Choosing the wrong salvage mini excavator parts can lead to serious problems. You might face unexpected downtime, waste money on replacements, or even damage your equipment. To avoid these headaches, focus on finding parts that match your excavator perfectly. Quality matters too—poorly inspected parts can fail quickly. Always source from trusted suppliers like YNF Machinery, who ensure reliability. When done right, salvaged parts offer great value. They save costs and keep your machine running smoothly without compromising performance.

Key Takeaways

Always verify compatibility by checking your mini excavator’s make, model, and serial number before purchasing salvaged parts.

Inspect salvaged parts thoroughly for visible damage, wear, or corrosion to avoid costly repairs and downtime.

Prioritize quality over price; investing in reliable parts from trusted suppliers like YNF Machinery ensures better performance and longevity.

Research suppliers and read reviews to find reputable sources that offer warranties and clear return policies.

Consider the long-term value of salvaged parts; they can save you money and reduce downtime compared to new parts.

Seek expert advice from suppliers to ensure you choose the right parts and avoid common mistakes.

A thorough inspection and understanding of a part’s history can help you make informed decisions and maintain your excavator’s efficiency.

Common Mistakes When Choosing Salvaged Mini Excavator Parts

Neglecting to Verify Compatibility and Fit

One of the biggest mistakes you can make when buying used parts is skipping the compatibility check. Every mini excavator has specific requirements, and not all salvaged parts will fit your machine. If you don’t verify the make, model, and serial number of your excavator, you risk purchasing a part that doesn’t work. This can lead to wasted money and additional downtime.

To avoid this, always double-check the part numbers and specifications. Consult your equipment manual or reach out to a trusted supplier like YNF Machinery. They can guide you in finding the right salvage mini excavator parts for your machine. Remember, a perfect fit ensures your excavator operates smoothly and efficiently.

Overlooking Quality and Condition of Salvaged Mini Excavator Parts

Quality matters when it comes to salvaged parts. Some salvage yards don’t inspect their inventory thoroughly, which means you could end up with a damaged or worn-out component. A poorly maintained part can fail quickly, causing more harm than good to your excavator.

Before making a purchase, inspect the part closely. Look for visible signs of wear, cracks, or corrosion. If possible, ask about the part’s history—how it was used and whether it underwent any repairs. Reliable suppliers like YNF Machinery ensure their parts meet high-quality standards, giving you peace of mind. Never compromise on quality, as it directly impacts the performance and longevity of your equipment.

Focusing Solely on Price Over Value

It’s tempting to go for the cheapest option when buying used parts, but focusing only on price can backfire. Low-cost parts might save you money upfront, but they often come with hidden risks. Poor quality or incorrect parts can lead to frequent replacements, costing you more in the long run.

Instead, think about value. A slightly higher-priced part from a reputable supplier offers better durability and reliability. Trusted sources like YNF Machinery provide parts that balance cost and quality, ensuring you get the most out of your investment. Always weigh the long-term benefits over short-term savings.

Buying from Unverified or Unreliable Sources

Purchasing from unverified or unreliable sources can lead to a host of problems. You might end up with damaged or incorrect parts, and returning them could be impossible if the seller has a no-return policy. Some sellers don’t inspect their inventory thoroughly, leaving you with parts that may have hidden defects or wear. Without proper checks, you risk wasting money on components that fail quickly or don’t fit your excavator.

To avoid these pitfalls, always research the supplier before making a purchase. Look for reviews or testimonials from other buyers. Reliable suppliers, like YNF Machinery, ensure their salvage mini excavator parts meet high-quality standards. They also provide clear return policies and warranties, giving you peace of mind. When you buy from a trusted source, you reduce the chances of costly mistakes and ensure your equipment performs as expected.

Failing to Inspect Mini Excavator Tracks and Other Parts Before Purchase

Skipping the inspection step is another common mistake. Used parts, especially mini excavator tracks, can have hidden damage that isn’t immediately visible. Cracks, corrosion, or excessive wear can compromise the part’s performance and lifespan. If you don’t inspect the parts thoroughly, you might end up with components that fail prematurely, leading to more downtime and expenses.

Before buying, take the time to examine the parts closely. Check for visible signs of damage, such as cracks or rust. If possible, test the functionality of the part. Ask the seller about its history—how it was used and whether it underwent any repairs. Trusted suppliers like YNF Machinery often provide detailed information about their parts, ensuring transparency. A careful inspection helps you make informed decisions and keeps your excavator running smoothly.

A Buyer’s Guide to Ensuring Compatibility with Your Mini Excavator

Identifying the Make, Model, and Serial Number

Understanding your mini excavator is the first step in finding the perfect fit for salvaged parts. Every machine has unique specifications, and knowing these details ensures you pick the right tracks or other components. Start by locating the make, model, and serial number of your excavator. These identifiers are usually found on a metal plate attached to the machine. If you’re unsure where to look, check the operator’s manual for guidance.

Having this information handy simplifies the process of choosing the right excavator parts. It helps you avoid mismatched components that could lead to costly downtime. When you know your machine inside and out, you’re already ahead in ensuring compatibility.

Matching Part Numbers and Models for a Perfect Fit

Matching your mini excavator tracks or other parts to the correct part numbers is crucial. Manufacturers design parts to fit specific models, so even a slight mismatch can cause issues. Before making a purchase, compare the part number on the salvaged component with the one listed in your equipment manual. This step ensures you’re selecting the right track pattern or other parts that align perfectly with your machine.

If you’re struggling to match part numbers, don’t hesitate to consult a trusted supplier. Experts like YNF Machinery can guide you through the process, helping you avoid mistakes. Finding the perfect fit isn’t just about functionality—it’s about keeping your excavator running smoothly and efficiently.

Consulting Equipment Manuals or Manufacturer Guidelines

Your equipment manual is a treasure trove of information when it comes to compatibility. It provides detailed guidelines for selecting the right excavator parts, including specifications for tracks, engines, and other components. If you’ve misplaced your manual, many manufacturers offer digital copies on their websites. These resources are invaluable for matching your mini excavator tracks or other parts accurately.

Manufacturer guidelines also help you understand the importance of selecting the right track pattern for your machine’s intended use. Whether you’re working on soft soil or rocky terrain, the right pattern enhances performance and durability. By following these guidelines, you ensure your excavator operates at its best.

“The key to compatibility lies in understanding your machine and using the resources available to you.”

Taking the time to research and verify ensures you’re not just buying parts—you’re investing in the longevity and efficiency of your equipment.

Seeking Expert Advice from Trusted Suppliers Like YNF Machinery

When you’re unsure about which salvaged mini excavator parts to choose, turning to a trusted supplier can save you time and effort. Experts like YNF Machinery have years of experience in the industry and can guide you through the process. They understand the importance of compatibility, quality, and value, ensuring you make the right choice for your equipment.

A trusted supplier provides more than just parts—they offer insights that help you avoid costly mistakes. For example, if you’re struggling to match part numbers or identify the correct component for your machine, their team can assist. They’ll ask for details like your excavator’s make, model, and serial number to recommend the best options. This personalized support ensures you get parts that fit perfectly and perform reliably.

Working with experts also gives you access to a wide selection of high-quality salvaged parts. Suppliers like YNF Machinery inspect their inventory thoroughly, so you can trust the condition of the components you’re buying. They’ll even share maintenance tips or usage history when available, helping you make informed decisions.

If you’re new to sourcing salvaged parts, don’t hesitate to ask questions. A good supplier will explain the differences between parts, suggest alternatives, and provide a buyer’s guide to simplify the process. Their goal is to ensure your excavator runs smoothly without unnecessary downtime or expenses.

“The right advice from a trusted supplier can turn a confusing process into a seamless experience.”

By seeking expert guidance, you not only save time but also gain confidence in your purchase. YNF Machinery’s commitment to quality and customer satisfaction makes them a reliable partner for all your excavator part needs.

Tips for Choosing the Best Mini Excavator Tracks and Other Salvaged Parts

Inspecting for Visible Damage or Wear

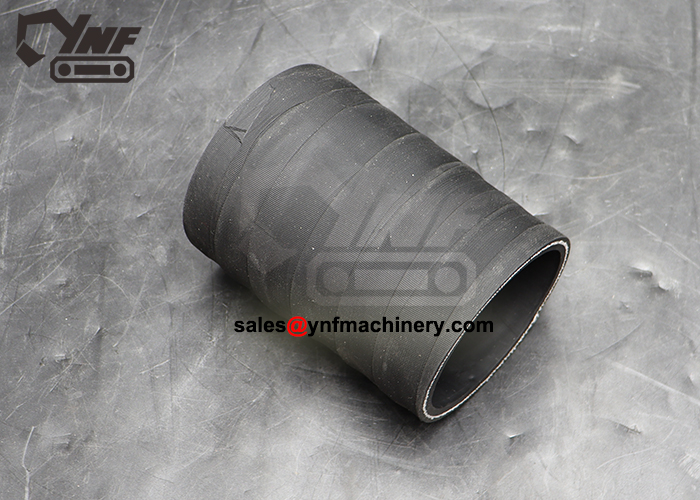

When you’re evaluating salvaged parts, the first thing to do is inspect them for visible damage or wear. This step is especially important for tracks since they endure constant stress during operation. Look closely for cracks, tears, or signs of excessive wear on the rubber treads. Damaged tracks can compromise your mini excavator’s performance and lead to costly repairs down the line.

Pay attention to the edges and the underside of the tracks. Uneven wear patterns or exposed metal can indicate that the part has been overused or improperly maintained. If you’re unsure about what to look for, compare the salvaged part to a new one or consult your equipment manual for reference. A thorough visual inspection ensures you avoid picking parts that won’t last.

“A quick inspection can save you from unexpected downtime and unnecessary expenses.”

Testing Functionality When Possible

Whenever possible, test the functionality of the salvaged parts before making a purchase. For mini excavator tracks, this might mean checking their flexibility and ensuring they can handle the type of terrain you’ll be working on. Stiff or brittle tracks are a red flag, as they may not perform well under pressure.

If you’re buying other components like hydraulic parts or couplings, ask the supplier if they can demonstrate the part in action. Some salvage yards or suppliers, like YNF Machinery, offer testing services or provide detailed reports on the part’s condition. Testing gives you confidence that the part will work as expected once installed.

Asking for Maintenance or Usage History

Understanding the history of the salvaged part can give you valuable insights into its condition. Ask the supplier about how the part was used and whether it underwent regular maintenance. For tracks for mini excavators, knowing the type of terrain they were used on can help you determine if they’re suitable for your needs. For example, tracks that were primarily used on rocky terrain may show more wear than those used on softer surfaces.

Suppliers like YNF Machinery often provide detailed information about their salvaged parts, including maintenance records or previous usage. This transparency helps you make an informed decision and ensures you pick the right tracks or other components for your mini excavator. Don’t hesitate to ask questions—it’s better to know upfront than to deal with surprises later.

“The more you know about a part’s history, the better equipped you are to make the right choice.”

By following these tips, you’ll be well on your way to choosing the best mini excavator tracks and other salvaged parts. A careful approach ensures you get durable, high-quality components that keep your machine running smoothly.

Avoiding Parts with Signs of Corrosion or Cracks

When you’re inspecting salvaged parts, corrosion and cracks are two major red flags you should never ignore. These issues can compromise the structural integrity and performance of the part, leading to costly repairs or even equipment failure. For tracks, this is especially critical since they endure constant wear and tear during operation.

Start by examining the surface of the part closely. Rust or corrosion often appears as discoloration or flaky material on metal components. Even small patches of rust can spread over time, weakening the part and reducing its lifespan. For mini excavator tracks, check the metal reinforcements embedded in the rubber. Corroded reinforcements can cause the tracks to fail under pressure, leaving your machine stranded mid-operation.

Cracks, on the other hand, are a clear sign of wear or damage. Look for visible splits or fractures along the rubber treads and edges of the tracks. Pay attention to areas that experience the most stress, such as the inner side of the track where it wraps around the rollers. Cracks in these areas can worsen quickly, especially if your excavator operates on rough or uneven terrain.

To avoid these issues, follow these steps:

Inspect Thoroughly: Take your time to examine every inch of the part. Use a flashlight to spot hidden cracks or corrosion in hard-to-see areas.

Test Durability: Bend or flex the tracks gently to check for brittleness. Stiff or inflexible tracks may already be compromised.

Ask Questions: If you’re buying from a supplier, ask about the part’s history. Reliable suppliers like YNF Machinery often provide details about previous usage and maintenance, helping you make an informed decision.

“A small crack today can turn into a big problem tomorrow. Always prioritize quality over convenience.”

By avoiding parts with signs of corrosion or cracks, you ensure your mini excavator operates efficiently and safely. This careful approach is key to choosing the best mini excavator tracks and keeping your equipment in top condition.

Finding Reliable Sources for Salvaged Mini Excavator Parts

Researching Salvage Yards with Good Reviews

When you’re buying from a salvage yard, start by checking reviews. Customer feedback gives you a clear picture of the yard’s reliability and the quality of its parts. Look for reviews that mention successful purchases, helpful staff, and well-maintained inventory. Positive reviews often indicate a reputable salvage yard that values its customers.

You can find reviews on platforms like Google, Yelp, or industry-specific forums. Pay attention to patterns in the feedback. If multiple customers praise the yard for providing high-quality parts, it’s likely a good choice. On the other hand, consistent complaints about poor service or defective parts should raise red flags. Researching reviews helps you avoid unreliable sources and focus on finding the right parts for your mini excavator.

“A little research upfront can save you from big headaches later.”

Choosing Suppliers with Certifications or Industry Affiliations

Certifications and industry affiliations show that a supplier takes their business seriously. Established used parts sellers often hold certifications that prove their commitment to quality and ethical practices. These credentials ensure that the parts meet industry standards and perform as expected.

When evaluating a supplier, check their website or ask directly about their certifications. Affiliations with respected industry organizations also add credibility. For example, a supplier who partners with well-known manufacturers or associations likely has access to high-quality salvaged parts. Choosing a reputable supplier with these credentials gives you confidence in your purchase.

Verifying Return Policies and Warranties

Before finalizing your purchase, always review the supplier’s return policy and warranty terms. A clear return policy protects you if the part doesn’t fit or fails to meet your expectations. Warranties provide additional assurance, covering potential defects or performance issues.

Ask the supplier about their policies. Reliable suppliers, like YNF Machinery, often offer transparent terms that prioritize customer satisfaction. For example, they might allow returns within a specific timeframe or provide a warranty that covers the part for several months. Verifying these details ensures you’re protected and helps you make an informed decision.

“A good return policy and warranty show that the supplier stands behind their products.”

By following these steps, you can confidently choose a reliable source for salvaged mini excavator parts. Whether you’re buying from a salvage yard or an established supplier, taking the time to research ensures you get high-quality components that keep your equipment running smoothly.

Exploring YNF Machinery’s Wide Range of Salvaged Mini Excavator Parts

When it comes to salvaged mini excavator parts, YNF Machinery stands out as a trusted source with an extensive selection. You’ll find everything you need to keep your equipment running smoothly. Whether you’re replacing worn-out tracks, upgrading engine components, or sourcing hydraulic parts, YNF Machinery has you covered.

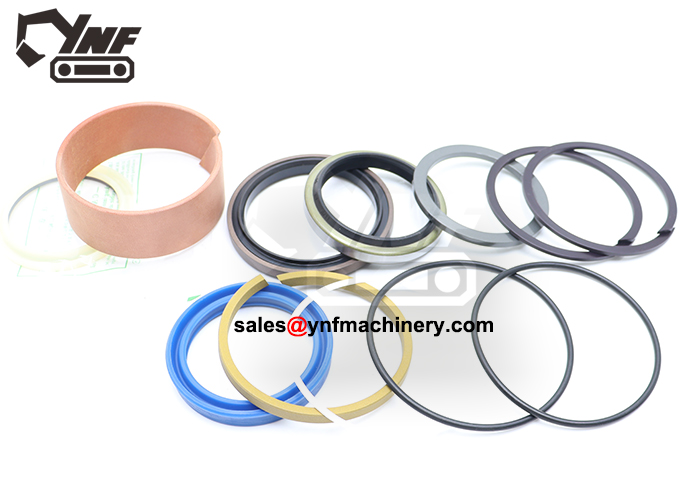

Their inventory includes high-quality salvaged parts for various excavator brands and models. This wide range ensures you have plenty of options when finding the right parts for your machine. Each part undergoes rigorous inspection to meet strict quality standards. You can trust that the parts you purchase will perform reliably and last longer.

YNF Machinery doesn’t just offer parts—they provide solutions. Their team of experts is ready to assist you in selecting the best components for your specific needs. If you’re unsure about compatibility, they’ll guide you through the process. They’ll help you match part numbers, identify the correct specifications, and ensure a perfect fit for your mini excavator.

Here’s what makes YNF Machinery’s salvaged parts a great choice:

Extensive Selection: You’ll find parts for over 26 excavator brands, covering a wide range of models and applications.

Quality Assurance: Every salvaged part is inspected thoroughly to ensure durability and performance.

Expert Support: Their knowledgeable team helps you make informed decisions, saving you time and effort.

Cost-Effective Options: Salvaged parts from YNF Machinery offer excellent value without compromising quality.

“Choosing the right supplier makes all the difference when sourcing salvaged mini excavator parts.”

By exploring YNF Machinery’s offerings, you gain access to reliable components that keep your equipment operating at its best. Their commitment to quality and customer satisfaction ensures you’ll have a seamless experience every step of the way.

Benefits of Working with Trusted Salvage Yards or Brokers

Access to a Wide Selection of Salvaged Mini Excavator Parts

When you work with a trusted salvage yard or broker, you gain access to a vast inventory of salvaged parts. These suppliers often stock a wide range of components, including mini excavator tracks, engines, and hydraulic systems. This variety ensures you can find the exact part you need without wasting time searching multiple sources. Whether you’re looking for excavator undercarriage parts or specialized components, a reliable salvage yard simplifies the process.

Trusted suppliers also maintain organized inventories, making it easier to locate specific parts. They often categorize their stock by make, model, and condition, so you can quickly identify compatible options for your machine. For example, if you need tracks for mini excavators, a reputable supplier will guide you to the right size and type for your equipment. This streamlined approach saves you time and reduces the risk of purchasing incompatible parts.

“A wide selection means you’re more likely to find the perfect fit for your excavator, ensuring smooth operation and minimal downtime.”

Assurance of Quality and Authenticity

Quality is a top priority when buying salvaged parts. Trusted salvage yards inspect their inventory thoroughly to ensure every component meets high standards. They check for visible damage, wear, and functionality, so you don’t have to worry about receiving defective parts. For instance, when you need used parts like caterpillar parts, a reliable supplier will verify their condition and authenticity before offering them for sale.

Reputable suppliers often follow industry guidelines to determine whether a part is reusable. They might inspect components against manufacturer standards, ensuring they perform as expected. This attention to detail gives you confidence in the parts you purchase. Whether it’s mini excavator tracks or other critical components, you can trust that they’ll deliver reliable performance.

Additionally, many trusted suppliers provide warranties or return policies. These protections ensure you’re covered if the part doesn’t meet your expectations. Always ask about these policies before making a purchase. Knowing you’re backed by a warranty adds peace of mind and reinforces the supplier’s commitment to quality.

Expert Guidance and Support from Suppliers Like YNF Machinery

Navigating the world of salvaged parts can feel overwhelming, especially if you’re unsure about compatibility or specifications. That’s where expert guidance makes all the difference. Trusted suppliers like YNF Machinery offer personalized support to help you make informed decisions. Their team of professionals understands the intricacies of excavators and can recommend the best options for your needs.

For example, if you’re unsure which tracks to choose, YNF Machinery’s experts will ask for details about your machine, such as its make, model, and serial number. They’ll use this information to guide you toward the right part, ensuring a perfect fit. This level of support saves you time and prevents costly mistakes.

Trusted suppliers also provide valuable insights into attachment options and customization. If you’re upgrading your excavator or adding new features, they’ll help you select compatible parts that enhance performance. Their expertise extends beyond sales—they’re partners in keeping your equipment running smoothly.

“Expert advice turns a confusing process into a seamless experience, giving you confidence in your purchase.”

By working with a trusted supplier like YNF Machinery, you gain access to high-quality parts, a wide selection, and unmatched support. These benefits ensure your excavator operates efficiently, saving you time and money in the long run.

Cost Savings Compared to New Parts

Opting for salvaged parts can significantly reduce your expenses compared to buying new ones. New parts often come with a hefty price tag, especially for heavy machinery like mini excavators. Salvaged parts, on the other hand, offer a cost-effective alternative without necessarily compromising quality or performance. This makes them an excellent choice for budget-conscious buyers.

When you choose salvaged parts, you’re not just saving money upfront. You’re also making a smart investment in long-term value. Reliable suppliers, like YNF Machinery, thoroughly inspect their inventory to ensure the parts meet high standards. For example, they follow guidelines similar to those used for assessing caterpillar parts, ensuring only reusable and reliable components make it to their shelves. This attention to detail means you get durable parts at a fraction of the cost of new ones.

Another way salvaged parts save you money is by reducing downtime. Imagine your mini excavator breaks down, and you need a replacement part immediately. New parts might take weeks to arrive, halting your operations and costing you more in lost productivity. Salvaged parts are often readily available, allowing you to get your machine back up and running quickly. This quick turnaround minimizes downtime and keeps your projects on schedule.

Additionally, salvaged parts often come with warranties or return policies when purchased from trusted suppliers. These protections give you peace of mind, knowing that your investment is secure. For instance, if a part doesn’t fit or fails prematurely, a good supplier will offer a replacement or refund. This level of assurance adds even more value to your purchase.

Here’s how salvaged parts help you save:

Lower Initial Costs: Salvaged parts cost significantly less than new ones, making them ideal for tight budgets.

Reduced Downtime: Quick availability ensures your equipment gets back to work faster, saving you money on delays.

Long-Term Value: High-quality salvaged parts last longer, reducing the need for frequent replacements.

Added Protections: Warranties and return policies safeguard your investment, ensuring you get what you pay for.

“Choosing salvaged parts isn’t just about saving money—it’s about making a smart, sustainable choice for your equipment.”

By sourcing from reputable suppliers like YNF Machinery, you can enjoy the cost savings of used parts while maintaining the reliability and performance of your mini excavator. This balance of affordability and quality makes salvaged parts a practical solution for any equipment owner.

Cost-Effectiveness: Balancing Price and Value

Comparing Prices Across Multiple Suppliers

When you’re shopping for salvaged parts, comparing prices across multiple suppliers is essential. Not all suppliers price their parts the same way, and some may offer better deals for the same quality. Take the time to research and gather quotes from different sources. This step helps you identify fair pricing and avoid overpaying.

For example, if you’re looking for mini excavator tracks, check with at least three suppliers. Compare not just the price but also what’s included. Some suppliers might bundle additional services like inspections or warranties, which add value to your purchase. Others may charge less upfront but provide lower-quality tracks that wear out quickly. By evaluating multiple options, you can strike a balance between affordability and reliability.

“A little extra effort in comparing prices can save you a lot of money and frustration in the long run.”

Considering Long-Term Durability Over Short-Term Savings

It’s tempting to choose the cheapest option when replacing parts, but focusing solely on price can lead to costly mistakes. A low-cost part might save you money today, but if it fails prematurely, you’ll end up spending more on replacements and repairs. Durability should always be a priority when making your decision.

Think about the tracks for mini excavators. These parts endure constant stress and wear during operation. Choosing durable tracks ensures they last longer, reducing downtime and maintenance costs. High-quality excavator undercarriage parts may cost more upfront, but their longevity makes them a better investment. Reliable suppliers like YNF Machinery inspect their parts thoroughly, ensuring you get components that stand the test of time.

“Durability isn’t just about saving money—it’s about keeping your equipment running smoothly and efficiently.”

Factoring in Shipping or Delivery Costs

Shipping or delivery costs can significantly impact the total price of your purchase. Some suppliers offer low prices on parts but charge exorbitant fees for shipping. Others might include free or discounted delivery, making their overall pricing more competitive. Always factor in these costs when comparing suppliers.

For instance, if you’re sourcing tracks for a specific model of mini excavator, ask about shipping fees upfront. Consider the distance between you and the supplier, as this often affects delivery times and costs. A nearby supplier might save you money and ensure faster delivery, minimizing downtime for your excavator. On the other hand, a supplier with slightly higher shipping costs but better-quality parts might still be the better choice.

“Don’t let hidden shipping fees catch you off guard. Always calculate the full cost before making a decision.”

By balancing price, durability, and shipping costs, you can make smarter purchasing decisions. This approach ensures you get the best value for your money while keeping your equipment in top condition.

Avoiding “Too Good to Be True” Deals

When a deal seems too good to be true, it usually is. You might come across salvaged mini excavator parts priced unbelievably low, but these bargains often come with hidden risks. Sellers offering such deals may cut corners on quality, leaving you with parts that fail quickly or don’t fit your machine. While saving money is important, sacrificing reliability can cost you more in the long run.

Take a moment to think about why the price is so low. Is the seller skipping inspections? Are they hiding damage or wear? These are common tactics used by unreliable sources. For example, a farmer once purchased salvaged parts from a new salvage yard that advertised great prices. However, the parts arrived in poor condition, requiring extensive repairs and delaying the project. This situation not only increased costs but also caused frustration and wasted time.

To avoid falling for these deals, follow these steps:

Research the Seller: Check reviews and testimonials. Reliable suppliers like YNF Machinery have a proven track record of delivering high-quality parts.

Inspect the Parts: Always examine the condition of the parts before buying. Look for signs of wear, cracks, or corrosion.

Ask Questions: Inquire about the part’s history, maintenance, and usage. A trustworthy seller will provide clear answers.

Compare Prices: If one seller’s price is significantly lower than others, investigate why. Quality parts usually have consistent pricing across reputable suppliers.

“A cheap part today can lead to expensive repairs tomorrow.”

By staying cautious and doing your homework, you can avoid deals that seem too good to be true. Focus on value and reliability instead of just the price. Trusted suppliers like YNF Machinery ensure you get durable parts that keep your equipment running smoothly without unnecessary risks.

Final Checklist Before Purchasing Salvaged Mini Excavator Parts

Confirming Compatibility and Fit with Your Equipment

Before making a purchase, ensure the salvaged part is compatible with your mini excavator. Compatibility is crucial for maintaining the efficiency and safety of your machine. Start by identifying the make, model, and serial number of your excavator. These details help you match the part to your equipment accurately. Without this step, you risk buying a component that doesn’t fit, leading to wasted time and money.

When finding the perfect fit, consult your equipment manual or reach out to a trusted supplier. Suppliers like YNF Machinery can guide you through the process, ensuring you select the right tracks or other parts. They’ll help you verify part numbers and specifications, so you avoid costly mistakes. Remember, a well-matched part keeps your excavator running smoothly and reduces the need for frequent replacements.

“The right part isn’t just about functionality—it’s about ensuring your machine operates at its best.”

Inspecting the Part’s Condition Thoroughly

A thorough inspection is essential when buying salvaged parts. Used components, especially tracks, can have hidden damage that affects their performance and lifespan. Look closely for visible signs of wear, such as cracks, rust, or uneven treads. Damaged tracks can compromise your excavator’s stability and lead to further issues down the line.

If possible, test the part’s functionality before purchasing. For tracks, check their flexibility and ensure they’re suitable for the terrain you’ll be working on. Stiff or brittle tracks may not perform well under pressure. Reliable suppliers like YNF Machinery often provide detailed information about the part’s condition, giving you peace of mind. By inspecting thoroughly, you ensure you’re investing in a durable and reliable replacement.

“A quick inspection today can save you from unexpected downtime tomorrow.”

Verifying the Supplier’s Reputation

The supplier you choose plays a significant role in the quality of the parts you receive. A reputable supplier ensures their inventory meets high standards, offering inspected and reliable components. Before committing to a purchase, research the supplier’s reputation. Look for reviews or testimonials from other buyers to gauge their reliability.

Trusted suppliers like YNF Machinery stand out for their commitment to quality and customer satisfaction. They provide warranties and clear return policies, protecting your investment. Additionally, they offer expert guidance to help you make informed decisions. Choosing a reliable supplier reduces the risk of receiving defective parts and ensures your excavator stays in top condition.

“A trusted supplier is your partner in keeping your equipment running efficiently.”

By following this checklist, you can confidently purchase salvaged mini excavator parts that meet your needs. Confirm compatibility, inspect the condition, and verify the supplier’s reputation to make a smart and cost-effective choice.

Reviewing the Return Policy and Warranty

Before you finalize your purchase, take a close look at the supplier’s return policy and warranty. These two factors can save you from unnecessary headaches if something goes wrong with the salvaged part. A clear return policy ensures you have options if the part doesn’t fit or meet your expectations. A solid warranty gives you peace of mind, knowing the supplier stands behind the quality of their product.

Why the Return Policy Matters

A return policy acts as your safety net. Imagine buying a salvaged mini excavator part, only to discover it doesn’t fit your machine. Without a return policy, you’re stuck with a useless component and wasted money. A good supplier will offer a straightforward return process, allowing you to exchange or return the part within a specific timeframe.

Here’s what to look for in a return policy:

Timeframe: Check how many days you have to return the part. Most reputable suppliers provide a reasonable window, such as 15 to 30 days.

Condition Requirements: Ensure the policy allows returns even if the part has been inspected or lightly tested.

Restocking Fees: Some suppliers charge a fee for returns. Make sure this is clearly stated upfront.

“A transparent return policy shows that the supplier values customer satisfaction and trusts the quality of their parts.”

The Importance of a Warranty

A warranty protects your investment by covering defects or performance issues. Salvaged parts, while cost-effective, may carry some risks due to their previous use. A warranty ensures you’re not left high and dry if the part fails prematurely.

When reviewing a warranty, pay attention to these details:

Coverage Period: Look for warranties that last at least a few months. This gives you enough time to test the part under real working conditions.

What’s Covered: Ensure the warranty includes defects, malfunctions, or other performance issues. Some suppliers also cover installation-related problems.

Replacement or Refund Options: Check if the warranty offers a replacement part or a full refund in case of failure.

Reputable suppliers like YNF Machinery often provide warranties that reflect their confidence in the quality of their salvaged parts. This assurance makes it easier for you to trust your purchase.

Questions to Ask Your Supplier

To avoid surprises, ask your supplier these key questions before buying:

What is your return policy, and are there any conditions I should know about?

How long does the warranty last, and what does it cover?

Will I receive a replacement or refund if the part fails?

Are there any additional fees for returns or warranty claims?

A trustworthy supplier will answer these questions clearly and confidently. Their transparency indicates they prioritize your satisfaction and stand by their products.

The Bottom Line

A strong return policy and warranty aren’t just nice-to-haves—they’re essential when buying salvaged mini excavator parts. They protect your investment, reduce risks, and give you confidence in your purchase. Always choose suppliers who offer clear policies and stand behind their products, like YNF Machinery. By doing so, you ensure a smoother buying experience and keep your equipment running efficiently.

Avoiding mistakes when selecting salvage mini excavator parts is essential for keeping your equipment running efficiently. By conducting thorough research, inspecting the condition of tracks and other components, and verifying compatibility, you can make smarter choices. Always prioritize quality and reliability by sourcing from trusted suppliers like YNF Machinery. Their expertise and commitment to high standards ensure you get durable parts that deliver long-term value. Apply these tips to save time, reduce costs, and maintain the performance of your excavator.

FAQ

What are the benefits of using salvaged mini excavator parts?

Salvaged parts offer a cost-effective solution for maintaining your mini excavator. They help you save money compared to buying new components while still providing reliable performance when sourced from trusted suppliers. Salvaged parts also reduce downtime since they are often readily available. By choosing high-quality salvaged parts, you can extend the lifespan of your equipment without breaking the bank.

“Opting for salvaged parts isn’t just about saving money—it’s about making a smart, sustainable choice for your equipment.”

How do I ensure compatibility when buying salvaged parts?

If you’re unsure, consult a trusted supplier like YNF Machinery. Their experts can guide you to the right part, ensuring a perfect fit for your mini excavator.

Why is inspecting salvaged parts before purchase important?

Inspection helps you avoid hidden damage or wear that could affect the part’s performance. Look for cracks, rust, or uneven wear, especially on critical components like tracks. Testing functionality, when possible, ensures the part works as expected. Reliable suppliers like YNF Machinery often provide detailed information about the condition of their parts, giving you peace of mind.

“A quick inspection today can save you from unexpected downtime tomorrow.”

What should I look for in a supplier of salvaged mini excavator parts?

Choose a supplier with a strong reputation for quality and reliability. Look for reviews or testimonials from other buyers. A good supplier will offer clear return policies, warranties, and expert guidance. YNF Machinery, for example, provides high-quality parts, thorough inspections, and excellent customer support to ensure you make the right choice.

Are salvaged parts as durable as new ones?

High-quality salvaged parts from trusted sources can perform just as well as new ones.

How can I avoid scams or unreliable sellers?

Research the supplier before making a purchase. Check online reviews and ask for recommendations. Avoid deals that seem too good to be true, as they often come with hidden risks. Trusted suppliers like YNF Machinery provide transparency, detailed product information, and warranties, ensuring you get what you pay for.

What role does a warranty play when buying salvaged parts?

A warranty protects your investment by covering defects or performance issues. It gives you confidence in the quality of the part. Look for suppliers who offer clear warranty terms. For example, YNF Machinery provides warranties that reflect their commitment to quality, ensuring you’re covered if something goes wrong.

How do I know if a salvaged part has been properly maintained?

Ask the supplier about the part’s history, including its previous usage and maintenance. Reliable suppliers often provide detailed records or insights into the part’s condition. For example, YNF Machinery shares maintenance history when available, helping you make an informed decision.

Can salvaged parts help reduce downtime?

Yes, salvaged parts are often readily available, allowing you to replace damaged components quickly. This reduces downtime and keeps your projects on schedule. Working with a trusted supplier ensures you receive the correct parts promptly, minimizing delays.

“A steady supply of high-quality parts keeps your equipment running smoothly, even during challenging times.”

Why should I choose YNF Machinery for salvaged mini excavator parts?

YNF Machinery offers a wide selection of high-quality salvaged parts for various excavator brands and models. Their rigorous inspection process ensures durability and reliability. With over 35 years of experience, they provide expert guidance, competitive pricing, and excellent customer support. Choosing YNF Machinery means you’re partnering with a trusted supplier dedicated to keeping your equipment in top condition.