Finding good parts for your excavator engine starts with knowing its model and serial number. You look in the manual to find the right details. You think about where your excavator works. You try to pick parts that are both good and not too expensive. You buy from trusted sellers to keep your excavator safe.

Tip: Always use parts that fit your excavator for the best results.

Find out your excavator’s model and serial number.

Look at the manual before you buy anything.

Think about where your excavator is used.

Get quality parts for excavator engine from sellers you trust.

Key Takeaways

Make sure you know your excavator’s model and serial number. This helps you buy the right parts and avoid expensive errors.

Buy good parts from sellers you trust. Use OEM parts for important engine pieces to keep your machine safe and strong.

Look at parts closely for fit, quality, and warranty. This helps stop breakdowns and saves you money on repairs.

Pick suppliers with good reviews and the right certifications. They should give strong support and deliver parts quickly.

Check your excavator often and change old parts on time. This helps your excavator last longer and stops surprise breakdowns.

Why the Right Parts Matter

Engine Performance

You use your excavator every day. The right parts help it work well. Good parts give your excavator the power you need. When you use the right engine parts, your machine works its best. Bad or old parts can make the engine weak. They can also cause it to get too hot or even break.

Your excavator needs the right parts to run smoothly and strong.

If you skip oil changes or use dirty filters, your machine works harder and wastes energy.

Bad or dirty fuel can block injectors and wear out the engine faster.

Checking your excavator often and changing old parts stops big problems and keeps it working well.

Tip: Learning how to use your excavator the right way helps the engine last longer and work better.

Longevity and Cost

Picking good parts for your excavator engine saves money over time. Using real parts, checking your machine often, and using the right fluids can help your excavator last much longer.

These steps stop most breakdowns and help your machine work more days.

You save a lot of money by not having surprise repairs.

Real parts keep your excavator working well. Fake or bad parts break more and cost more to fix.

Good parts stop early damage and help your excavator stay on the job.

Learning how to use your excavator is important too. If you know how to use it well and spot problems early, you spend less on repairs and protect your machine.

Safety and Compliance

Safety is important on every job site. Your excavator must pass checks and follow safety rules.

Checking engine and hydraulic parts often helps stop accidents and keeps your machine safe.

Digital tools and Heavy Vehicle Inspection software help you remember checks and warn you about safety problems.

You must follow OSHA, DOT, and environmental laws like the Clean Air Act and Clean Water Act.

Using real parts lowers the chance of problems that can cause accidents, like hydraulic or brake failures.

Note: Training and getting certified are very important for safe excavator use and following all the rules.

Identify Your Excavator

Model and Serial Number

You need to know your excavator’s model and serial number. These numbers help you get parts that fit your machine. If you use the wrong number, you might buy the wrong part. This can make your excavator work badly or even break it.

Here are some easy ways to find your excavator’s model and serial number:

Look in the operator’s manual. The manual has both numbers.

Find the identification plate on your excavator. It is usually on the outside, on the dashboard, or near a cylinder.

Check for the product identification number (PIN). Each excavator has its own PIN. It can have 8 or 17 letters and numbers. The last eight numbers are usually the serial number.

Use online tools from the company or dealer. These tools let you search for parts by model or serial number. Some websites show a green checkmark if the part fits.

Save your excavator’s details in ‘My Equipment’ on parts websites. This helps you find parts faster next time.

Try mobile apps like SIS2.0 or SIS2GO. These apps show you diagrams and help you order the right parts.

Getting the right numbers keeps your excavator working well. It also stops you from making expensive mistakes and keeps your machine safe.

Tip: Always check the model and serial number before you order any part.

Consult the Manual

Your excavator’s manual is very helpful. It gives you part numbers, sizes, and tips for taking care of your machine. The manual tells you the right sizes and pressure for engine parts. It also shows the model and serial numbers again, so you can check them.

If you use the manual, you will not buy the wrong parts. You also learn how to keep your excavator in good shape. The manual tells you when to change old parts and how to pick between OEM and aftermarket parts. Following the manual helps you make good choices and keeps your excavator working longer.

Types of Excavator Engine Parts

OEM vs Aftermarket

When you pick engine parts, you choose between OEM and aftermarket. OEM parts are made by the company that built your excavator. They always fit right and are made to high standards. Aftermarket parts come from other companies. Some are good, but some may not last or fit well.

Here is a simple table to help you pick:

Factor | OEM Parts | Aftermarket Parts | Recommendation |

|---|---|---|---|

Cost | More expensive, but save money over time | Cheaper at first, many prices | Save money → Aftermarket; Important parts → OEM |

Quality | Always good, made by the manufacturer | Quality changes; some are as good as OEM, some are not | Not important → Aftermarket; Engine parts → OEM |

Compatibility | Always fits, no changes needed | Might need changes; good brands fit like OEM | Old machines → Aftermarket; Need perfect fit → OEM |

Lead Time | Might take longer to get | Usually comes faster | Need fast → Aftermarket; Can wait → OEM |

Warranty | Good warranty, often 1–2 years | Warranty changes; some have little or none | Want warranty → OEM; No warranty needed → Aftermarket |

Use OEM parts for important engine jobs and when you want the best. Aftermarket parts are okay for small repairs or when you need parts fast. Always check if the seller is trusted before buying aftermarket.

Tip: Both OEM and aftermarket parts are useful. Use OEM for the most important engine jobs.

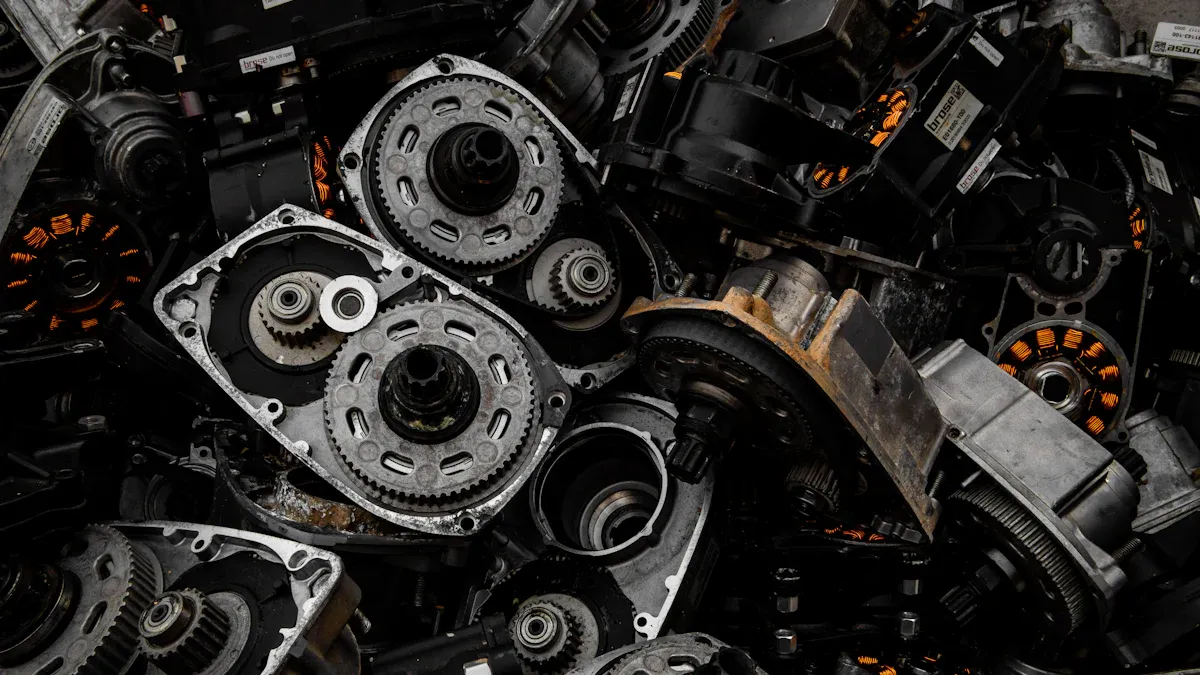

Remanufactured and Used

You can also find remanufactured and used engine parts. Remanufactured parts are fixed by experts. They clean them, test them, and put in new pieces. These parts often have a warranty and work almost like new. Used parts cost less, but you do not know if they will last. They might break sooner and often have no warranty.

Feature | New Parts (OEM/Genuine) | Remanufactured Parts | Used Parts |

|---|---|---|---|

Cost | Most expensive | 30%-60% less than new | Cheapest |

Reliability | Best, always works well | Good, depends on how it was fixed | Not good, might break soon |

Failure Rate | Very low | Medium, depends on quality | High, you do not know history |

Warranty | Best, longest | Shorter, but still has one | Little or no warranty |

Lifespan | Lasts longest | Good, depends on fixing | Short, not sure how long |

Risk | Very low | Medium, depends on seller | Very high |

Remanufactured parts are a good choice if you want to save money and still get good quality. Used parts are cheap, but they can cause more problems and repairs.

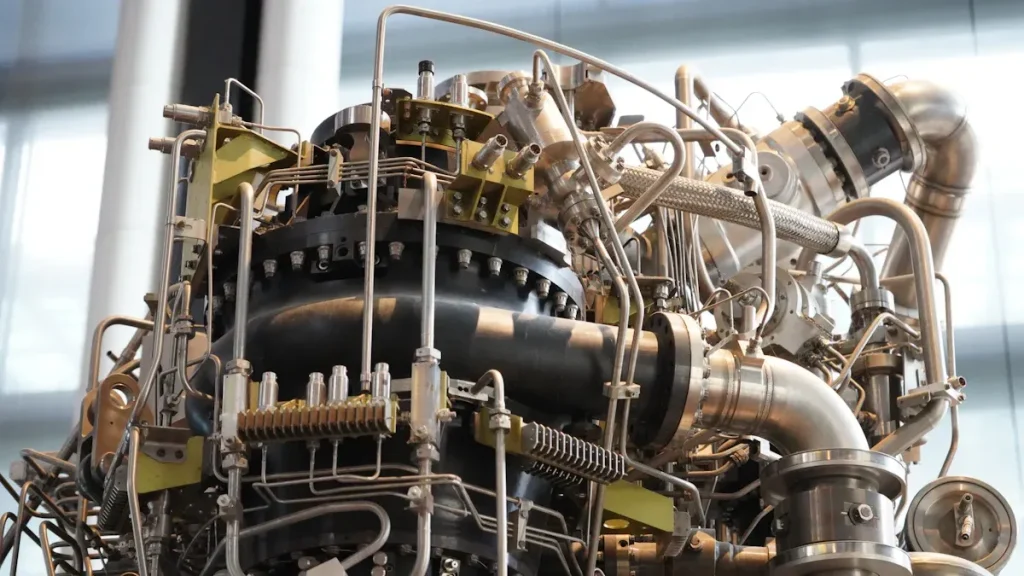

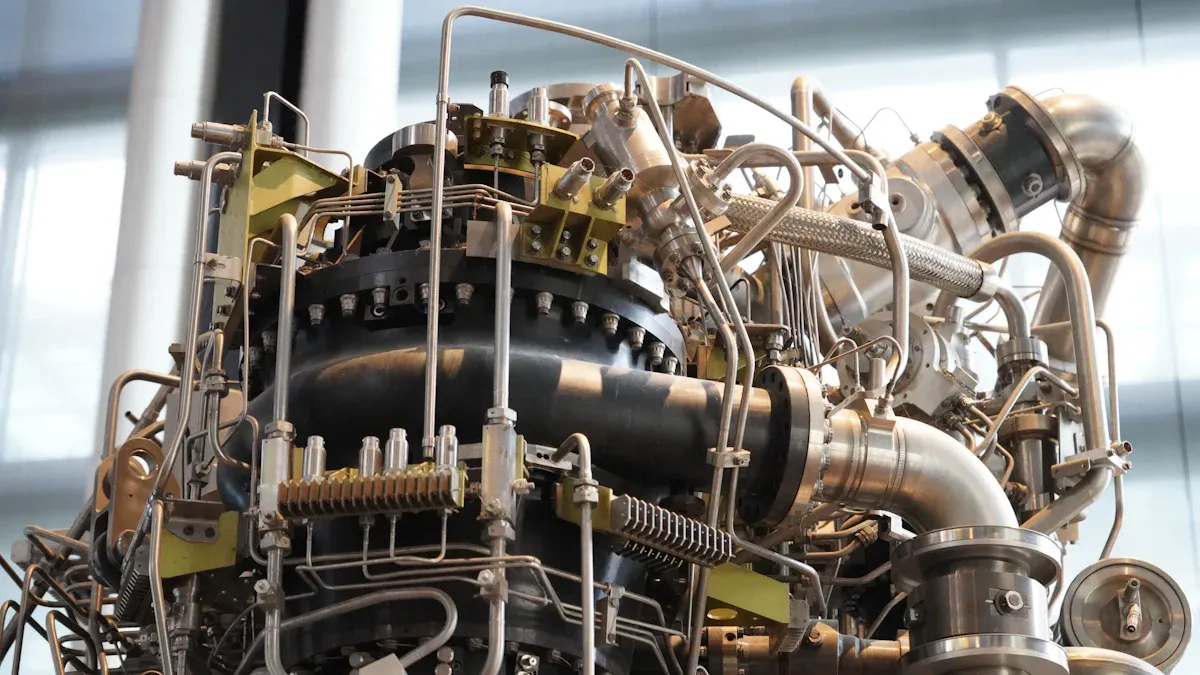

Key Engine Components

You should know which engine parts are most important. Some parts wear out fast and need to be checked or changed often. These are:

Air and fuel filters: They keep dirt out and protect your engine. Change them often.

Cooling system parts: Radiators, fans, and water pumps keep the engine cool.

Hydraulic pumps and seals: These work hard and often need new parts.

Fuel system: Brings diesel to the engine for power.

Engine: This is what makes your excavator work.

Always use good mini excavator parts for these jobs. OEM parts are best for important engine parts. For small repairs, you can use aftermarket parts if the seller is trusted.

Note: Check and change these important parts often to keep your excavator working well.

Evaluating Parts for Excavator Engine

Compatibility Check

You need to make sure each part fits your excavator. First, know your excavator’s make, model, and serial number. These numbers help you order the right parts. Sometimes, manufacturers change designs during production. This means some parts may not fit every machine. Always check the part number in your manual and on the manufacturer’s website. Many sellers have online tools to help you check if a part fits. Look for special stickers or marks on the box to see if the part is real.

When you compare parts, look at how they attach, their size, power, and connections. Check if the fuel system and emission controls match. If you are not sure, ask your manual or talk to a trusted seller. Good sellers give you papers or proof that the part is real and will work.

Tip: Do not buy parts that are very cheap. They might be fake and can hurt your excavator.

Here is a checklist to help you check if a part fits:

Know your excavator’s make, model, and serial number.

Check the part number with the manual.

Use the official website to see if it fits.

Look for security marks on the box.

Ask the seller for proof or papers.

Compare the size and how it connects.

Picking the right parts helps your excavator work well and not break down.

Quality and Reliability

You need good parts to keep your excavator working for a long time. Manufacturers use special rules and new technology to make strong parts. They test each part to make sure it works well and lasts.

Good sellers only get parts from trusted companies. They check the materials, the brand, and if there is a warranty. Reliable sellers have quality certificates like ISO 9001. This means they follow high standards. They also have good supply chains and help you with questions or problems.

When you look at parts, check for damage, rust, dents, or cracks. Look at service records to see if the part is real and in good shape. For important parts like batteries and hoses, check how long they last and when they were made. Always test the part to see if it works well in your excavator.

Note: Good sellers tell you where parts come from and how they are made. Lots of good reviews and worldwide sales mean you can trust them.

Use this table to check if a part is good:

Criteria | What to Check | Why It Matters |

|---|---|---|

Material Quality | Strong and does not wear out fast | Lasts longer |

Brand Reputation | Well-known brands and good reviews | Shows you can trust it |

Warranty Support | How long and what the warranty covers | Protects your money |

Certification | ISO 9001 or OEM papers | Means high quality |

Supplier Transparency | Clear info about where it comes from | Builds trust |

Testing for Performance and Durability | Test results and field tests | Shows it works well |

Good parts keep your excavator safe and working hard. Reliable parts stop breakdowns and save you money on repairs. You protect your machine and make sure it works its best.

Choosing Reliable Suppliers

Reputation and Reviews

When you pick suppliers for excavator spare parts, reputation is important. You want a supplier who sends parts on time and supports their products. Customer reviews and ratings help you know if a supplier is honest. Websites like Google and forums show real opinions from buyers. If most reviews are good, the supplier is probably trustworthy. Good reviews talk about quick delivery, clear answers, and helpful support after buying. You should check if the supplier has been in business for a long time and is stable with money. Reliable parts supplier companies show their business licenses and let others check their work. You can ask for client references to learn about their service and how they fix problems.

Tip: Be careful if you see bad communication, missing certificates, or prices that are too low.

Key points to check:

How much they can make and if they meet deadlines

Quality of materials in heavy equipment parts

Warranty and help after you buy

Clear and regular communication

Money stability and how they handle risks

Certifications

Certifications show a supplier follows strict quality rules. When you buy heavy equipment parts, look for suppliers with the right certificates. ISO certification means the supplier uses international quality rules. CE certification shows the parts are safe for Europe. OEM certification means the parts are original and made by the brand. A clear warranty helps you feel safe if something breaks.

Certification | Relevance | What It Indicates About Product Quality |

|---|---|---|

ISO Certification | Shows they follow international quality rules | High standards and products are always good |

CE Certification | Shows parts are safe for Europe | Safe and good for European use |

OEM Certification | Means parts are original and made by the brand | Parts fit and are real |

Warranty | Gives repair or replacement if parts break | Reliable products and good quality |

Support and Service

You need more than just parts when you buy heavy equipment parts. Reliable suppliers for excavator spare parts give strong support and service. They answer questions fast, usually in two hours. They keep parts ready and deliver quickly, so your excavator keeps working. Good suppliers help with advice and give clear records for care. Many let you visit their factory or take a virtual tour. They know how to ship parts to other countries, so buying heavy equipment parts is easier for you.

Note: Buying from a reliable parts supplier keeps you safe from fake or bad products. You get better help, faster delivery, and support when you need it.

If you choose reliable suppliers, your excavator gets the best heavy equipment parts. This keeps your machine working and your projects moving forward.

Spare Parts for Excavators: Budget and Value

Balancing Cost and Quality

When you buy spare parts, you need to think about price and quality. The cost of excavator engine parts can be very different. It depends on the brand, type, and where you buy them. OEM parts from brands like Caterpillar or Komatsu cost a lot more than aftermarket parts. They can be 40–80% higher in price. These parts fit better and last longer, but you pay more at first. Aftermarket parts, like those from ITR or AmoParts, have many prices. Some might not fit right away and need changes. BRIKERS sells rebuilt engine parts for much less than new OEM parts. You can save up to 60%. They also ship fast and give you a warranty.

Here are some ways to get the best deal:

Pick suppliers with good reviews and helpful service.

Find suppliers who have certificates and test their parts.

Compare top brands with cheaper options to see what is best.

Buy parts when prices are lower during certain seasons.

Make long-term deals to save money on repairs.

Keep important spare parts like hydraulic seals, engine filters, and electrical parts ready so you do not have to stop work.

Ask suppliers for tips to help your excavator last longer.

Think about how much you will spend over time. A cheap part now might break soon and cost more later. Use cost-benefit checks to see if your money is well spent. Picking the right spare parts helps you get the best mix of price, quality, and trust for your excavator.

Warranties and Returns

Warranties help protect you when you buy spare parts for excavators. Most new parts come with a warranty for 1 to 2 years or up to 2,000 hours. OEM replacement parts often have a 6-month or 750-hour warranty. Some sellers give longer warranties that cover big repair costs. One repair can cost $12,000, but a long warranty might pay for it all. Warranties also help you lose less money if your excavator stops working. Downtime can cost up to $22,000 every hour.

You can get special warranties that last 10 years or 10,000 hours. Some companies let you give the warranty to a new owner if you sell your machine. Warranties for used equipment are shorter, but they still help. Always check what the warranty covers. Many do not pay for travel or things like fluids and filters.

Tip: Getting warranties and support helps you feel safe and keeps your money safe. Warranties are even more important when you use spare parts and mini excavator parts every day.

If you buy from sellers with clear return rules, you can send back parts that do not fit or are broken. This saves you money and keeps your excavator working well.

Maintenance for Engine Reliability

Regular Inspections

You keep your excavator working well by checking it often. Daily checks take about 15 to 20 minutes. You look at engine oil and hydraulic fluid. You also check track tension and the cooling system. Lubrication and safety systems are important too. These checks help you find most problems early. Weekly checks take about an hour. You look at hydraulic and air filters. You grease moving parts and tighten track bolts. You clean the cooling system. Monthly checks go deeper. You test hydraulic fluid and run engine diagnostics. You also check the structure and electrical systems. This routine helps you find almost all issues before they get worse.

Here is a table that shows when to do key tasks:

Component/Task | Recommended Interval |

|---|---|

Filter Changes | Every 250 to 500 hours |

Lubrication | Every 50 to 100 hours |

Engine Oil Change | Every 250 to 500 hours |

Hydraulic Fluid & Coolant | Every 1,000 to 2,000 hours |

Component Inspections | Every 250 to 500 hours |

Track Maintenance | Every 250 to 1,000 hours |

Doing these checks helps stop surprise breakdowns. Engines with dirty oil or blocked filters wear out faster. You save money by checking often and using good replacement parts.

Tip: Training operators helps them do better checks and avoid mistakes.

Timely Replacement

You keep your excavator strong by changing old parts on time. Waiting too long to replace parts makes your engine weaker. It uses more fuel and can stop working suddenly. Worn fuel filters and injectors make the engine work harder. Changing hydraulic seals and valves on time helps your engine use fuel better. Predictive maintenance helps you find leaks early. You can change parts during planned service and avoid downtime.

Here is a table that shows how changing parts on time helps:

Engine Component | Lifespan (hours) | Symptoms of Wear | Maintenance Tips |

|---|---|---|---|

Engine Oil Filters | 250 – 500 | More noise, need oil changes often | Check often, change oil and filters on time |

Fuel Injectors | 1,500 – 4,000 | Rough idle, misfires, bad fuel economy | Use good parts, follow the schedule |

Pistons | >10,000 | Less power, more oil use | Avoid tough jobs, check often |

Cooling Fans | 2,000 – 5,000 | Overheating, strange sounds | Replace quickly, watch the cooling system |

Using smart maintenance plans helps your engine last longer. These plans lower repair costs and stop emergencies. You also cut downtime and help your excavator last more years. Changing parts on time keeps your machine working and saves money.

Note: Doing maintenance early and changing parts when needed keeps your excavator safe and working well.

You can get good excavator engine parts if you follow some easy steps:

Find out your machine’s model and serial number first.

Check important parts often and write down what you do.

Pick sellers you trust and use OEM parts when you can.

Keep spare parts in a clean and tidy place.

Use apps or computers to watch your parts and plan fixes.

If you check your machine often, plan your money, and train workers, you will stop big repairs. These steps help your engine stay strong. Doing this keeps your machine safe and working well for a long time.

FAQ

How do you know if a part will fit your excavator?

First, find your excavator’s model and serial number. Look in your manual for the right part number. Trusted sellers have online tools to help you check. If you are not sure, ask the seller for help.

Should you always buy OEM parts?

OEM parts fit best and are high quality. Use them for big engine repairs. For smaller jobs, good aftermarket parts can work too. Always read reviews and check if the seller is trusted before you buy.

What should you do if a part fails soon after installation?

Tell your seller right away if a part breaks fast. Most good sellers give you a warranty or let you return it. Keep your receipt and take pictures of the broken part. This helps you get a new part or your money back faster.

How often should you replace engine filters?

Change engine filters every 250 to 500 hours of use. Check your manual for the right time. Dirty filters can hurt your engine and make it weak. Set reminders so you do not forget to change them.

Can you use used or remanufactured parts safely?

You can use remanufactured parts from sellers you trust. These parts are tested and often have a warranty. Used parts cost less but can break sooner. Always look for damage and ask about the part’s past.