When you look for excavator replacement parts, you want to feel sure your machine will work safely and well. Picking the wrong part can cause sudden breakdowns, high repair bills, and long waits. Reports show that using the wrong excavator replacement parts can make a simple $200 fix become a $2,000 emergency. Downtime can cost hundreds of dollars each day. You keep your excavator safe by finding the right model, buying from trusted suppliers, and making sure parts fit and are good quality. Checking your machine often helps you avoid big problems and keeps your excavator working well.

Key Takeaways

Always know your excavator’s model and serial number. This helps you get parts that fit. It also keeps your machine safe.

Use OEM codes and manuals to choose the right parts. This makes sure the parts match your excavator. It helps you avoid expensive mistakes.

Check if the parts are strong and last a long time. Look for good materials and certifications like ISO 9001.

Buy from suppliers people trust. They should have good reviews. Make sure they offer clear warranties. They should also give good help after you buy.

Check your machine often and look for worn parts. Replace old parts on time. This stops breakdowns and saves you money.

Identify Your Excavator

Model and Serial Number

First, you need to find your excavator’s model and serial number. These numbers help you get the right parts for your machine. Most excavator parts manufacturers use these numbers to check if parts will fit. If you cannot find the serial number, you might have trouble. Here are some problems you could face:

The serial number plate might be missing or hard to read.

Sometimes, the paperwork does not match the real serial number.

Sellers may not give you the right serial number.

It can be hard to know if an excavator is real, especially if you buy from far away or from someone you do not know.

Some equipment is fake or stolen, which makes it hard to check the excavator’s identity.

Some sellers post pictures that hide the serial number.

The serial number plate might not be there.

If the price is very low, the equipment might not be real.

You should ask sellers questions to avoid scams.

If you check the serial number, you can avoid buying stolen or fake excavators.

When you talk to excavator parts manufacturers, always check the model and serial number again. This helps you get the right parts and keeps your machine safe.

Machine Specifications

You need to know your excavator’s specifications before you buy parts. These details include the size, hydraulic capacity, and what kind of work your excavator does. Excavator parts manufacturers make parts for certain models and jobs. If you pick parts that do not match your machine, they might not fit or could break.

Machine specifications help you choose parts that fit your excavator’s size, mounting points, and connections. The right parts help your machine work better and last longer. If you pick parts that fit your hydraulic system and size, you stop damage and keep your machine running well. Always ask excavator parts manufacturers if the parts fit your machine. This helps your excavator work well and saves you money in the long run.

Choose Compatible Excavator Replacement Parts

OEM Codes and Manuals

You should use OEM codes and manuals when picking parts. These codes help you find the right excavator replacement parts for your machine. Many people pick parts that look the same but do not fit. Each excavator model needs special parts for things like the boom or arm. Using the wrong part can make your machine work badly or be unsafe.

Tip: Always read the equipment manual before buying any replacement part. The manual gives you the part numbers and shows how to change each part. You can see repair steps, pictures, and bolt settings. For example, if you fix a Caterpillar track system, the manual helps you with each step.

You can use the manufacturer’s part number system to get the right excavator parts. Some suppliers have apps or online tools to scan your excavator’s factory plate. These tools help you find compatible excavator replacement parts fast. Manuals also teach technicians, so repairs are safer and better.

Here are ways OEM codes and manuals help you:

They show the part numbers for your excavator.

They help you not buy parts that only look the same.

They give repair steps and safety tips.

They help you check if the part fits your excavator model.

They let you use supplier tools to scan and match parts.

Industry professionals use steps to check if OEM codes are real. They look at the box, check seals, and match part numbers with the manual. They scan barcodes and check supplier catalogs for details. They watch for fake parts by looking for low prices, bad print, and no warranty. Working with an authorized dealer helps you get real excavator parts and support.

Fit and Function

You must make sure every excavator part fits your machine and works right. Compatibility is very important. If you pick the wrong excavator replacement parts, you can hurt your excavator or make it break. Many people make mistakes by not reading the manual or picking parts just because they are cheap.

Common mistakes include:

Picking parts that do not match your excavator model.

Choosing cheap parts that break quickly.

Not checking the manual for part numbers.

Ignoring supplier reputation and warranty.

Not looking at the quality of the replacement part.

You can avoid these mistakes by always checking compatibility. Use the manual and supplier tools to match part numbers. Ask for help from industry professionals or trusted suppliers. Look for suppliers who give charts and customer support to check part numbers. These tools make sure the part fits and works, so you do not waste money on the wrong excavator parts.

Note: OEM parts always fit and have a warranty. Aftermarket parts from trusted suppliers can also work well and save money. Always check for certifications and warranty.

Here is a simple table to help you check fit and function:

Step | What to Do | Why It Matters |

|---|---|---|

Check Manual | Find part numbers and specs | Makes sure you get the right part |

Use Supplier Tools | Scan factory plate or use online charts | Checks if the part fits |

Inspect Quality | Look at materials and workmanship | Stops early failure |

Ask for Support | Contact supplier for advice | Gets expert help |

Verify Warranty | Check warranty and after-sales support | Keeps your investment safe |

If you follow these steps, your excavator will work well. You will avoid downtime and expensive repairs. Checking and changing worn excavator parts helps your machine last longer and work better.

Assess Excavator Parts Quality

Materials and Durability

When picking excavator parts, look at what they are made of. Strong materials help your machine last longer and stay safe. Many manufacturers use high-strength alloy for important parts like the arm, bucket, breaker, and grab. These alloys can make excavator parts last over 20% longer. Hydraulic system parts must handle very high pressure, about 300-350 bar. You should use good hydraulic oil and change the oil and filters every 2,000 to 3,000 hours. This helps your excavator work well.

Check if chassis parts can resist wear and absorb shocks. Test track wear every 1,000 hours. Adjusting track tension can lower chassis problems by about 15%. Buy excavator parts from original makers or certified dealers. These parts meet ISO or CE standards. This lowers the chance of failure by about 20%. Buying the right way and getting a pro to install parts keeps your excavator steady and safe.

Low-quality excavator parts can have bubbles, slag, or small cracks in welds. These problems make welds weak and less tough. Bad casting can cause weak sprocket teeth. This makes them wear out faster. If the part is too soft or rusts easily, it will not last long. Heavy use can make chain plates and pins crack or break over time.

Brands like Caterpillar, Hitachi, and Volvo make parts that last and are comfortable to use. Caterpillar’s GC models are easy to fix and save fuel. Hitachi uses smart hydraulics for smooth work. Volvo makes parts that lower shocks and keep operators safe. These brands show that good parts help your excavator work better.

Quality Certifications

Quality certifications help you pick good excavator parts. OEM parts follow ISO 9001 rules. Makers check materials, parts in progress, and finished parts for strength and accuracy. OEM approval means the parts match the design and technical rules. This makes sure you get strong and reliable replacement parts.

Systems like ERP and MES help watch production and inventory all the time. This makes delivery and product quality better. OEM parts come from the real brand or trusted suppliers. They fit your excavator and work well, sometimes for less money. OEM parts also help your excavator keep its value. They last longer and handle more pressure, so they break less. You also get a warranty and support from the maker.

Manufacturer | Country | Durability & Quality Strengths |

|---|---|---|

Caterpillar Inc. | United States | Tough, long-lasting excavator parts; innovations reduce maintenance and downtime; global service network. |

Hitachi Construction | Japan | Skilled engineering and advanced hydraulics; reliable, easy to maintain excavator parts. |

Volvo Construction | Sweden | Durable excavator parts; focus on safety, fuel efficiency, and intelligent controls. |

Komatsu Ltd. | Japan | Advanced technology; sustainable and fuel-efficient excavator parts. |

JCB | United Kingdom | User-friendly, tough excavator parts; strong after-sales support. |

Liebherr Group | Germany | German-made excavator parts; designed for reliability in harsh environments. |

Doosan Infracore | South Korea | Efficient, dependable excavator parts; custom solutions and worldwide service. |

Bobcat Company | United States | Versatile, easy-to-maintain excavator parts; strong dealer network. |

Always check for certifications like ISO 9001 when buying excavator parts. This helps you avoid bad products and makes sure your excavator gets good replacement parts.

Select Reliable Suppliers for Excavator Spare Parts

Reputation and Reviews

You need to trust the companies that sell you excavator parts. Trust comes from clear facts, good help, and honest deals. When you shop for excavator spare parts, see if the supplier gives equipment history and warranty info. Good suppliers answer your questions fast and explain what you are buying. This trust lowers your risk and makes you want to buy again.

Experts say you should check how long a supplier has sold excavator parts. A strong market history shows they can deliver the excavator spare parts you need. You should also see if they follow safety and quality rules, like ISO or CE certifications. These rules mean the excavator parts meet high standards.

Customer reviews help you know if a supplier is good. Reviews show if the supplier keeps enough excavator spare parts in stock. They also tell if the supplier gives quick and helpful service. Some reviews talk about clear prices and warn about hidden fees. You can use these reviews to find reliable suppliers who care about your needs.

Tip: Always read reviews and ask for testimonials before you buy excavator parts. This helps you avoid problems and find the best excavator spare parts for your machine.

Warranty and Support

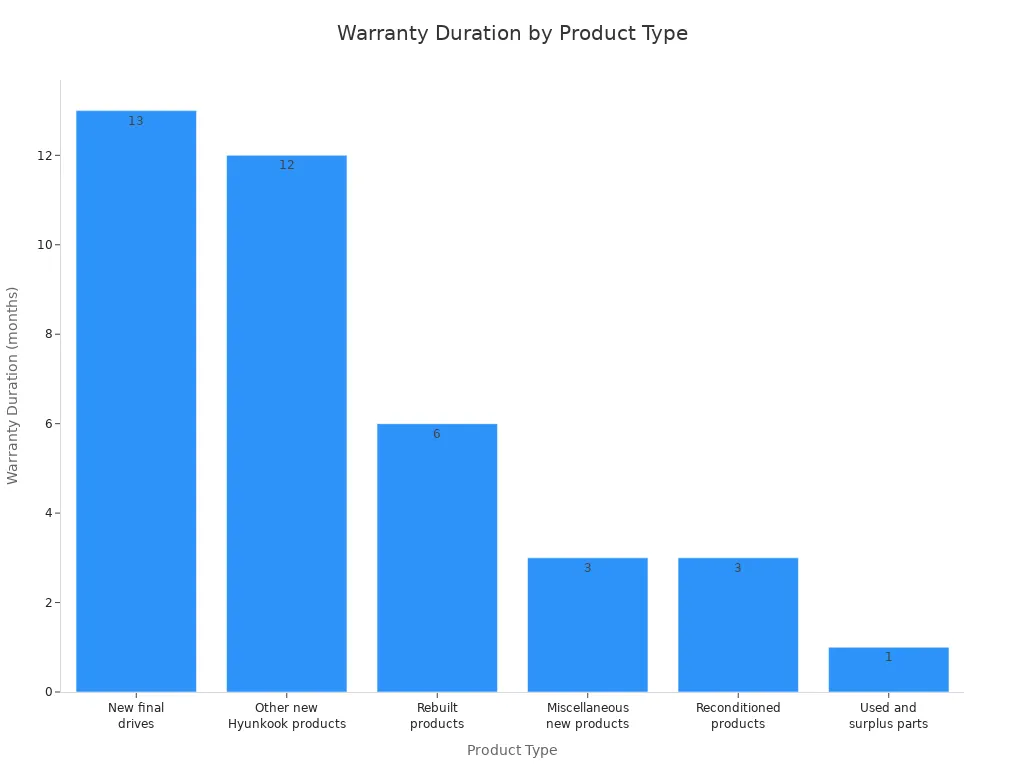

Warranties protect you when you buy excavator parts. A good warranty means the supplier stands behind their excavator spare parts. You should check what the warranty covers and how long it lasts. Some suppliers give longer warranties for new excavator parts, but used or rebuilt parts may have shorter coverage.

Here is a table showing common warranty terms for excavator spare parts:

Product Type | Warranty Duration | Special Conditions/Exclusions |

|---|---|---|

New final drives | 13 months | – |

Other new products | 12 months | – |

Rebuilt products | 6 months | – |

Miscellaneous new products | 3 months | – |

Reconditioned products | 3 months | – |

Used and surplus parts | 30 days | – |

Vendor-sourced products | Vendor-specific warranty | Depends on original vendor warranty |

Core or parts-only products | No warranty | Not covered |

Some suppliers let you buy more warranty time for your excavator spare parts. Extra warranties can cover more parts, like the powertrain or hydraulics. You may also get help with rental machines or transport if your excavator breaks down.

You should always follow the maintenance rules in your manual to keep your warranty good. Use only approved excavator parts and report any problems right away. Good after-sales support means you get help fast if something goes wrong. This support keeps your excavator working and saves you money.

Remember: Reliable suppliers offer strong warranties and support. They help you keep your excavator running with the right excavator spare parts.

Maintain and Replace Excavator Parts

Scheduled Inspections

You keep your excavator working well by checking it often. Do a walkaround every day to look for leaks or loose bolts. Check for worn excavator parts before they break. Grease moving parts every 10 to 50 hours. The time depends on how hard your excavator works. Change air filters every 250 to 500 hours. If you work in dust, change them more often. Change hydraulic fluid every 2,000 hours to protect the hydraulic system.

Here is a simple guide for inspection tasks:

Maintenance Activity | Recommended Frequency | Notes |

|---|---|---|

Walkaround Inspections | Daily | Look for leaks, cracks, loose parts |

Greasing | Every 10-50 hours | Adjust for heavy use |

Air Filter Replacement | Every 250-500 hours | More often in dusty conditions |

Hydraulic Fluid Change | Every 2,000 hours | Follow manufacturer’s advice |

If you follow these schedules, you find problems early. This helps you avoid expensive repairs. Regular checks help you plan to replace worn excavator parts before they fail. Your excavator keeps working and your projects stay on track.

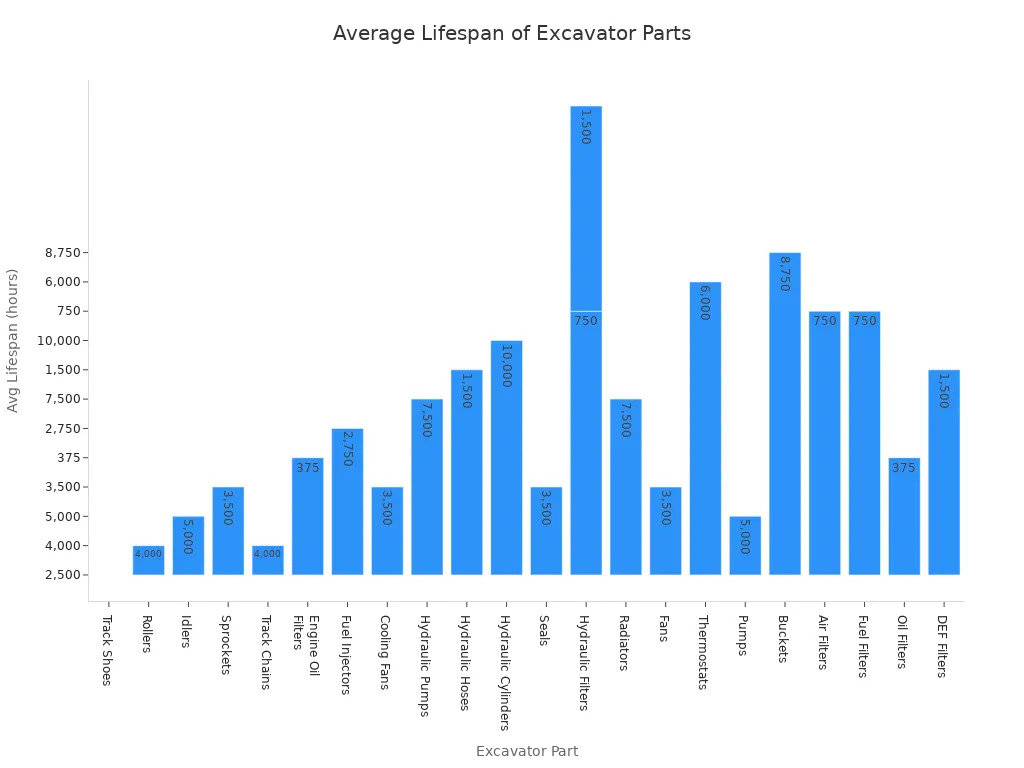

You can see how long different excavator parts last on average:

Signs of Wear

You need to know when to change excavator parts to keep your machine safe. Watch for these signs:

If your excavator moves slowly or digs weakly, hydraulic parts or tracks may be worn.

Grinding or squeaking noises can mean problems with bearings or pumps.

Leaking oil or coolant shows damaged seals or hoses.

Uneven track wear can mean alignment problems or worn undercarriage parts.

Slow hydraulic response can come from clogged filters or bad pumps.

Cracks, dents, or bent excavator parts mean you need new ones.

More noise or shaking during work means parts are worn out.

Tip: If you spot these signs early, you can stop sudden breakdowns and save money. Ignoring wear can lead to bigger repair bills, lost work time, and safety risks.

Doing regular maintenance and changing excavator parts on time saves money. You stop emergency repairs, cut downtime, and help your excavator last longer. Keeping good records and following the manufacturer’s rules keeps your excavator reliable for years.

You can help your excavator work well by following easy steps. First, match the model and serial numbers. Next, pick parts that fit and buy from trusted suppliers. Check your excavator often and replace parts when needed. This helps you avoid big repair bills. Look at the table below to see why this plan is good:

Benefit Category | Explanation |

|---|---|

Compatibility Assurance | Using the right parts stops damage and keeps your excavator safe. |

Quality and Durability | Strong parts help your excavator last longer. |

Safety | Certified parts make accidents less likely. |

Operational Efficiency | The right parts help your excavator work its best. |

Cost Savings | Good choices save money on repairs and lost time. |

Good replacement parts help your excavator work better and stop long breaks.

Checking every day and following a schedule stops most hydraulic problems and keeps your excavator safe.

Doing maintenance on time makes your excavator last longer and saves money.

Remember these steps to help your excavator work well and last a long time.

FAQ

How do you know if a part is genuine or fake?

You can check the part number and look for quality seals. Ask the supplier for proof. Read the manual and compare the part to pictures. Trusted suppliers give you real parts and clear information.

Can you use aftermarket parts instead of OEM parts?

You can use aftermarket parts if they come from a trusted supplier. Always check for quality certifications and a good warranty. Aftermarket parts can save money, but you must make sure they fit and work well.

What should you do if a part does not fit your excavator?

Stop and do not force the part. Check the model and serial number again. Contact the supplier for help. Using the wrong part can damage your machine.

How often should you replace excavator parts?

You should follow the schedule in your manual. Some parts need checking every day. Others last hundreds or thousands of hours. Replace parts when you see signs of wear or if the manual says so.