Understanding your Hitachi EX60 excavator parts is essential for keeping the machine in top condition. When you know how each component works, you can identify issues early and prevent costly repairs. A lack of knowledge often leads to improper operation, unsafe practices, and missed maintenance checks. These challenges can result in accidents or equipment failure. By familiarizing yourself with the parts, you ensure safer operations and extend the lifespan of your excavator.

Key Takeaways

Knowing your Hitachi EX60 excavator parts avoids expensive repairs and keeps it safe.

Checking and servicing it daily and monthly makes it last longer.

Picking the right parts, either original or good aftermarket ones, keeps it working well.

Taking care of the hydraulic system and undercarriage stops problems and improves work.

Using catalog numbers makes finding and ordering the right parts easier.

Overview of the Hitachi EX60 Excavator

General Features and Capabilities

The Hitachi EX60 excavator is a compact yet powerful machine designed for versatility and efficiency. Its specifications make it suitable for a wide range of tasks. Below is a table highlighting its key features:

Specification | Value |

|---|---|

Max Digging Depth | 15.3 ft |

Max Loading Height | 18 ft |

Operating Weight | 13,889 lbs |

Rotation Capability | 360-degree |

Engine Power | 54 hp |

Hydraulic System Relief Pressure | 4550 psi |

These features allow the Hitachi EX60 to perform with precision and reliability. Its 360-degree rotation capability enhances maneuverability, while the hydraulic system ensures smooth and powerful operations. The compact size and robust engine make it ideal for both small-scale and medium-scale projects.

Applications and Use Cases

The Hitachi EX60 excavator is widely used across various industries due to its adaptability. Common applications include:

Construction

Earthworks

Light excavation work

You can rely on this machine for tasks like trenching, foundation digging, and material handling. Its compact design allows it to operate in confined spaces, making it a preferred choice for urban construction projects. The machine’s efficiency and reliability also make it suitable for landscaping and agricultural tasks.

Importance of Understanding Hitachi EX60 Excavator Parts

Understanding the parts of the Hitachi EX60 excavator is crucial for maintaining its operational efficiency. Familiarity with its components helps you plan maintenance effectively. This knowledge allows you to identify parts that need attention, reducing downtime and ensuring smooth operations. Proactive maintenance not only enhances productivity but also extends the lifespan of the machine. By knowing how the parts work together, you can optimize the performance of your excavator and avoid costly repairs.

Key Hitachi EX60 Excavator Parts and Their Functions

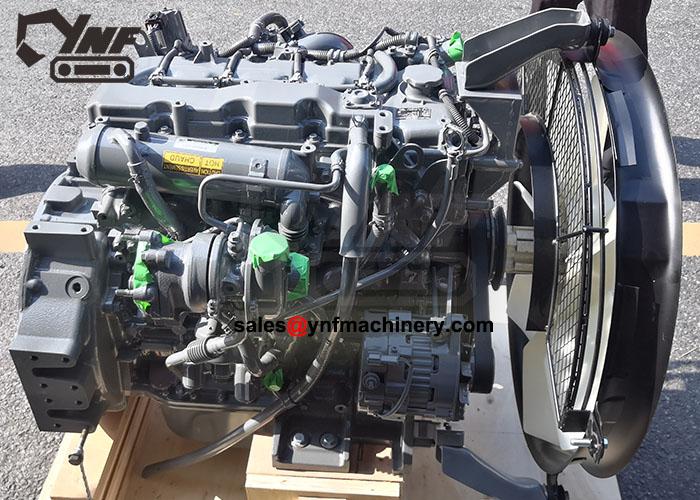

Engine Assembly

Components of the Engine Assembly

The engine assembly is the heart of your Hitachi EX60 excavator. It powers the machine and ensures smooth operation. Below is a table highlighting its critical components:

Component | Description | Part Numbers |

|---|---|---|

Engine Assembly | Includes the cylinder block, cylinder head, pistons, crankshaft, and camshaft. | 4195960 |

Fuel System | Consists of the fuel pump, injectors, fuel filters, and fuel lines. | 4140047 |

Cooling System | Comprises the radiator, water pump, hoses, and thermostat. | 4271097 |

Each component plays a vital role. For example, the cylinder block houses the pistons, while the fuel system ensures efficient combustion. The cooling system prevents overheating, maintaining optimal engine performance.

Role in Excavator Performance

The engine assembly directly impacts the performance of your excavator. A well-maintained engine ensures consistent power delivery, enabling the machine to handle heavy loads and challenging tasks. Regular inspection of the fuel and cooling systems helps prevent breakdowns and extends the engine’s lifespan.

Hydraulic System

Key Hydraulic Components

The hydraulic system powers the movement of your excavator’s arm, boom, and bucket. Key components include the hydraulic pump, cylinders, hoses, and control valves. These parts work together to convert hydraulic fluid into mechanical force, enabling precise and powerful operations.

Importance in Excavator Operations

A properly functioning hydraulic system is essential for smooth and efficient operations. Signs of wear and tear, such as leaks or unusual noises, can indicate potential issues. Watch for these common signs:

Leaks: Visible or hidden hydraulic fluid leaks can reduce performance.

Banging Sounds: Air in the system may cause knocking noises.

High Temperatures: Fluid temperatures above 82°C (180°F) can damage seals.

Weak Final Drive Motor: Reduced power may signal low hydraulic pressure.

Addressing these issues promptly ensures your excavator operates at peak efficiency.

Undercarriage

Tracks, Rollers, and Idlers

The undercarriage supports the excavator and allows it to move across various terrains. Its main components include tracks, rollers, idlers, and the track frame. Below is a breakdown of their roles:

Component | Description |

|---|---|

Tracks | Composed of track chains, track shoes (pads), rollers, idlers, and sprockets. |

Track Frame | Supports tracks and distributes the machine’s weight. |

Final Drives | Provide power to tracks from hydraulic motors. |

Tracks ensure stability, while rollers and idlers guide and support the movement. The final drives transfer power from the hydraulic motors to the tracks.

Maintenance for Longevity

Proper maintenance of the undercarriage is crucial for extending its lifespan. Clean the tracks regularly to remove debris and inspect for wear. Lubricate the rollers and idlers to prevent friction. Replacing worn-out parts promptly reduces the risk of further damage.

Swing Mechanism

Function and Importance

The swing mechanism allows your Hitachi EX60 excavator to rotate its upper structure. This rotation provides the flexibility to move materials without repositioning the entire machine. The swing motor, gear, and bearing work together to enable smooth and precise movements. This mechanism is essential for tasks like trenching, loading, and unloading, where accuracy and efficiency are critical. A well-functioning swing mechanism ensures seamless operation, saving time and effort on the job site.

Common Problems and Solutions

Swing mechanisms can face issues over time. Common problems include unusual noises, reduced rotation speed, or jerky movements. These issues often result from worn-out bearings, low hydraulic pressure, or damaged gears. To address these problems:

Inspect Bearings Regularly: Replace worn bearings to prevent further damage.

Check Hydraulic Pressure: Ensure the hydraulic system operates at optimal levels.

Lubricate Gears: Proper lubrication reduces friction and wear.

Routine maintenance and timely repairs keep the swing mechanism in top condition, ensuring your excavator performs efficiently.

Structural Components

Boom, Arm, and Bucket

The boom, arm, and bucket form the primary structural components of your excavator. These parts handle digging, lifting, and material handling tasks. The boom connects to the excavator’s body, providing reach and height. The arm extends the boom’s range, while the bucket performs the actual digging or scooping. Together, these components determine the machine’s versatility and efficiency.

Specifications and Compatibility

Understanding the specifications of these components helps you choose compatible replacements. Below is a table summarizing their roles and importance:

Component | Description |

|---|---|

Boom | Provides reach and height for digging and lifting. |

Arm | Extends the boom’s range for deeper or farther digging. |

Bucket | Performs digging, scooping, and material handling tasks. |

When selecting replacements, ensure they match your excavator’s model and intended use. Using compatible parts enhances performance and prevents unnecessary wear. YNF Machinery offers high-quality replacements for these components, ensuring durability and efficiency for your Hitachi EX60 excavator.

Common Replacement Parts for the Hitachi EX60

Engine Components by YNF Machinery

Engine components are among the most commonly replaced parts in the Hitachi EX60 excavator. These parts ensure the machine operates efficiently and reliably. YNF Machinery offers a wide range of high-quality engine components, including pistons, crankshafts, and cylinder heads. These parts are designed to withstand the demanding conditions of heavy-duty operations.

Regular maintenance of the engine is essential. Replacing worn-out components like fuel injectors and turbochargers can prevent engine failure. YNF Machinery provides both OEM and aftermarket options, ensuring compatibility with your excavator. By choosing durable and efficient parts, you can reduce downtime and extend the lifespan of your machine.

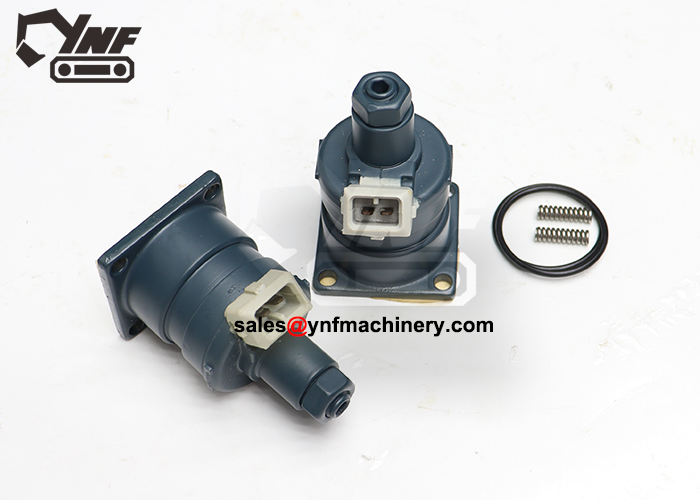

Hydraulic System Parts

The hydraulic system is vital for the operation of your excavator. Key parts like hydraulic filters and seals require frequent replacement. Hydraulic filters remove contaminants from the fluid, protecting the system from damage. Replacing these filters every 1,000 hours helps maintain optimal performance. Seals prevent fluid leaks and ensure the system operates smoothly. Inspecting and replacing worn seals regularly can avoid costly repairs.

YNF Machinery supplies high-quality hydraulic system parts that meet or exceed OEM standards. These parts are designed for durability and efficiency, ensuring your excavator performs at its best. Proper maintenance of the hydraulic system not only enhances performance but also reduces the risk of breakdowns.

Undercarriage Components

The undercarriage supports the excavator and allows it to move across different terrains. Tracks, rollers, and idlers are the most commonly replaced undercarriage components. Tracks provide stability, while rollers and idlers guide and support movement. Regular inspection and cleaning of these parts can prevent wear and tear.

YNF Machinery offers durable undercarriage components that are compatible with the Hitachi EX60 excavator. These parts are designed to withstand harsh conditions, ensuring long-lasting performance. Replacing worn-out components promptly can reduce further damage and keep your machine running smoothly.

Tip: Always use high-quality replacement parts to maintain the efficiency and reliability of your Hitachi EX60 excavator.

Catalog Numbers and How to Identify Parts

Identifying the correct catalog numbers for your Hitachi EX60 excavator parts is essential for accurate replacements and efficient maintenance. Each part has a unique number that helps you locate and order the exact component you need. By understanding how to find and use these numbers, you can save time and avoid costly mistakes.

Using Catalog Numbers for Easy Identification

Catalog numbers simplify the process of identifying and ordering parts. These numbers are typically listed in the excavator’s parts manual or on the component itself. For example, here are some common parts and their corresponding catalog numbers:

Part Name | Part Number | Link |

|---|---|---|

Water pump | A21010-40K05 | |

Starter motor | S25-158, 23100-06J01 |

These catalog numbers ensure you receive the correct part for your machine. Always double-check the numbers before placing an order to avoid compatibility issues.

Exploring the Parts List

The Hitachi EX60 parts list contains over 70 individual components. These are grouped into sections for easier navigation. Each section includes detailed diagrams and part numbers, making it simple to identify the required part. Here’s an overview of what the parts list offers:

Component | Description |

|---|---|

Parts List | Contains over 70 individual parts grouped into sections for various components of the Hitachi EX60-1 excavator. |

Part Numbers | Each component is listed with its corresponding part number for easy identification. |

You can use these diagrams to locate the exact part you need. Once identified, contact a trusted supplier with the part number to order genuine replacements.

Tips for Accurate Identification

Look for part numbers directly on the component. Many parts have numbers stamped or labeled on them.

Refer to the parts manual for detailed diagrams and descriptions.

Keep a record of frequently replaced parts and their numbers for quick reference.

Pro Tip: Always verify the part number with your supplier to ensure compatibility with your Hitachi EX60 excavator. Genuine parts improve performance and extend the lifespan of your machine.

By mastering the use of catalog numbers, you can streamline maintenance and keep your excavator running smoothly.

Tips for Maintenance and Part Selection

Regular Inspection and Servicing

Regular maintenance ensures your Hitachi EX60 excavator operates efficiently and avoids costly breakdowns. Following a structured inspection schedule helps you identify potential issues early. Here’s a breakdown of best practices:

Daily Checks:

Inspect fluid levels, including engine oil, hydraulic fluid, and coolant.

Examine the undercarriage for damage or debris.

Check hydraulic hoses and connections for leaks.

Weekly Maintenance:

Lubricate key components to reduce wear.

Inspect the air filter and clean or replace it if necessary.

Adjust track tension to maintain stability.

Monthly Tasks:

Change fluids like engine oil and hydraulic fluid.

Tighten bolts and fasteners to prevent loosening.

Test the battery and clean its terminals.

Annual Servicing:

Schedule a full inspection with a certified technician.

Replace major components as needed.

Update software and control systems for optimal performance.

When conducting maintenance, always follow these steps:

Park the excavator on a level surface.

Lower the bucket to the ground.

Turn off the engine and relieve hydraulic pressure.

Allow the machine to cool before starting any work.

These practices keep your excavator in top condition and extend its lifespan.

Choosing Genuine vs. Aftermarket Parts

Selecting the right parts for your excavator is crucial for maintaining performance. Genuine parts are manufactured by the original equipment manufacturer (OEM) and guarantee compatibility. They often come with warranties, ensuring peace of mind. However, they can be more expensive.

Aftermarket parts, on the other hand, are produced by third-party manufacturers. High-quality aftermarket parts, like those offered by YNF Machinery, meet or exceed OEM standards. They provide a cost-effective alternative without compromising quality.

When choosing between genuine and aftermarket parts, consider the following:

Compatibility: Ensure the part fits your Hitachi EX60 excavator.

Warranty: Check if the part comes with a warranty for added security.

Supplier Reputation: Purchase from trusted suppliers like YNF Machinery to guarantee quality.

By weighing these factors, you can make an informed decision that balances cost and reliability.

Storing and Handling Spare Parts

Proper storage and handling of spare parts prevent damage and ensure they’re ready for use when needed. Follow these tips to maintain your inventory:

Store fluids at room temperature and protect them from freezing.

Keep rubber components away from direct sunlight to avoid degradation.

Use a clean, climate-controlled room to prevent dust and moisture damage.

Label and organize parts for easy identification.

Arrange parts by class or replacement frequency for efficient access.

Implement a first-in, first-out system to use older parts first.

Maintaining an organized storage system reduces downtime and ensures you always have the right parts on hand. Proper handling and storage also preserve the quality of your spare parts, keeping your Hitachi EX60 excavator parts in excellent condition.

Extending the Lifespan of Key Components

Proper care and maintenance of your Hitachi EX60 excavator ensure its components last longer and perform efficiently. By following a structured maintenance routine, you can prevent costly repairs and downtime.

Start with daily pre-operation inspections. Check fluid levels, including engine oil, hydraulic fluid, and coolant. Examine the undercarriage for debris or damage, and inspect hydraulic hoses for leaks. These quick checks help you identify potential issues early, keeping your machine in top condition.

Weekly tasks include lubricating key components to reduce wear and tear. Pay attention to the air filter—clean or replace it if necessary. A clean air filter ensures the engine operates efficiently and prevents contaminants from entering the system.

Monthly maintenance involves more comprehensive tasks. Change fluids like engine oil and hydraulic fluid to maintain optimal performance. Tighten bolts and fasteners to prevent loosening during operation. These steps protect critical components from unnecessary strain.

Tip: Schedule annual inspections with a certified technician. They can identify hidden issues and recommend replacements before problems escalate.

Here’s a simple checklist to help you extend the lifespan of key components:

Regularly inspect and replace filters (air, fuel, hydraulic) to maintain performance.

Keep hydraulic fluid and engine oil at recommended levels to avoid damage.

Monitor undercarriage components for wear and replace them promptly.

By following these practices, you ensure your Hitachi EX60 excavator operates efficiently and reliably for years to come. Consistent maintenance not only saves money but also maximizes the machine’s productivity.

Understanding the essential parts of the Hitachi EX60 excavator ensures its longevity and optimal performance. Familiarity with these components allows you to implement better maintenance practices, reducing downtime and maximizing uptime. Regular inspections and servicing help identify potential issues early, preventing costly repairs. For example, daily checks, pre-operation inspections, and maintaining a detailed log can significantly enhance the machine’s reliability. By prioritizing maintenance and informed part selection, you can keep your excavator running efficiently, ensuring productivity and safety on the job site.

FAQ

What are the most commonly replaced parts in the Hitachi EX60 excavator?

The most commonly replaced parts include engine components, hydraulic filters, seals, tracks, and rollers. These parts experience wear due to regular use. Replacing them promptly ensures your excavator operates efficiently and avoids costly downtime.

Tip: Keep spare parts like filters and seals in stock for quick replacements.

How often should you inspect the hydraulic system?

Inspect the hydraulic system daily for leaks, unusual noises, or temperature changes. Regular checks help you identify issues early. Replace hydraulic filters every 1,000 hours to maintain optimal performance and prevent system damage.

Why is track maintenance important for the undercarriage?

Tracks support the excavator’s movement and stability. Regular cleaning removes debris that can cause wear. Inspecting and lubricating rollers and idlers prevents friction. Proper maintenance extends the lifespan of the undercarriage and ensures smooth operation.

How do you identify the correct replacement part for your Hitachi EX60?

Use the part number listed in the excavator’s manual or stamped on the component. Cross-check this number with your supplier to ensure compatibility. YNF Machinery provides detailed catalogs to help you find the right part quickly.

Should you choose genuine or aftermarket parts for your excavator?

Both options work well if sourced from trusted suppliers. Genuine parts guarantee compatibility and often include warranties. High-quality aftermarket parts, like those from YNF Machinery, meet or exceed OEM standards and offer cost-effective alternatives.

Note: Always verify the supplier’s reputation before purchasing aftermarket parts.