Black cat excavator bucket wear parts are special because they are made with smart designs and are very tough. Each part has new features, like the hammerless pin system, which helps people put them on safely and quickly. Workers see that these parts last longer and need less fixing. These parts work with many excavator models, so owners think they are simple to use. People trust these parts for hard work in many places.

Key Takeaways

Black Cat wear parts are made from tough materials. They use smart designs to last a long time. These parts do not wear out fast.

The hammerless pin system helps workers change bucket teeth fast. They do not need hammers to do this. It is safer and quicker for everyone.

The parts fit many excavator models very well. This makes it easy to put them on. It also stops parts from coming loose.

Strong parts and quick shipping mean less waiting time. Machines can work longer and save more money.

Safety features like grip steps help protect workers. Tight fits also stop accidents from happening at job sites.

Product Range

Black Cat has many excavator bucket wear parts. These parts fit lots of machine models and job types. You can pick standard or custom parts. This makes it simple to find what you need for your machine.

Types of Wear Parts

There are many wear parts for different jobs and places. The main types are:

Teeth and adapters help dig and break hard ground.

Pins and retainers keep parts attached tightly.

Weld-in bucket base edges and bolt-on edges come straight or with teeth.

Side cutters and strike-off plates give more cutting power.

Weld-in corners and wear bars make buckets stronger.

Safety steps help people climb safely.

Bucket protection parts include weld-on heel shrouds, corner protectors, cast alloy lip shrouds, sidebar protectors, and mounted wear plates.

Black Cat also has half arrow edges and segments made from HighSpec Alloy X14 steel. These parts help buckets last longer and work better in tough places. Their replacement teeth and adapters fit Caterpillar J-series machines from 3 to 150 tonnes. Each part uses strong alloy steel and special heat treatment to last longer.

Custom and OEM Options

Black Cat makes both OEM replacement and custom wear parts. Their team uses computers and metal tests to design parts for special needs. You can order base edges in many thicknesses, widths, and lengths for different buckets. Bolt-on edges come in one-piece or three-piece sets, with many sizes.

Note: Black Cat ships small orders fast, often in 7 days. Big orders can take up to 25 days. Fast shipping helps workers get back to work sooner.

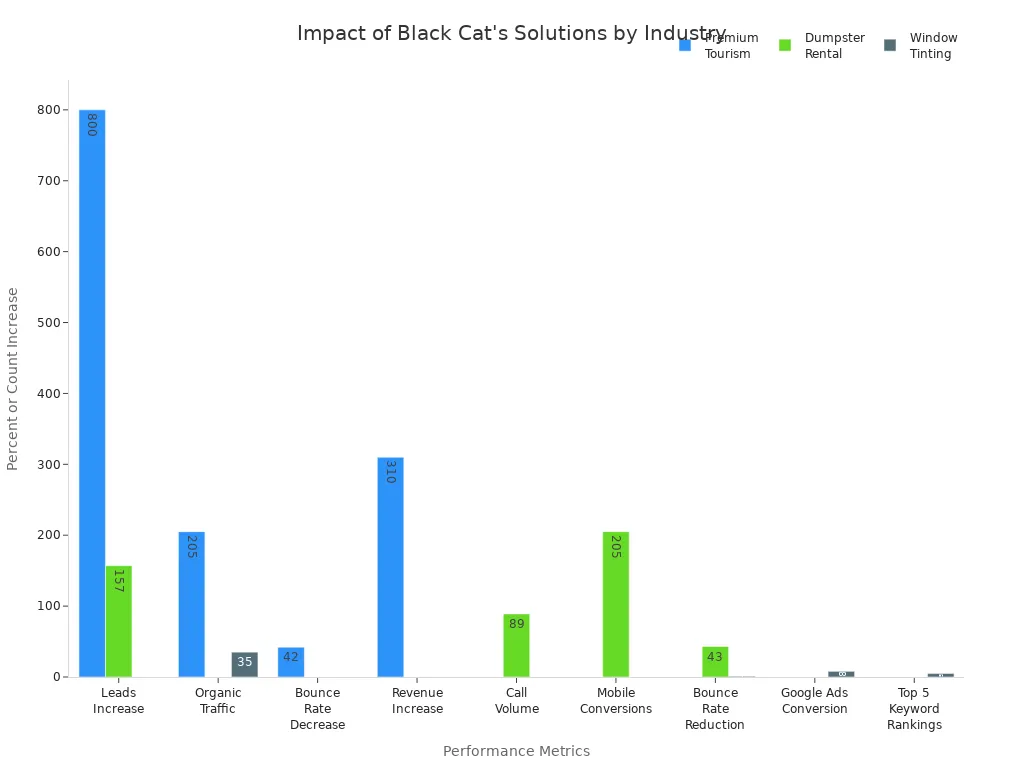

Custom parts help fix special problems in many jobs. The table below shows how Black Cat’s custom parts helped clients in tourism, dumpster rental, and window tinting.

Industry / Client | Operational Challenges | Custom Solutions Provided | Measurable Results Achieved |

|---|---|---|---|

Premium Tourism (Smart VIP Tours) | High bounce rates, poor lead conversion, hard to stand out in a busy market | New mobile website, special landing pages, SEO for top keywords, better content | 800% more leads, 205% more traffic, 42% lower bounce rate, 310% more revenue |

Dumpster Rental (Lupo Dumpster) | Old website, bad mobile use, unclear service and price, few leads | New website, clear service pages, smart lead forms and CTAs, easier navigation | 157% more leads, 89% more calls, 205% more mobile conversions, 43% lower bounce rate |

Window Tinting (Tinterz) | Not found in search, old website, wasted ad money | New website for sales, local SEO, better Google Ads, content showing top services | 35% more traffic, 8% Google Ads conversion rate, Top 5 local keywords, lower bounce rate |

Black Cat’s big product range and many choices make their excavator bucket wear parts a good pick for many jobs.

Engineering and Materials

Design for Wear Life

Black Cat makes each part to last longer. Engineers use computers to see how parts wear out. They look at digging and loading jobs. The teeth, adapters, and shrouds are shaped to spread force. This helps stop weak spots from forming. The design keeps cracks and chips away. It works even with hard rocks or heavy loads. Black Cat adds special coatings to slow down wear. These steps help their parts last longer than other brands.

Tip: Parts that last longer need fewer changes. Workers spend less time fixing machines. This helps jobs finish faster and saves money.

Material Quality

Black Cat uses strong alloys for its Revolution loader bucket teeth. These alloys make the parts hard and tough. They also help parts handle hits and stress. The materials are cast to make them strong. These alloys work better than many other brands. This means fewer breaks and longer use.

Black Cat Wear Parts makes parts in ISO-certified places.

Each part gets checked for quality.

All products meet or beat industry standards.

Lab and field tests help improve performance.

Special alloy mixes and heat treatment fight wear.

High-chrome, high-manganese steel stops bending and cracking.

Heat treatment makes a fine structure for longer life.

These steps show Black Cat cares about design and materials. Their careful work helps customers trust their parts for hard jobs.

black cat excavator bucket wear parts Features

Hammerless Pin System

The hammerless pin system is a big new idea for black cat excavator bucket wear parts. This special technology lets workers put on and take off bucket teeth without a hammer. It uses a unique pin and lock to turn J Series teeth into a hammerless setup. Workers can change teeth fast and safely. This lowers the chance of getting hurt by swinging hammers.

The hammerless pin system has a special pin and lock to keep teeth on tight.

Workers do not need extra tools, so it is faster and safer.

The system keeps teeth and adapters steady during hard jobs.

This design makes job sites safer. It also saves time because workers do not spend long on repairs. The easy setup means machines stop working for less time. Operators can start working again sooner. This helps them get more done and spend less money. Many companies pick black cat excavator bucket wear parts for these reasons.

Tip: Hammerless systems help stop hand injuries and make it easier for everyone to change teeth.

Wear Protection Technologies

Black cat excavator bucket wear parts use strong materials and smart designs to fight wear. The company uses high-spec alloy steel for bucket teeth. Each part gets special heat treatment to make it hard, between HRC46 and HRC52. This makes the parts strong for digging and heavy work.

The way they make the parts helps inside and outside. Engineers use investment casting for a smooth surface and strong build. After casting, each part is painted for shine and extra protection. These steps help stop cracks, chips, and bending during tough jobs.

High-chrome and high-manganese steel keep parts from breaking or wearing out fast.

Special heat treatment gives the steel a fine inside, so it lasts longer.

Smart design spreads force, which stops weak spots and slows down wear.

Operators see that black cat excavator bucket wear parts protect important parts of the bucket. The parts stay strong and keep their shape after many hours. This means fewer times to replace them and less fixing.

Note: Picking wear parts with strong materials and smart designs helps machines last longer and saves money in the long run.

Compatibility and Safety

Fit and Integration

Black Cat designs each wear part to fit many excavator brands and models. Engineers measure bucket shapes and sizes. They test parts on real machines. This helps each part match the bucket closely. Operators can install new teeth, adapters, or shrouds without trouble. The parts slide into place and lock tight. This strong fit keeps the bucket working well during digging and loading.

Parts match OEM standards for size and shape.

Adapters and pins connect with no gaps.

Teeth and edges line up for smooth digging.

A good fit means less shaking and fewer loose parts. Machines run better and last longer. Operators spend less time fixing buckets. They finish jobs faster.

Note: Always check the part number and machine model before ordering. This helps avoid mistakes and saves time.

Operator Safety

Safety matters on every job site. Black Cat uses smart designs to protect workers. The hammerless pin system lets operators change teeth without hammers. This lowers the risk of hand injuries. Workers do not need special tools. They can remove and install parts quickly.

Engineers add safety steps and grip plates to some bucket parts. These features help workers climb safely. The strong fit of each part keeps pieces from falling off during work. Fewer loose parts mean fewer accidents.

Safety Feature | Benefit |

|---|---|

Hammerless pin system | Less risk of hand injuries |

Safety steps | Easier and safer climbing |

Tight fit | Fewer loose parts, less risk |

Operators trust Black Cat for safe and easy-to-use wear parts. They know the parts help prevent injuries and keep machines running.

Tip: Regular checks and quick part changes help keep workers safe and machines in good shape.

For those seeking reliable suppliers, YNF Machinery offers a wide range of excavator bucket wear parts for many brands.

Maintenance and Value

Reduced Downtime

Operators need machines that work without long stops. Black Cat designs bucket wear parts to make repairs quick and easy. The hammerless pin system lets workers change teeth fast. They do not need special tools or extra help. This saves time on the job site. Strong materials and smart shapes help parts last longer. Fewer breaks mean fewer repairs. Machines stay in action for more hours each day.

Tip: Quick part changes help teams finish projects on time. Less downtime means more work gets done.

Many companies see less waiting for new parts. Black Cat ships orders quickly. Fast delivery helps crews get back to work sooner. When machines run longer, owners save money and avoid delays.

Long-Term Cost Savings

Choosing strong wear parts helps owners spend less over time. Black Cat uses tough alloys and heat treatment. These steps make parts last through hard digging and heavy loads. Fewer replacements mean lower costs for new parts. Less time spent fixing machines saves on labor.

Here is a simple table showing how strong wear parts help save money:

Benefit | How It Saves Money |

|---|---|

Longer wear life | Fewer replacements needed |

Quick installation | Less labor cost |

Fast shipping | Less waiting, more work |

Strong materials | Fewer breaks and repairs |

Owners see real savings after using these parts for months. Machines need less fixing. Crews spend more time working. The value grows with every project.

Note: Picking quality wear parts helps companies control costs and keep machines running strong.

For those looking for reliable suppliers, YNF Machinery offers a wide selection of excavator bucket wear parts for many brands.

Black Cat excavator bucket wear parts are known for being tough and well-designed. They last a long time and give good value. Many people who work in construction, mining, and road jobs trust these parts. The parts help machines work longer and keep workers safe. Operators do not have to fix their machines as often. They can finish more work every day. If you want black cat excavator bucket wear parts you can count on, YNF Machinery is a trusted place to buy them.

FAQ

What makes Black Cat bucket wear parts last longer?

Black Cat uses strong alloy steel and gives it special heat treatment. Engineers make each part to spread out force and stop weak spots. These steps help the parts stay strong and not crack or wear out.

How does the hammerless pin system improve safety?

The hammerless pin system lets workers change bucket teeth without hammers. This lowers the chance of hurting hands. It also makes changing teeth faster and safer for everyone.

Can Black Cat wear parts fit different excavator brands?

Black Cat makes wear parts that fit many excavator models. Each part matches OEM size and shape. Operators can put them on most machines without trouble.

How quickly can operators replace Black Cat bucket teeth?

Operators can change bucket teeth in just a few minutes. The hammerless pin system does not need special tools. This fast change helps keep machines working with less waiting.

Where can buyers find reliable Black Cat bucket wear parts?

YNF Machinery sells many Black Cat excavator bucket wear parts. Buyers trust YNF Machinery for quick shipping and good quality products.