You need the best excavator track parts to keep your machine working well. Each part of the undercarriage, like track shoes and chains, helps with grip, stability, and strength. The right replacement parts make your excavator work better and help you stick to a maintenance plan. Good care means less time fixing things and saves you money. If you pick strong parts, you can trust your equipment to do hard jobs and last a long time.

Key Takeaways

Pick track parts that fit your job site. Using the right parts helps your machine work better and last longer. It also stops parts from wearing out fast.

Take care of your excavator tracks often. Look at them and clean them every day. This keeps you safe and stops big repairs.

Choose track shoes that match the ground. Steel shoes are good for rocky places. Rubber shoes keep finished areas safe and stop damage.

Watch track tension and change old parts quickly. Doing this makes your undercarriage last longer. It also helps your machine work well.

Buy good parts for your excavator. Strong parts last longer and work better. This saves you money over time.

Excavator Track Parts Overview

Track Chains

Track chains are very important for your excavator. They help hold up the machine’s weight. Track chains let your excavator move over many types of ground. These chains are made from strong materials. This helps them last during hard jobs and gives good grip. If you keep the chains tight, they will not slip off. This also helps them last longer. You should clean and oil the chains often. This keeps them working well. Track chains help send power from the engine to the tracks. This makes your excavator work better and last longer.

Track Shoes

Track shoes connect to the track chains. They help your excavator grip the ground. You pick track shoes based on where you work. Steel track shoes are tough and last a long time. Rubber track shoes are good for soft or finished surfaces. The type of track shoe changes how your machine moves on mud, rocks, or roads. Track shoes also protect the track chains from getting hurt. This helps your undercarriage last longer.

Tip: Track shoes made with high manganese steel are very strong and last a long time.

Rollers

Rollers help guide the track chains. They also hold up the weight of your machine. There are two kinds of rollers. Top rollers keep the chains in place. Bottom rollers carry the load. Good rollers help your excavator move smoothly. They also keep the tracks straight. In rough places, rollers last about 5,000 to 8,000 hours. In easy places, they can last up to 15,000 hours.

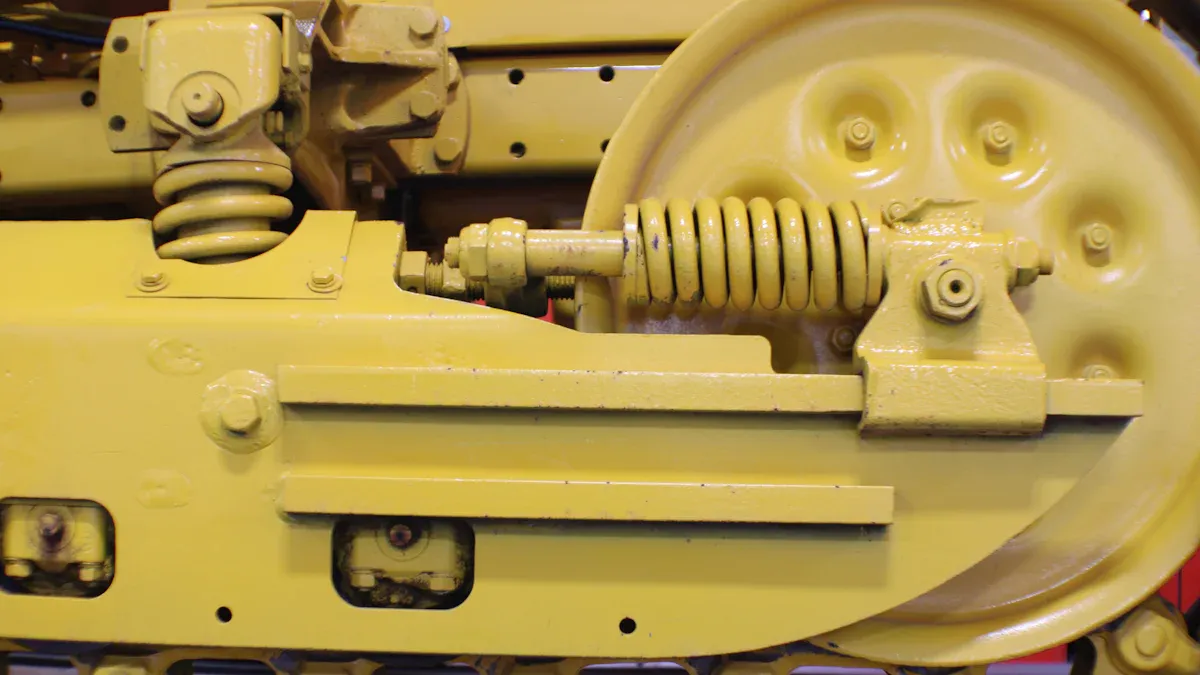

Idlers

Idlers keep the track chains tight and straight. They help take in bumps from rough ground. Idlers stop the chains from slipping off the sprockets. They also change the tension by themselves. This helps other parts last longer and keeps your machine steady.

Sprockets

Sprockets are round and have teeth that fit into the track chains. When the engine is on, sprockets turn and move the tracks. Sprockets help send power from the engine to the tracks. This lets your excavator move. How well your sprockets work changes how your machine grips the ground.

Track Bolts

Track bolts hold the parts of your excavator together. They connect things like track shoes and chains. You need strong bolts to keep your machine safe. Grade 8 bolts are the strongest and best for hard jobs. You should check and change bolts often. This stops problems and keeps your machine working.

Track Pads

Track pads go on the track shoes and help with grip. You can pick rubber, polyurethane, or steel track pads. Rubber pads are quiet and good for soft ground. Steel pads are strong and handle heat but can hurt soft ground. The right track pads help protect the ground and keep your excavator steady.

Track Pad Type | Traction Benefits | Ground Protection Benefits |

|---|---|---|

Rubber | Good grip on smooth ground | Less damage, quieter use |

Polyurethane | Tough, works in hard places | Helps machines last longer |

Steel | Handles heat and heavy weight | Keeps shape when stressed |

Rubber Tracks

Rubber tracks give a smooth ride and protect roads. They cost less than steel tracks. Rubber tracks also make less shaking for the driver. They work best on finished roads and in cities. But they do not last as long on rough ground. They are also harder to fix.

Steel Tracks

Steel tracks are made from linked steel plates. They are very strong. You use steel tracks for hard jobs like tearing down buildings or working in forests. They last a long time and grip well. Steel tracks are best for tough places but can hurt soft ground.

Note: Picking the right mix of excavator parts, like track chains, track shoes, and track pads, helps your machine work its best and last longer. Take care of your parts and change them when needed to keep your undercarriage in good shape.

Track Chains and Shoes

Track Chain Types

You need to choose the right track chain for your excavator. Each type works best in certain conditions. Here is a table to help you understand the main types:

Track Chain Type | Advantages | Applications |

|---|---|---|

Standard Track Chains | Low cost, easy maintenance, strong wear resistance | Urban construction, mining |

Wear-resistant Track Chains | Extra durability for tough jobs | Mines, heavy earthwork |

Swamp Track Chains | Great traction and buoyancy on soft ground | Swamps, wetlands |

Steel Track Chains | High strength, handles heavy loads | Extreme environments |

Rubber Track Chains | Low ground pressure, protects sensitive surfaces | Urban areas, gardening |

Heavy-duty Track Chains | Handles very heavy loads in harsh conditions | Large mines, big earthwork projects |

You should pick a track chain that matches your job site. This helps your undercarriage last longer and keeps your excavator working well.

Track Shoe Types

Track shoes connect to the chains and touch the ground. The right shoe improves performance and protects your machine. Here are the main types:

Track Shoe Type | Advantages | Applications |

|---|---|---|

Double Grouse Track Shoe | Low cost, strong for flat ground | Small or medium excavators |

Triple Grouse Track Shoe | High strength, resists wear and impact | Heavy loads, rough terrain |

Flat-bottomed Track Shoe | Wide contact, better grip on soft ground | Sand, mud, loose soil |

Swamp Track Shoe | Wide, special design for wet ground | Swamps, wetlands |

Special Track Shoe | Custom for extreme conditions | High/low temp, corrosive sites |

Tip: Use flat-bottomed or swamp shoes if you work in muddy or wet places. These shoes help your excavator stay on top of soft ground.

Benefits for Different Terrains

You need to match your track shoes and chains to the ground you work on. This choice boosts performance and reduces the need for replacement parts.

Steel tracks work best on rocky ground. The grouser design bites into hard surfaces and gives you great traction.

Rubber tracks protect finished surfaces and lower ground pressure. They help you avoid sinking in soft areas.

On sharp rocks, steel tracks last longer. Rubber tracks can tear or cut in these places.

If you pick the right excavator track parts, you get better durability and easier maintenance. Your undercarriage will last longer, and your machine will work better on every job site.

Rollers and Idlers

Top Rollers

Top rollers are also called carrier rollers. They sit on top of your excavator’s undercarriage. These rollers keep the track chain lined up. Top rollers help spread out the machine’s weight. This makes your excavator move smoothly. They also stop the tracks from slipping off. Strong top rollers help your excavator work better and last longer.

Bottom Rollers

Bottom rollers hold up all the weight of your excavator. They guide the track chain as the machine moves. Good bottom rollers give strong grip and help your excavator stay steady. They work well on rough ground. If you check and change worn bottom rollers, you protect your undercarriage. This helps you avoid expensive repairs.

Here is a quick look at how top and bottom rollers help your machine:

Roller Type | Function | Impact on Stability and Wear |

|---|---|---|

Bottom Rollers | Hold up the machine’s weight and guide the track chain. | Needed for grip and keeping the machine steady. |

Top Rollers | Keep the track lined up and spread out weight. | Important for stopping early wear and keeping tracks straight. |

Idler Types

Idlers are found at the ends of your tracks. They keep the track chain tight and straight. There are different idler types for different jobs. Some idlers can adjust tension by themselves. Others need you to set the tension. Good idlers guide the track chain and stop it from slipping off. They also help spread out the load and lower stress on other parts.

Idlers do more than just guide the chain. They also:

Spread out weight for better balance.

Take in bumps and shakes to protect your undercarriage.

Keep the right tension for smooth movement and longer life.

Help hold up attachments and let your excavator do tough jobs.

Support and Stability

Rollers and idlers work together to give strong support. They help your excavator stay steady. The right rollers and idlers spread weight across the undercarriage. This keeps your machine safe and the tracks in place. Good support means less wear and fewer new parts needed. You also get better control on rough ground. If you take care of these parts, your excavator will last longer and work better.

Sprockets and Bolts

Sprocket Types

You must pick the right sprocket for your excavator. Sprockets come in many types, like drive sprockets. These parts fit with the tracks and help your machine move. The CAT345 sprocket is made for strong power transfer. The XE490 sprocket lines up well for better strength and use. Choosing the right sprocket helps your undercarriage last longer and work better.

Power Transfer

Sprockets help turn engine power into movement. The drive sprocket connects to the track chain and moves the tracks. Sprocket size changes how your machine works. Big sprockets give more torque for hard jobs. Small sprockets make your machine faster but with less torque. You need to keep sprockets in good shape. Check them often to stop wear and keep your excavator running well. Good sprockets help your machine work better and carry heavy loads.

Note: Drive and driven sprockets must work together. If you do not care for sprockets, your machine may lose power and break other track parts.

Track Bolts Importance

Track bolts hold track shoes to the link assembly. These bolts keep your undercarriage safe and tight. If a bolt breaks, it can be dangerous and cost a lot to fix. The undercarriage can be half of your machine’s repair costs. Every part, even bolts, is important for your machine.

Track bolts keep track shoes on the link assembly.

Broken bolts can cause big safety problems and stop your work.

Each bolt helps protect your machine and lowers repair needs.

Check your track bolts often. Tighten or change them if needed. This easy step keeps your excavator safe and helps your undercarriage last longer.

Track Pads and Traction

Pad Types

You can pick from different track pads for your excavator. Each pad helps your machine work well on certain ground. Bolt-on track pads are easy to put on and take off. You can use them on many types of ground. Chain-on track pads are strong and give good grip. These pads work best on rough ground. Clip-on track pads are quick to put on. They work well on soft ground.

Bolt-on track pads: Easy to put on and take off.

Chain-on track pads: Strong and grip well on hard ground.

Clip-on track pads: Quick to install, good for soft ground.

Track pads made from tough rubber last longer in hard places. They protect finished ground like concrete and asphalt from damage. These pads give great grip, so your excavator can do hard jobs. If you pick the right pad, your undercarriage works better and you need fewer new parts.

Traction Benefits

Track pads help your excavator move and stay safe. Special treads give your machine a strong grip, even on slippery ground. Better grip means you can work faster and safer. You lower the chance of slipping or accidents. The SY155U-Traction Pad uses tough treads to keep your machine steady and working well.

Feature | Benefit |

|---|---|

Improved Traction | Better grip and balance, lowers slips and accidents. |

Pressure Distribution | Pads last longer and protect grousers, so you fix less. |

Surface Protection | No need for extra mats, saves time and work. |

Versatility | Easy to move between different ground, helps you work better. |

Reduced Ground Disturbance | Less harm to the ground and machine, keeps everyone safe. |

You get more work done when your track pads grip well. Your machine stays steady, and you spend less time fixing things. Good grip also helps your tracks last longer and keeps your undercarriage strong.

Rubber vs. Steel Tracks

Rubber Track Benefits

Rubber tracks give your excavator a smooth ride. You can use them in cities or on finished roads because they protect the ground. These tracks cost less at first, so you save money when you buy them. Rubber tracks also make less noise and shake less. This helps the driver stay comfortable. You can move your machine over grass, asphalt, or concrete without leaving marks. Rubber tracks work best for light jobs and soft ground.

Track Type | Cost Range | Durability Comparison |

|---|---|---|

Rubber Tracks | $85 to $5,000 | Wear out faster |

Tip: Rubber tracks help you avoid damage to lawns and sidewalks. You can finish jobs in neighborhoods without extra cleanup.

Steel Track Benefits

Steel tracks give your excavator strong grip and support. You can use them on rocky ground, steep hills, or in forests. Steel tracks last much longer than rubber tracks. They handle heavy loads and tough jobs. You pay more at first, but you save money over time because you need fewer replacements. Steel tracks help your undercarriage stay strong and safe.

Track Type | Upfront Cost | Durability | Long-term Cost Impact |

|---|---|---|---|

Steel Tracks | Higher | Greater | More cost-effective for tough applications |

Steel tracks also give better performance in hard conditions. You can trust them to keep working when the ground is rough.

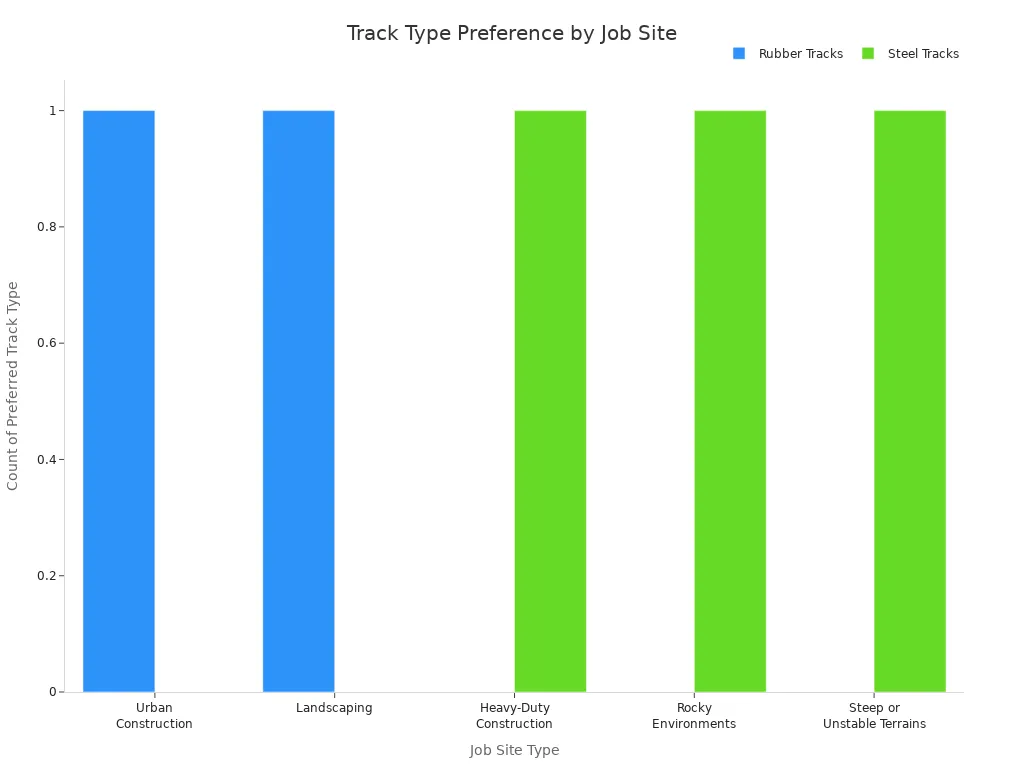

Best Uses

You need to pick the right tracks for your job site. Here is a table to help you choose:

Job Site Type | Preferred Track Type | Reason for Preference |

|---|---|---|

Urban Construction | Rubber Tracks | Ground preservation is critical in urban settings. |

Landscaping | Rubber Tracks | Minimizes damage to soft ground and landscaped areas. |

Heavy-Duty Construction | Steel Tracks | Designed for rugged terrains and heavy loads. |

Rocky Environments | Steel Tracks | Provides better traction and durability on rocky surfaces. |

Steep or Unstable Terrains | Steel Tracks | Offers stability and support in challenging conditions. |

You get the best performance and durability when you match your excavator track parts to your job. Rubber tracks work well for city work and landscaping. Steel tracks fit best for heavy-duty jobs and rough ground. Good maintenance and timely replacement keep your undercarriage in top shape.

Choosing Best Excavator Track Parts

When you want the best excavator track parts for your job, you need to look at several important factors. Each job site is different. You must match your parts to the ground, your machine, and the work you plan to do. This helps you get the best performance, longer durability, and fewer replacement needs. Let’s break down what you should check before you choose.

Assessing Site Conditions

You need to look at your job site before you pick track parts. The ground, weather, and work area all change what you need. Here is a table to help you see what matters most:

Factor | Description |

|---|---|

Width of Track Shoes | Wider shoes give better flotation on soft soil. They can make turning harder and wear out faster. |

Compatibility with Machine | Make sure the parts fit your excavator model for top performance. |

Work Environment | Different terrains need different track parts to avoid damage and keep working well. |

Materials and Processes | Strong materials and good manufacturing mean longer life and better durability. |

Alignment and Maintenance | Keep everything lined up and do regular maintenance to stop early wear and downtime. |

You also need to think about these parts:

Bottom rollers support your machine’s weight and help it move smoothly.

Idlers keep the tracks tight and stop them from coming off.

Sprockets send engine power to the track chain.

Track shoes touch the ground. Their width changes how much grip and stability you get.

Tip: Always check your site for mud, rocks, or soft ground. Pick wider track shoes for soft soil. Use narrow shoes for hard or rocky ground. This helps your excavator undercarriage last longer and work better.

Machine Size and Weight

Your machine’s size and weight change what track parts you need. Bigger machines need stronger parts. Smaller machines can use lighter parts. You want the best excavator track parts that fit your machine and your job.

The undercarriage of an excavator plays a fundamental role in its lifting capacity, with aspects such as the track width and the design providing stability and support. A wider track width offers better distribution of the machine’s weight, improving stability during lifting tasks.

You can find zero or close to zero swing radius machines in lower weight excavators. These are easy to move in tight spaces. Heavier excavators do not move as easily, especially on tough ground. They make up for this with more power. You need to match the track width and design to your machine’s weight. This gives you the best support and keeps your undercarriage safe.

Choosing the right excavator depends on many factors. Size, controls, and jobsite locations rank high on the list of things to consider.

Project Type

You must match your track parts to your project. Each job needs something different. Here are some best practices for picking the right parts:

Choose the right size. Use mini excavators for landscaping or city work. Pick larger machines for mining or heavy construction.

Assess power needs. Match the horsepower to how deep you need to dig and how tough the ground is.

Consider adaptability. Use the right attachments for your job. For demolition, use hydraulic breakers. For landscaping, use special buckets.

If you pick the best excavator track parts for your project, you get better performance and fewer breakdowns. You also save money on replacement and maintenance. Your excavator will work better and last longer, no matter what job you do.

Best Excavator Track Parts for Job Sites

Picking the right excavator track parts helps your machine work better. It also makes the parts last longer and keeps the undercarriage in good shape. If you use the right parts for your job site, you spend less on fixing and replacing things.

Taking care of your equipment can be 15-25% of your yearly costs.

Good parts and checking your machine often help it last longer.

Experts say you should look at track tension, clean the undercarriage, and change old parts to get the best results.

Look at and clean your tracks a lot.

Change the tension when you need to.

Watch for worn parts and swap them out on time.

FAQ

What is the most important part of an excavator undercarriage?

You need to pay close attention to the track chains. These parts carry the machine’s weight and help it move. If you keep them in good shape, your excavator will work better and last longer.

How often should I perform maintenance on track parts?

You should check your track parts every day before you start work. Clean off dirt and look for damage. Regular maintenance helps you find problems early and keeps your machine running safely.

Can I use rubber tracks on rocky ground?

You should avoid using rubber tracks on sharp rocks. Rubber tracks can tear or wear out quickly on rough surfaces. Steel tracks work better for rocky areas and last longer.

How do I know when to replace rollers or idlers?

You should look for signs like uneven wear, cracks, or loud noises. If your excavator feels shaky or the tracks slip, you may need new rollers or idlers.

What track pads are best for city work?

You should use rubber track pads for city jobs. These pads protect roads and finished surfaces. They also make less noise and help your machine move smoothly in urban areas.