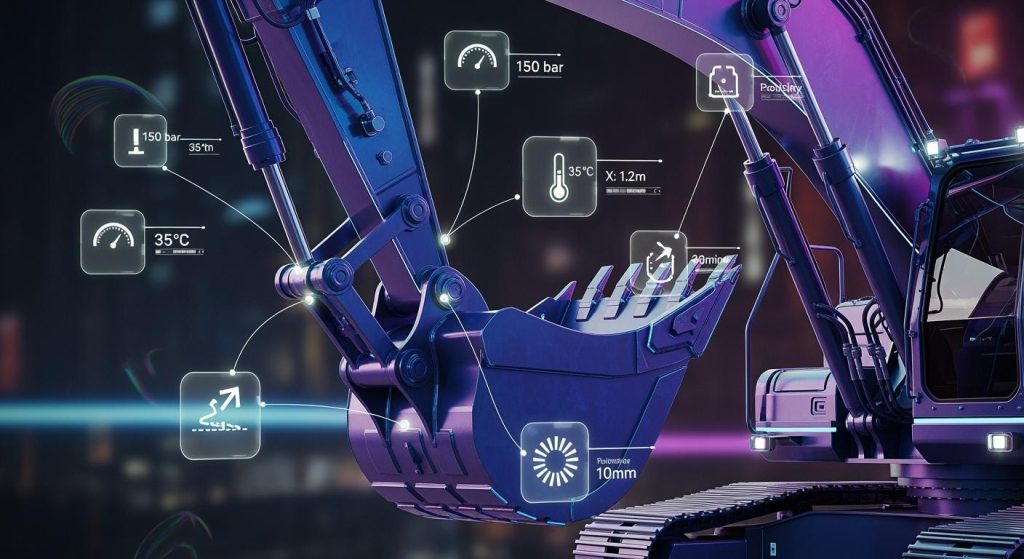

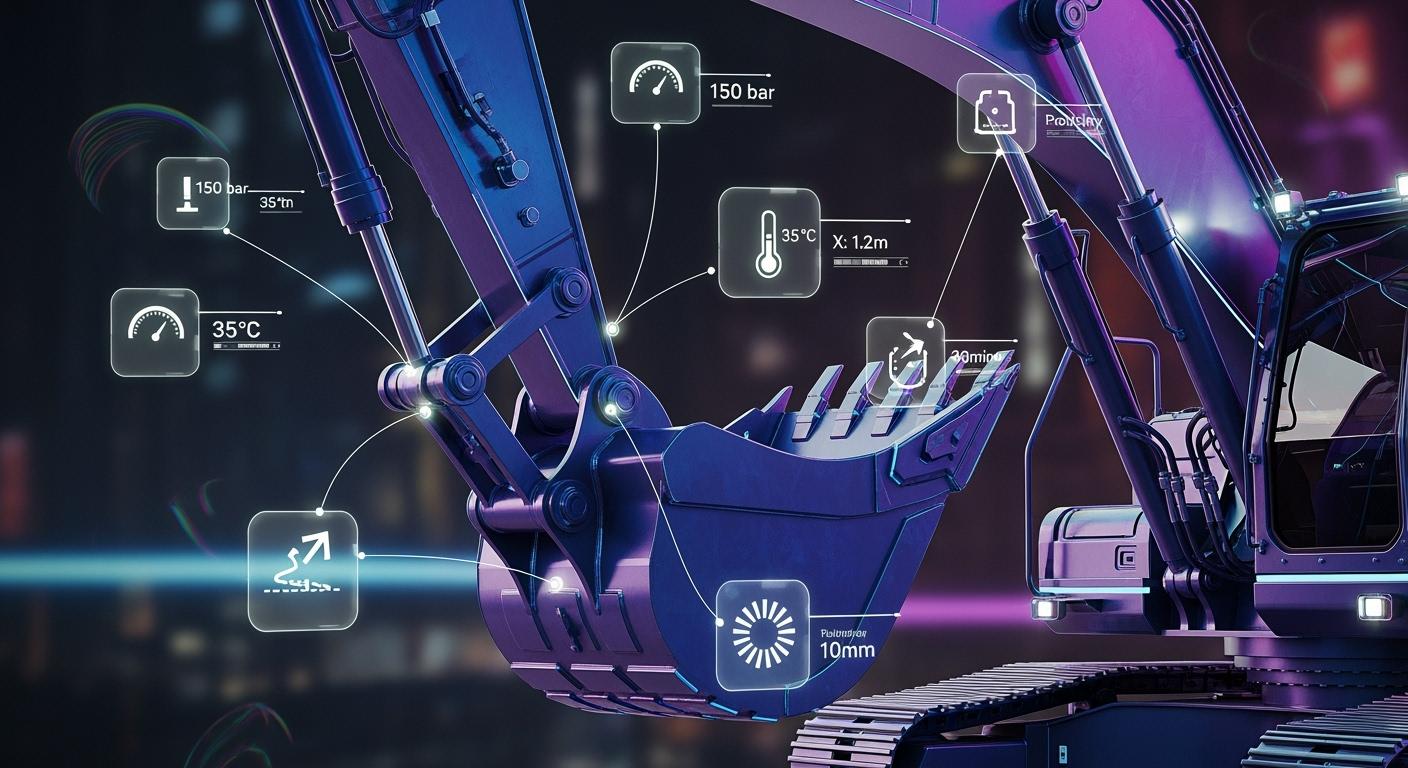

You can find many types of sensor for excavator parts. These sensor for excavator parts help the equipment operate safely and efficiently. Some common sensor for excavator parts include hydraulic pressure sensors, oil pressure sensors, temperature sensors, revolution sensors, proximity sensors, fluid level sensors, accelerometers, geophones, rotary encoders, and linear displacement sensors. Reports show that modern excavators use sensor for excavator parts such as pressure sensors, temperature sensors, speed sensors, position sensors, diagnostic sensors, level sensors, flow sensors, coolant sensors, optical sensors, and gas sensors. Each sensor for excavator parts monitors important functions. Sensor for excavator parts make the equipment safer and also assist with maintenance.

Key Takeaways

Sensors help keep people safe by giving quick warnings about dangers. This helps stop accidents from happening at work sites. Checking and taking care of sensors often can stop sudden problems. It also helps your excavator last longer. Sensors can help save money by finding problems early. This is called predictive maintenance. There are many kinds of sensors, like pressure and temperature sensors. These sensors watch important parts to make sure excavators work well. Buying better sensors makes your excavator work more accurately and faster. This makes your machine more useful and trustworthy.

Main Types of Sensors for Excavator Parts

Hydraulic Pressure and Oil Pressure Sensors

Pressure sensors help keep your excavator safe. Hydraulic pressure sensors check the force inside the hydraulic system. You usually see these sensors on the boom and arm. They warn you if the load is too heavy or too light. This helps you change the load for better safety. Hydraulic pressure sensors also help with advanced controls. Volvo Active Control is one example. It makes using the machine easier.

Oil pressure sensors protect your engine. These sensors watch the oil pressure in the lubrication system. If the oil pressure drops, the sensor warns you fast. This helps you stop engine damage. Low oil pressure can happen from a blockage or sensor problem. It can cause big engine trouble. You need these sensors to keep your excavator working well. They help you avoid expensive repairs.

Tip: Check your pressure sensors often. Make sure they work right. This can help you avoid sudden breakdowns.

Manufacturers test sensors in tough conditions. They use mechanical tests and load simulations. This makes sure sensors last a long time. The table below shows how they test reliability:

Test Method Description |

|---|

Mechanical tests under real conditions |

Measurement technology matches forces with load conditions |

Load tests simulate years of use in a few weeks |

Special sensor designs give accurate data in harsh environments |

Strain gauges measure steel part deformation with high accuracy |

Temperature and Fluid Level Sensors

Temperature sensors help keep your excavator safe. You find temperature sensors in the engine and hydraulic system. The coolant temperature sensor checks engine heat. The hydraulic oil temperature sensor checks fluid heat. If the temperature gets too high, these sensors warn you. This helps you stop the machine before it overheats.

Fluid level sensors measure oil or coolant in the tank. These sensors tell you when to add more fluid. If you ignore low fluid levels, you can hurt the engine or hydraulic system.

Humidity sensors also protect your excavator. High humidity can cause electrical parts to short-circuit. It can send wrong signals. Dust can build up on moving parts. This makes them harder to move. It can affect force sensors. Keep sensors clean and dry for best results.

Environmental Factor | Effect on Sensor Accuracy |

|---|---|

Humidity | Can cause short-circuits and signal problems |

Dust | Increases friction and affects movement and force transmission |

Most heavy equipment sensors are built for tough jobs. Temperature sensors work in wide temperature ranges. Some work from -20° to 85° F. Others work from -40° to 150° F. They resist vibration and electrical noise. You can trust them in harsh places.

Revolution and Proximity Sensors

Revolution sensors measure how fast excavator parts move. Speed sensors are another name for them. The timing gear sensor is one example. It gives the ECU information about engine speed and timing. If one sensor fails, the engine still runs but with less power. If both sensors fail, the engine will not start. You need these sensors to keep the engine at the right speed.

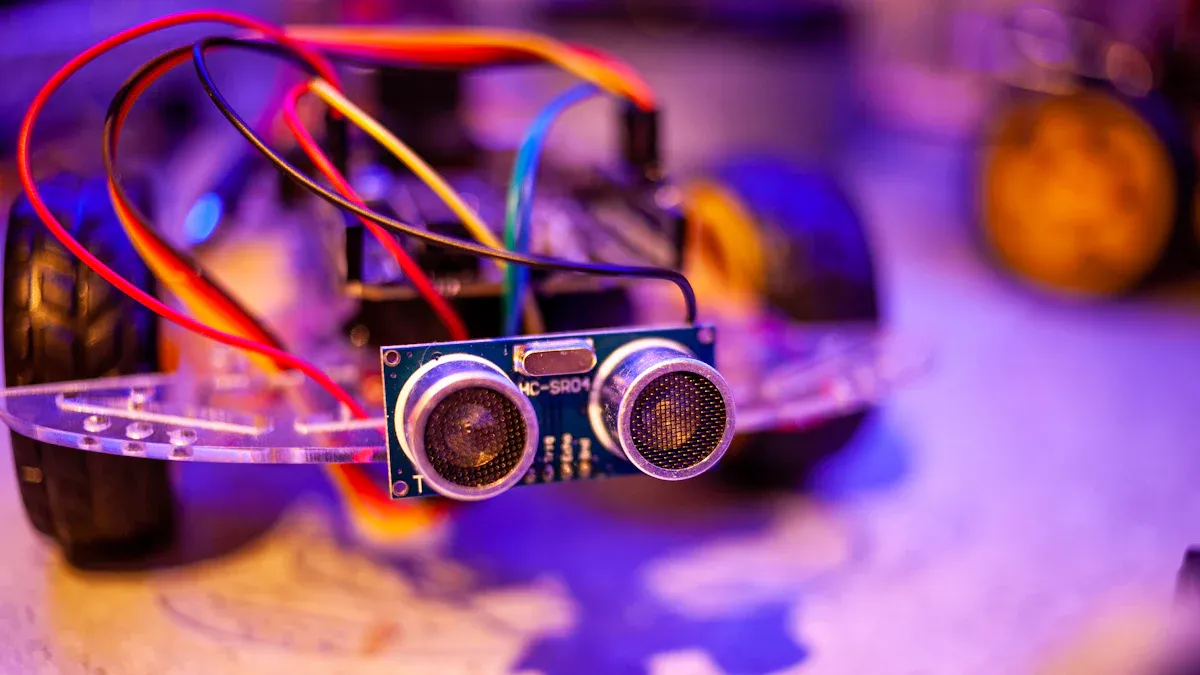

Proximity sensors help keep you safe in small spaces. These sensors warn you if something gets too close. They use ultrasonic or LiDAR to find obstacles, workers, or equipment. You get alerts in real time. This helps you avoid accidents. Studies show proximity sensors lower incidents on job sites.

Note: Proximity sensors help you see better in hard-to-see areas. They make your worksite safer for everyone.

Some excavators have inclination sensors and force sensors. Inclination sensors measure the angle of the machine. Force sensors check how much force is used. Both help you work safely and accurately.

Most sensor for excavator parts last as long as the machine. Sensors are made for long-term use. You do not need to replace them often.

Component | Lifespan |

|---|---|

Sensors | Designed for long-term use |

Wiring Harnesses | Last the equipment’s life |

Control Panels | Last the equipment’s life |

Using the right sensors helps your excavator work better. Heavy equipment sensors give you important information. This helps you make smart choices every day.

Position and Movement Sensors in Heavy Equipment

Rotary Encoders and Linear Displacement Sensors

Rotary encoders and linear displacement sensors help track movement. Rotary encoders measure how much something turns or spins. They send digital signals to the control system. This lets you know where the excavator arm or bucket is. For example, AHM36 CANopen absolute encoders in tilt rotators help move the bucket very accurately. You do not need to move the machine as much. This saves time and makes work faster.

Linear displacement sensors measure straight movement. They use a transducer and a scale to see how far a part moves. You can compare rotary encoders and linear displacement sensors in the table below:

Feature | Rotary Encoders | Linear Encoders |

|---|---|---|

Motion Type | Rotational motion | Linear motion |

Application | Motor speed, robotics | Linear motors, metrology |

Construction | Rugged design | Varies in size and complexity |

Both sensors help you control the excavator well. Rotary encoders tell you the arm’s position and angle. This keeps your work safe and correct. Linear displacement sensors make sure moving parts work together. You can trust these sensors for jobs that need high accuracy, like digging or lifting.

Accelerometers and Geophones

Accelerometers and geophones watch for vibration and ground movement. Accelerometers are vibration sensors. They learn what normal vibrations look like by collecting data. When the machine works, they check real-time data against the normal data. If something changes, they warn you about problems. This helps you find issues before damage happens.

Geophones are also vibration sensors. They find tiny movements in the ground during excavation. You can use them to measure vibrations from building work. Geophones are sensitive and pick up small vibrations. They help protect buildings and keep people safe.

Tip: Use current sensors with these systems to check electricity flow. Current sensors help you find electrical problems early. You can stop breakdowns and keep your excavator working well.

Position sensors, vibration sensors, and current sensors help with automation. They give you real-time data for machine control. You can use this data to automate digging, lifting, and moving. This makes your work faster, safer, and more efficient.

Why Sensors Matter for Excavator Operation

Safety and Efficiency Benefits

Sensors help keep everyone safe at work. They give you alerts right away to stop accidents. Sensors can find obstacles and check how heavy a load is. These features protect you and your team. You can see how sensors make things safer in the table below:

Safety Improvement | Description |

|---|---|

Real-time pedestrian detection | AI systems spot people fast, so you get alerts only when needed. |

Instant alerts to operators | You hear or see warnings as soon as someone enters a danger zone. |

360° coverage | Sensors watch all around the excavator, so you have fewer blind spots. |

Heatmaps for risk assessment | You can see risky areas and change your workflow to stay safe. |

Reduction in near-misses | Fewer close calls happen when you use these sensors. |

Improved operator focus | Alerts help you pay attention and feel less tired. |

Insurance savings | Fewer accidents mean you save money on insurance. |

Sensors also help you use less fuel. Telematics systems let you check fuel use as you work. These systems make reports to show where you can do better. You can set goals and see how you improve. The ESCORT TD-BLE sensor gives you good fuel data. This helps you waste less and trust your machine more. When you use sensors to watch engine performance, your excavator works better every day.

Predictive Maintenance and Downtime Reduction

Predictive maintenance uses sensors to check your machine’s health all the time. This helps you find problems early, like low oil pressure or high temperature. You can fix small problems before they get worse. Many companies have up to 30% less downtime with predictive maintenance. You also avoid repairs you do not need, which saves money.

Here are some benefits of predictive maintenance:

You have 73% fewer equipment failures.

You get 30-50% less downtime.

You spend 18-25% less on maintenance.

Your equipment lasts 40% longer.

The most common sensor failures that stop work are NOx sensors, DEF level sensors, and oil pressure sensors. You should check these sensors often to keep your excavator working well.

If you want good sensors for excavators, look at YNF Machinery. They have quality products to keep your equipment safe and working right.

You need sensors to help your excavator work well. Pressure, temperature, revolution, and position sensors keep it safe. Advanced sensors make your machine more exact. They help you make fewer mistakes. Buyers like machines with good sensors. This makes your excavator worth more.

Advanced sensors help you do jobs more accurately.

New features have proximity sensors, camera systems, and IoT for real-time safety.

Learn about new sensor technology. This helps your equipment stay safe and work its best.

FAQ

What does a hydraulic pressure sensor do in an excavator?

A hydraulic pressure sensor checks force in the hydraulic system. This sensor helps keep your machine safe. It also helps your excavator work well.

How do proximity sensors improve safety?

Proximity sensors warn you if something is too close. You get alerts before an accident can happen. These sensors help stop damage and protect workers.

Where can you find temperature sensors on an excavator?

Temperature sensors are in the engine and hydraulic system. They watch for overheating. You can stop the machine before it gets damaged.

Why should you check sensors often?

Tip: Check sensors often to find problems early. This helps you avoid breakdowns. It keeps your excavator working smoothly.