You want your 120 John Deere excavator to work well, right? Taking care of 120 John Deere excavator parts often keeps it from breaking. This also saves you money. Get your manuals and diagrams; they help you find problems quickly.

Industry studies show that taking care of your 120 John Deere excavator early can save up to $7,900 each year. It also helps stop downtime.

You will see less downtime, fewer times it breaks, and better work.

Key Takeaways

Use the parts manual to find and order the right parts before fixing anything. This helps you save time and make fewer mistakes.

Check your excavator often by following a set inspection schedule. Look at important systems like hydraulics and undercarriage. This lets you find problems early and stop expensive repairs.

Pick the correct lubricants and use them on a regular schedule. Good lubrication stops parts from wearing out and helps your excavator parts last longer.

Manuals and Diagrams

When you want to keep your 120 John Deere excavator running smoothly, you need the right guides. Manuals and diagrams help you spot issues fast and make every repair easier. Let’s break down how you can use these tools every day.

Parts Manual Overview

You should always start with the John Deere 120 Excavator Parts Manual. This manual shows you every part with clear diagrams. You can find part numbers, see how pieces fit together, and order the right items. If you need to repair something, the parts manual helps you know exactly what you need.

Tip: Keep your parts manual close when you do any repair. It saves time and helps you avoid mistakes.

Technical Manual Tips

The repair technical manual is your best friend for fixing your excavator. This guide gives you step-by-step repair instructions. You can follow along for any repair, big or small. The repair technical manual also has troubleshooting charts. These charts help you find problems fast.

You should use the repair technical manual every time you work on your machine. If you want to test a system, the operation and test manual gives you the right steps. The operation and test manual also explains how to check if your repair worked.

If you ever feel stuck, check the repair technical manual. It often has the answer you need.

Here’s a quick checklist for using your manuals:

Use the parts manual to identify and order parts before any repair.

Follow the repair technical manual for every repair step.

Check the operation and test manual to confirm your repair worked.

Regular Excavator Maintenance

Taking care of your excavator means following a good routine. This helps your machine last longer and work better. Let’s see how you can make a smart inspection plan and check the most important systems.

Inspection Schedule

You should plan to check your John Deere 120 excavator often. Regular checks help you find problems before they get worse. Most people look at their machines every week. You need to check filters, fluids, hydraulics, the undercarriage, and electrical systems.

Tip: Use your operator’s manual to know when to do maintenance. The manual gives advice for fixing problems and tells you when to check each part.

Here’s an easy checklist you can use:

Check engine oil and hydraulic fluid levels.

Look at filters for dirt or clogs.

Check hoses and seals for leaks.

Clean the undercarriage after each use, especially if it’s muddy.

Test electrical systems for loose wires or weak batteries.

If you follow this plan, you can avoid big repairs and downtime. You also make sure your excavator maintenance is on track.

Key Systems Check

Some parts of your John Deere 120 excavator need extra care. If you skip these checks, you might have breakdowns and high costs.

The hydraulic system is very important. If you don’t check it, you could see leaks, weak power, or overheating. You should check fluid levels, hoses, and seals once a week.

The undercarriage also needs cleaning and checking. Dirt and debris can cause damage quickly. Clean it after every job, especially if you work in mud.

Here are the systems that can fail if you don’t check them:

Hydraulic system (fluid leaks, overheating, less power)

Undercarriage (damage from dirt and debris)

Filters (clogging causes poor performance)

Electrical system (loose wires, battery problems)

You may wonder if regular maintenance is worth it. Look at this table to compare costs and benefits:

Maintenance Type | Annual Cost | Potential Savings/Benefits |

|---|---|---|

Reactive Maintenance | $300,000 | Higher costs from emergency repairs and downtime. |

Preventive Maintenance | $264,000 | Fewer big repairs, longer equipment life, and better work. |

If you pick preventive maintenance, you can save money and keep your excavator working longer. Unplanned repairs can cost two to five times more than planned maintenance. Emergency repairs often cost three times more because you need help fast. Downtime can cost up to $300,000 each year.

Regular maintenance can make your equipment last 20-40% longer. You spend less time fixing things and more time working.

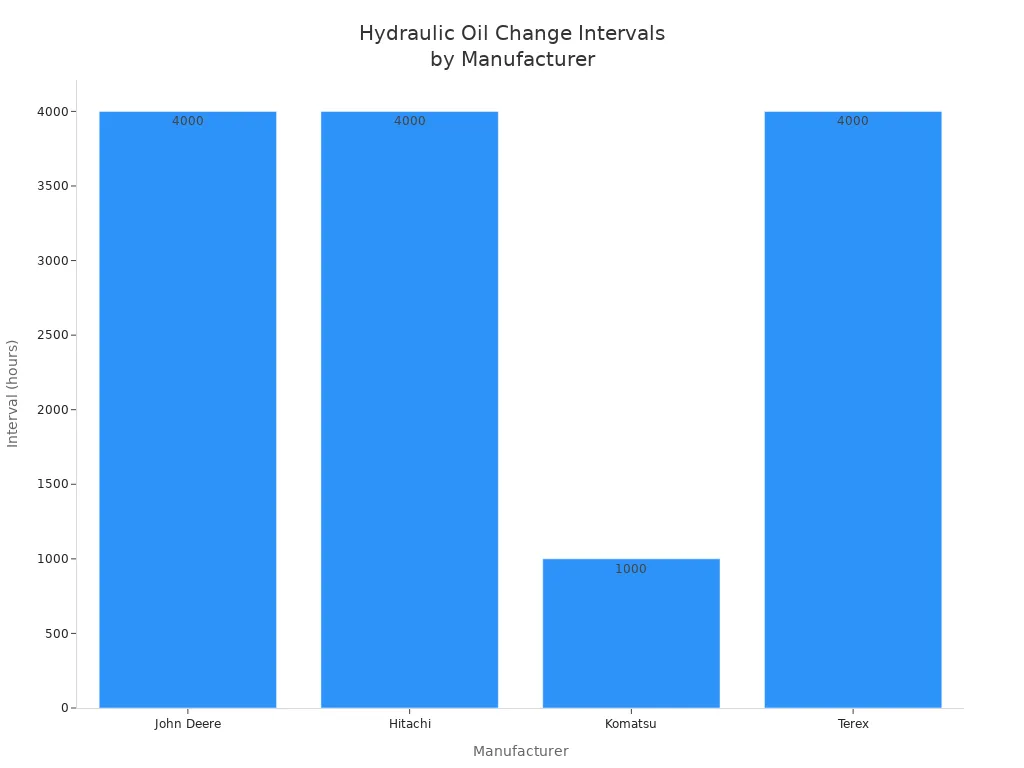

How often should you change fluids and grease your machine? John Deere says to change hydraulic oil every 4,000 hours and engine oil every 500 hours. Other brands like Hitachi and Terex have about the same times. Komatsu wants hydraulic oil filter changes every 1,000 hours.

Note: Always check your operator’s manual for the right times to do maintenance. Following the manual helps you avoid mistakes and keeps your excavator working well.

By following a regular inspection plan and checking key systems, you make excavator maintenance easy and helpful. You save money, avoid downtime, and get more work done.

120 John Deere Excavator Parts Checklist

It is smart to keep track of your 120 John Deere excavator parts. This helps you find problems early. You can plan when to fix things. Use this checklist to look at the most important parts.

Bucket and Attachments

Buckets and attachments do a lot of work. Check them for cracks or bent edges. Look for pins that are loose. Most contractors stop using hydraulic excavators for big jobs after 9,800 hours. By this time, buckets and attachments may need repairs or new parts. Excavators last about 10,000 hours. So, check these parts often.

Look for teeth that are worn or bolts that are missing.

Check for leaks in hydraulic connections.

Make sure quick couplers are locked tight.

Tip: If you see deep wear or cracks, get a new bucket before it breaks during work.

Tracks and Rollers

Tracks and rollers help your excavator move. Dirt and rocks can wear them out fast. Clean the undercarriage after every use. Check for bolts that are loose and rollers that are worn.

Check track tension every week.

Look for cuts or pads that are missing.

Check rollers for leaks or flat spots.

If you see uneven wear, you may need to fix or replace the tracks. Good care of the undercarriage and final drives keeps your machine working well.

Engine and Cooling

The engine gives power to your excavator. The cooling system stops it from getting too hot. Check oil and coolant every week.

Listen for strange sounds from the engine.

Look for leaks near hoses and radiators.

Change filters when the manual says to.

A clean engine and cooling system help all 120 John Deere excavator parts last longer. Regular care here stops expensive breakdowns.

Electrical Components

Electrical parts run lights, sensors, and the starter. Weak batteries or loose wires can stop your excavator.

Test battery voltage once a month.

Check wires for cracks or damage.

Look at fuses and relays.

If you find a problem, fix it right away. Good electrical parts mean less downtime for your 120 John Deere excavator parts.

Keeping this checklist close makes your maintenance easier. You protect your machine and keep every part working well.

Lubrication Routine

Lubricant Selection

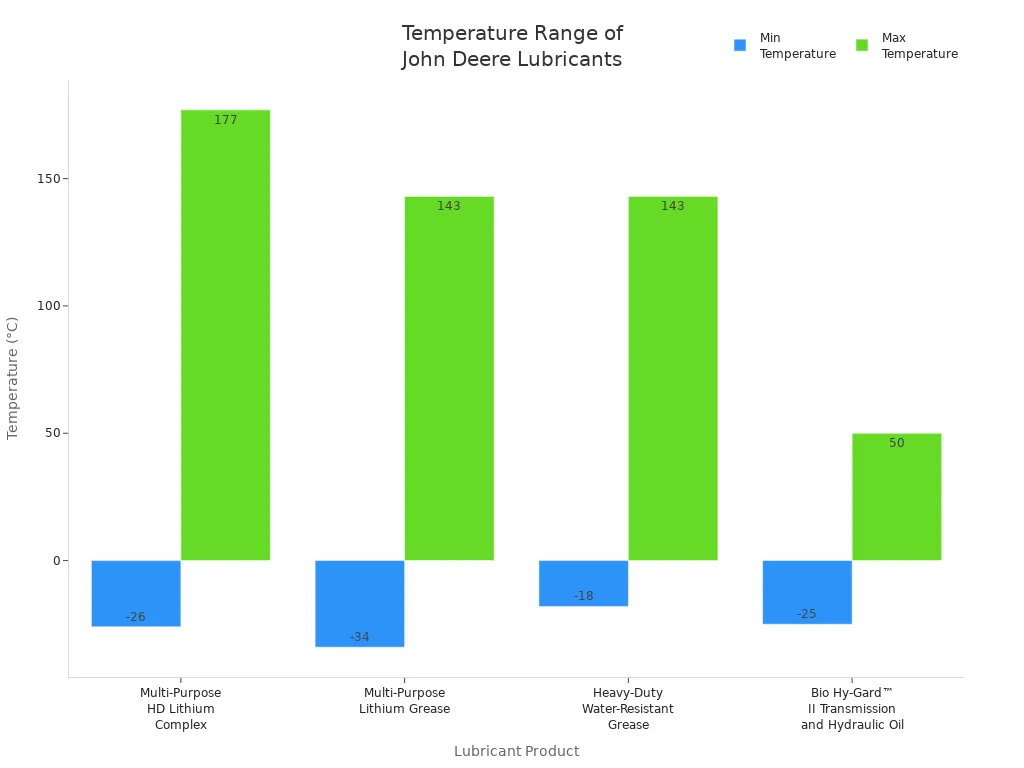

Choosing the right lubricant is very important for your John Deere 120 excavator. If you use the wrong oil or grease, parts can get damaged. John Deere has special products for different jobs and weather. Here is a table that shows which ones work best:

Product Name | Description | Temperature Performance | NLGI Grade |

|---|---|---|---|

Multi-Purpose HD Lithium Complex | Protects wheel bearings, U-joints, and other grease points | -26 to 177° C (-15 to 350° F) | NLGI Grade 2 |

Multi-Purpose Lithium Grease | Good for all-season, general use | -34 to 143° C (-30 to 290° F) | NLGI Grade 2 |

Heavy-Duty Water-Resistant Grease | Works in wet or muddy conditions | -18 to 143° C (0 to 290° F) | NLGI Grade 2 |

Bio Hy-Gard™ II Hydraulic Oil | For transmissions, hydraulics, and wet brakes | -25 to 50° C (-13 to 122° F) | N/A |

If you do not use the right lubricants, your parts may wear out faster. You could have more breakdowns and your parts might not last as long.

Lubrication Schedule

You need to follow a regular schedule to keep your excavator working well. Grease the moving parts and change the oils when needed. This stops rust, wear, and overheating. Here is why a schedule is important:

What You Do | How It Helps Your Excavator Parts Last Longer |

|---|---|

Use advanced synthetic oils and additives | Less wear, longer service life |

Check oil and grease often | Catch problems early, avoid breakdowns |

Monitor oil with analysis | Know when to change, prevent failures |

Use water-resistant grease in wet areas | Protects parts from rust and damage |

Tip: Write down each time you do a lubrication job on your calendar. Most experts say to grease pins and bushings every 50 hours. Change hydraulic oil every 4,000 hours.

A good lubrication routine means you will have fewer repairs. You will spend more time working. Your excavator will last longer and work better.

Identifying Wear and Repair Needs

Signs of Wear

You want your John Deere 120 excavator to work well every day. Finding wear early helps you stop big problems. Watch for these signs:

Look for scratches, dents, or cracks on buckets, rods, or attachments.

Check for leaks near hydraulic hoses, seals, or cylinders.

Listen for strange noises from the engine or moving parts.

Make sure bolts, pins, or couplers are not loose.

Watch for weak batteries or lights that flicker.

Sometimes your excavator feels weaker or moves slower. You might see dirt or metal bits in the hydraulic fluid. These signs mean something needs fixing.

The main reasons parts break too soon are:

Sideloading puts extra force on the piston rod and makes it misaligned.

Dirty fluid lets grit hurt seals and rods.

Bad fluid care lets dirt build up in the hydraulic system.

A rough or scratched rod can damage seals and cause more repairs.

Tip: If you see any of these problems, check your operator’s manual for help. The manual tells you how to look at each part and if you need a repair.

When to Replace

Knowing when to change a part saves time and money. If you wait too long, small problems get bigger. Waiting to fix worn parts costs more and causes more downtime. One broken part can stop your work and slow your project.

Here’s a table to help you know when to replace or fix a part:

Part/Area | Signs You Need to Replace | Can You Repair? | Replace Now? |

|---|---|---|---|

Bucket Teeth | Cracked, missing, worn | Sometimes | Yes |

Hydraulic Hoses | Leaking, bulging | Rarely | Yes |

Engine Filters | Dirty, clogged | No | Yes |

Electrical Wires | Frayed, broken | Sometimes | Yes |

Tracks/Rollers | Flat spots, loose pads | Sometimes | Yes |

If you see leaks, cracks, or hear odd sounds, plan a repair soon. Waiting can cause sudden breakdowns. You could lose hours or days of work. Always check your manuals for tips on repairs and troubleshooting. The manuals give you steps to fix problems before they get worse.

Note: If you are not sure about a repair, ask a trained technician. They can help you choose if you need a new part or just a quick fix.

You keep your excavator working longer when you act fast. Regular checks and quick repairs mean less downtime and lower costs. Your John Deere 120 excavator will work better and have fewer problems.

Service and Parts Providers

Qualified Technicians

You want your John Deere 120 excavator to work well. Skilled technicians help your machine run better. These experts know a lot about your excavator. They use the right tools for every job. They follow the newest repair steps. If you pick John Deere service, you get help from trained people. You can ask them questions and get easy answers.

Technicians look for hidden problems in your excavator.

They use official manuals and diagrams to fix things.

You get honest advice about repairs and care.

Tip: If you are not sure about a repair, talk to a certified technician. They can find problems early and help you avoid bigger issues.

Genuine Parts Sourcing

Getting the right parts helps your excavator work hard. Always look for high-quality replacement parts. John Deere dealers work with many trusted suppliers around the world. This means you get real parts that fit your machine. Parts experts help you choose the right items and answer your questions.

Evidence Type | Description |

|---|---|

Supplier Relationships | Over 3,000 trusted suppliers help give quality parts for the John Deere 120 excavator. |

When you buy parts, check part numbers in your manual. Even small mistakes can cause big problems. Use online catalogs to find the exact part you need. Always think about cost and how well the part works. Sometimes aftermarket parts cost less, but you should check reviews and certifications first.

If you want good parts for your John Deere 120 excavator, YNF Machinery is a great choice. They offer real parts and quick service. You can trust their team to help you find what you need.

Use official resources to check part numbers.

Ask for reviews or references before you buy.

Pick suppliers with good reputations and certifications.

Note: Choosing the right supplier means fewer breakdowns and better work from your excavator.

When you use manuals, your John Deere 120 excavator works better. Doing regular maintenance keeps it strong. Fixing parts quickly stops bigger problems. Checking your machine every day helps keep you safe. You can find leaks or worn parts early. If you track and plan your care, you avoid breakdowns. This makes your work safer for you and your team.

Quick-Reference Checklist:

Look at manuals before you repair anything

Check for leaks or damage every day

Write down all maintenance jobs

Repair problems as soon as you see them

FAQ

How often should you check your John Deere 120 excavator for wear?

You should inspect your excavator every week. Regular checks help you spot problems early and keep your machine running strong.

What is the best way to order replacement parts?

Always use your parts manual to find the right part number. You can order genuine parts directly from YNF Machinery for fast and reliable service.

Can you use any grease or oil for your excavator?

No, you should use lubricants recommended by John Deere. The right products protect your parts and help your excavator last longer.