Choosing between aftermarket and OEM parts for Hitachi excavator undercarriage parts can feel overwhelming. Each option offers unique advantages, but your decision should depend on factors like cost, quality, and availability. Many equipment owners lean toward aftermarket parts because they are more affordable and easier to find, especially for older machines. However, OEM parts ensure compatibility and meet original specifications, making them ideal for newer models or critical components. By carefully weighing these factors, you can make a choice that balances performance and budget effectively.

Key Takeaways

OEM parts fit Hitachi excavators perfectly, offering strong and lasting performance.

Aftermarket parts cost less and are easier to find, helping save money.

Always check aftermarket part details to make sure they work with your machine.

Think about long-term costs; aftermarket parts can save money and still work well.

Buy from trusted sellers like YNF Machinery for good aftermarket parts that match or beat OEM quality.

Understanding Hitachi Excavator Undercarriage Parts

What Are OEM Undercarriage Parts?

OEM, or original equipment manufacturer, parts are components made by the same company that produced your Hitachi excavator. These parts are designed to meet the exact specifications of your machine, ensuring a perfect fit and reliable performance. For undercarriage components, this includes items like track assemblies, rollers, sprockets, and idlers. OEM parts undergo strict quality control processes, including durability testing and ISO 9001 certification, to guarantee they meet high standards. This level of precision ensures compatibility with your equipment and minimizes the risk of performance issues during operation. While OEM parts often come with a higher cost, their quality and reliability make them a trusted choice for many operators.

Evidence Description | Details |

|---|---|

Strict Quality Control Processes | Parts designed based on precise OEM specifications for perfect fit and installation. |

Testing for Durability | Parts undergo testing to simulate real-world conditions and measure wear resistance. |

ISO Certification | All products meet ISO 9001 standards ensuring quality and reliability. |

What Are Aftermarket Undercarriage Parts?

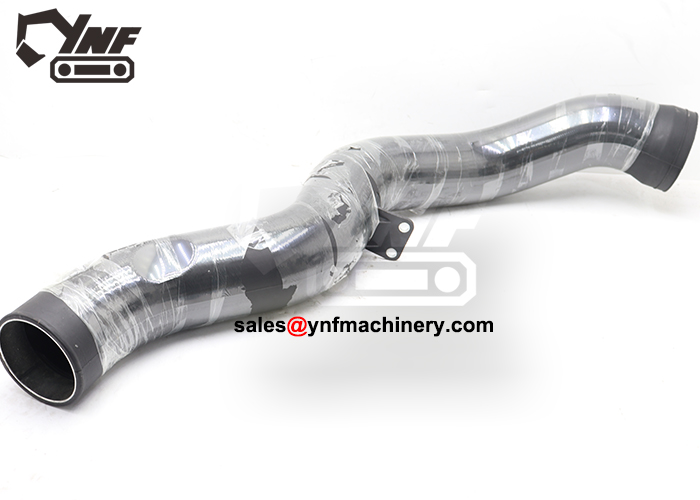

Aftermarket parts are produced by third-party manufacturers rather than the original equipment manufacturer. These parts are designed to function like OEM components and are often made from durable materials such as steel and rubber. Aftermarket undercarriage parts include track pads, rollers, and complete undercarriage assemblies. They are widely available, making them a practical option for urgent undercarriage replacement needs. Many aftermarket parts meet or exceed OEM standards, offering reliable performance in heavy-duty applications. Additionally, aftermarket options often come at a lower cost, making them an attractive choice for budget-conscious operators.

Key Differences Between Aftermarket and OEM Parts

When comparing aftermarket vs OEM undercarriage parts, several key differences stand out. OEM parts are built to Hitachi’s exact specifications, ensuring compatibility and a guaranteed fit. They undergo rigorous testing and meet strict quality standards. However, they are typically more expensive and may have longer lead times for delivery. In contrast, aftermarket parts are more affordable and readily available. They are crafted from high-quality materials like steel and rubber, which provide durability in demanding conditions. Some aftermarket manufacturers even improve upon the original design, addressing flaws and enhancing performance. While both options have their advantages, your choice should depend on your priorities, such as cost, quality, and availability.

Tip: To ensure compatibility when choosing aftermarket parts, verify the specifications and consult with a trusted supplier like YNF Machinery.

Cost Comparison: Aftermarket vs OEM

Why Aftermarket Undercarriage Parts Are More Affordable

Aftermarket undercarriage parts often cost less than OEM parts. Third-party manufacturers produce these parts without the branding or licensing fees associated with OEM components. This allows them to offer competitive pricing while maintaining durability and performance. Many aftermarket parts are made from high-quality materials like steel and rubber, ensuring they can handle demanding conditions. Their affordability makes them a practical choice for operators managing tight budgets or replacing multiple components at once. Additionally, aftermarket undercarriages are widely available, which reduces sourcing costs and ensures you can quickly address undercarriage replacement needs.

The Premium Pricing of OEM Undercarriage Parts

OEM parts come with a higher price tag due to their precision engineering and brand assurance. These parts are designed specifically for Hitachi excavator undercarriage parts, guaranteeing compatibility and performance. The rigorous testing and strict quality control processes involved in their production also contribute to their premium pricing. While the upfront cost may seem steep, many operators value the peace of mind that comes with using components built to original specifications. However, the higher cost and potential delays in availability can make OEM parts less appealing for urgent repairs or budget-conscious projects.

Long-Term Cost Implications

When evaluating long-term costs, aftermarket parts can offer significant savings. Many aftermarket components meet or exceed OEM standards, which helps reduce maintenance expenses over time. Their widespread availability minimizes downtime, allowing you to keep your equipment operational and avoid costly delays. In contrast, OEM parts often involve longer lead times, which can increase downtime and associated costs. Choosing a reliable supplier, such as YNF Machinery, ensures you receive high-quality aftermarket parts that balance affordability and durability. This makes aftermarket options a cost-effective quality choice for many operators.

Note: Always verify compatibility and quality when selecting aftermarket undercarriage parts to maximize their value and performance.

Quality and Durability of Undercarriage Parts

OEM Parts: Built to Hitachi Standards

OEM parts are designed to meet the exact specifications of Hitachi excavators. These components undergo rigorous quality control measures to ensure they deliver exceptional performance and durability. Manufacturers implement stringent protocols to monitor every stage of production, from material selection to final assembly. This guarantees that the parts meet high standards and fit perfectly with your equipment.

Quality Control Measure | Description |

|---|---|

Material Quality Control | Stringent protocols ensure the durability and performance of undercarriage parts through suitable raw materials. |

Manufacturing Process Control | Every production step is closely monitored, from shaping to final assembly, to maintain high standards. |

Compatibility Quality Control | Parts are designed based on precise OEM specifications for a perfect fit and hassle-free installation. |

Durability Quality Control | Strict testing simulates real-world conditions to ensure parts meet and exceed durability standards. |

By choosing OEM parts, you can trust that they will withstand demanding conditions and provide reliable performance over time. Their compatibility with Hitachi excavator undercarriage parts ensures a seamless installation process, reducing the risk of operational issues.

Aftermarket Parts: Quality Varies by Manufacturer

The quality of aftermarket parts can vary significantly depending on the manufacturer. While many aftermarket parts meet or exceed OEM standards, others may fall short due to inconsistent production practices. Common issues include wear and tear, misalignment, and track damage caused by debris or improper tensioning. Corrosion and lack of lubrication can also lead to premature failure.

Wear and tear: Constant exposure to harsh conditions leads to degradation of components.

Misalignment: Improper tensioning or uneven loading causes uneven wear.

Track damage: Impacts from debris can cause cuts or punctures, affecting performance.

Leaks: Hydraulic fluid leaks reduce performance and increase wear.

Corrosion: Coastal environments can lead to premature wear due to rust.

Lack of lubrication: Insufficient lubrication increases friction and wear.

Overloading: Exceeding load limits accelerates wear and potential failure.

To mitigate these issues, you should conduct regular inspections, clean components, and follow proper lubrication schedules. Ensuring correct track tension and avoiding excessive loads can also extend the lifespan of aftermarket parts.

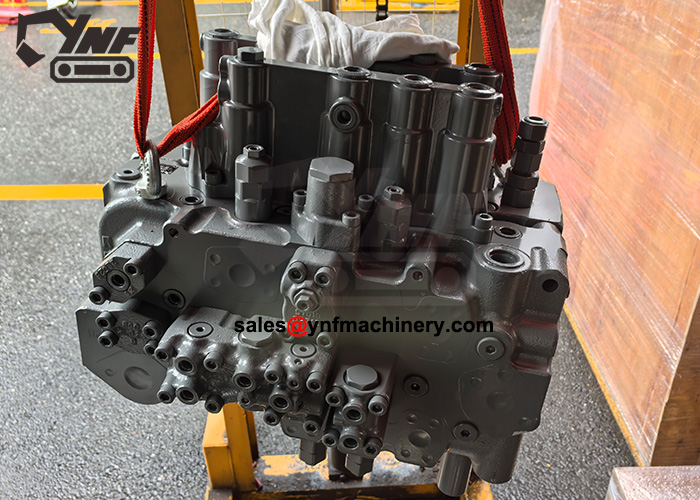

How YNF Machinery Ensures High-Quality Aftermarket Parts

YNF Machinery stands out by offering high-quality aftermarket parts that rival OEM components. The company uses durable materials like steel and rubber to produce undercarriage parts capable of withstanding heavy-duty applications. Each part undergoes rigorous quality inspections to ensure it meets high standards for durability and compatibility.

YNF Machinery also prioritizes customer satisfaction by providing parts that fit seamlessly with Hitachi excavators. Their commitment to quality and reliability ensures you receive components that perform well in demanding conditions. By choosing YNF Machinery, you can enjoy the cost benefits of aftermarket parts without compromising on performance or durability.

Tip: Always verify the specifications of aftermarket parts to ensure compatibility with your equipment.

Compatibility and Fit for Hitachi Excavators

OEM Parts: Guaranteed Fit and Performance

OEM parts provide a seamless fit for Hitachi excavators. These components are designed to match the exact specifications of your machine, ensuring optimal performance. Manufacturers test OEM parts rigorously to meet high standards for quality and reliability. This guarantees that they integrate perfectly with your equipment, reducing the risk of operational issues. When you choose OEM parts, you can trust their long-term durability and compatibility with your excavator. This makes them a reliable choice for undercarriage replacement, especially when performance is critical.

Aftermarket Parts: Addressing Compatibility Concerns

Aftermarket parts offer a cost-effective alternative to OEM components, but compatibility can sometimes be a concern. Not all aftermarket parts are created equal, and some may not fit your Hitachi excavator as precisely as OEM options. However, many reputable manufacturers produce aftermarket parts that meet or exceed OEM standards. These parts often undergo quality testing to ensure they deliver reliable performance. By selecting high-quality aftermarket parts from trusted suppliers, you can address compatibility concerns while enjoying significant cost savings.

Tips for Ensuring Compatibility with Aftermarket Parts

Ensuring compatibility with aftermarket parts requires careful consideration. Follow these steps to make the right choice:

Understand Your Equipment’s Requirements: Identify your Hitachi excavator’s model and serial number. Refer to the manufacturer’s manual for detailed specifications.

Choose Between OEM and Aftermarket Parts: Decide whether OEM parts are necessary for guaranteed fit or if aftermarket parts meet your cost-effectiveness goals.

Evaluate the Quality and Durability of Parts: Look for parts made from durable materials that can handle heavy-duty use. Ensure they have been tested for reliability.

Consult with Experts: Seek advice from professionals if you are unsure about which parts to select.

By following these steps, you can confidently choose aftermarket parts that fit your equipment and maintain its performance. Trusted suppliers like YNF Machinery simplify this process by offering high-quality undercarriage parts designed for Hitachi excavators.

Tip: Always verify the specifications of aftermarket parts before purchasing. This ensures compatibility and reduces the risk of operational issues.

Warranty and Support for Undercarriage Parts

OEM Warranty Coverage for Hitachi Excavators

OEM warranties provide peace of mind when you invest in undercarriage components. These warranties often cover defects in materials or workmanship, ensuring you receive reliable parts for your Hitachi excavator undercarriage parts. Manufacturers design OEM parts to meet strict quality standards, which reduces the likelihood of failure. Most warranties also include support services, such as technical assistance, to help you resolve issues quickly. However, OEM warranties may come with limitations, like shorter coverage periods or restrictions on usage. Always review the terms carefully to understand what is included.

Aftermarket Warranty Options and What to Look For

Aftermarket warranties vary widely depending on the manufacturer or supplier. Some offer comprehensive coverage that rivals OEM warranties, while others provide limited protection. When buying high-quality aftermarket parts, look for warranties that cover defects and ensure durability. Reliable suppliers often include customer support to address concerns about compatibility or performance. You should also verify the warranty period and any conditions, such as proper installation or maintenance requirements. Choosing aftermarket rubber tracks or other undercarriage components with a solid warranty can maximize the benefits of aftermarket parts while minimizing risks.

YNF Machinery’s Commitment to Warranty and Support

YNF Machinery stands out by offering robust warranty options for its aftermarket parts. The company ensures that every undercarriage replacement part meets high standards for quality and reliability. YNF Machinery’s warranty coverage reflects its confidence in the durability and performance of its products. In addition to warranties, the company provides excellent customer support to guide you through the selection and installation process. Whether you need aftermarket rubber tracks or other undercarriage components, YNF Machinery ensures compatibility and long-term equipment performance. This commitment makes them a trusted partner for your undercarriage needs.

Tip: Always choose suppliers like YNF Machinery that back their products with strong warranties and reliable support.

Availability and Lead Times

OEM Parts: Limited Availability Through Authorized Dealers

OEM parts for Hitachi excavator undercarriage parts are only available through authorized dealers. This exclusivity ensures you receive components that meet the original specifications. However, sourcing these parts can sometimes be challenging. Limited stock or specific manufacturing schedules may lead to delays.

Several factors contribute to these delays:

Reason | Description |

|---|---|

Availability of Parts | Delays can occur if the required parts are not readily available from suppliers. |

Transportation Delays | Issues in logistics can lead to significant delays in receiving parts. |

Supplier Reliability | Dependability of suppliers affects the timely delivery of high-quality parts. |

These challenges can extend lead times, especially for older or less common models. If you need urgent replacements, this limited availability might disrupt your operations.

Aftermarket Parts: Wider Range of Suppliers

Aftermarket parts offer a broader range of suppliers, making them easier to source. You can find these parts from multiple manufacturers and distributors, ensuring faster access to the components you need. Several factors contribute to their wider availability:

Cost savings: Aftermarket parts are often more affordable than OEM parts, allowing you to save money without sacrificing quality.

Wide availability: Aftermarket parts are readily available from various suppliers, making it easier to find the parts you need for your specific equipment.

High-quality materials: Many aftermarket manufacturers use high-quality materials to ensure durability and performance comparable to OEM parts.

Compatibility: Aftermarket parts are designed to fit and function like the original parts, ensuring a seamless installation and optimal performance.

Versatility: Aftermarket parts are available for a wide range of brands and models, giving you more options to choose from.

This versatility and accessibility make aftermarket parts a practical choice for operators who prioritize quick replacements and cost efficiency.

How YNF Machinery Streamlines the Sourcing Process

YNF Machinery simplifies the process of sourcing undercarriage parts. The company maintains a vast inventory of high-quality aftermarket parts, ensuring you can find what you need without delays. Their streamlined logistics system reduces lead times, allowing you to keep your equipment running smoothly. YNF Machinery also provides comprehensive support, helping you select compatible parts for your Hitachi excavator undercarriage parts. By choosing YNF Machinery, you benefit from reliable service, competitive pricing, and quick delivery, ensuring minimal downtime for your operations.

Tip: Partnering with a trusted supplier like YNF Machinery ensures you receive durable aftermarket parts without the hassle of long lead times.

Choosing Between Aftermarket and OEM Undercarriage Parts

When OEM Parts Are the Best Choice

OEM parts are the ideal choice when you prioritize reliability and compatibility. These parts are manufactured by the original equipment maker, ensuring they fit your Hitachi excavator undercarriage parts perfectly. Their precision engineering guarantees optimal performance, which is essential for maintaining the efficiency of your equipment. If your work involves demanding environments or critical operations, OEM parts provide the peace of mind you need. They undergo rigorous quality control, making them a dependable option for long-term use. Although they come at a higher cost, their durability and seamless integration often justify the investment.

You should also consider OEM parts when warranty coverage is a priority. These parts typically include comprehensive warranties that protect against defects and ensure reliable performance. This makes them a smart choice for operators who value long-term security and support.

When Aftermarket Parts Are a Better Fit

Aftermarket parts are a better fit when cost savings and availability are your top concerns. These parts are generally more affordable than OEM options, allowing you to reduce upfront expenses. This is especially beneficial if you manage a large fleet of equipment or need to replace multiple components. Aftermarket parts also offer a wide selection, catering to various equipment models and brands. This makes them a practical choice for operators who need quick replacements or have older machines.

However, you should carefully evaluate the quality of aftermarket parts before purchasing. Look for parts made from durable materials and verify their compatibility with your equipment. Trusted suppliers like YNF Machinery ensure you receive high-quality aftermarket parts that perform reliably in heavy-duty applications.

Balancing Cost, Quality, and Performance with YNF Machinery

Balancing cost, quality, and performance can feel challenging, but YNF Machinery simplifies the process. The company offers high-quality aftermarket parts that rival OEM components in durability and reliability. Each part undergoes rigorous inspections to ensure it meets high standards, giving you confidence in your purchase. YNF Machinery also provides competitive pricing, making it easier to manage your budget without compromising on performance.

By choosing YNF Machinery, you gain access to a wide range of undercarriage parts designed for Hitachi excavators. Their streamlined sourcing process ensures quick delivery, minimizing downtime for your operations. Whether you prioritize cost savings or long-term durability, YNF Machinery helps you find the right balance for your needs.

Tip: Always assess your equipment’s requirements and consult with experts to make an informed decision between aftermarket and OEM parts.

Understanding the differences between aftermarket and OEM Hitachi excavator undercarriage parts helps you make informed decisions. OEM parts guarantee a precise fit and high quality, while aftermarket options offer cost savings and broader availability. Evaluating factors like cost, durability, compatibility, warranty, and lead times ensures you choose the right undercarriage solution for your needs. For guaranteed performance, OEM parts work best. When cost savings matter, aftermarket parts from trusted suppliers like YNF Machinery provide a reliable alternative. Always prioritize quality and compatibility to keep your excavator running efficiently.

FAQ

What are the most common undercarriage parts that need replacement?

Tracks, rollers, and sprockets often require replacement due to wear and tear. Tracks endure constant friction and heavy loads, making them prone to damage. Regular inspections help identify worn parts early, ensuring your excavator operates efficiently.

How can you extend the lifespan of your tracks?

Maintain proper tension, clean debris regularly, and avoid overloading. Tracks last longer when you operate the excavator on suitable terrain and follow the manufacturer’s maintenance guidelines. Routine lubrication also reduces friction and prevents premature wear.

Are aftermarket tracks as durable as OEM ones?

Aftermarket tracks can match OEM durability if sourced from reputable suppliers like YNF Machinery. High-quality materials and rigorous testing ensure aftermarket tracks perform well in demanding conditions. Always verify the specifications to ensure compatibility with your equipment.

How do you know when to replace your tracks?

Replace tracks when you notice cracks, uneven wear, or reduced traction. Excessive vibration during operation also indicates worn tracks. Regular inspections help you identify these signs early, preventing further damage to your excavator.

Can you mix aftermarket tracks with OEM parts?

Yes, you can mix aftermarket tracks with OEM parts if they meet the required specifications. Ensure the tracks fit your excavator model and maintain proper alignment. Trusted suppliers like YNF Machinery provide compatible aftermarket tracks for seamless integration.