You can make smart choices for aftermarket bobcat excavator engine parts by following a few important steps. Start by identifying your bobcat excavator using its model and serial number. This information helps you avoid mistakes and ensures you order the right part. Saving these numbers in an organized system lets you find compatible products quickly and keeps your maintenance on track.

Choosing parts that meet or exceed original equipment standards protects your investment and supports long equipment life. Always check part numbers for accuracy and compare quality, price, and seller reputation. Reliable sellers offer warranties and support, which can improve equipment performance by up to 15%.

Statistic Category | Data / Value |

|---|---|

Maintenance Intervals | – Engine oil & filter replacement every 250 hours |

Service Life Comparison | – High-quality hydraulic cylinders last over 3,000 hours, much higher than industry average |

Failure Cause | – 80% of hydraulic system failures relate to contamination |

Cost Consideration | – Downtime from poor parts can cost up to $250,000 per hour |

Key Takeaways

Always identify your Bobcat excavator by its model and serial number to find the right parts and avoid costly mistakes.

Know the exact part you need and compare aftermarket options carefully with original parts for fit, function, and quality.

Use part numbers and diagrams to check compatibility; never rely only on how a part looks.

Balance cost, quality, and warranty when choosing parts; good warranties and return policies protect your investment.

Choose sellers with strong reviews, certifications, and good customer support to ensure smooth installation and reliable parts.

Identify Your Bobcat Excavator

Find Model and Serial Numbers

You need to start every search for aftermarket parts by identifying your bobcat excavator. The model and serial number are your best tools for this job. These numbers help you find the right parts and avoid costly mistakes. Most bobcat excavators have the serial number plate in a visible spot, often on the front face of the machine. The plate lists the model number, year, and a nine-digit serial number.

Here is a simple way to find and use these numbers:

Look for the serial number plate on your bobcat excavator. The location can change based on the year and type of machine.

Read the plate. You will see the model and serial number together.

Decode the serial number. The first four digits show the model and engine combination.

Use the serial number when you order parts, ask for service, or check your warranty.

If you cannot find the plate, check your manual or ask your bobcat dealer for help.

Tip: Many new bobcat excavators use smart technology and telematics. These systems help you track your machine’s performance and make it easier to find the model and serial number.

You should always keep a record of your bobcat’s model and serial number. This habit saves time and helps you get the right parts fast.

Gather Engine Details

Engine details matter when you choose aftermarket parts for your bobcat excavator. The engine size, type, and year all affect which parts will fit and work well. Technical guides show that you must use the correct engine information to meet safety and emission rules.

Aspect | Description |

|---|---|

Durability Demonstration Vehicle Selection | Pick the “worst case” bobcat configuration based on engine size and other factors to test aftermarket parts. |

Statistical Test Part Selection | Use random samples of real bobcat parts for testing and keep records of how you choose them. |

Emission-Critical Parameter Analysis | Analyze engine details to make sure parts meet emission standards. |

Certification Compliance Testing | Test parts on the toughest bobcat engine setups to check for compliance. |

Notification of Intent to Certify | List all engine and model details when you certify a new part. |

Exemptions and Approvals | Use data and technical reasons if you need to change test rules. |

You should write down your bobcat excavator’s engine size, year, and any special features. This information helps you and your supplier pick the best aftermarket parts. When you know your bobcat’s details, you make smarter choices and keep your machine running strong.

Choose the Right Aftermarket Parts

Know the Needed Part

You need to know exactly which part you want before you buy. Start by checking your bobcat manual or maintenance records. These documents list the parts made for bobcat machines. Write down the part number, name, and where it fits on your bobcat excavator. This step helps you avoid mistakes and saves time.

When you look for aftermarket parts, always compare the new aftermarket parts with the original ones. Use professional tools or diagrams to check if the size, shape, and function match. Many experts suggest you:

Prefer original and certified parts when possible. These meet design standards and help your bobcat last longer.

Pick brands with strong supply chains and good after-sales service. This makes it easier to get quick replacements if something fails.

Use tools to compare durability, compatibility, and cost. This helps you make a smart choice.

Tip: Keep a list of all the aftermarket parts you use. Update it after each repair. This record helps you track what works best for your bobcat.

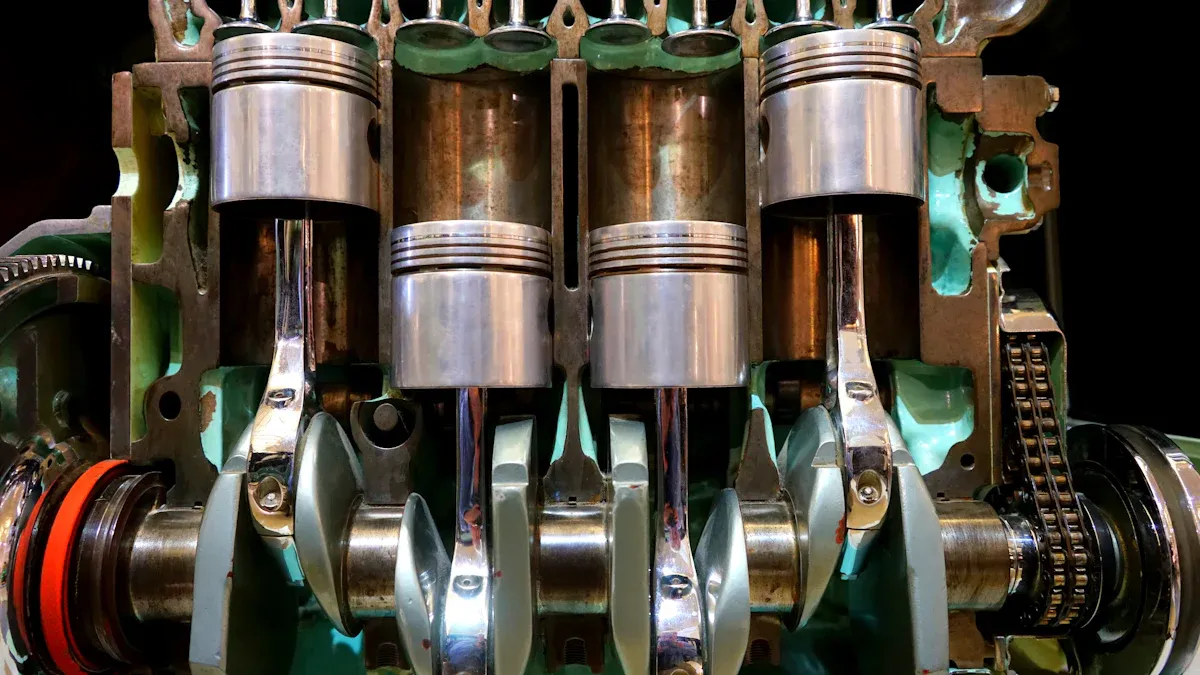

Understand Part Function

You should know how each part works in your bobcat excavator. Some parts, like filters or belts, seem simple. Others, such as hydraulic pumps or engine sensors, play a big role in machine performance. If you choose the wrong aftermarket parts, your bobcat may not work right or could break down.

Try to learn about the function of each part before you buy new aftermarket parts. Use your equipment manual or ask a technician for help. Many shops use detection tools to test key systems like engines and hydraulics. They also use smart monitoring systems to watch for problems. These steps help you pick the right aftermarket parts and avoid costly repairs.

A good maintenance plan includes regular checks and updates. You can use monthly, quarterly, and yearly inspections to spot worn parts early. Keep records of every change. This helps you see patterns and predict when you need new aftermarket parts for your bobcat.

Maintenance Step | Benefit |

|---|---|

Regular inspections | Find worn parts early |

Use of detection tools | Check engine and hydraulics |

Record keeping | Track part performance |

Smart monitoring | Get real-time fault warnings |

Note: If you use parts made for bobcat and follow a solid maintenance plan, you reduce the risk of sudden breakdowns.

Checking Compatibility

Use Part Numbers and Diagrams

When choosing aftermarket parts for your Bobcat excavator, verifying compatibility is essential. You can avoid costly mistakes by using part numbers and diagrams to cross-reference the parts that fit your machine. These tools provide precise information about dimensions, placement, and functionality, ensuring the parts you select meet your equipment’s requirements.

Visual comparisons alone are not enough. A part may look similar but fail to perform correctly due to subtle differences in design or material. Research highlights that visual elements, such as diagrams, must include clear labels, annotations, and legends to prevent misinterpretation. Cross-referencing these visuals with part numbers ensures clarity and accuracy. For example, a hydraulic pump may appear identical to the original, but without matching part numbers, it could lead to performance issues or even damage.

To make the process easier, follow these steps:

Locate the part number in your Bobcat manual or maintenance records.

Compare the part number with the one listed for the aftermarket option.

Use diagrams to confirm the part’s dimensions and placement.

Consult with your supplier or technician if you notice discrepancies.

Tip: Keep a digital record of part numbers and diagrams for quick access during future repairs. This habit saves time and ensures you always choose parts that fit your Bobcat excavator.

Compare OEM and Aftermarket

Understanding the differences between OEM (Original Equipment Manufacturer) and aftermarket parts helps you make informed decisions. OEM parts are designed specifically for Bobcat machines, ensuring a perfect fit and consistent performance. Aftermarket parts, on the other hand, are produced by third-party manufacturers and may offer similar or enhanced functionality at a lower cost.

Comparative analysis reports reveal key distinctions between OEM and aftermarket parts. For example, OEM parts follow strict design standards provided by the purchaser, while aftermarket manufacturers often innovate and customize their designs. This customization can lead to improved functionality but may require additional testing to ensure compatibility.

Performance Aspect | OEM Parts Characteristics | Aftermarket Parts Characteristics |

|---|---|---|

Design Participation | Strict adherence to purchaser-provided designs | Innovation and customization opportunities |

Cost Advantage | Reduced unit cost through batch processing | Lower branding and distribution expenses |

Delivery Speed | Faster due to standardized processes | Longer lead times due to design and testing phases |

Quality Control Focus | Stable production and inspection processes under ISO standards | Combined design verification and production inspection, often including third-party certifications |

Aftermarket parts often use predictive maintenance technologies and data analytics to forecast failures, reducing downtime and improving reliability. These advancements make aftermarket options attractive for cost-conscious buyers seeking dependable alternatives to parts made for Bobcat excavators.

Note: Balancing cost, quality, and delivery speed is crucial when comparing OEM and aftermarket options. Always prioritize compatibility and performance to protect your investment.

Compare Quality and Price

Assess Aftermarket Bobcat Excavator Engine Parts

You want your bobcat to run smoothly and last a long time. To do this, you need to look closely at the quality and price of aftermarket bobcat excavator engine parts. Not all aftermarket parts are the same. Some may look like a good deal, but poor quality can lead to big problems. Cheap or poorly fitting parts can damage your bobcat and cause expensive repairs. You should always check if the parts meet or exceed OEM standards.

You can use several ways to judge quality:

Check the part number and make sure it matches your bobcat’s needs.

Look for supplier quality metrics and reviews from other users.

Ask about testing methods like dimensional, material, load, and durability testing.

See if the part has passed field tests or has certifications.

You should also compare the price. Aftermarket parts often cost less than OEM parts, sometimes by as much as 65%. However, you must balance cost with quality and reliability. A part that costs less but fails quickly will cost you more in the long run. The high cost of downtime, which can reach up to $250,000 per hour, shows why you should pick good-quality parts.

Here is a table to help you compare OEM and aftermarket parts:

Aspect | OEM Parts | Aftermarket Parts |

|---|---|---|

Durability & Quality | Generally superior durability and consistent quality due to manufacturer standards and testing | Quality varies; some manufacturers improve on OEM designs, offering equal or better quality |

Fit & Compatibility | Guaranteed perfect fit as parts are made by original manufacturer | Fit can vary; reverse-engineered parts may fit well but require careful selection |

Warranty | Typically 1-3 year unlimited mileage warranty, providing peace of mind | Warranties vary; some limited or none, but major brands offer at least 1 year warranty |

Cost | About 65% more expensive than aftermarket parts | Generally 65% cheaper on average |

Selection | Limited to original parts, simpler selection process | Much greater selection due to many suppliers |

Field Test Results | Proven performance in crash and safety tests | Some aftermarket parts perform equally or better in safety scenarios |

Industry Acceptance | Standard for repairs, trusted for reliability | Accepted by insurers as equal to OEM parts; certifications support quality assurance |

Risk | Low risk of subpar parts | Higher risk of poor quality without thorough vetting |

You should use asset maintenance plans to track how long parts last and how well they work. Look at performance indicators like mean time between failures and total cost of ownership. These steps help you choose reliable parts and avoid surprises.

Tip: Always ask your supplier for installation and warranty help. Proper installation can improve equipment performance by up to 15%.

Review Warranty and Return Policies

You should never ignore the warranty and return policies when buying aftermarket bobcat excavator engine parts. A good warranty shows that the seller stands behind the quality of their product. Some aftermarket parts come with a 3-year warranty covering up to 4,000 hours. This kind of coverage gives you peace of mind and protects your investment.

Return policies matter, too. Market surveys show that flexible return policies make buyers feel safer and more willing to try new aftermarket parts. When you know you can return a part if it does not fit or work right, you feel more confident in your purchase. Studies also show that fair return policies increase trust and satisfaction. You should always read the warranty and return policy before you buy.

Here are some steps to follow:

Check the length and details of the warranty. Look for coverage on both parts and labor.

Read the return policy. Make sure you can return or exchange the part if needed.

Look for customer reviews about how the seller handles returns and warranty claims.

Choose sellers with a good reputation for honoring their policies.

Note: Customer reviews and feedback are great ways to see if a seller offers good support and stands by their products.

You should always balance cost, quality, and support. Good-quality parts with strong warranties and fair return policies help you keep your bobcat running well. When you choose new aftermarket parts, you protect your machine and your wallet.

Evaluate Sellers and Support

Check Reviews and Credentials

You should always check reviews before you buy aftermarket Bobcat excavator engine parts. Reviews from other buyers give you real-world information about part quality and seller reliability. Many equipment owners share their experiences with installation and performance. You can find these reviews on supplier websites, forums, and even social media. Look for patterns in the reviews. If many people mention easy installation or fast shipping, you can expect a similar experience.

A seller’s credentials matter as much as their reviews. Reputable sellers often display certifications or awards. These show that the seller meets industry standards. You should avoid sellers with poor reviews or no credentials. Low-quality parts from unreliable sellers can cause equipment problems and even void your warranty. Always choose suppliers known for delivering quality parts that meet OEM specifications.

Tip: Partner with local heavy equipment professionals for expert installation help and support. This step can make your installation smoother and safer.

Here is a quick checklist to help you evaluate sellers:

Read multiple reviews for each seller.

Check for industry certifications or awards.

Avoid sellers with many negative reviews.

Ask about installation help and after-sales support.

Look for clear return and warranty policies.

Consider Installation and Customer Support

Installation plays a big role in how well your aftermarket parts work. Good sellers offer installation help, guides, or even professional services. You should ask about installation help before you buy. Some sellers provide step-by-step videos or phone support. This support can save you time and prevent mistakes during installation.

Case studies show that strong customer service and installation support help companies grow and keep customers happy. For example, My Fan Parts grew across many platforms by working with a partner who offered fast shipping and personal support. Another example comes from Daimler Truck North America. They improved installation and customer service by using technology and on-site help. This led to fewer disputes and higher sales.

You should also look for customer feedback about installation help. Many buyers mention installation in their reviews. If you see positive comments about installation help, you can trust the seller to support you. Good customer support means you get answers fast if you have questions during installation.

Support Feature | Benefit |

|---|---|

Installation help | Easier, faster installation |

Customer support lines | Quick answers to questions |

Online guides/videos | Step-by-step installation tips |

Local professionals | Expert installation and service |

Note: Routine inspection and maintenance after installation help maximize the lifespan and reliability of your aftermarket parts.

You make smart choices when you follow each step for finding aftermarket Bobcat excavator engine parts. Always check for parts that fit your machine by using model and serial numbers. Look at part diagrams to confirm you have parts that fit your needs. Check the quality and reputation of every seller. Choose support and warranty options that protect your equipment. Put quality, fit, and support first to keep your Bobcat running strong.

FAQ

What information do you need before ordering aftermarket Bobcat engine parts?

You need your Bobcat’s model and serial number. Write down the engine size and year. Check the part number in your manual. This information helps you find the right part and avoid mistakes.

How can you tell if an aftermarket part fits your Bobcat excavator?

Check the part number and compare it with your manual. Use diagrams to match the size and shape. Ask your supplier for help if you feel unsure. Never rely only on how a part looks.

Do aftermarket parts affect your Bobcat’s warranty?

Some aftermarket parts may affect your warranty. Always read your warranty terms before you buy. Ask your dealer if you have questions. Using certified aftermarket parts often helps protect your coverage.

What should you look for in a reputable aftermarket parts seller?

Look for sellers with strong reviews and industry certifications. Choose those who offer clear return policies and good customer support. Reliable sellers answer questions and help with installation.

Are aftermarket parts as reliable as OEM parts?

Some aftermarket parts match or exceed OEM quality. Check for certifications and reviews. Ask about testing and warranties. Reliable aftermarket parts can last as long as OEM parts if you choose carefully.