You should first find your excavator’s make, model, and serial number. This information helps you pick parts that fit your machine. Think about what jobs you do and where you use your excavator. Some parts, like tracks and track pads, wear out often. Make sure you know the different types of 220 excavator parts. Pick a supplier you can trust. Check and fix your excavator often to keep it safe and working well.

Key Takeaways

Always check your excavator’s make, model, and serial number before you order parts. This helps you get the right part that fits well.

Pick parts that match the job you need to do. Some jobs need stronger parts, while others need lighter ones for better work.

Choose suppliers who are trustworthy and sell good parts. Make sure they have helpful customer service. This stops problems and keeps your excavator working well.

Look at your excavator parts often and take care of them. Doing this stops your machine from breaking and helps it last longer.

Learn about genuine, OEM, and aftermarket parts. Pick the best one for your needs to save money and get good quality.

Identify Your 220 Excavator Parts and Model

Find Model and Serial Numbers

Start by finding your excavator’s model and serial number. These numbers help you get the right parts for your machine. You can find them on a metal plate on the frame or inside the cab. The operator’s manual also has this information. Two excavators can look the same but have different model and serial numbers. These numbers are important when you order new parts.

Tip: Write down your excavator’s model and serial number before you talk to a supplier. This step saves time and helps you not make mistakes.

Look for the metal plate on your excavator.

Check the operator’s manual for the numbers.

Keep the model and serial number in a safe place.

Match Parts to Specifications

After you have the model and serial number, you can match parts to your excavator’s needs. Manufacturers make parts for certain models. If you use the wrong part, your machine might not work right. The operator’s manual tells you the exact part numbers for your excavator. Use these numbers when you order new parts.

Use the operator’s manual to find the right part numbers.

Check the part numbers with what the supplier has.

Make sure the part fits your excavator’s model and serial number.

Note: Even small changes between models can mean you need different parts. Always check before you buy.

Getting the right parts helps your excavator work well. You stop breakdowns and save money over time.

Assess Job Needs and Compatibility

Choose the Right Excavator Parts for Your Work

You must pick the right excavator parts for your job. Each project is different. Some jobs need strong parts for rocky ground. Other jobs need lighter parts for soft dirt. Match the part to the job to keep your excavator safe and working well.

Tip: Always look at your job site before buying new parts. The ground, material, and job size all change what parts you need.

Here is a table that shows important things to think about when picking parts for your excavator:

Factor | Benefit |

|---|---|

Equipment Failures | Nearly 40% of failures come from wrong parts. |

Service Life Increase | A good idler cap helps parts last 20% longer. |

Cost Implications | Wrong parts cost more to fix and slow down work. |

If you use the wrong excavator parts, you might have breakdowns and spend more money. Good choices help your machine last longer and save you cash.

When picking excavator parts, think about the attachments you use. Attachments like buckets, rippers, and thumbs must fit your machine and job. Check the tooth model, shape, and size for digging tools. If you choose the wrong size, your excavator may not work right or could be unsafe.

Picking the right size for attachments helps you avoid problems and stay safe.

If an attachment is too big, your excavator may not have enough hydraulic power. This can slow your work.

Heavy attachments can make your job site unsafe.

Check Attachment and Sizing Compatibility

You need to make sure your excavator attachments fit your machine. Compatibility is key for safety and good performance. Follow these steps to check if your attachments work with your excavator:

Check your excavator’s model year.

Make sure the hydraulic flow matches.

Measure pin diameters to see if they fit.

Look at electrical connections for a good match.

Read the machine manual and attachment specs for details.

Note: Always use your operator’s manual and the attachment guide. These tools help you avoid mistakes.

Common compatibility problems can cause trouble on the job site. Here are some issues you might see:

Pin sizes that do not match: Use bushings or sleeves to fix pin sizes.

Wrong linkage geometry: Custom kits or adaptors may help.

Hydraulic flow problems: Flow control valves can help adjust output.

Weight differences: Make sure your excavator can lift the attachment.

Control system issues: You may need to upgrade or change control systems.

Always check your job site before picking new excavator attachments. The ground, material, and job size all matter. If you work with rocks, you need stronger parts. If you work on soft ground, lighter parts may be better.

Callout: Planning ahead helps you avoid mistakes and keeps your excavator safe.

Choosing the right excavator parts and attachments makes your machine work better and safer. You also save time and money by stopping breakdowns and delays.

Compare Genuine, OEM, and Aftermarket Excavator Parts

When you shop for excavator parts, you have three choices. You can pick genuine parts, OEM parts, or aftermarket parts. Each type has good and bad sides. You should learn the differences to make smart choices.

Pros and Cons of Each Type

Genuine parts are made by the original company. They fit your machine best and work very well. These parts last a long time, but they cost more money. OEM parts are just as good as genuine parts. They cost less and still last a long time. Aftermarket parts come from many brands. Some are as strong as OEM parts, but some do not last as long.

Here is a table that shows how durable each part type is:

Type of Part | Durability Characteristics |

|---|---|

Genuine Parts | Best fit and performance, most durable, higher price. |

OEM Parts | Same quality as genuine, lower price, still strong. |

Aftermarket Parts | Quality changes; good brands can be as strong as OEM. |

Tip: Always read reviews and check supplier ratings before buying aftermarket parts. This helps you avoid bad parts.

Quality, Cost, and Warranty Factors

You want parts that last and save you money. Genuine parts cost the most, but they come with strong warranties and support. OEM parts give you good value and protection. Aftermarket parts cost less, but you may not get a warranty.

Here is a table with warranty details for each part type:

Type of Part | Warranty Period | Additional Notes |

|---|---|---|

Genuine Parts | 4 years / 4,000 hours | For newer excavators. |

OEM Parts | 12 months / Unlimited | First buyer gets limited warranty. Extended warranty is possible. |

Aftermarket Parts | N/A | No set warranty terms. |

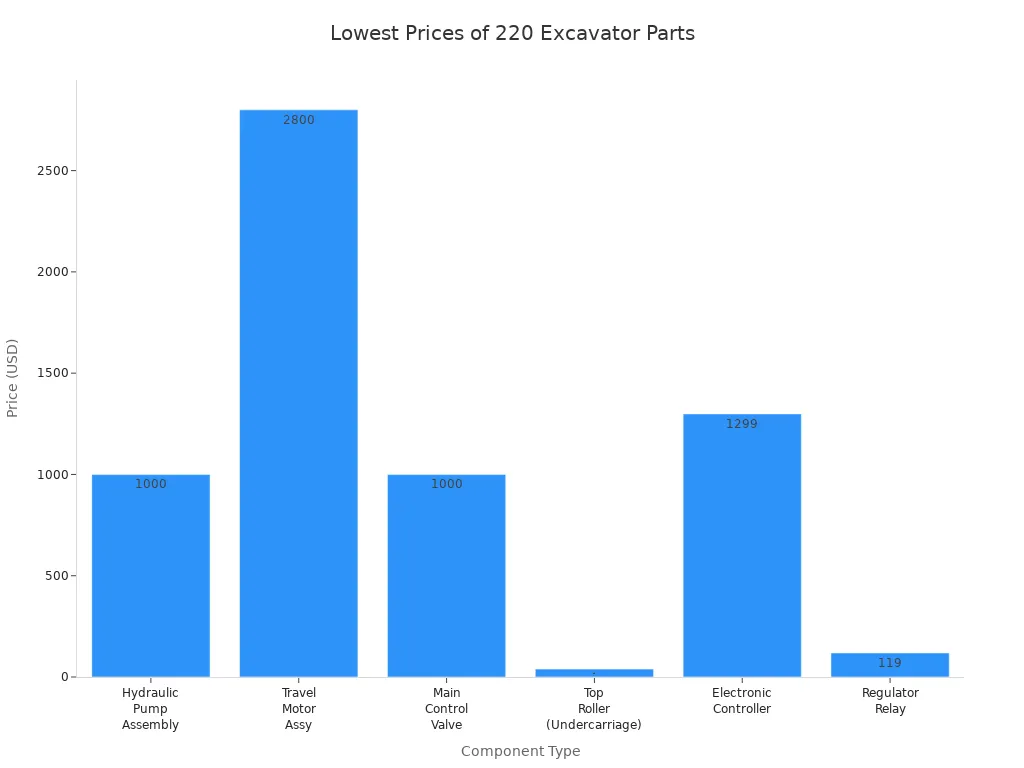

You also need to think about price. The chart below shows prices for common excavator parts:

If you want the best reliability and value, pick genuine or OEM parts. Aftermarket parts can work well if you choose trusted brands. Always match the part to your excavator and check the warranty before buying.

Note: Good parts help your excavator last longer and break down less. You save money and keep your job site safe.

Source Reliable Suppliers for 220 Excavator Parts

Evaluate Supplier Reputation

You want your excavator to work well for a long time. To make this happen, you need to pick a good supplier for your 220 excavator parts. Not every supplier is the same. Some give better service and higher quality. Some offer more help when you need it. Use the table below to check if a supplier is good for you:

Criteria | Description |

|---|---|

Supplier Credibility | Find vendors with business licenses and a strong name. |

Customer Feedback | Read reviews to see if buyers got the right excavator parts. |

Quality Standards | Make sure the supplier follows ISO rules and gives test reports. |

Technical Support Availability | See if the supplier helps you after you buy parts. |

Mean Time Between Failures | Ask how long their excavator parts last compared to others. |

You can use this checklist:

Pick suppliers with real business licenses.

Read what other customers say about their excavator parts.

Ask if the supplier meets quality standards.

Make sure you can get help if you have a problem.

A good supplier helps you feel safe. You know your excavator will get the right parts and work well.

Review Warranty and Support

Always check the warranty and support before you buy excavator parts. Good support means you get help fast if something breaks. Some suppliers give help with repairs and maintenance. Others let you track your excavator with special tools.

“We know Canadian mini excavators work in tough places. We make parts that last and work well. We help you get parts fast and give support when you need it.”

Here are things to look for:

How long the warranty lasts and what it covers.

Support services like ProCare for repairs and maintenance.

Tools to track your excavator and find problems early.

If you pick a supplier with strong support, you fix your excavator faster. You spend more time working and less time fixing. This helps you finish projects and save money.

Maintain and Inspect Excavator Parts

Regular Inspection Tips

You need to check your excavator often. Look for worn parts, loose bolts, or leaks. Make a schedule so you remember to inspect it. Write down every check and fix in a notebook. This helps you see problems and plan repairs.

Look for weak hydraulic arms and oil leaks.

Watch for hot pumps or slow boom movement.

Clean tracks after each shift to stop dirt buildup.

Turn sprockets and check track tension.

Check rollers and undercarriage for early wear.

Tip: Cleaning your excavator and using it carefully helps it last longer.

Here is a table that shows when to do important maintenance:

Maintenance Task | Recommended Frequency | Effect on Lifespan |

|---|---|---|

Oil & Filter Change | Every 250–500 hours | Stops inside parts from wearing out |

Undercarriage Inspection | Every 500 hours | Stops parts from wearing too soon |

Coolant & Hydraulic Fluid Check | Every 1,000 hours | Stops breakdowns |

Your excavator parts last longer if you do not overload them. Use smooth moves when you drive. Sharp turns and backing up too much can hurt the undercarriage.

Avoid Common Mistakes

Many people make mistakes that break their excavator. You can stop these problems if you know what to look for.

Starting problems can happen from weak batteries or bad spark plugs.

Hydraulic system trouble can cause slow movement, leaks, or overheating.

Track problems can make your excavator move slowly or go off course.

Electrical problems, like dead batteries or broken connectors, stop your work.

Engine trouble can show as less power or smoke from dirty filters.

Stress on the boom or arm can break parts.

Cooling system problems can make your excavator get too hot.

Loud noises or shaking can mean hydraulic trouble or worn parts.

Note: Always look for these signs when you inspect your excavator. Finding problems early saves you time and money.

You keep your excavator safe and working well by following these tips. Checking and fixing things often helps you avoid big repairs and long delays.

You can keep your excavator working well by picking the right 220 excavator parts. Always make sure the parts fit your machine and job. Good suppliers give you quality parts and help you avoid problems. Checking and caring for excavator spare parts saves money on repairs. Look at this table to see how taking care of spare parts helps:

Maintenance Practice | Benefit |

|---|---|

Regular Inspection and Cleaning | Stops dirt from building up and wearing out parts. |

Teeth Replacement and Rotation | Makes parts wear evenly and last longer. |

Pin and Bushing Lubrication | Cuts down rubbing, so parts do not break as fast. |

Wear Monitoring and Early Warning | Lets you fix things early and avoid big repairs. |

Professional Recommendations | Helps you take care of your machine and keep it working longer. |

When you buy 220 excavator parts from good suppliers, you get these good things:

Benefit | Description |

|---|---|

Quality Assurance | Makes sure parts are made right and do not break easily. |

Risk Mitigation | Uses ways to lower buying risks, like checking parts before buying. |

Operational Efficiency | Makes getting parts easier and helps your excavator work more and break less. |

Check your excavator spare parts and how you buy them. Make smart choices for your 220 excavator parts to keep your machine working its best.

FAQ

What information do you need before ordering 220 excavator parts?

You need your excavator’s make, model, and serial number. Write these down before you contact a supplier. This helps you get the right parts and avoid mistakes.

How do you know if a part fits your 220 excavator?

Check the part number in your operator’s manual. Match it with the supplier’s listing. If you see a difference, ask the supplier for help.

Should you choose genuine, OEM, or aftermarket parts?

Genuine and OEM parts offer the best fit and reliability. Aftermarket parts can save money, but quality varies. Read reviews and check warranties before you buy.

How often should you inspect your excavator parts?

Inspect your excavator every 250–500 hours. Look for wear, leaks, and loose bolts. Regular checks help you catch problems early and keep your machine running.

What should you do if you notice a problem with a part?

Stop using your excavator. Contact your supplier or a technician. Fixing issues early prevents bigger repairs and saves money.