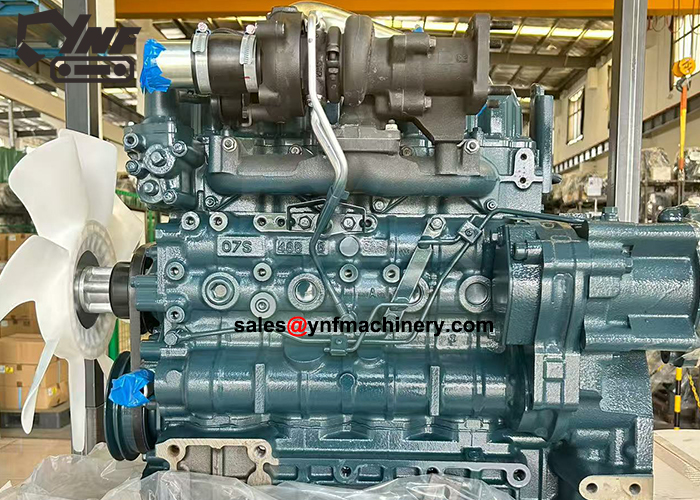

Kubota excavator parts diagrams make repairs easier by offering clear visual guidance. You can quickly identify components and understand their placement, reducing confusion during maintenance. These diagrams, often found in manuals, help you minimize downtime by ensuring accurate part identification and efficient reassembly. Using them ensures your equipment stays in top condition. Partnering with reliable suppliers like YNF Machinery guarantees access to high-quality parts, making your repair process smoother and more effective. With the right tools and resources, you can maintain your excavator’s performance effortlessly.

Key Takeaways

Kubota excavator parts diagrams show clear pictures of parts. This helps you find parts and where they go during repairs.

These diagrams lower mistakes when taking apart and putting back parts. They help fix your excavator correctly and keep it working well.

You can find parts diagrams in Kubota manuals or from trusted sellers like YNF Machinery. This ensures you get the right details for your model.

Check parts diagrams often to plan maintenance. They help you spot parts needing care and make your machine last longer.

Understanding Kubota Excavator Parts Diagrams

What Are Kubota Excavator Parts Diagrams?

Definition and purpose of parts diagrams.

Kubota excavator parts diagrams are detailed illustrations that show the components of your excavator and how they fit together. These diagrams serve as a visual guide, helping you identify parts and understand their placement within the machine. They simplify repairs by providing a clear reference, reducing guesswork during maintenance tasks. Whether you need to replace a damaged part or perform routine servicing, these diagrams ensure you can locate the exact component quickly.

How they are organized for easy navigation.

Parts diagrams are typically organized by system or assembly, such as the engine, hydraulic system, or electrical components. Each section includes exploded views, showing how individual parts connect and interact. Labels and part numbers accompany each component, making it easier for you to identify and order the correct part. For example, a diagram of the hydraulic system might display the pump housing, gear pump, and related components in a logical sequence. This organization ensures you can navigate the diagrams efficiently, even if you’re not a technical expert.

Where to Access Kubota Excavator Parts Diagrams

Official Kubota resources and manuals.

You can find Kubota excavator parts diagrams in official resources like parts manuals and service guides. These manuals are tailored to specific models, ensuring accuracy and compatibility. They often include step-by-step instructions alongside the diagrams, making them a valuable tool for both repairs and preventive maintenance.

Reliable third-party suppliers like YNF Machinery.

Third-party suppliers also provide access to parts diagrams. YNF Machinery, for instance, offers comprehensive support for excavator owners. Their resources include detailed diagrams and part catalogs, ensuring you can find the right components for your machine. Other platforms, such as Messicks and Equipment Share, also provide online catalogs with detailed diagrams for various Kubota models.

Key Features of Kubota Excavator Parts Diagrams

Exploded views and labeled components.

One of the standout features of Kubota excavator parts diagrams is the use of exploded views. These illustrations break down complex assemblies into individual components, showing how they fit together. Each part is labeled clearly, making it easy for you to identify what you need. For example, a diagram of the basic engine might include components like the crankcase, oil pan, and camshaft, each labeled with a unique part number.

Component Type | Part No. | Description |

|---|---|---|

BASIC ENGINE | 01S001 | CRANKCASE |

01S002 | OIL PAN | |

01S003 | PISTON, CRANKSHAFT | |

01S004 | MAIN BEARING CASE | |

01S005 | CAMSHAFT | |

01S006 | CYLINDER HEAD | |

01S007 | VALVE, ROCKER ARM | |

01S008 | CYLINDER HEAD COVER | |

FUEL SYSTEM | 01S014 | NOZZLE HOLDER, GLOW PLUG |

ELECTRICAL SYSTEM | 01S028 | FLYWHEEL, STARTER |

HYDRAULIC SYSTEM | 01S089 | PUMP HOUSING |

Part numbers and descriptions for accurate identification.

Each component in the diagram includes a part number and description. This feature ensures you can order the correct part without confusion. For instance, if you need a replacement for the cylinder head cover, you can refer to its part number in the diagram. This level of detail minimizes errors and speeds up the repair process, saving you time and effort.

Benefits of Using Kubota Excavator Parts Diagrams

Simplifies Repairs and Maintenance

Identifies the exact part needed for repairs.

Kubota excavator parts diagrams help you pinpoint the exact part required for a repair. These diagrams provide detailed illustrations, showing how components fit together. By using them, you can avoid confusion and focus on the specific part that needs attention. For instance, if your hydraulic system malfunctions, the diagram will guide you to the faulty component, whether it’s a pump housing or a gear pump. This precision ensures you don’t waste time guessing or dismantling unnecessary sections of the machine.

Reduces errors during disassembly and reassembly.

Disassembling and reassembling an excavator can be complex. Parts diagrams simplify this process by offering clear visual guidance. You can follow the illustrated parts step by step, reducing the risk of errors. For example, when working on the engine, the diagram ensures you place each component, like the crankshaft or camshaft, in its correct position. This accuracy prevents costly mistakes and ensures your excavator operates efficiently after the repair.

Saves Time and Costs

Avoids unnecessary purchases and delays.

Using a Kubota excavator parts diagram helps you avoid buying the wrong parts. Each component is labeled with a part number and description, ensuring you order the correct item. This eliminates unnecessary purchases and delays caused by returning incompatible parts. Additionally, the diagrams streamline your workflow, allowing you to focus on completing the repair quickly.

Speeds up the repair process with accurate part identification.

Accurate part identification accelerates the repair process. These diagrams reduce training time for new technicians, enabling them to identify parts visually. By interacting with intuitive diagrams, you can confirm the correct parts needed for repairs. This efficiency minimizes errors in ordering and speeds up the entire process, ensuring your excavator is back in operation sooner.

Enhances Preventive Maintenance

Ensures correct parts are used for servicing.

Preventive maintenance becomes more effective with the help of parts diagrams. You can identify the correct parts needed for servicing, ensuring your excavator remains in top condition. For example, when replacing seals or gaskets, the diagram ensures you select the right size and type, preventing future issues.

Helps plan maintenance schedules effectively.

Parts diagrams also assist in planning maintenance schedules. By understanding the layout and function of each component, you can anticipate when certain parts might need servicing. This proactive approach reduces unexpected breakdowns and extends the lifespan of your equipment. Work shop manuals often include these diagrams, providing you with all the information needed to maintain your excavator efficiently.

Step-by-Step Guide to Using Kubota Excavator Parts Diagrams

Step 1: Identify the Problem

Inspect the excavator and determine the issue.

Start by thoroughly inspecting your Kubota excavator to identify the problem. Pay close attention to high-wear components like bucket teeth, sprockets, and the undercarriage. Daily inspections can help you spot visible damage, leaks, or unusual wear. For example, if you notice oil leakage near the hydraulic system, it could indicate a faulty seal or damaged cylinder. Cleaning the undercarriage weekly also prevents dirt buildup, which can lead to unnecessary repairs.

Note the affected system or component.

Once you identify the issue, determine which system or component is affected. For instance, if the engine struggles to start, the problem might lie in the fuel system or electrical components. Create a machine log to document the condition and lifespan of parts. This record will help you track recurring issues and plan for replacements. Use the parts book to locate the relevant section for your Kubota excavator model. Refer to the column headings, which include part numbers, descriptions, and quantities, to narrow down the faulty component.

Step 2: Locate the Relevant Diagram

Use the manual or online resources to find the diagram.

Accessing the correct diagram is crucial for efficient repairs. Manuals provided by Kubota are an excellent starting point. These manuals include detailed diagrams tailored to specific models, ensuring accuracy. Online resources like Messick’s and Coleman Equipment also offer comprehensive parts catalogs and diagrams for various Kubota excavator models, such as the KX080-3 and U35-4. These platforms provide easy navigation, helping you find the exact diagram you need.

Match the diagram to your Kubota excavator model.

Ensure the diagram matches your excavator model to avoid confusion. Check the model number and serial number range to confirm compatibility. For example, if you own a Kubota KX101, use resources that specifically cater to this model. Matching the diagram ensures you can accurately identify parts and their placement, streamlining the repair process.

Resource | Description |

|---|---|

Coleman Equipment | Parts for Kubota KX080-3 Excavators, detailed parts catalogs and diagrams. |

Messick’s | Detailed part diagrams for various Kubota models including U35-4 and KX101. |

Step 3: Identify the Part

Use the diagram to locate the faulty part.

Refer to the kubota excavator parts diagram to pinpoint the faulty part. Exploded views in the diagram break down complex assemblies into individual components, making it easier to locate the issue. For example, if the hydraulic system leaks, the diagram will guide you to the specific seal or cylinder causing the problem. Closely inspect high-friction areas and consult the operation manual for preventive maintenance tasks.

Note the part number and description for ordering.

Once you identify the faulty part, note its part number and description. This information ensures you order the correct replacement. For instance, if you need a new cylinder head cover, the diagram will provide the exact part number, description, and quantity required. Maintaining an inventory of commonly worn parts can also prevent delays during repairs. Always verify the part’s compatibility with your excavator model before placing an order.

Step 4: Order the Part

Purchase from trusted suppliers like YNF Machinery.

When it’s time to order the part, choosing a reliable supplier ensures a smooth process. YNF Machinery offers high-quality excavator parts that meet or exceed OEM standards. Their extensive catalog includes components for various Kubota models, making it easy to find what you need. You can browse their user-friendly platform to locate the exact part using the part number from the diagram. This eliminates guesswork and reduces the risk of ordering the wrong item.

Tip: Ordering online from trusted suppliers like YNF Machinery saves time compared to traditional methods. It avoids inefficiencies caused by lengthy phone calls or miscommunication.

Verify compatibility with your excavator model.

Before finalizing your purchase, confirm the part’s compatibility with your Kubota excavator model. Cross-check the part number and description from the diagram with the supplier’s catalog. This step ensures the replacement fits perfectly and functions as intended. YNF Machinery provides detailed product descriptions and expert support to help you verify compatibility. Taking this precaution prevents delays caused by returns or incorrect orders.

Note: Poor inventory management can lead to overstocking or cash flow issues. Use parts diagrams to identify essential components and maintain an efficient inventory.

Step 5: Perform the Repair

Follow repair instructions using the diagram as a reference.

Once the part arrives, use the Kubota excavator parts diagram to guide the repair process. The exploded views in the diagram show how components fit together, making it easier to disassemble and reassemble the affected area. For example, if you’re replacing a hydraulic seal, the diagram will illustrate its exact placement within the cylinder. This visual aid reduces errors and ensures the repair is done correctly.

Tip: Interactive diagrams tailored to your excavator model can help new staff quickly understand the repair process. This minimizes mistakes and boosts confidence.

Ensure proper reassembly with the help of the diagram.

After completing the repair, reassemble the components carefully. Use the diagram to double-check each part’s position and orientation. This step is crucial for maintaining the excavator’s performance and preventing future issues. For instance, when working on the engine, ensure all bolts and seals are tightened to the correct specifications. The diagram acts as a reliable guide, helping you avoid common mistakes during reassembly.

Reminder: Accurate reassembly not only restores functionality but also extends the lifespan of your equipment. Always refer to the diagram for a seamless repair process.

Tips for Maintenance Using Kubota Excavator Parts Diagrams

Plan Preventive Maintenance

Use diagrams to identify parts requiring regular servicing.

Kubota excavator parts diagrams are invaluable for planning preventive maintenance. They help you pinpoint components that need regular attention, such as filters, seals, and gaskets. Start by conducting daily walkarounds to inspect high-wear areas like bucket teeth and sprockets. Weekly cleaning of the undercarriage prevents dirt buildup, which could lead to costly repairs. Use the diagrams to create a log of parts that require replacement and note their servicing frequency. This proactive approach ensures your excavator stays in peak condition.

Tip: Consult the operator’s manual for service intervals and maintenance checklists. Following the OEM-recommended service plan keeps your machine cost-effective and compliant with warranty terms.

Create a maintenance schedule based on the diagram.

A well-organized maintenance schedule reduces downtime and extends the life of your equipment. Use the parts diagrams to map out servicing tasks for each system, such as the hydraulic cylinders or electrical components. Daily inspections of hoses, fluid levels, and other critical areas ensure you catch potential issues early. Work shop manuals often include diagrams and detailed information to guide you in creating a comprehensive schedule tailored to your excavator model.

Stock Essential Spare Parts

Use diagrams to determine which parts to keep on hand.

Parts diagrams simplify the process of identifying essential spare parts. They highlight components prone to wear and tear, such as rubber tracks, final drives, and hydraulic cylinders. Keeping these items in stock minimizes downtime during repairs. Additionally, diagrams help you identify smaller but equally important parts like filters, seals, and gaskets. Maintaining an inventory of these items ensures you’re always prepared for routine maintenance or unexpected breakdowns.

Avoid delays caused by unavailable parts.

Unplanned delays can disrupt your operations. By using parts diagrams to anticipate your needs, you can avoid waiting for replacements. For example, if the diagram shows that a specific gasket is critical for the hydraulic system, having it on hand prevents extended downtime. Reliable suppliers like YNF Machinery make it easy to source high-quality parts, ensuring you’re never caught off guard.

Ensure Proper Lubrication and Cleaning

Identify lubrication points using the diagram.

Proper lubrication is essential for keeping your excavator running smoothly. Parts diagrams clearly indicate lubrication points, such as pivot joints and bearings. Use this information to apply the correct type and amount of lubricant to each area. Regular lubrication reduces friction and prevents premature wear, extending the lifespan of your machine.

Use the correct cleaning methods for each component.

Cleaning your excavator properly prevents dirt and debris from damaging critical parts. Diagrams help you understand the structure of each component, guiding you in selecting the right cleaning methods. For instance, you can use the diagram to identify areas like the hydraulic system or engine that require special attention. Following these guidelines ensures thorough cleaning without causing damage.

Reminder: Always refer to the parts manual for detailed instructions on lubrication and cleaning. This ensures you follow best practices and maintain your equipment effectively.

Common Mistakes to Avoid When Using Kubota Excavator Parts Diagrams

Misidentifying Parts

Double-check part numbers and descriptions.

Misidentifying parts can lead to delays and wasted resources. Always double-check the part numbers and descriptions provided in the diagram. These details ensure you order the correct component. For example, if you need a hydraulic seal, verify its part number and description to avoid purchasing the wrong size or type. Keeping a record of frequently used parts can also help you cross-reference and confirm accuracy.

Ensure the diagram matches your excavator model.

Using the wrong diagram for your excavator model creates confusion. Check the model and serial number of your machine before referencing a diagram. For instance, a diagram for a Kubota KX040-4 may not apply to a KX080-3. Matching the diagram to your specific model ensures you identify parts correctly and avoid unnecessary errors.

Skipping Preventive Maintenance

Use diagrams to stay on top of maintenance tasks.

Neglecting preventive maintenance often results in costly repairs. A ‘run-to-failure’ approach forces you to perform emergency or deferred corrective maintenance, which is more expensive. Parts diagrams help you plan maintenance tasks by identifying components that require regular servicing. For example, you can use the diagram to locate filters or seals that need periodic replacement.

Tip: Create a maintenance log based on the diagram to track service intervals and avoid missing critical tasks.

Avoid costly repairs caused by neglect.

Skipping maintenance increases the risk of unexpected breakdowns. Diagrams provide a clear view of your excavator’s systems, helping you integrate preventive, corrective, and emergency maintenance into a comprehensive plan. This proactive approach reduces downtime and extends the life of your equipment.

Using Incorrect Parts

Always verify compatibility before purchasing.

Using incorrect parts can damage your excavator. Before purchasing, confirm the part’s compatibility with your machine. Cross-check the part number and description from the diagram with the supplier’s catalog. This step ensures the replacement fits perfectly and functions as intended.

Choose high-quality parts from suppliers like YNF Machinery.

Low-quality parts may fail prematurely, leading to additional repairs. Reliable suppliers like YNF Machinery offer high-quality components that meet or exceed OEM standards. Their extensive catalog ensures you find the right part for your Kubota excavator. Investing in quality parts reduces downtime and enhances your machine’s performance.

Reminder: High-quality parts save money in the long run by minimizing the need for frequent replacements.

Kubota excavator parts diagrams simplify your repair and maintenance tasks by providing clear visual guidance. They help you save time, reduce costs, and keep your equipment running efficiently. Using these diagrams ensures you identify the right parts and perform accurate repairs. For high-quality components, rely on trusted suppliers like YNF Machinery. Their extensive catalog includes reliable options like Excavator Engine Parts and Hydraulic Cylinder Seal Kits. By combining these diagrams with YNF Machinery’s parts, you can maintain your excavator’s performance and extend its lifespan effortlessly.

Tip: Visit YNF Machinery for expert support and premium excavator parts.

FAQ

What is the purpose of Kubota excavator parts diagrams?

Kubota excavator parts diagrams help you identify components and understand their placement. They simplify repairs, reduce errors, and ensure accurate part identification. These diagrams also assist with preventive maintenance by showing which parts need regular servicing.

Where can I find Kubota excavator parts diagrams?

You can access these diagrams in Kubota manuals or through trusted suppliers like YNF Machinery. Online platforms such as Messick’s and Coleman Equipment also provide detailed diagrams for various Kubota models.

How do I ensure I order the correct part?

Use the part number and description from the diagram to confirm accuracy. Cross-check this information with your supplier’s catalog. Reliable suppliers like YNF Machinery provide expert support to verify compatibility with your excavator model.

Why should I choose YNF Machinery for parts?

YNF Machinery offers high-quality excavator parts that meet or exceed OEM standards. Their extensive catalog, competitive pricing, and expert support ensure you get the right part quickly and efficiently. They also provide fast shipping and international delivery.

How do parts diagrams help with preventive maintenance?

Parts diagrams show you which components need regular servicing, such as filters or seals. They help you plan maintenance schedules and identify high-wear areas. This proactive approach reduces downtime and extends your excavator’s lifespan.

Tip: Always keep a maintenance log to track service intervals and part replacements.