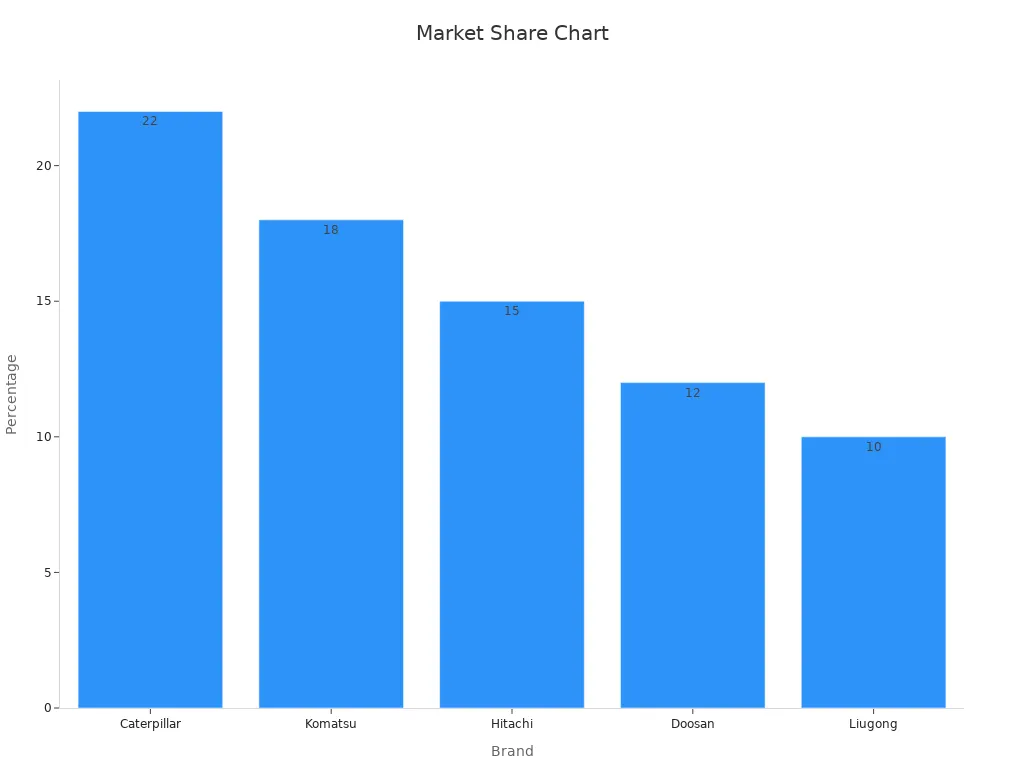

Choosing the right excavator buckets parts is crucial for the success of your project. Selecting the proper bucket and parts ensures your machine operates more efficiently and has a longer lifespan. Leading brands like Caterpillar and Komatsu offer excavator buckets parts that are durable and built to handle tough jobs.

Excavator Part Type | Key Statistical Data / Insight |

|---|---|

Hydraulic Cylinders | Service life is more than 3,000 hours in normal use |

Track Shoes | Wide shoes are best for gravel, narrow shoes for rocks |

It’s important to match your excavator buckets parts to the specific job and material you’re working with. Consider the type of material, bucket size, teeth configuration, and overall strength. This approach helps you save money, reduce repairs, and maximize the productivity of your excavator.

Key Takeaways

Pick bucket parts that fit your project’s material and job. This helps you work faster and keeps your machine safe.

Choose the right bucket size and type for your excavator. This keeps your machine safe, steady, and working well.

Check pin spacing and coupler fit before you use the bucket. This helps stop damage and keeps everyone safe.

Use strong, wear-resistant teeth and parts on your bucket. This means you will fix it less and it will last longer.

Take care of your bucket by greasing and changing parts on time. This saves money and stops your machine from breaking down.

Project Needs

Material Type

When you plan your project, think about what you will move. The weight of the material is important. Heavy things like rock or clay need smaller buckets. This keeps your excavator safe and steady. Lighter things like sand or soil can use bigger buckets. Bigger buckets help you work faster.

General duty buckets are good for sand, gravel, and loose soil.

Heavy duty buckets are best for hard-packed stone or clay.

Rock buckets are extra strong for tough things like granite or iron ore.

Tip: Pick a bucket size that fits the heaviest or most common material. If you use a bucket that is too big, your machine can become unstable and wear out faster.

Site and Terrain

You also need to look at the ground where you will work. Flat ground helps your excavator work better. If the ground is bumpy or sloped, the bucket may not work the same. Even small hills can change how high the bucket lifts. The angle of the bucket can also change. This can affect how much you can carry and how hard your machine works.

Soil type is important too. Sticky or rocky soil makes the bucket teeth wear out faster. You might need stronger or special bucket parts for these places.

Job Scope

The job scope tells you what the excavator needs to do. Are you digging trenches, leveling land, or breaking rocks? Each job needs a different kind of bucket. Trenching buckets are narrow and deep for digging pipes. Grading buckets are wide for making the ground smooth.

Utility jobs need buckets that do not break pipes.

Rock breaking needs buckets with strong teeth.

Landscaping uses tilt or special buckets for shaping the ground.

Looking at what your project needs helps you pick the right bucket and tools. This makes your work safer and helps you finish faster.

Choosing the Right Excavator Bucket

Bucket Types

There are many kinds of excavator buckets you can use. Each bucket works best for a certain job or material. Knowing how they are different helps you choose the right one.

Bucket Type | Specific Excavation Task/Application |

|---|---|

Digging bucket | General digging and moving material in construction projects |

Rock bucket | Breaking up hard, compact surfaces like rock |

Utility bucket | Excavation near utility pipes and cables |

Grading bucket | Smoothing and finishing softer materials |

Tilt ditch cleaning | Angled smoothing and finishing on slopes |

V bucket | Creating V-shaped trenches for piping and cables |

Frost bucket | Breaking extremely compact or frozen ground |

Micro trenching bucket | Narrow trenches for cables and irrigation |

Skeleton bucket | Sifting and separating larger aggregate from soil |

Rake riddle bucket | Removing roots and landscaping debris |

Clean-up bucket | Picking up and moving loose materials |

A digging bucket is the most common type. You use it for soil, clay, or sand. It has a shape and teeth that work for many jobs. This bucket is good for most building work. If you need to dig a trench for pipes, use a trenching bucket. It is narrow and deep, so it cuts the ground well.

For hard jobs, you need stronger buckets. A rock bucket has thick steel and strong teeth. You use it for breaking hard rock or working in quarries. Grading buckets have a wide, flat edge. You use them to make the ground smooth. Utility buckets help you dig near pipes without breaking them.

Some jobs need special buckets. A V bucket makes V-shaped trenches for cables or drains. Frost buckets break up frozen or very hard ground. Skeleton buckets let dirt fall through but keep rocks. Rake riddle buckets pull out roots and trash when you do landscaping.

Tip: Always pick the bucket that matches your job and material. The wrong bucket can slow you down and wear out your machine.

Application Fit

To pick the right excavator bucket, look at your project. Match the bucket’s features to what you need. Make sure the bucket fits your machine and the job.

Use a digging bucket for most digging and moving jobs. It works well with soil, clay, and sand.

Pick a rock bucket or heavy-duty bucket for hard ground. These buckets are strong and last longer.

Use a trenching bucket for narrow, deep trenches. It makes clean sides and saves time.

Choose a grading bucket for smoothing and finishing. Its wide edge makes the ground flat.

Use a utility bucket near pipes or cables. Its shape helps you avoid breaking things underground.

The right bucket makes your work faster and easier. For example, a trenching bucket saves time when digging for pipes. A rock bucket can break hard ground without damage. Using the right bucket also keeps your machine from wearing out too soon.

Studies show matching the bucket to the trench and soil helps you work better. Special buckets like tilt or V buckets help you finish jobs faster. The right bucket can make you up to 20% more productive. It also helps your machine last longer and keeps your project on track.

Think about your excavator’s size and lifting power too. Small machines need small buckets. Big machines can use bigger buckets. The wrong size can make your machine tip or break.

Note: Always check that your bucket fits your machine and the job. This keeps you safe and helps you work better.

When you choose the right excavator bucket, your project goes smoother. You save time, spend less money, and protect your machine. Picking the right bucket helps you finish your work well.

Excavator Bucket Size and Compatibility

Excavator Specs

You must pick a bucket that fits your excavator’s power and weight. Each excavator is made for a certain bucket size. For example, a 20-ton excavator works best with buckets from 0.8 to 2.5 cubic meters. If you use a bucket that is too big, your machine can break down faster and use more fuel. If the bucket is too small, you will need more trips to move dirt. This slows down your work. The right bucket size helps you work safely and quickly. Studies show that matching the bucket to the machine saves money and time. It also keeps your equipment safe and helps it last longer.

Pin Spacing and Coupler

Pin spacing and coupler choice are important for a good fit. Pins hold the bucket to the excavator arm. If the pin size or space is wrong, the bucket will not fit well. A loose bucket can shake and wear out fast. Always check the pin size and follow the rules. The table below shows some common sizes:

Parameter | Specification / Standard |

|---|---|

Safety Standards Compliance | ISO13031, EN474, AS 4772:2008 |

Minimum Pin Spread | 18.86 in (479 mm) |

Maximum Pin Spread | 23.35 in (593 mm) |

Front Pin Diameter (Stick) | 3.94 in (100 mm) |

Rear Pin Diameter (Link) | 3.54 in (90 mm) |

Coupler Features | Redundant locking, abrasion-resistant steel |

A strong coupler keeps the bucket steady and safe. It also lets you change buckets quickly for different jobs. Always use a coupler that fits your bucket and meets safety rules.

Hauler and Depth

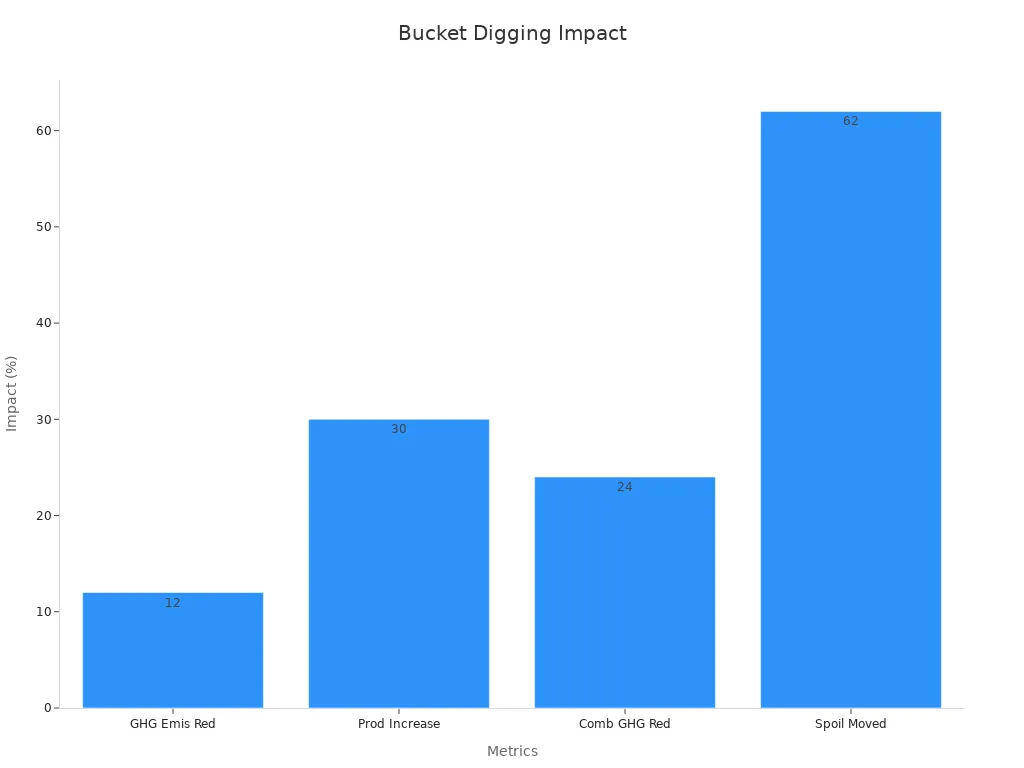

Think about the hauler and how deep you need to dig. The hauler is the truck that takes away the dirt. The bucket size should match the hauler’s size. If the bucket is too big, you might overload the hauler. If it is too small, you will need more trips. Digging depth is important too. The right bucket helps you dig deep enough without hurting your machine. Studies show that using the right bucket and digging depth can help you work up to 30% faster and cut greenhouse gases by 12%. You also move more dirt for each gallon of fuel.

Tip: Always check your bucket size, pin spacing, and coupler before you start. This helps you avoid problems, save money, and keep everyone safe.

Excavator Buckets Parts Selection

Teeth and Edges

When you pick excavator buckets parts, look at the teeth and edges. The right teeth and edges help you cut tough stuff. They also keep your bucket safe from damage. Good teeth are made from martensitic steels with tiny grains. This makes them hard and tough at the same time. Hard teeth last longer and can take strong hits. For example, Hardox 500 steel does well in rough places. It lasts longer when you dig in sand or rocks.

Material Type | Hardness | Impact Toughness | Wear Resistance | Suitable Working Conditions | Cost Index | Repairability |

|---|---|---|---|---|---|---|

High Manganese Steel | Medium (HB450-550) | Excellent | Medium | Impact-based | 1.0 | Easy |

Alloy Steel Bucket Teeth | High (HRC55-60) | Good | Good | Medium to high stress | 1.3-1.5 | Difficult |

Tungsten Carbide Coating | Very High (HRA90+) | Poor | Excellent | Highly abrasive | 2.5-3.0 | Not repairable |

You can use wear rate numbers to see which teeth last longer. Lab tests like ASTM G65 show that good materials wear out slower. This helps your excavator work for more hours.

Wear Parts

Wear parts are things like teeth, adapters, side cutters, and edges. These parts get damaged the most when you dig. Good wear parts fight off scratches and last longer. If you change them when they are half worn, your bucket lasts twice as long. Check these parts every day and week for cracks or worn spots. Change and turn the teeth so they wear out evenly.

Change wear parts before they are all used up.

Look for cracks or damage every week.

Turn teeth so they wear the same.

Tip: Good wear parts help you work more and fix less.

Material Quality

Always pick excavator buckets parts made from strong materials. These parts last longer and work better on hard jobs. Good bucket teeth use strong steel and special heat. This makes them tough against wear and helps them dig hard dirt. Good materials mean you fix your bucket less and work more.

Every part of your bucket should be made from good stuff. Strong materials help you work faster and safer. They also make your machine last longer and protect your money.

Durability, Maintenance, and Cost

Build Quality

When you pick an excavator bucket, check how strong it is. Buckets made with thick metal last longer. They help you avoid spending money on repairs. Some brands, like Caterpillar, use extra metal in important spots. This makes the bucket much stronger than old ones. You will have fewer problems and the bucket will last longer. The table below shows how good build quality helps you save money and work better:

Aspect | Evidence Detail |

|---|---|

Structural Durability | Cat 374 excavator buckets last twice as long as older models due to thicker plates and frames. |

Maintenance Intervals | Hydraulic filter life increased by 50% to 3,000 hours. |

Maintenance Cost | Up to 20% less maintenance cost than previous models. |

Wear Prevention | Features like “Auto Hammer Stop” reduce unnecessary wear. |

Monitoring Technology | Real-time data helps you plan maintenance and avoid downtime. |

Good buckets also have features that make checks easy. You can check oil and fluids from the ground. This saves time and keeps you safe. These upgrades show that strong buckets are worth it.

Upkeep

Taking care of your bucket helps it last longer. Simple jobs like greasing every few hours stop rust and wear. Changing filters and fluids on time keeps your machine working well. The table below shows how often you should do these jobs and why they help:

Maintenance Task | Frequency (Hours) | Benefit |

|---|---|---|

Greasing | 10–100 | Reduces wear, prevents corrosion |

Filter Changes | 250–500 | Keeps fluids clean, protects components |

Fluid Changes (Engine Oil) | 250–500 | Maintains smooth operation |

Hydraulic Fluid Change | 1,000–2,000 | Extends hydraulic system life |

Wear Parts Replacement | As needed | Maintains digging efficiency |

Tip: Grease your bucket and change filters on time. This helps you avoid big repairs and keeps your bucket working longer.

Value

You get the most for your money when you choose a strong bucket and take care of it. A good bucket might cost more at first, but you save money later. You will not need as many repairs and can work more before buying a new one. Features like real-time checks and easy service points help you plan ahead. When you follow the right upkeep steps, you protect your bucket and keep your machine running well. Picking a bucket that is tough and easy to care for gives you the best deal.

When you pick the right excavator bucket, you work faster and save money. The right bucket type, size, and parts help your machine do a better job. This means less damage and more accurate work. It also makes the job safer and easier for the operator. Studies show the right bucket can make digging much quicker, sometimes by 30%. Always make sure your bucket fits your machine before you begin. If you have a special job, ask an expert for help. Think about what will help you work well for a long time.

FAQ

What is the best way to know if a bucket part fits my excavator?

Always check your excavator’s manual for size and pin measurements. You can also ask your dealer for help. Matching the part numbers ensures a good fit.

How often should I replace bucket teeth?

You should check bucket teeth every day. Replace them when you see cracks, chips, or if they look worn down. Worn teeth make digging harder and can damage your bucket.

Can I use one bucket for all types of jobs?

You can use one bucket for simple jobs. For best results, use a bucket made for your material and task. Special buckets work better for rock, trenching, or grading.

What are signs that my bucket needs maintenance?

Cracks or dents on the bucket

Loose or missing teeth

Rust or worn edges

Tip: Fix problems early to save money and keep your machine safe.

Do stronger bucket parts cost more?

Yes, stronger parts usually cost more at first. They last longer and need fewer repairs. Over time, you save money because you do not replace them as often.