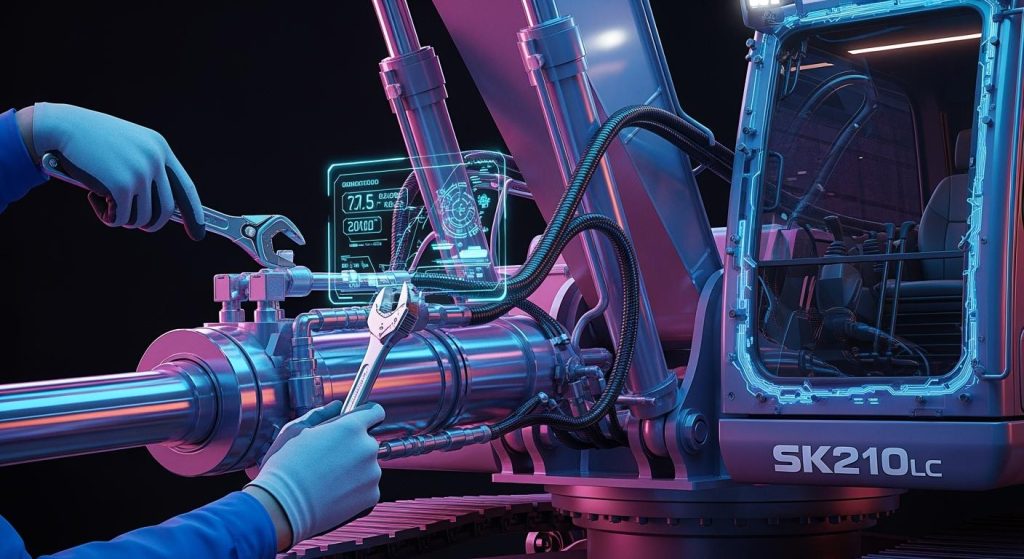

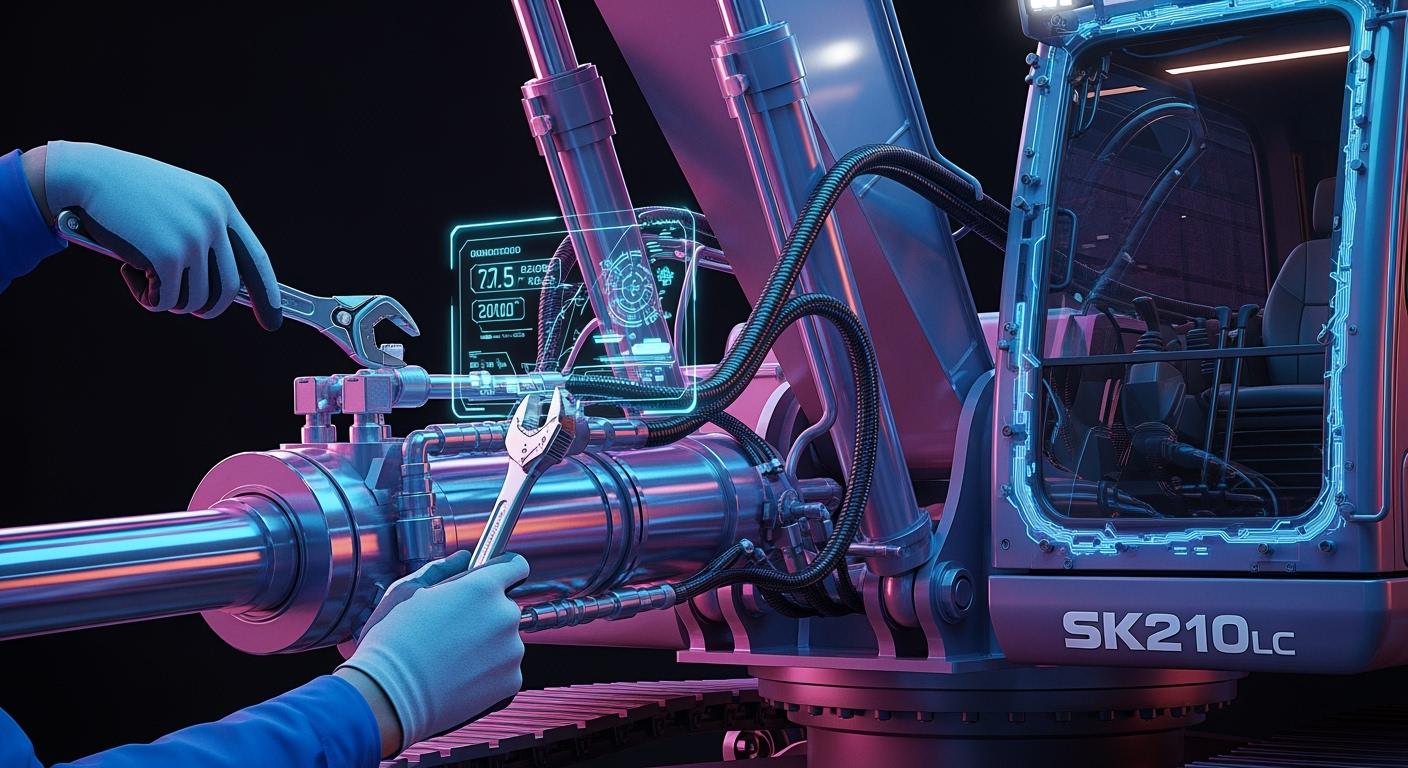

You can service SK210LC hydraulic parts by following easy steps. Use the service manual to stay safe and do things right. Bad maintenance causes 10% of hydraulic problems. Some dangers are fluid leaks and pinch points:

Hazard Type | Description |

|---|---|

Hydraulic Fluid Leaks | High-pressure fluid leaks can hurt people. |

Pinch Points and Moving Parts | Workers can get stuck and get crushed. |

Changing oil too soon or using the wrong fluids can hurt the system. Always look at the oil before you change it to ensure proper service for SK210LC hydraulic parts.

Key Takeaways

Always put safety first by wearing safety gear. Read the service manual before you work on hydraulic parts.

Pick the right hydraulic oil for your work conditions. This helps the machine work well and stops damage to the system.

Check for leaks often and test the system. This keeps your hydraulic system safe and working well.

Service Steps for SK210LC Hydraulic Parts

Preparation and Safety

Start by getting ready before you work on SK210LC hydraulic parts. Safety is very important. Read the Kobelco service manual and operator’s manual first. These books help you stay safe and avoid mistakes.

Get all your tools and safety gear. You need safety glasses or a face shield. Wear cut-resistant gloves and long sleeves. Use oil-resistant gloves when you touch fluids. Put on steel-toe boots. If the machine is running, use hearing protection. Arm guards keep you safe from high-pressure leaks. Wear long pants and other clothes that protect your skin.

Make your work area clean and bright. Wipe up spills and move things out of the way. Make sure you have enough light to see. Before you touch any hydraulic part, let out the pressure in the system. This step stops dangerous sprays and keeps you from getting hurt.

Tip: Keep a fire extinguisher close when you work with hydraulic fluids.

YNF Machinery gives you good SK210LC hydraulic parts. Their parts help you fix your machine safely.

Changing Hydraulic Oil

Changing hydraulic oil is an important job for SK210LC hydraulic parts. Pick the right oil for your weather and how hard you use the machine. Kobelco says to use ISO VG 32 for cold places. Use ISO VG 46 for most weather. Use ISO VG 68 for hot or heavy work. Perlus H 46 and Perlus AF 46 are good for normal weather. Perlus H 32 and Perlus AF 32 are best for cold places.

Follow these steps:

Park the machine on flat ground.

Turn off the engine and wait for all parts to stop.

Let the pressure out of the hydraulic tank.

Take out the drain plug and let the old oil go into a safe container.

Put the drain plug back in and fill the tank with new oil. Use a clean funnel.

Check the oil level with the dipstick.

Note: Do not mix different oil types. Mixing oils can hurt the system and make it work badly.

Measuring Wear and Clearances

You need to measure wear and clearances every time you work on SK210LC hydraulic parts. Good measurements help you find problems early. Use calipers to check bore and rod sizes. Micrometers give you exact rod size numbers. Use a measuring tape to find the cylinder stroke length. Bore gauges check the inside size of the cylinder tube. Seal identification kits help you pick the right seal size. Use a straight edge to see if rods are bent or twisted.

Write down your numbers. Look at the Kobelco service manual and compare your numbers. Change any part that does not match the standard.

Tip: Clean all parts before you measure. Dirt can mess up your numbers.

Lubrication and Maintenance Guidelines

Lubrication helps your hydraulic system work well. Use the right lubricants when you work on SK210LC hydraulic parts. Pick products that stop wear, rust, and oil breakdown. Here are some good lubricants:

Product Name | Description |

|---|---|

Hydraulic Oil Anti Wear | Gives great anti-wear help and keeps oil thick when hot. |

Bosse Lubricants™ AW32 Zinc-Free Hydraulic Oil | Works well, has no zinc, and fits many uses. |

Bosse Lubricants™ Premium AW100 Hydraulic Oil | Made from paraffin oils with anti-wear, rust, oil breakdown, and foam help. |

Bosse Lubricants™ Premium AW32 Hydraulic Oil | Made from paraffin oils with anti-wear, rust, oil breakdown, and foam help. |

Bosse Lubricants™ Premium AW46 Hydraulic Oil | Made from paraffin oils with anti-wear, rust, oil breakdown, and foam help. |

Bosse Lubricants™ Premium AW68 Hydraulic Oil | Made from paraffin oils with anti-wear, rust, oil breakdown, and foam help. |

Lubricate all moving parts after you clean them. Check seals and hoses for leaks. Change old seals so you do not lose fluid. Follow the Kobelco maintenance schedule for the best results.

YNF Machinery sells strong SK210LC hydraulic parts for all your repair jobs. Their parts help your machine stay safe and work well.

Reminder: Regular service for SK210LC hydraulic parts makes your excavator last longer and break down less.

Hydraulic Pump Removal and Installation

Releasing Pressure and Accessing the Pump

Let the pressure out of the hydraulic oil tank before you start. This keeps you safe from leaks and sprays. Park the SK210LC excavator on flat ground. Turn off the engine and wait for all parts to stop moving. Put on your safety gear. Use the service manual from kobelco to help you.

Here are the steps to get to the pump:

Take out six cap screws (M10×20) from the shield.

Remove the shield so you can see the suction filter assembly.

Take out the suction filter assembly.

Put in the suction plug to stop oil from leaking.

Remove the protective device.

Move anything that blocks the hydraulic pump.

Take off the bleed hose under the muffler.

Tip: Put all the parts you remove in a clean tray. This makes it easy to find them when you put things back together.

Hydraulic Pump Removal

You need to be careful when you remove the hydraulic pump. You have to disconnect hoses and pipes to take out the pump. Use wrenches and screwdrivers that fit the bolts and clamps.

Here is how you do it step by step:

Loosen the clamps and screws on the hoses.

Take off the two hoses used for moving the machine.

Remove the suction pipe and other hoses from the pump.

Take off the connector.

Remove the main pump from its place.

Alert: Some hoses might still have fluid inside. Drain them slowly so you do not spill oil.

Inspecting and Replacing Components

After you take out the pump, check all the parts for damage or wear. Look for leaks, rust, and small cuts on the rods. Check the cylinder head for signs of fluid loss. Listen for strange sounds from the pump. These noises can mean there is a problem inside.

Look for these types of wear:

Abrasive wear

Adhesive wear

Fatigue wear

Cavitation wear

Erosive wear

Corrosive wear

Test if the valves move smoothly and do not stick. Check the oil level and temperature every day. Look at hoses, pipes, and fittings every week for rust or cracks. Change filters when kobelco says to. Replace the hydraulic fluid if you see dirt or other things in it.

Note: Clean all the parts before you check them. Dirt can hide damage and make it hard to see problems.

Reassembly and Installation Steps

Put the hydraulic pump back in by doing the steps backwards. Make sure all the connections are tight and safe. Use alignment tools to check if everything fits right. You can use a straight edge for a quick check. Dial indicators give better results. Laser alignment is the best but costs more.

Method | Description | Accuracy Level | Cost Level |

|---|---|---|---|

Straight Edge | Look with a straight edge and feeler gauges | Least accurate | Lowest cost |

Dial Indicators | Gives exact numbers, needs some skill | Very accurate | Moderate cost |

Laser Alignment | Uses lasers and sensors for the best fit | Most accurate | Highest cost |

Tighten all bolts and clamps. Put the hoses and pipes back on. Install new filters if you need to. Fill the tank with new hydraulic fluid. Check for leaks when you finish.

Reminder: Always use the kobelco service manual for torque and tips. This helps you do things right and keeps your machine safe.

Final Checks and Testing Steps

Inspecting for Leaks and Proper Operation

After you finish reassembling the hydraulic system, you need to check for leaks and make sure everything works well. Start by wiping down all fittings, hoses, and connections. This helps you spot any new fluid leaks. Turn on the engine and let the system build pressure. Watch for drips or wet spots around the pump, hoses, and seals.

Leaks can happen for many reasons. You might see leaks if dirt or debris gets inside the system. High pressure or heat can also cause problems. Old seals and O-rings may crack or shrink. Sometimes, loose fittings let fluid escape. Damaged hoses can also lead to leaks. If you find a leak, stop the engine and fix the problem before you continue.

Tip: Use a clean piece of cardboard to check for leaks. Never use your hands because high-pressure fluid can hurt you.

System Testing and Troubleshooting

You should test the kobelco excavator’s hydraulic system before you return it to work. Move the controls slowly and listen for strange noises. The system should run smoothly without jerks or delays. Check the pressure gauge and make sure it matches the numbers in the kobelco manual.

If you notice weak movement or slow response, look for air in the lines or low fluid levels. Unusual sounds may mean a problem with the pump or valves. If you see foam in the oil, you might have a leak in the suction line. Always fix these issues before you use the machine again.

Common Issue | What to Check First |

|---|---|

Weak operation | Fluid level, air in system |

Noisy pump | Loose parts, worn bearings |

Jerky movement | Air, sticky valves |

Regular testing keeps your hydraulic system safe and reliable.

You help your SK210LC hydraulic system stay strong by following each service step carefully. Always use the service manual for every job you do. Look at the table below for tips that make your machine last longer:

Maintenance Tip | Description |

|---|---|

Cleaning and Flushing | Clean parts and flush the system to keep dirt out. |

Filter Replacement | Change filters often to keep parts safe. |

System Calibration | Adjust valves and regulators so things do not break early. |

Record Keeping | Write down repairs and checks to help plan next service. |

Operator Training | Learn the right way to do maintenance for the best results. |

For regular care, remember these steps:

Check oil for dirt and change it when needed.

Keep dust away from places where it can get in.

Look at rods, seals, hoses, and fittings for damage.

Watch fluid levels and system temperature.

Clean breathers and change filters often.

Be safe. If you are not sure what to do, ask a professional for help.

FAQ

How often should you check hydraulic fluid levels?

You should check fluid levels every day before you use your machine. This helps you spot leaks early and keeps your system working well.

What tools do you need for hydraulic pump removal?

Wrenches

Screwdrivers

Alignment tools

Safety gloves

Clean tray for parts

Why does your hydraulic system make noise?

Cause | Solution |

|---|---|

Air in lines | Bleed the system |

Worn pump | Replace the pump |

Loose parts | Tighten fittings |