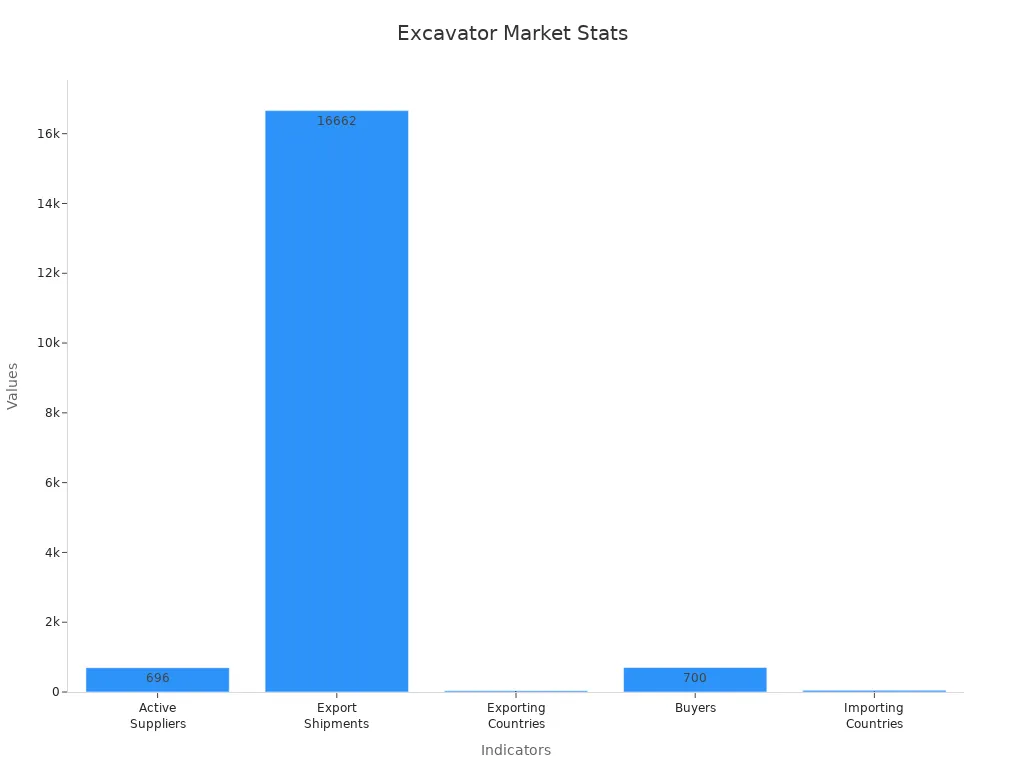

To pick the best excavator undercarriage parts suppliers, focus on quality, compatibility, brand reputation, and long-term value. Using good materials that meet industry standards is crucial. Komatsu reports that high-quality undercarriage parts can reduce failure rates by 30% and last up to 25% longer. Choosing excavator undercarriage parts suppliers with strong support and a solid reputation helps you avoid costly downtime. The chart below highlights a few top suppliers leading the market, emphasizing the importance of reputation and quality when selecting a supplier.

Key Takeaways

Pick undercarriage parts that match your excavator’s size. Make sure the parts fit the job and the work area. This helps the parts last longer and work better.

Always choose parts made from strong, tested materials. OEM parts are better for quality, fit, and warranty.

Choose suppliers with a good name and fast delivery. Good customer support helps you avoid costly delays and repairs.

Find suppliers who give clear warranties and helpful service. They should talk with you in a way that works for you. This gives you better value and support.

Do not buy cheap, low-quality parts. These can cause expensive repairs and slow you down. Trusted suppliers help you save money over time.

Define Your Needs

Machine Specs

First, look at your excavator’s specs. The size and weight of your machine matter. These things decide which undercarriage parts you need. Think about these points:

Bucket capacity shows how much you can move. This affects the strength and size of the undercarriage.

Reach length changes how stable your machine is. It also changes the undercarriage design.

How you move your machine and get it to the site matters. This limits the biggest size and weight you can use.

Dig depth and lifting power tell you how hard the undercarriage will work.

Hydraulic system power changes which attachments you can use and how well they work.

Undercarriage Component | Typical Lifespan (Operational Hours) |

|---|---|

Track Shoes | 2,000 to 3,000 |

Rollers | 3,000 to 5,000 |

Idlers | 4,000 to 6,000 |

Sprockets | 3,000 to 4,000 |

Track Chains | 3,000 to 5,000 |

Picking the right undercarriage parts for your specs helps your machine last longer and work better.

Usage & Environment

You need to match your undercarriage parts to the job and place. The ground type, like sand or rocks, changes how fast parts wear out. What you do with the machine, like digging or loading, also matters. How the operator drives, such as turning or going fast, can make parts wear out quicker. Keeping up with maintenance, like cleaning and adjusting track tension, keeps your undercarriage working well.

Tip: Use steel tracks for rough ground. Use rubber tracks for soft or gentle ground. Always check for wear and change your maintenance plan if the site changes.

Specific Undercarriage Parts

Figure out which undercarriage parts you need. Each part does something special. Track chains move power from the engine. Rollers hold up the machine’s weight. Idlers keep the track tight. Sprockets help the chain move the excavator. Track pads help the machine grip the ground. Good materials and careful building make parts last longer and fit right. Always pick parts that fit your machine’s size, job, and work area. This stops early wear, breakdowns, and expensive repairs.

Quality & Compatibility

Material Standards

Always check what materials are in the undercarriage parts. Good materials help your undercarriage last longer. Companies like Komatsu use strong steel and special alloys. These materials help parts handle hard jobs. They also help stop wear from rocks, sand, and mud. If you pick parts made with good materials, you get better quality and fewer breakdowns.

Note: The ground and how you use your excavator change how fast parts wear out. Hard, rocky ground wears out bushings, rollers, and shoes faster. Wet ground and mud can also make parts wear out quicker. Always ask your supplier about the materials and how they test for quality.

Look for suppliers who follow industry rules. These rules help parts fit well and last longer. Parts that meet these rules give you more value and less downtime.

OEM vs. Aftermarket

When you compare OEM and aftermarket undercarriage parts, think about a few things. OEM parts come from the company that made your excavator. They fit perfectly and match the original specs. This means you get top quality, strong parts, and good performance.

OEM parts are tested for quality and fit, so you avoid damage and downtime.

OEM parts come with a warranty, which protects your money.

OEM parts often last longer, so you save money over time.

Aftermarket parts can cost less, sometimes up to 40% cheaper, but the quality is not always the same.

Some aftermarket parts may not fit well or last as long. They might not have a warranty, which can cost you more later.

Using OEM parts keeps your excavator’s warranty safe. Aftermarket parts can void it.

Studies show that using OEM undercarriage parts can make equipment last up to 30% longer. Some rebuilt OEM parts also meet factory rules and come with warranties, so you get a good mix of price and quality. Aftermarket parts may save money at first, but you might have more repairs and downtime.

Fit for Excavator Undercarriage Parts

Getting the right fit is very important for your excavator’s undercarriage. If parts do not fit right, you can get early wear, bad performance, and even machine damage. OEM parts are made for your exact model, so they fit and work as they should. Brands like Komatsu make their undercarriage parts to fit perfectly, so you do not have to guess.

Other brands may be cheaper, but they may not fit as well or work as long. Badly fitting parts can mean more repairs and higher costs. Always check part numbers and ask your supplier if the parts fit your machine. Good suppliers help you find the right undercarriage parts for your excavator, so you get the best performance and longer life.

Tip: Pick suppliers with a strong dealer network and good reviews. This helps you get the right parts fast and keeps your excavator working longer.

Excavator Undercarriage Parts Suppliers

Reputation & Experience

When you look for excavator undercarriage parts suppliers, reputation and experience are very important. Good manufacturers get a strong reputation by doing a good job for many years. You can tell if a supplier is trusted by how long they have been working and how well they help customers. Many good suppliers give long warranties, like 3 years or 4,000 hours. This shows they trust their undercarriage parts. Some companies, like GFM, have made parts for over 14 years. Others, like ITR America, are known for parts that last a long time and work well.

You will not see official number scores for supplier reputation in this field. Instead, you should look at these things:

How good and reliable the excavator undercarriage parts are

How fast and helpful customer service is

If parts arrive on time and are in stock

How long the warranty lasts and what it covers

If the supplier has many parts that fit your excavator

A supplier who always gives good undercarriage parts and helps after you buy stands out from others. Picking a trusted supplier with a good history means less chance of your machine breaking and fewer expensive repairs.

Tip: Always ask about the warranty. A longer warranty usually means better quality and more trust from the supplier.

Reviews & References

You should always read reviews and check references before you choose. Customer reviews tell you what real people think about the supplier. Look for comments about how long the parts last, if they fit well, and if the supplier fixes problems fast. Good suppliers often get good reviews for making parts last longer and shipping quickly.

Some brands, like Caterpillar, have special tools to watch undercarriage wear and help plan repairs. These tools show the supplier cares about quality and keeping your machine working. Programs like Custom Track Service (CTS) Pro and Customer Value Agreements (CVAs) give you repair data, set repair costs, and different repair choices. These services mean the supplier supports you for the life of your equipment.

You can also ask the supplier for references. Ask for stories or contact details for other customers. This helps you check if the supplier is really good and trusted.

Full inspections and regular maintenance records show the supplier is reliable.

Training for operators and feedback systems help keep your excavator working well.

Keeping records and reports helps you take care of your machine.

Note: A supplier with lots of good reviews and references is more likely to give you good parts and service.

Delivery & Availability

Getting your excavator undercarriage parts fast is very important. Good suppliers have big warehouses and good shipping plans to keep parts ready. Some suppliers have warehouses as big as 3,000 square meters. This helps them send parts quickly. Some suppliers also offer special delivery choices to get you parts even faster.

A good maintenance team should answer your questions in 24 hours. If you have a problem at your work site, the best suppliers try to fix it in 48 hours. This keeps your excavator working and stops long breaks.

When you check excavator undercarriage parts suppliers, ask about:

How big their warehouse is and how many parts they have

How fast they deliver and what shipping choices they offer

How quickly they answer online questions

How fast they fix problems at your site

Market research reports, like the ‘Undercarriage Component Market Report 2025,’ give you facts about how suppliers work and how good they are. These reports look at company details, market trends, and how suppliers compare. You can use this to find good suppliers and see who delivers parts the fastest.

Callout: Pick suppliers who always deliver fast and help you quickly. This makes sure you always have the undercarriage parts your excavator needs.

Service & Value

Warranty & Support

When picking a supplier, always check the warranty and support. Authorized suppliers give warranties that protect you from bad parts. This helps you feel safe about your money. Many suppliers have experts who help you pick the right parts. You can expect:

Warranties on all parts, but the time depends on the part.

Easy and quick return rules.

Support teams who answer questions and help with setup.

Good shipping so you get your parts fast.

Brands like Caterpillar give strong help after you buy. This means less time waiting for repairs. Good support and help save you money over time.

Pricing & Total Cost

Do not just look at the price tag when you compare parts. The real cost includes the warranty, help, and how long the part lasts. Some suppliers have extra help plans and service deals. These help you plan your money and keep your machine working longer.

Aspect | Details |

|---|---|

Warranty Coverage | 12-month limited warranty for broken parts from failure. |

Extended Support | Plans that cover big moving parts after normal warranties end. |

Product Durability | Heavy Duty Extended Life (HDXL) parts last 40% longer. |

Dealer Support | Service plans you can change for your budget and time. |

Picking good brands gives you better value and fewer surprise bills. You also get checklists and tips to help your parts last longer.

Best Excavator Undercarriage Parts Manufacturers

You should work with the best makers of undercarriage parts. Caterpillar makes its own parts and checks them with tough tests. Cat parts can last twice as long as some other brands. Mustang and Gehl also make strong aftermarket parts that are sometimes better than OEM. These brands use tough steel and special ways to make parts strong. They give warranties and good help after you buy, so your money is safe and you can trust them.

Tip: Pick suppliers who follow the rules and give full support. This helps you get strong, long-lasting parts for your excavator.

Right Excavator Undercarriage Parts Supplier

Communication & Flexibility

You need a supplier who listens and answers fast. Good communication helps you get parts on time. When you ask questions, the supplier gives clear answers. They also tell you about your order. Flexible suppliers can handle urgent orders or special needs. They help you fix problems quickly, so your excavator keeps working. If your project changes or you need a new part, a flexible supplier can adjust easily.

Tip: Pick suppliers who let you contact them by phone, email, or chat. This makes it simple to get help when you need it.

Long-Term Partnership

Working with the same supplier for a long time has many benefits. You always get good undercarriage parts, so your excavator lasts longer. Trusted suppliers often give better prices and support, even when parts are hard to find. They offer quick help and send replacement parts fast. You know the parts fit your machine and meet industry rules. Warranties protect you if a part breaks early. Sharing feedback and having regular check-ins helps you fix problems fast and keep your excavator running well.

Always get real, high-quality parts

Get special help and good prices

Fast answers when you need them most

Warranty keeps your undercarriage safe

Avoiding Low-Quality Deals

Cheap suppliers may look like a good deal, but they can cost you more later. Hidden problems, fake years, or missing papers can mean big repair bills and delays. The table below shows some risks and what they can cost you:

Risk Type | Potential Impact | Risk Level |

|---|---|---|

Hidden Mechanical Faults | Repairs costing $3,000–$10,000+ | High |

Fake Manufacturing Year | Lower resale value, customs problems | High |

Missing Documents | Customs clearance delays or refusals | High |

Non-Compliance (EPA/CE) | Import restrictions | High |

Fixing undercarriage parts like final drives or hydraulic pumps can cost $2,000 to $8,000. These repairs lower your excavator’s value and can stop your work. Always read reviews and ask for proof that parts follow the rules. The right supplier gives you real, tested parts and all the needed papers.

Note: Saving money with cheap parts often means bigger costs later. Pick suppliers who care about quality and trust.

When you look at different excavator undercarriage parts suppliers, first think about what you need. Check if the parts are good quality and if they fit your machine. It is also important to see if the supplier has a good reputation. Make sure the supplier gives good service and fair value. This helps you get the best results. Countries like China and Japan have top suppliers. These suppliers have big factories, lots of parts in stock, and ship parts quickly. This can help you avoid losing time and money. Always pick quality, trust, and long-lasting value instead of just picking the lowest price. If you follow these tips, you can pick the right supplier. This will help your excavator work well for a long time.

FAQ

What should you check before buying undercarriage parts?

Check the part numbers to make sure they match. Look at the material quality to see if it is strong. Make sure the parts fit your excavator. Ask for test reports and warranty details. Good suppliers give you clear papers and answer questions fast.

How do you know if a supplier is trustworthy?

Read customer reviews to see what others say. Pick suppliers who have worked in the industry for many years. Trusted suppliers give long warranties and help you quickly. You can also ask for names of other customers to check.

Are aftermarket parts as good as OEM parts?

Aftermarket parts can cost less, but quality is not always the same. OEM parts always fit and last longer. Always look at test results, warranty, and what customers say before you pick.

How can you avoid delays in getting parts?

Tip: Pick suppliers with lots of parts in stock and fast shipping. Ask about how long delivery takes before you buy. Good suppliers answer fast and tell you where your order is.