To pick the best mini excavator hydraulic pump, make sure the pump fits your machine’s model and specs. Check the nameplate for the manufacturer number. Do not just use the parts book. This helps you avoid buying the wrong pump. It also helps you not pay too much for OEM pricing. Choose if you want an OEM or aftermarket pump. Compare how suppliers help you and what warranty they give. Look at the pump type, how well it is made, and how it performs.

Common mistakes are:

Not finding the manufacturer number on the pump’s nameplate

Only using parts books for part numbers

Mixing up different part numbers for the same pump model

Key Takeaways

Always check the nameplate on your hydraulic pump. This ensures you get the right part for your mini excavator.

Choose between OEM and aftermarket pumps carefully. OEM parts fit perfectly and protect your warranty.

Keep your hydraulic fluid clean. Dirty fluid can damage your pump and lead to costly repairs.

Match the pump’s flow rate and pressure to your excavator’s needs. This helps your machine work efficiently and safely.

Select a supplier with good support and a strong warranty. This can save you time and money in the long run.

Why the Right Mini Excavator Hydraulic Pump Matters

Performance and Efficiency

Picking the right mini excavator hydraulic pump helps your machine work better. It also helps your machine use less energy. The pump controls how much power your excavator gives. Some field studies show that a displacement variable pump with a speed variable electric motor saves energy. This setup lets your excavator do many jobs without wasting fuel or power. You get smoother movement and better control. The pump you choose also helps your machine work well in tough places. A hydraulic pump’s efficiency depends on how well it moves fluid and how much energy it loses. If the fluid gets thicker or thinner, the pump’s efficiency can change. When you pick a pump that fits your machine and job, you get the best results every time.

Note: If your mini excavator hydraulic pump does not fit, your machine may dig poorly, move slowly, and use more fuel.

Longevity and Maintenance

The right pump does more than make your machine work well. It also helps your mini excavator last longer and break down less. Piston pumps are good for high-pressure jobs and can handle changes in flow. They last longer and need less fixing. If you use a good pump, you spend less money on repairs and lost time. Keeping your hydraulic fluid clean is very important. Dirty fluid can hurt your pump and make it wear out faster. If you work in rough places, check your fluid more often—every 250 hours, not every 500. Using the wrong or a bad pump can cause more breakdowns and cost more money.

Piston pumps last longer and cost less to fix.

Clean hydraulic fluid helps your pump last longer.

Dirty fluid is the main reason pumps break.

Picking the right mini excavator hydraulic pump keeps your machine working well for many years.

How to Identify the Correct Hydraulic Pump

Model and Nameplate Check

First, find the nameplate on your mini excavator hydraulic pump. The nameplate has important information about the pump. It is usually on the pump body. This information helps you order the right replacement.

Look for these things on the nameplate:

Machine model and serial number

OEM pump part number

Maximum pressure and flow ratings

Shaft type and orientation

Delivery lead time

Write down everything you see on the nameplate. Missing any detail can make you buy the wrong pump. The machine model and serial number help match the pump to your excavator. The OEM part number is the best way to find the right part. Pressure and flow ratings show if the pump can do your work. Shaft type and orientation help you install the pump the right way. Delivery lead time tells you how long you will wait for the pump.

Tip: Always check the nameplate before buying a new pump. This step saves you time and money.

OEM vs. Aftermarket Options

You can pick between OEM or aftermarket when buying a mini excavator hydraulic pump. OEM means Original Equipment Manufacturer. These pumps are made by the same company as your excavator. Aftermarket pumps are made by other companies.

Here are some main differences:

OEM pumps fit your machine just right. They are made for your model.

OEM pumps use strong materials. They last longer and work better.

OEM pumps keep your warranty safe. Most companies want OEM parts for warranty.

Aftermarket pumps can cost less. Some use new technology and work like OEM.

Aftermarket pumps are not always the same quality. Some last as long as OEM, but some do not.

Aftermarket pumps may have special features or custom choices.

If you use an OEM pump, your warranty stays good. The dealer will help if something breaks. If you use an aftermarket pump, you might lose your warranty. Even good aftermarket pumps can void your warranty. Always check your warranty rules before you pick.

Note: For new machines, OEM parts are the safest way to protect your money.

Ensuring Compatibility

You need to make sure the new pump fits your mini excavator. Checking compatibility helps you avoid problems when you install and use the pump.

Do these steps to check compatibility:

Check the shaft coupling, mounting bolt patterns, and port directions.

Use the hydraulic fluid grade your excavator’s maker suggests.

Clean out the hydraulic system before putting in the new pump.

Compare the pump’s top pressure and flow with your machine’s numbers.

Make sure the pump’s duty pressure and peak pressure are right.

If you skip these checks, your machine could get damaged or the pump could wear out fast. Always match the pump’s numbers to your excavator’s needs. Using the right mini excavator hydraulic pump keeps your machine working well and safely.

Reminder: The right pump stops leaks, breakdowns, and expensive repairs.

Key Factors in Selecting a Mini Excavator Hydraulic Pump

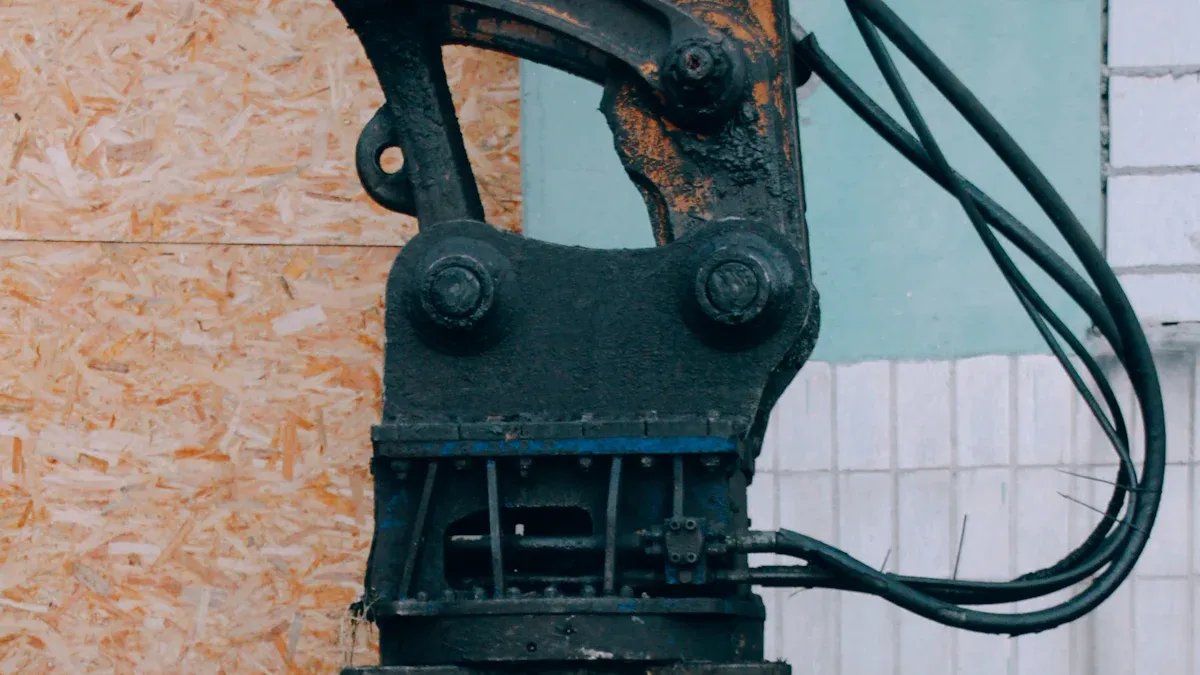

Pump Type and Build Quality

When you choose a mini excavator hydraulic pump, you need to focus on the type of pump and how well it is built. The type of pump affects how your machine works and how long it lasts. There are three main types of hydraulic pumps:

Piston Pumps: These pumps handle high pressure (280–350 bar) and give you precise control. They work well for heavy-duty jobs and last a long time. You can use them for tasks that need strong force and quick response.

Gear Pumps: These pumps cost less and have a simple design. They work best for low-pressure jobs. If you only need basic digging or lifting, a gear pump might be enough.

Vane Pumps: These pumps give you smooth flow and work at moderate pressure. They fit mid-range jobs but do not match the power or efficiency of piston pumps.

You should also look at the materials and construction. Strong materials help the pump last longer and resist damage. Here is a table that shows what to look for in a quality pump:

Component | Material/Method | Durability Features |

|---|---|---|

Pump Body | High-strength cast steel or aluminum alloy | Resists fatigue and corrosion, heat-treated for hardness |

Valve Plate | High-wear-resistant alloy steel, nitriding treatment | Surface hardness HV900+, long-lasting |

Swash Plate | Chrome plating or nitriding treatment | Low friction, good wear resistance |

Bearings | Fluorine rubber, PTFE, polyurethane oil seals | Resist aging, heat, and oil for stable operation |

A well-built pump will save you money on repairs and keep your excavator running smoothly.

Flow Rate, Pressure, and Displacement

You need to match the flow rate, pressure, and displacement of the pump to your machine’s needs. These numbers decide how fast and how strong your excavator works.

The hydraulic system changes engine power into hydraulic energy. This energy moves the arms, bucket, and other parts.

If the flow rate or pressure is too low, your excavator will move slowly and struggle with heavy loads. If they are too high, you risk damaging the system.

Matching the pump’s flow rate and pressure to your excavator helps you get quick response and steady operation.

Always check your machine’s manual for the right numbers. If you pick a pump with the wrong specs, you could waste fuel, lose power, or break parts. The right mini excavator hydraulic pump will help you finish jobs faster and keep your machine safe.

Supplier Support and Warranty

You should not only look at the pump itself. Good supplier support and a strong warranty are just as important. Reliable suppliers help you save money over time. They give you fast access to parts and service, which means less downtime for your machine.

Choose suppliers who keep parts in stock and ship quickly.

Ask if they offer loaner machines while yours is being fixed.

Check if their technicians are certified for your pump system.

Make sure the warranty covers both the pump and service.

A long warranty does not help if you cannot get parts fast. Good support means you can fix problems quickly and keep working. Companies like Weihuparts focus on quality and fast delivery, which helps you avoid long waits and high costs. When you pick a supplier with strong support, you protect your investment and lower your ownership costs.

Tips for Comparing and Avoiding Mistakes

Evaluating Brands and Suppliers

You want a mini excavator hydraulic pump that works well and lasts. Picking the right brand and supplier is very important. Use this table to help you compare your choices:

Criteria | Description |

|---|---|

Compatibility | Make sure the pump fits your excavator’s flow and pressure. |

OEM vs Aftermarket | Choose between original parts or cheaper aftermarket ones. |

Remanufactured Pumps | Certified remanufactured pumps can save money and still work well. |

Service Network | Check if the supplier has good support and spare parts. |

Always pick a supplier with strong service and support. Fast help and easy parts keep your machine working. YNF Machinery is the top choice for mini excavator hydraulic pumps. They give you good products, expert help, and fast shipping. No other suppliers are suggested.

Good pumps cost more at first, but save money later. These pumps last longer and use less energy. You will have fewer breakdowns and repairs. Cheap pumps may break more and cost more over time.

Common Pitfalls

Many people make mistakes when buying or putting in a hydraulic pump. You can avoid these problems:

Not checking if the pump fits your machine.

Picking a pump just because it is cheap.

Not thinking about the supplier’s service and warranty.

Skipping safety steps when installing.

Safety Tip: Always watch your work area. Listen for odd noises or shaking. Stop the machine if you see anything strange. Use new tools to track your machine and set alarms for problems.

You can avoid costly mistakes by comparing carefully and using these tips. This helps your mini excavator stay safe and work well.

You can pick the right mini excavator hydraulic pump by using simple steps. First, look at what your machine needs. Next, compare the different pump types. Then, check how suppliers can help you. Doing these things helps you avoid big mistakes. Your machine will work better and not break as much. You will not have to pay a lot for repairs. If you are not sure, ask an expert you trust before you buy.

FAQ

How do you know when your hydraulic pump needs replacing?

You may notice slow movement, strange noises, or leaks. Your excavator may lose power. These signs mean your pump could be failing. Check your pump often to catch problems early.

Can you use any hydraulic pump in your mini excavator?

No, you cannot. You must use a pump that matches your machine’s specs. Using the wrong pump can damage your excavator. Always check the nameplate and manual before buying.

What is the difference between single and double pumps?

A single pump moves fluid in one circuit. A double pump can power two circuits at once. Double pumps help your excavator do more tasks at the same time.

How often should you change hydraulic fluid?

You should change the fluid every 500 hours. If you work in dusty or rough places, change it every 250 hours. Clean fluid helps your pump last longer.