To get a correct measurement of your excavator stick, do these important steps:

-

Collect your tools.

-

Find each spot you need to measure on your excavator, like pin-to-pin length, width, and pin diameter.

-

Measure each spot with care.

-

Write down your results so they are easy to read.

Look at every detail closely. Correct numbers help you take care of your excavator and make sure it works well.

Key Takeaways

-

Use the right tools like tape measures, calipers, and laser distance meters. These tools help you get correct excavator stick measurements.

-

Follow safety steps like turning off the machine. Wear protective gear and work with a helper to stay safe.

-

Measure important parts carefully. Check pin-to-pin length, stick width, pin diameter, and tip radius. Write down each number right away.

-

Double-check your measurements to avoid mistakes. You might read the tape wrong or measure from the wrong place.

-

Measure your excavator stick often. This helps you keep good performance, find wear early, and keep your machine working well.

Preparation

Tools Needed

Before you start to measure your excavator stick, you need the right tools. Using the correct equipment helps you get accurate numbers. Leading equipment manufacturers suggest these tools for the job:

-

Tape Measure: This is the main tool you will use. Choose a long tape measure if your excavator is large. You need to reach from one pin to another without moving the tape.

-

Laser Distance Meter: This tool helps you get quick and precise measurements, especially on bigger machines.

-

Caliper: Use a caliper to check the diameter of each pin hole. You will need to measure the bucket connection, bucket link connection, bucket cylinder connection, and boom connection.

-

Notepad and Marker: Write down each number as soon as you finish a measurement. Mark the points you have measured on your excavator stick to avoid confusion.

-

Helper: For some measurements, a second person can hold the tape or help you steady the tool. This makes it easier to measure long distances and keeps your results accurate.

Tip: Always double-check your tools before you start. Make sure your tape measure and caliper are in good condition.

Safety Steps

Safety comes first when you work around heavy equipment like an excavator. Follow these steps to protect yourself and others:

-

Turn off the excavator before you begin. Remove the key and keep it in your pocket.

-

Park the machine on flat, stable ground. This keeps the excavator from moving while you measure.

-

Wear safety gear. Put on a hard hat, gloves, and steel-toe boots.

-

Use a second person for large excavators. A helper can hold the tape measure and watch for hazards.

-

Stay clear of the stick and bucket when you move around the machine. Watch your step and keep your hands away from pinch points.

You need to measure the excavator stick carefully to get the right pickup dimensions. Good preparation keeps you safe and helps you get the numbers you need.

Measurement Steps

Accurate measurements of your excavator stick are essential for safe operation and proper attachment fit. Follow these steps to measure excavator pickup dimensions and ensure your machine performs at its best. Always position the stick and bucket at a 90-degree angle to the ground before you start. This setup gives you the most reliable results.

Pin-to-Pin Length

You need to measure the length from the center of the bucket pin to the center of the boom pin. This is the main dimension that defines your excavator stick. Use these steps:

-

Place the excavator on stable ground and lower the stick until it is horizontal.

-

Make sure the bucket and stick form a 90-degree angle with the ground.

-

Use a tape measure or a vernier caliper for the most accurate measurement.

-

Stretch the tape measure straight from the center of the bucket pin hole to the center of the boom pin hole. Avoid any sag in the tape.

-

Take at least three measurements and calculate the average to ensure accuracy.

-

Record the length in your notepad right away.

Tip: Double-check your measurements. Even a small error in length can affect how attachments fit and work.

Stick Width at Bucket Pin

The width at the bucket pin is another key dimension for your excavator stick. This measurement helps you match attachments and avoid equipment damage.

-

Keep the excavator arm steady and horizontal.

-

Use a caliper or a measuring bar to measure the internal distance between the attachment plates or bushings at the bucket pin area.

-

If your machine has bushings, measure the internal surfaces of the bushings, not the overall gap.

-

Take several measurements at different points to confirm the width.

-

Write down the width for your pickup measurements.

Note: Accurate width measurements help you avoid loose or tight fits that can cause wear or failure.

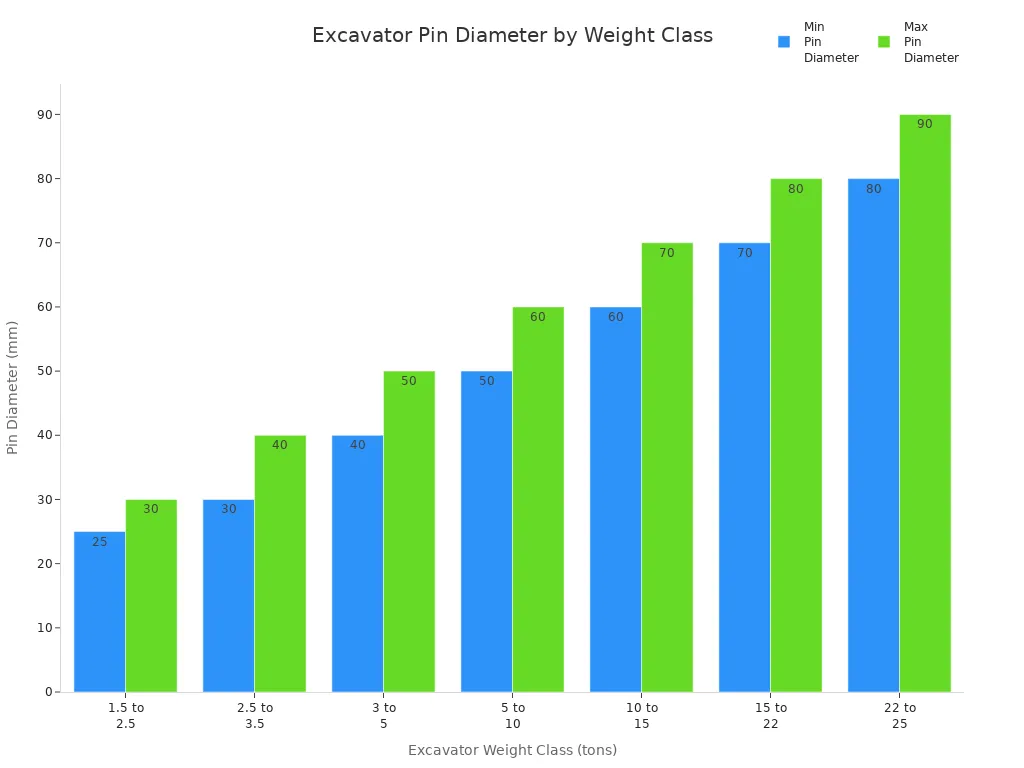

Pin Diameter

Pin diameter is critical for safe and secure attachment. You must measure this dimension with care.

-

Use a caliper for the most precise measurement.

-

Measure the diameter of each pin hole at the bucket, stick, and boom connections.

-

Take multiple measurements around the pin to check for wear or ovality.

-

Average your results for the most accurate diameter.

-

Compare your measurements with the standard pin diameter range for your excavator’s weight class.

Here is a table to help you match your excavator’s weight to the correct pin diameter:

|

Excavator Weight Class (tons) |

Standard Pin Diameter Range (mm) |

|---|---|

|

1.5 to 2.5 |

25 – 30 |

|

2.5 to 3.5 |

30 – 40 |

|

3 to 5 |

40 – 50 |

|

5 to 10 |

50 – 60 |

|

10 to 15 |

60 – 70 |

|

15 to 22 |

70 – 80 |

|

22 to 25 |

80 – 90 |

Always check your measurements against OEM specifications to make sure your pickup fits perfectly.

Tip Radius

The tip radius is the distance from the center of the stick’s bucket pin to the tip of the bucket or attachment. This length affects how far your excavator can reach and dig.

-

With the stick and bucket at 90 degrees, measure from the center of the bucket pin to the furthest tip of the bucket or attachment.

-

Use a tape measure or laser distance meter for this measurement.

-

Record the length and check it against your attachment’s requirements.

The tip radius helps you plan your work and ensures your excavator stick can handle the jobs you need.

When you measure excavator pickup dimensions, always use the right tools and take your time. Accurate pickup measurements keep your excavator running smoothly and help you avoid costly mistakes. Each dimension—pin-to-pin length, stick width, pin diameter, and tip radius—plays a role in how your excavator stick performs. Write down every measurement and double-check your results before you order new attachments or parts.

Accuracy Tips

Common Mistakes

You want your excavator to be safe and work well. To do this, you need to avoid some common mistakes when measuring. Many people read the tape measure wrong or pick the wrong spots to measure. Sometimes, people forget to use metric units, which can make things confusing. If you do not write down your numbers right away, you might have problems later.

Here are some mistakes you should look out for:

-

Looking at the tape measure from the wrong side

-

Measuring from the edge, not the pin’s center

-

Using inches when you should use millimeters

-

Not writing down each number as soon as you finish

-

Skipping steps or going too fast

Always take your time and check your work. Good measurements need you to pay close attention.

Reliable Results

You can get good results if you follow some easy tips. Always measure each part the right way. Ask a helper to hold the tape or check your numbers if you need help. Measure two times to make sure your numbers are the same. Write down your numbers in your notepad right away.

Experts suggest some advanced ways to get better measurements for your excavator stick:

-

Mechanism modeling uses math and science to help, but it can be hard to do.

-

Strain gauges show how much load there is, but they are tricky to put on and can break.

-

Hydraulic cylinder pressure analysis makes it easier to get data, but it is not always exact.

-

Pin sensors measure forces at the bucket-arm joint and help block outside problems.

-

Data-driven modeling, like machine learning, uses lots of data to guess working resistance very well.

-

Physics-informed machine learning mixes science models with data, so you get the best and most exact results.

Tip: Use both old tools and new tech to get the best numbers for your excavator. This helps your machine work well and stay safe.

Why It Matters

Performance

Accurate measurements of your excavator stick make a big difference in how your machine works. When you measure each part correctly, you help your excavator perform at its best. The length of the stick changes how much force your excavator can use and how far it can reach. If you use the wrong stick length, you might lose digging power or reach too far, which can make your work harder.

Here is a table that shows how stick length affects performance:

|

Arm Length |

Arm Force (lbs) |

Recommended Bucket Size (cu. yd.) |

Impact on Performance |

|---|---|---|---|

|

Short (8 ft. 9 in.) |

45,914 |

2.8 |

Highest arm force and largest bucket. Great for tough digging but less reach. |

|

Medium (10 ft. 6 in.) |

39,930 |

2.6 |

Balanced force and reach. Good for most jobs. |

|

Long (13 ft. 1 in.) |

34,314 |

2.4 |

Longest reach but less digging force. Best for jobs that need extra reach. |

Longer sticks give you more reach but less digging force. Shorter sticks give you more power but less reach. If you match the stick length and bucket size to your job, your excavator will work better and last longer. You also need to think about how fast the machine swings and how much stress the stick takes. Careful machine hitch measurements help you pick the right parts and avoid damage.

Tip: Always check your measurements before you choose a new attachment. This keeps your excavator safe and strong.

Maintenance

Good measurements help you plan for repairs and keep your excavator running. If you measure the stick, pins, and width often, you can spot wear before it causes problems. Worn parts can make your excavator less safe and cost you more money. When you use the right machine hitch measurements, you know when to replace pins or bushings.

You should write down each measurement and compare it to the last one. If you see a big change, you can fix the problem early. This helps you avoid breakdowns and keeps your excavator ready for work. Regular checks also help you follow the manufacturer’s maintenance plan.

Note: Accurate measurements save you time and money. They help you keep your excavator in top shape and ready for any job.

You can get the right measurement for your excavator stick by doing a few easy things. Use sensors or simple tools to check the cylinder length and how the links move. Do not change anything on the excavator’s structure. Always check your numbers with real measurements and CAD models. If you check often, you can find problems early and keep your excavator safe. Here is a short checklist:

-

Collect all your tools and safety gear

-

Measure pin-to-pin length, width, and pin diameter

-

Use sensors to get exact data

-

Write down and check every number

Be careful and keep your excavator working well by using these tips.

FAQ

How often should you measure your excavator stick?

You should check your excavator stick measurements every few months. If you use your machine daily or notice any wear, measure more often. Regular checks help you spot problems early.

What if your measurements do not match the manual?

If your numbers do not match the manual, check your tools and try again. Worn parts or wrong points can cause mistakes. Always use the right method for your excavator.

Can you use a laser distance meter for all measurements?

A laser distance meter works well for long, straight measurements. For small parts like pin diameter, use a caliper. Choose the best tool for each part of your excavator.

Why do you need to record every measurement?

Recording each measurement helps you track changes over time. You can spot wear or damage early. Good records keep your excavator safe and ready for work.