for maintaining awareness of your surroundings, thus enhancing safety.

Modern cabs are designed to offer a comfortable and secure environment. Features like air conditioning and sound insulation further contribute to operator comfort, reducing fatigue and enhancing focus. By understanding and utilizing the cab’s features, you can improve your operational efficiency and ensure a safer working environment.

The Boom and Arm of an Excavator

The boom and arm of an excavator are essential components that enable the machine to perform its primary functions, such as digging and lifting. Understanding these parts of the excavator can enhance your operational skills and ensure efficient use of the machine.

Boom

The excavator boom acts as the backbone of the machine’s digging capabilities. It extends from the cab and provides the necessary reach and height for various tasks. There are different types of excavator booms, each designed for specific applications:

Mono-booms: These are standard booms that offer a straightforward design, ideal for general excavation tasks.

Articulated or knuckle booms: These provide more flexibility and movement, especially useful in confined spaces where maneuverability is crucial.

For specialized tasks, you might consider using a long reach boom arm. This attachment extends the reach of the excavator, allowing you to access areas beyond the typical range. It’s particularly beneficial for dredging, slope shaping, and working in deep trenches.

Arm

The excavator arm, also known as the stick, connects the boom to the bucket. It plays a pivotal role in controlling the depth and angle of digging. Different types of excavator arms cater to various operational needs:

Standard arms: Suitable for most excavation tasks, providing a balance between reach and power.

Long-reach arms: These are designed for tasks requiring extended reach, such as working in aquatic environments or wetland construction.

By selecting the appropriate type of excavator arm, you can optimize the machine’s performance for specific tasks.

Bucket

The excavator bucket is the attachment at the end of the arm, responsible for digging, lifting, and moving materials. Understanding the types of excavator buckets and their features can significantly impact your efficiency on the job site.

Types of Buckets

There are various types of excavator buckets, each suited for different materials and tasks:

General-purpose buckets: Ideal for everyday digging and loading tasks.

Heavy-duty buckets: Designed for tougher materials like rock or compacted soil.

Trenching buckets: Narrower buckets used for digging trenches.

Choosing the right type of excavator bucket ensures that you can handle the specific demands of your project effectively.

Bucket Teeth

Bucket teeth are crucial for improving penetration into hard soil or rock. They are typically made of high-strength steel and are replaceable, allowing you to maintain optimal performance. Regular inspection and replacement of bucket teeth can prevent wear and enhance the efficiency of your excavator.

By understanding the boom, arm, and bucket, you can maximize the capabilities of your excavator. Selecting the right excavator parts for your specific needs ensures that you can tackle a wide range of tasks with precision and efficiency.

The Hydraulic System in Excavators

The hydraulic system serves as the powerhouse of an excavator, enabling its various movements and operations. You rely on this system to transfer power to the moving parts, ensuring controlled and powerful actions. Understanding the components of excavator hydraulics is essential for maintaining efficiency and performance.

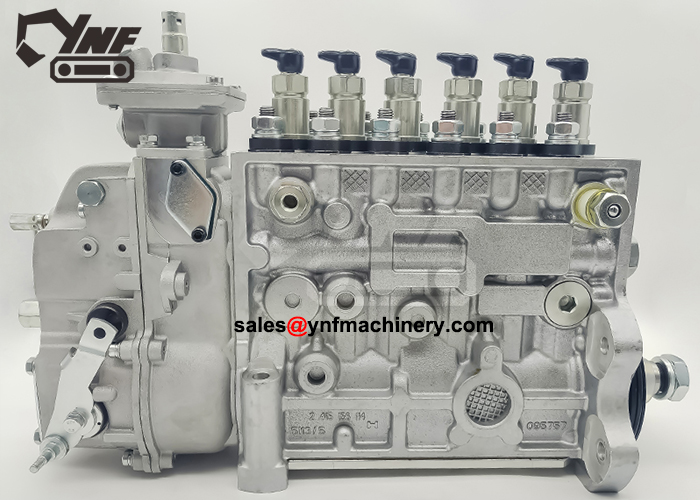

Hydraulic Pumps

Hydraulic pumps play a pivotal role in excavator hydraulics. They generate the necessary pressure to move hydraulic fluid throughout the system. This fluid powers the movement of the boom, arm, and bucket. Regular maintenance of hydraulic pumps ensures that your excavator operates smoothly and efficiently. By keeping these pumps in top condition, you prevent potential breakdowns and maintain optimal performance.

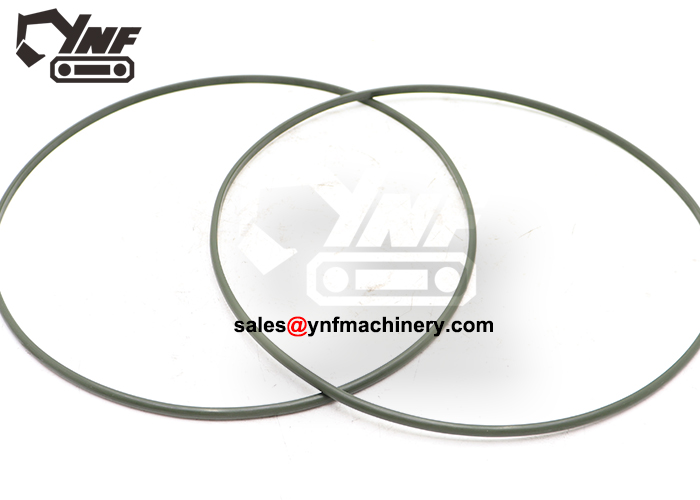

Hydraulic Cylinders

Hydraulic cylinders are crucial components in excavator hydraulics. They convert the hydraulic fluid’s pressure into mechanical force, allowing precise control over the boom, arm, and bucket. You depend on these cylinders for the excavator’s lifting and digging capabilities. Regular inspection and maintenance of hydraulic cylinders are vital. This practice ensures that they function correctly and safely, preventing any unexpected failures during operation.

Hydraulic Hoses

Hydraulic hoses connect the various components of the hydraulic system, allowing fluid to flow between them. These hoses must withstand high pressure and harsh conditions. You should regularly check hydraulic hoses for signs of wear or damage. Replacing worn hoses promptly prevents leaks and maintains the integrity of the hydraulic system. By ensuring the hoses are in good condition, you contribute to the overall efficiency and safety of your excavator.

Expert Insight: Innovative electro-hydraulic technology offers smoother control and greater precision in excavators. This advancement contributes to lower fuel consumption and enhanced operator comfort.

Understanding and maintaining the hydraulic system in your excavator is crucial. By focusing on hydraulic pumps, cylinders, and hoses, you ensure that your machine operates efficiently and safely. Regular maintenance not only extends the life of these components but also enhances the overall performance of your excavator.

Excavator Attachments by YNF Machinery

Excavators become truly versatile machines with the right attachments. excavator attachments offers a range of excavator attachments that transform your equipment into a multi-functional powerhouse. By selecting the appropriate attachments, you can expand the capabilities of your excavator, allowing it to perform tasks beyond just digging. This adaptability increases productivity and reduces the need for additional machinery.

Quick Couplers

Quick couplers are essential for efficient attachment changes. They allow you to switch between different tools swiftly, minimizing downtime and maximizing productivity. With quick couplers, you can easily transition from one task to another without the hassle of manual attachment changes. This feature is particularly beneficial in projects requiring multiple attachments, as it enhances operational efficiency and saves valuable time.

Specialized Attachments

Specialized attachments cater to specific tasks, enabling your excavator to handle a variety of operations with precision and ease.

Grapples

Grapples are perfect for handling bulky materials like logs, rocks, or debris. They provide a firm grip, allowing you to move and position heavy objects with accuracy. Whether you’re involved in forestry, demolition, or recycling, grapples enhance your excavator’s functionality, making it an indispensable tool for material handling tasks.

Hammers

Hammers, also known as breakers, are designed for demolition and breaking tasks. They deliver powerful blows to break through concrete, rock, or asphalt. By equipping your excavator with a hammer, you can efficiently tackle demolition projects, roadwork, or any task requiring substantial breaking force. This attachment turns your excavator into a formidable demolition machine, capable of handling tough materials with ease.

By utilizing these specialized attachments, you can significantly enhance the versatility and efficiency of your excavator. YNF Machinery provides high-quality attachments that ensure reliable performance and durability, helping you achieve optimal results in your projects.

Engine and Powertrain of the Excavator

The engine and powertrain form the core of an excavator, driving its performance and efficiency. Understanding these components helps you maintain your machine’s optimal functionality.

Engine

The engine serves as the heart of the excavator. It provides the power needed to operate all systems, from the hydraulic pump to the swing drive. Typically, excavators use diesel engines due to their torque and durability, which are essential for heavy-duty work. The engine size and power output vary depending on the excavator’s size and type. A powerful engine allows you to perform demanding tasks, crucial in construction and mining. Modern excavator engines focus on fuel efficiency and environmental compliance, meeting emission standards without sacrificing power.

Transmission

The transmission system in an excavator transfers power from the engine to the tracks or wheels, enabling movement. It plays a vital role in controlling speed and direction. You rely on the transmission to ensure smooth operation and maneuverability. Regular maintenance of the transmission system is essential. This practice prevents wear and ensures that your excavator operates efficiently. By understanding the transmission’s function, you can better manage the machine’s performance and longevity.

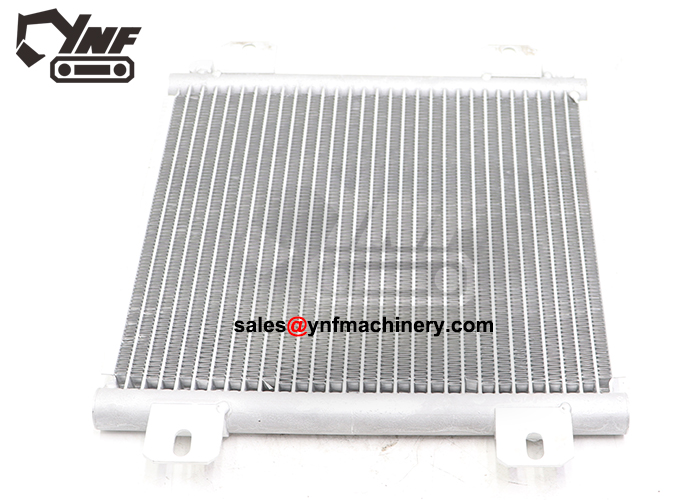

Cooling System

The cooling system in an excavator prevents the engine from overheating. It maintains the engine’s temperature within optimal limits, ensuring reliable performance. You should regularly check the cooling system for leaks or blockages. Proper maintenance of this system prevents engine damage and extends the life of your excavator. By keeping the cooling system in good condition, you contribute to the overall efficiency and safety of your machine.

Understanding the engine and powertrain components of your excavator is crucial. By focusing on these areas, you ensure that your machine operates at peak performance, enhancing productivity and reducing downtime.

Use and Maintenance Tips for Excavator Parts

Proper use and maintenance of excavator parts are crucial for ensuring the longevity and efficiency of your machine. By following these tips, you can keep your excavator in top condition and avoid costly repairs.

Daily Inspections

Conducting daily inspections is essential for maintaining the health of your excavator. Before starting your work, check all critical components to ensure they are functioning correctly. Look for any signs of wear or damage on the tracks, rollers, and drive sprockets. Inspect the hydraulic hoses for leaks or cracks, as these can lead to significant issues if left unchecked. Examine the excavator buckets and attachments for any signs of wear or damage. Regular inspections help you identify potential problems early, allowing you to address them before they escalate.

Maintenance Experts emphasize, “Regular monitoring and maintenance of hydraulic fluid levels are essential for optimal excavator performance.”

Regular Maintenance

Regular maintenance is vital to keep your excavator running smoothly. Change the lubricating oil and hydraulic oil at recommended intervals to ensure the machine operates efficiently. Clean and inspect mechanical parts regularly to prevent dirt and debris from causing damage. Pay special attention to the hydraulic system, as it plays a crucial role in the machine’s operation. By maintaining the hydraulic fluid levels and replacing worn-out parts, you can extend the service life of your excavator and improve its working efficiency.

Maintenance Experts advise, “Regular replacement of lubricating oil and hydraulic oil, and cleaning and inspection of mechanical parts can extend the service life of the excavator, improve its working efficiency, and stability.”

Safe Operation Practices

Safe operation practices are essential for preventing accidents and ensuring the safety of both the operator and the machine. Always follow the manufacturer’s guidelines when using excavator attachments. Ensure that the operator’s seat and control panel are adjusted for comfort and ease of use. Familiarize yourself with the visibility features, such as windows and mirrors, to maintain awareness of your surroundings. Properly secure all excavator buckets and attachments before use to prevent accidents. By adhering to safe operation practices, you can enhance the efficiency and safety of your excavator.

Maintenance Experts highlight, “Regular maintenance and repair work are vital to ensure that the excavator can withstand the harsh conditions and demands of excavation tasks.”

By implementing these use and maintenance tips, you can ensure that your excavator remains in excellent condition, providing reliable performance for years to come.

Major Parts of an Excavator by YNF Machinery

Understanding the major parts of an excavator is crucial for anyone involved in operating or maintaining these powerful machines. YNF Machinery provides high-quality components that ensure your excavator performs efficiently and reliably. Let’s explore some of these essential parts.

Hydraulic Components

Hydraulic components form the backbone of an excavator’s functionality. They power the movement of the boom, arm, and bucket, allowing you to perform tasks with precision and control. YNF Machinery offers a range of hydraulic parts, including pumps, cylinders, and hoses. These components are designed to withstand the rigors of heavy-duty operations, ensuring smooth and efficient performance. Regular maintenance of hydraulic systems is vital. It prevents leaks and maintains the integrity of the system, contributing to the overall efficiency of your excavator.

Rubber Mounts

Rubber mounts play a significant role in enhancing the stability and performance of an excavator. They absorb vibrations and reduce noise, providing a smoother operation. This feature is particularly important in maintaining the comfort of the operator and the longevity of the machine. YNF Machinery supplies durable rubber mounts that are essential for various applications. By choosing the right rubber mounts, you can significantly improve the functionality and efficiency of your excavator. Properly maintained rubber mounts ensure that your machine operates smoothly, even in challenging conditions.

Final Drives

Final drives are critical components that transfer power from the engine to the tracks, enabling movement. They play a key role in controlling the speed and direction of the excavator. YNF Machinery offers robust final drives that ensure reliable performance and durability. Regular inspection and maintenance of final drives are essential. This practice prevents wear and ensures that your excavator operates efficiently. By understanding the importance of final drives, you can better manage the performance and longevity of your machine.

By focusing on these major parts of an excavator, you can ensure that your machine operates at peak performance. YNF Machinery provides high-quality components that support the efficient and reliable operation of your excavator, helping you achieve optimal results in your projects.

Understanding the various parts of an excavator is crucial for anyone involved in its operation or maintenance. This knowledge ensures you can use the machine effectively, enhancing both safety and efficiency on the job site. Regular maintenance and correct operation prevent costly repairs and downtime, extending the machine’s lifespan. By investing in high-quality excavator parts, you support the seamless functioning of your equipment. YNF Machinery offers reliable components that help maintain your excavator’s performance, ensuring it remains a valuable asset in your operations.