Crawler excavator spare parts help machines work well. Important parts are the boom, arm, bucket teeth, hydraulic cylinders, undercarriage, tracks, cab, and engine. Each part does a special job like lifting, digging, or moving. Companies that check excavator spare parts every 100 hours or every week during hard work have fewer problems and longer machine life.

KPI | Before Improvement | After Improvement | Impact |

|---|---|---|---|

Parts-Related Downtime | 30% | Under 10% | Less downtime, faster project finish |

Spare Parts Availability | 95% | Near 100% | Parts ready, less waiting |

Knowing the main parts of an excavator, like the undercarriage and bucket, helps workers stop costly delays and keep machines working their best in the important world of excavator spare parts. Every worker should know the key parts of an excavator to keep track excavator and construction machines working well.

Key Takeaways

Knowing important excavator parts like the boom, bucket teeth, and undercarriage helps machines work well and stops expensive delays. Regular checks and quick replacement of parts like bucket teeth, hydraulic cylinders, and track bolts stop breakdowns and save money. Taking care of the hydraulic system and engine parts makes the machine work better, uses less fuel, and helps the equipment last longer. Picking the right materials and parts, like OEM or good aftermarket choices, keeps things safe and helps the machine work better. Storing and handling spare parts with care, and following expert maintenance plans, keeps excavators ready and dependable for work.

Main Excavator Parts

Boom & Arm

The boom and arm are very important parts of an excavator. The boom connects to the main body and sticks out. The arm is attached to the boom and reaches out to the bucket. These parts help the machine lift, reach, and move heavy things. The boom gives height and support. The arm adds more reach and lets the machine move in different ways. These parts can be made from steel or aluminum. The material changes how heavy and strong the excavator is. If you use aluminum instead of steel, the machine can be about 65% lighter. A lighter machine can work better because it needs less power. It can also move faster and use less energy. The boom and arm decide how much the excavator can lift and how far it can reach.

Bucket Teeth

Bucket teeth are small but very important. They go on the edge of the bucket. They help the bucket dig into dirt, rocks, or trash. Bucket teeth break up hard ground and keep the bucket from wearing out. These parts get worn down and must be replaced to keep the machine working well.

Computer tests show bucket teeth can last up to 29 years if you take care of them.

After 25 years, they can break more easily, so you should check them often.

When the boom is flat, it puts more stress on the bucket and teeth, so they can break faster.

With good care, bucket teeth and other big parts can last up to 50 years.

These facts show why checking and changing bucket teeth is important for safety and good work.

Hydraulic Cylinders

Hydraulic cylinders are very important for crawler excavators. They make the boom, arm, and bucket move. These cylinders use fluid under pressure to make force. This lets the excavator lift, dig, and move things. Hydraulic cylinders turn fluid power into movement. Tests and models show that good cylinders can control speed and pressure. This helps save money on repairs. Studies say hydraulic cylinders last about 6,967 hours before breaking. But experts say you should check them every 3,500 hours to stop sudden problems. About 30% of cylinder problems are from leaks. Leaks can make the machine work 20% slower and cost a lot to fix. Checking and replacing these parts on time keeps the machine working well and saves money.

Counterweight

The counterweight is at the back of the excavator. It helps balance the boom, arm, and bucket when the machine works. The main job of the counterweight is to keep the machine from tipping over when lifting heavy things.

Note: Counterweights are very important. In 2024, the market for counterweights was $4.5 billion. Excavators are the fastest-growing part of this market. By 2028, people will need even more counterweights. Cast iron is used a lot because it is three times heavier than concrete. This makes the machine more stable without making it bigger. The counterweight helps the excavator work safely, especially with big or uneven loads.

Metric | Value | Explanation |

|---|---|---|

Market Size (2024) | $4.5 billion | Shows how many counterweights are used |

Projected Market Volume (2028) | 500 million metric tons | More people will need counterweights |

Construction Equipment Market Share | 45% | Excavators use the most counterweights |

Material Density | Cast iron 3x denser than concrete | Makes machines more stable |

Cab

The cab is where the operator sits and controls the excavator. It keeps the operator safe from weather, noise, and flying dirt. New cabs have seats you can move, air conditioning, and big windows to see better. The cab gives a safe and comfy place to work. This helps the operator work longer and make fewer mistakes. A survey asked 212 operators about cab comfort. About 56% said the cab was good or very good. Many wanted better seats, more space, and better views. Good cab design helps the operator feel less tired and stay safe. New things like cameras and screens help the operator work better and safer. The cab is a big part of keeping the operator safe and helping the machine work well.

Undercarriage Components

The undercarriage holds up the whole track excavator. It lets the machine move on many surfaces. This group has tracks, track pads, rollers, sprockets, track bolts, and idlers. Each part does a job to keep the excavator steady and able to move.

Tracks

Tracks carry the excavator’s weight and help it move. They work on mud, rocks, or pavement. There are three main types of tracks. Rubber tracks are good for soft ground but wear out fast on rocks. Steel tracks last longer and grip rough ground better. But steel tracks can hurt finished surfaces. Hybrid tracks mix the best parts of both types. The tread pattern is important too. Straight bar treads grip mud. Block treads work well on gravel. Wide tracks help on soft ground. Narrow tracks fit in small spaces. Picking the right tracks and keeping them clean helps them last. Signs of wear are cracks, cuts, or uneven treads. Good tracks use strong rubber and steel cords to stop damage.

Track Pads

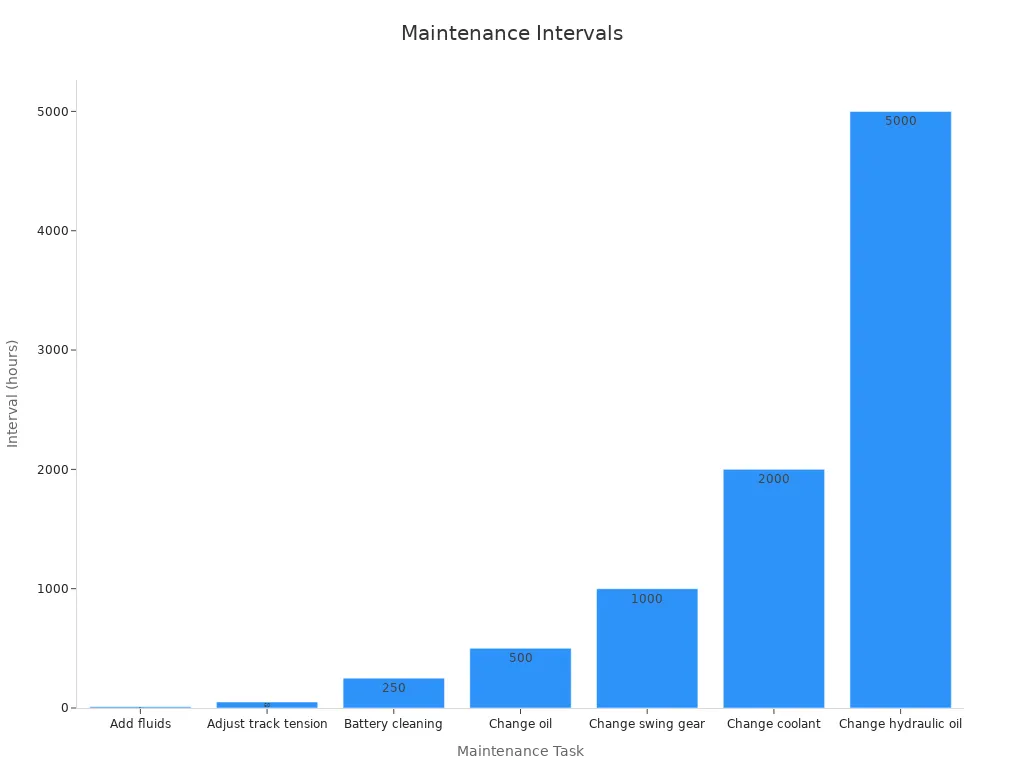

Track pads go on the tracks and protect them. They also protect the ground. Track pads spread the excavator’s weight. This helps stop ground damage. Checking and adjusting track pads often keeps them working well. The table below shows when to check and care for them:

Maintenance Interval (hours) | Maintenance Task Description |

|---|---|

10 | Check and add fluids (hydraulic, radiator, engine) |

50 | Inspect and adjust track tension (important for track pad life) |

250 | Battery inspection and cleaning |

500 | Change filter and engine oil |

1,000 | Change swing reduction gear case |

2,000 | Change radiator coolant |

5,000 | Change hydraulic oil |

Rollers

Rollers hold up the tracks and help them roll. There are single-sided and double-sided rollers. Single-sided rollers need checks every 200 to 400 hours. Double-sided rollers last up to 800 hours before checks. Most roller problems come from uneven wear or seal trouble. Sometimes bearings jam too. Laser tools and heat cameras help find problems early. If a roller gets too hot or worn, the tracks can slip or break.

Sprockets

Sprockets turn the tracks and pull them forward or back. If the sprocket is worn, the excavator moves roughly. This makes it less efficient. Studies show sprockets and tracks change load and torque. This affects how smooth the excavator moves. Keeping sprockets in good shape helps the machine work better and last longer.

Track Bolts

Track bolts hold the tracks and pads together. They use strong steel and special coatings to stop rust. Tightening bolts the right way is important. Loose bolts cause 80% of breakages. Checking bolts often and using lock nuts in bumpy areas helps stop problems. Good bolts keep the undercarriage safe and strong.

Track bolts use tough alloy steel to stay strong.

Special coatings stop rust for over 1,000 hours.

Tightening bolts right and checking them stops breaks.

Idlers

Idlers guide the tracks and keep them tight. They help the tracks stay in place. This lowers the chance of the tracks coming off. Most wear happens inside the idler rim. If the idler gets too hot or cannot tighten, it may need to be changed. Over 35% of excavator problems come from the undercarriage. Most are from missed wear. Worn idlers can use 25% more energy. They also make track derailment 40% more likely. Checking and changing idlers on time saves money and keeps the excavator working well.

The undercarriage is a key group of excavator spare parts. Each part works with the others to give the machine balance, movement, and long life. Good care and the right parts help the excavator do its job well.

Hydraulic System Spare Parts

The hydraulic system makes almost every part move. These parts work together to lift, dig, and carry heavy things. Each part has its own job. This helps the machine work safely and smoothly.

Hydraulic Pumps

Hydraulic pumps push fluid through the system. This fluid gives power to the boom, arm, and bucket. Pumps must fit the machine’s power and pressure needs. Using the right fluid and keeping it clean helps pumps last longer. It also helps them work better.

If you take care of the pump, the machine can work up to 25% better. The table below shows what is important for pumps:

Performance Metric | Description | Impact on Efficiency and Lifespan |

|---|---|---|

Flow Capacity (GPM) | How much fluid moves each minute | More flow helps with hard jobs |

Pressure Rating (PSI) | The most pressure the pump can take | Higher ratings mean pumps last longer |

Rotation Speed (RPM) | How fast the pump spins | Right speed stops damage |

Main Control Valve

The main control valve sends fluid to different parts. This valve controls how fast and smooth the boom, arm, and bucket move. Different valves change how the machine feels to use.

A table shows that quick-opening valves move fast but are harder to control. Linear and equal percentage valves give smoother and more exact control. New control ideas can save up to 10% energy. They also stop big jumps in pressure. This makes the system work better and last longer.

Hydraulic Fluid Tank

The hydraulic fluid tank holds the oil for the system. It keeps the oil clean and cool. A good tank stops leaks and keeps the right pressure. Checking for leaks and filling the tank with the right oil helps all parts work well.

Hoses & Fittings

Hoses and fittings move fluid between parts. They must handle high pressure and lots of movement. Most hoses last 1,000 to 2,000 hours. Checking for cracks or leaks helps stop sudden problems.

How you place hoses is important. Even a small twist can make hoses wear out 70% faster. Using covers and keeping hoses away from sun and chemicals helps them last longer.

Filters

Filters take dirt and metal out of the fluid. Clean fluid keeps pumps, valves, and other parts safe. Changing filters on time keeps the system working well. It also helps all hydraulic parts last longer.

Tip: Check and change hydraulic parts often. This stops breakdowns and keeps the excavator working well.

Engine and Related Parts

The engine and its parts are very important. They give the excavator power and help it work well. These parts help the machine work in hard places.

Engine

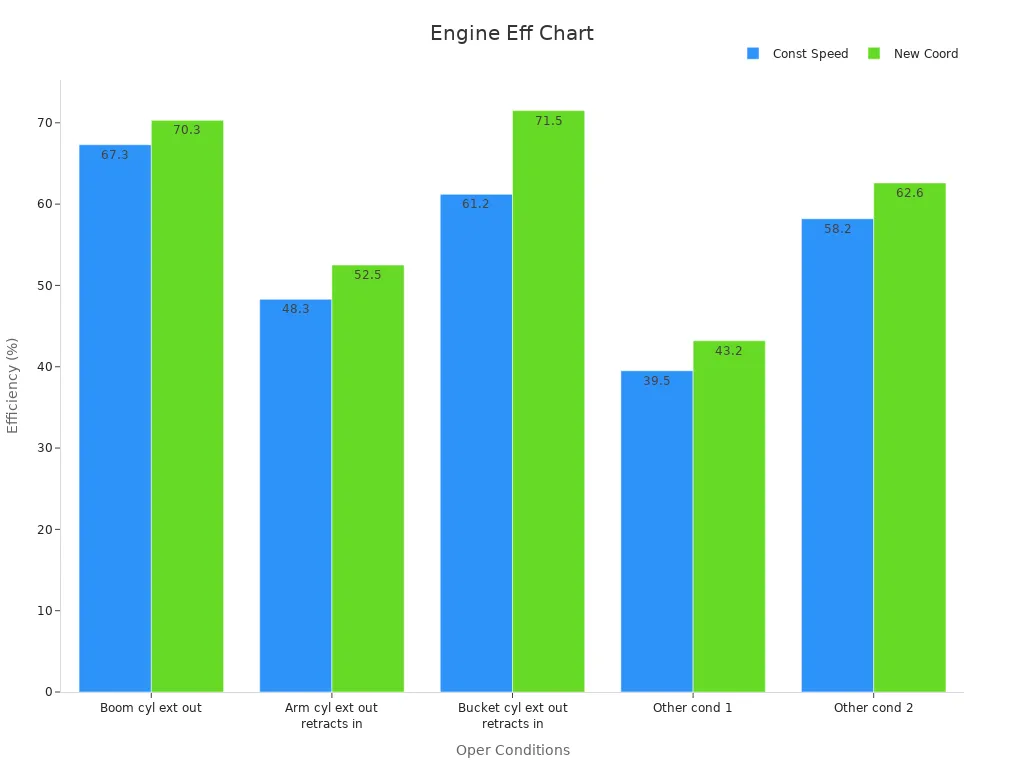

The engine gives power to the excavator. It burns fuel to make energy. This energy moves the hydraulic system and undercarriage. New engines use smart technology to save fuel. For example, Cat 317 Next Gen excavators work up to 45% better with smart power. Maintenance costs can go down by 20%. Hybrid systems can save energy from the boom cylinder. This saves about 9.44% fuel and makes regeneration 10.51% better. The table shows how energy efficiency changes in different jobs:

Operating Condition | Energy Efficiency (Constant Speed Method) | Energy Efficiency (New Coordination Method) | Efficiency Improvement |

|---|---|---|---|

Boom cylinder extends out | 67.3% | 70.3% | ~3% |

Arm cylinder extends out and retracts in | 48.3% | 52.5% | ~4.2% |

Bucket cylinder extends out and retracts in | 61.2% | 71.5% | ~10.3% |

Other conditions (various) | 39.5%, 58.2% | 43.2%, 62.6% | ~3.7% – 4.4% |

Fuel Tank

The fuel tank holds the diesel or gasoline for the engine. A strong tank with no leaks keeps the engine running. Checking for leaks or dirt helps stop problems. Clean fuel helps the engine work better and last longer.

Air Filters

Air filters clean the air before it goes into the engine. Dust and dirt can hurt engine parts and make it less efficient. Changing air filters often helps the engine work up to 25% better. Clean filters also help the engine last longer and keep the excavator working well.

Cooling System

The cooling system stops the engine from getting too hot. It uses coolant and fans to take away heat. If the cooling system breaks, the engine can get too hot and stop working. Checking coolant and cleaning the radiator helps protect the engine and keep it working well.

Starter Motor

The starter motor helps turn the engine on. It uses battery power to start the engine fast. A good starter motor makes sure the excavator is ready to work. If the starter motor does not work, the machine cannot start. Checking it often is important.

Tip: Keeping engine parts in good shape helps the excavator run well, saves fuel, and lowers repair costs.

Maintenance for Excavator Spare Parts

Inspection

Checking excavator spare parts often keeps them working well. Operators should have a schedule to check each part. Most brands say to check fluids and look for damage every day. Every 250 hours, workers need to change engine oil, check air filters, and fix track tension. At 500 hours, they should change hydraulic oil filters and add grease to moving parts. A full check every 1,000 hours means changing hydraulic oil and looking at the undercarriage. Komatsu says to do maintenance at 500, 1,000, 1,500, and 2,000 hours. These steps help oem and aftermarket parts last longer.

Tip: Doing regular checks is a great way to stop breakdowns and save money.

Replacement Indicators

It is important to know when to change parts for safety. Some signs are strange noises, shaking, or leaks. If engine oil pressure drops by 5%-10%, it can mean big problems. If hydraulic pressure drops over 10% or oil gets hotter, there may be trouble. Tracks and undercarriage parts may crack or wear out more than 30%. Using oem or aftermarket parts changes how often you need new ones. Studies say oem parts fail about 20% less, but good aftermarket parts work well if they meet standards. Having a pro install parts helps stop mistakes.

System | Sign of Wear | Data Indicator |

|---|---|---|

Engine | Noise, vibration | Oil pressure drop 5%-10% |

Hydraulic | Leaks, slow response | Pressure drop >10% |

Undercarriage | Cracks, unstable walking | Track wear rate >30% |

Accessories | Cracks, loose connections | Wear rate >20% of design life |

Storage & Handling

Storing and handling spare parts the right way keeps them safe. Workers should put parts in a dry, clean place away from sun and chemicals. Heavy things like tracks or counterweights need safe storage so they do not get damaged. Always label parts and use the oldest ones first. Handle parts gently to keep them working right. Picking oem or aftermarket parts depends on what the job needs and the quality you want.

Knowing about crawler excavator spare parts helps operators stay safe. It also helps them work better and faster. When you know what each part does, you can make good choices. This means the machine stops less often. Companies that plan ahead get many good results:

Engine failures can drop by up to 90%. There is less surprise downtime.

Checking and changing parts on time saves money. It also helps machines last longer.

Using real-time data and AI makes things safer. It also means parts are ready when needed.

Operators should always use expert tips and manuals. This keeps the machine working well.

FAQ

What is the most common crawler excavator spare part to replace?

Operators usually change bucket teeth first. These parts wear down fast when digging. Checking them often helps stop sudden problems. If teeth are worn, work slows down. The bucket can also get damaged.

How often should operators inspect undercarriage components?

Experts say to check undercarriage parts every day. Operators should look for cracks or loose bolts. Worn tracks are also a problem. A full check every 250 hours finds issues early. This keeps the machine safe.

Can aftermarket parts work as well as OEM parts?

Aftermarket parts can work well if they meet standards. Many people pick them to save money. OEM parts often last longer and fit better. Always check the quality before buying any part.

What are signs that hydraulic hoses need replacement?

Check hoses for cracks or leaks. Bulges are also a bad sign. If you see fluid on the ground, there is a problem. Slow machine response means trouble too. Change hoses as soon as you see wear.

Why is regular maintenance important for excavator spare parts?

Regular maintenance keeps machines safe and working well. It helps stop breakdowns and saves money. Operators who follow a schedule make their machines last longer. This also helps avoid big repairs.