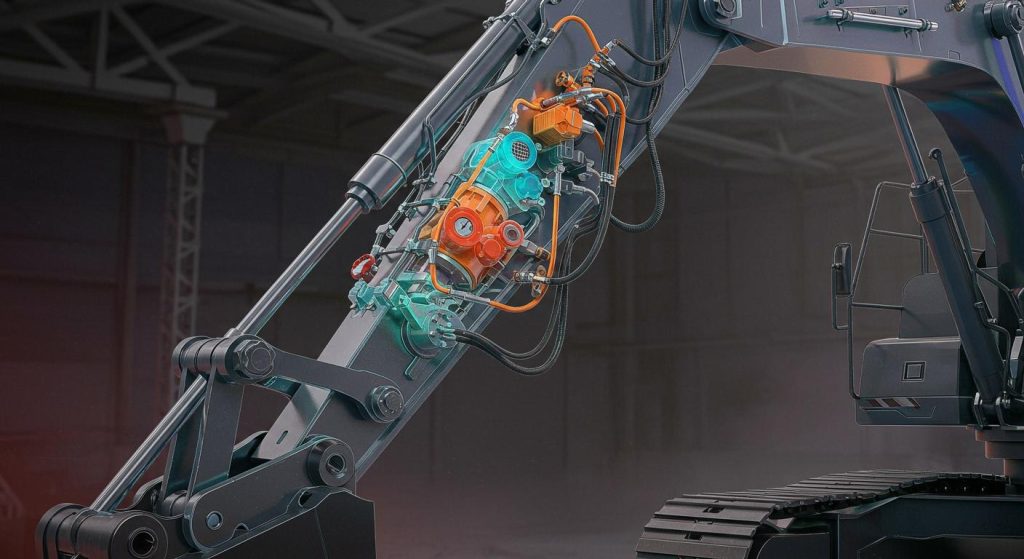

Each time you operate an excavator, you rely on the plumbing valves and the excavator hydraulic pump. The engine drives the hydraulic pump, which circulates hydraulic fluid throughout the machine. Control and pilot valves, along with plumbing valves, allow you to manage movement and precision. The plumbing valves and excavator hydraulic pump work together as essential components in this system.

Hydraulic failures account for 45% of major excavator issues. Most of these problems are caused by dirty fluid, worn parts, faulty seals, excessive heat, or lack of proper maintenance.

System Type | Fuel Efficiency Improvement |

|---|---|

Conventional Cylinders with Main Control Valve | Baseline |

Adapted STEAM System | 34%–50% Improvement |

Key Takeaways

Hydraulic pumps and valves help excavators work. They control how the machine moves and how exact it is.

It is important to take care of your excavator. Check fluid levels every day. Change filters after 500 hours. This helps stop problems before they start.

You need to know about pressure and flow. Right pressure helps the excavator lift and dig well. Flow decides how fast it works.

Pick good parts from trusted suppliers like YNF Machinery. Good pumps and valves make your excavator last longer and work better.

Watch out for common problems. Look for leaks, old parts, and overheating. This helps your excavator stay in good shape.

Pump and Valve Roles

Excavator Hydraulic Pump

The engine makes the hydraulic pump work in your excavator. This pump takes hydraulic fluid from the reservoir. It sends the fluid through the system. The pump gives pressurized fluid to the boom, arm, and bucket. It controls how much fluid moves and how fast it goes. This helps you use the excavator easily.

The pump gives pressurized hydraulic fluid to actuators.

It takes fluid from the reservoir and pushes it through lines and valves.

It controls pressure and flow for smooth work.

Excavators use different types of hydraulic pumps. Each type has good and bad points.

Pump Type | Advantages | Disadvantages |

|---|---|---|

Gear | High volumetric efficiency, low noise, cheap, easy to fix | Not good for high pressure, can get damaged by dirt and wear |

Vane | Runs smoothly, can handle high pressure, works with many fluids | Not as efficient as gear pumps, can get damaged by dirt and wear |

Piston | Handles high pressure, very efficient, lasts long, works with many fluids | Costs more, can be hurt by dirt |

Modern excavators often use Rexroth-Uchida AP2D pumps and Kawasaki K3V/K5V series. These pumps give high pressure, work well, and last long for tough jobs. If you want good hydraulic pumps, YNF Machinery has strong choices for your excavator.

Plumbing Valves

Plumbing valves are important in your excavator’s hydraulic system. These valves guide the hydraulic fluid and keep the system working right. You use them to control the direction, speed, and pressure of the fluid. This keeps your excavator safe and working well.

Valves stop too much pressure, which can break equipment or cause explosions.

They control system pressure and act as safety tools.

Valves work as checkpoints and safety stops, keeping the system safe.

You will see a few common plumbing valve types in excavator hydraulic systems:

Pressure Control Valve: Controls hydraulic pressure, including safety and overflow valves.

Flow Control Valve: Keeps fluid flow steady, changing how fast the machine works.

Direction Control Valve: Changes the way fluid moves. Spool-type valves are used a lot in hydraulic excavators.

When you pick plumbing valves excavator hydraulic pump from YNF Machinery, you get strong parts that help protect your machine and keep it working well.

Tip: Take care of plumbing valves and the excavator hydraulic pump often to stop breakdowns and expensive fixes.

Control and Pilot Valves

Control and pilot valves help you move fluid for careful movement. Control valves change the flow and pressure of hydraulic fluid to different actuators. Pilot valves use low-pressure fluid to run the main control valves, which handle high-pressure fluid for strong movements.

Control valves send fluid to actuators.

They let you do careful work with accuracy.

You can lift heavy things well with good valve control.

Pilot control valves help you control the excavator’s movements better. They send hydraulic pressure to the right parts, making lifting and digging more exact. These valves also help save energy and make the machine work better.

Hydraulic pilot control valves are very important for new excavators. They let you control fluid flow exactly, which makes the machine work better and saves energy. When you need good control and pilot valves, YNF Machinery has options that work for you.

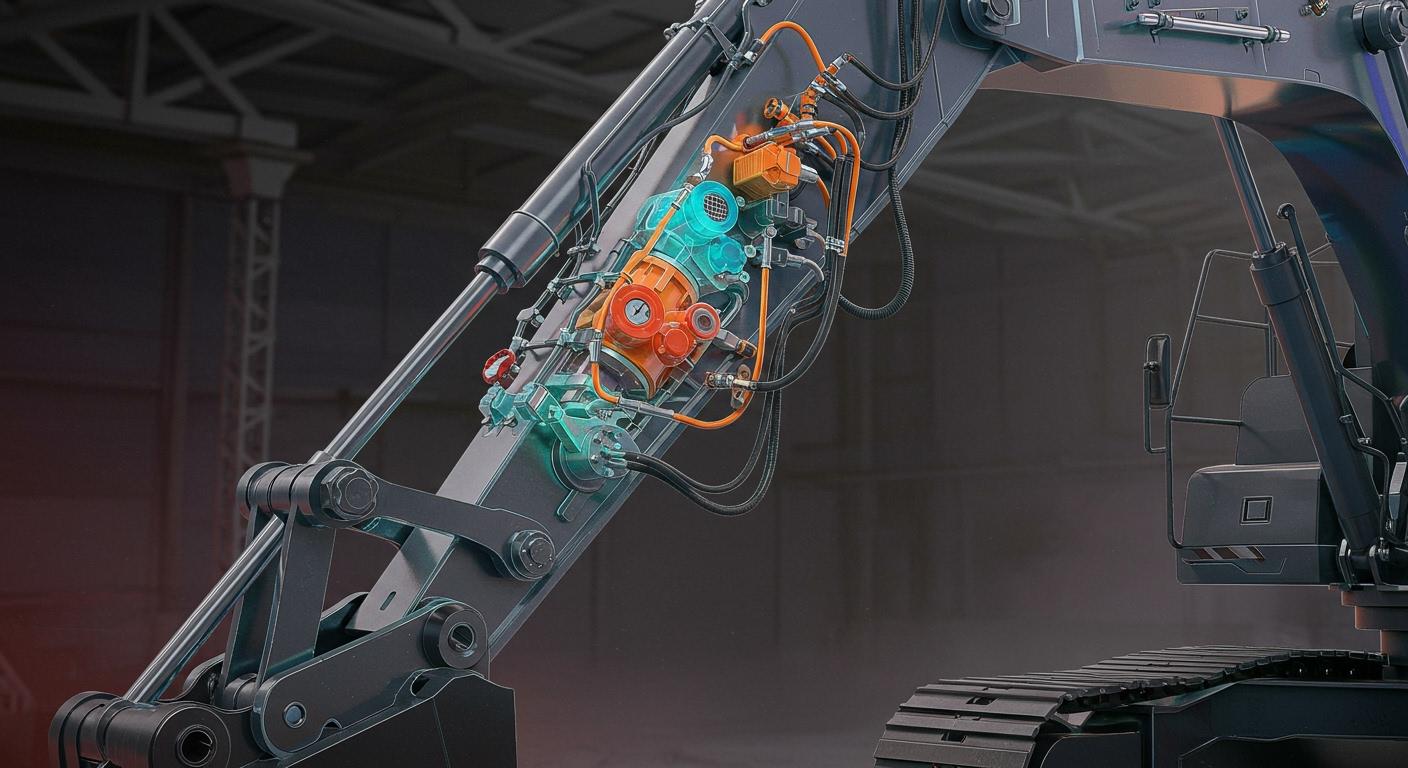

Fluid Flow Process

When you know how hydraulic fluid moves, you see why each part is important. The fluid starts in the reservoir. It ends with the boom, arm, or bucket moving with power. Every step needs the plumbing valves excavator hydraulic pump and other parts to work together.

Pressure Generation

You begin by turning on the excavator. The engine makes the hydraulic pump work. The pump takes fluid from the reservoir and builds pressure. Pressure gives the excavator its strength. It helps break hard ground and lift heavy things. The pump also controls how fast the fluid moves. This changes how quickly the boom, arm, and bucket move.

Pressure gives power, which helps break hard ground and lift heavy things.

More pressure lets the excavator push harder and do more.

Flow changes speed, so the boom, arm, and bucket can move faster.

Your excavator needs the right mix of pressure and flow to work well. If pressure is too low, it will not work well. Too much pressure can break parts. YNF Machinery has pumps that help you get the right pressure for your work.

Fluid Direction

After the pump makes pressure, the fluid must go to the right spot. Valves and hoses guide the fluid through the system. Main control valves, plumbing valves, and hoses all help with this. The main control valve sends fluid to different parts. Plumbing valves keep fluid going the right way and stop it from going backward.

Mechanism | Function |

|---|---|

Main Control Valve | Sends hydraulic fluid to different parts of the system. |

Linear Actuators | Move the boom, arm, and bucket in a straight line. |

Rotary Actuators | Turn the top of the excavator compared to the bottom. |

Check valves work like one-way doors. They let fluid go one way only. This stops fluid from going backward and keeps things safe. Hoses move pressurized fluid between parts. Hoses bend for moving parts. Pipes are strong and connect parts that do not move. Valves control where the fluid goes, so your excavator works well.

Hoses move fluid between parts and let them move.

Pipes are strong and connect parts that stay still.

Valves control where fluid goes, which is important for good work.

Check valves stop fluid from going backward and keep things safe.

Cylinder Operation

The last step happens in the hydraulic cylinders. When fluid under pressure goes into a cylinder, it pushes the piston. This makes the rod move in or out. The boom, arm, or bucket moves because of this. The size of the cylinder and the fluid pressure decide how strong the movement is. This is how your excavator lifts heavy things or digs hard dirt.

Hydraulic fluid moving inside the cylinder makes straight force. This force moves the piston and the part it is attached to. More pressure means stronger movement. The plumbing valves excavator hydraulic pump must work together for smooth and steady action.

You might see some common problems with cylinders:

Leaks from old seals or broken parts can make things work badly and be unsafe.

Sticking or binding makes the piston move unevenly and can hurt the cylinder.

Losing power often happens when fluid is low or there are system issues.

Noise and shaking can mean air is in the system or parts are worn out.

Overheating can happen if the system gets too hot or works too hard for too long.

Tip: Check and take care of your machine often to stop these problems and keep your excavator working well.

Performance Impact

Efficiency

You want your excavator to work hard and not waste energy. The hydraulic pump and valves work together to use power. If the system loses energy, you waste fuel. Four-side spool valves often cause these losses. New systems like independent metering and pump-controlled hydraulic cylinders help stop waste. These systems make your excavator more efficient. Look at the table below to see the difference:

Aspect | Description |

|---|---|

Problem | Old hydraulic systems lose power because of valve control. This makes them less efficient. |

Solution | Pump-controlled hydraulic cylinder systems lower these losses and save energy. |

Findings | New systems work about 18.9% better and use 39% less energy than old ones. |

Modern designs, like the Dextreme System, can save up to 50% energy. They change pump flow to match what you need. Dextreme Flex and Dextreme Swap also help cut fuel use and pollution. Advanced systems let you do more work with less fuel.

Other things help your excavator work better:

Factor | Description |

|---|---|

Mechanical structure design | Good arm and dipper angles lower shock and help you reach farther. |

Electronic control | Smart controls set hydraulic settings and stop energy waste. |

Oil characteristics | Clean oil with the right thickness keeps everything working well. |

Matching of components | Pumps, valves, and cylinders that fit together make the system stable and quick. |

Operation proficiency | Training helps you use the excavator better. |

Terrain and soil adaptability | Changing hydraulic settings for different soils helps you work better. |

Precision

You need good control to dig, lift, and move things safely. Hydraulic cylinders move the boom, arm, and bucket. The main control valve lets you move each part where you want. Hydraulic fluid tanks hold the fluid, and filters keep it clean. Clean fluid and good valves stop jerky movements and help you work accurately.

Hydraulic cylinders give you power for careful digging and lifting.

Main control valves help you move smoothly.

Filters and tanks keep the system clean and ready.

Using plumbing valves excavator hydraulic pump from YNF Machinery gives you strong parts for precise work.

Maintenance

Taking care of your excavator keeps it working well. Check fluid levels every day. Change filters every 500 hours. Look at air, hydraulic, and fuel filters and change them when needed. Good care helps pumps and valves last 5,000 to 10,000 hours.

Task | Frequency |

|---|---|

Check fluid levels | Daily |

Replace filters | Every 500 hours |

Do these things to keep your system healthy:

Look for leaks, damage, and worn parts.

Check oil level and color to see if it is good.

Use pressure gauges to check system pressure.

Change seals, O-rings, and gaskets often.

Use good hydraulic fluid.

Learn to find problems early.

Regular care stops breakdowns and saves money on repairs. You make your excavator last longer and work better.

Tip: Check your machine early and use the right oil to find problems before they get worse.

The hydraulic pump and valves work as a team in your excavator. This teamwork gives you smooth moves and strong lifting. You can control the machine more easily because of this.

The pump pushes fluid under pressure to make things move.

Valves help guide the fluid for digging, lifting, and swinging.

Main control valves send fluid to the right spot for careful work.

Feature | Description |

|---|---|

Summation System | Puts pump flow together for faster work and better results. |

Boom Priority | Lifts the boom fast for loading and deep digging jobs. |

Swing Priority | Makes swinging and digging better at the same time for trenching. |

When you know how these parts work, your excavator lasts longer. It also works more quietly and saves you money. YNF Machinery has pumps and valves you can trust to help you do your job well.

FAQ

What does a hydraulic pump do in an excavator?

You use the hydraulic pump to move fluid through the system. The pump creates pressure. This pressure powers the boom, arm, and bucket. Without the pump, your excavator cannot move or lift anything.

Why are plumbing valves important for excavators?

Plumbing valves guide and control the hydraulic fluid. They keep the system safe and working well. You rely on these valves to prevent leaks, control pressure, and direct fluid to the right parts.

How often should you check hydraulic fluid and filters?

You should check fluid levels every day. Replace filters every 500 hours. Clean fluid and good filters help your excavator last longer and work better.

Tip: Regular checks stop big problems before they start.

What happens if a valve or pump fails?

If a valve or pump fails, your excavator may lose power or stop moving. You might see leaks, slow movement, or strange noises. Fix problems quickly to avoid damage.

Where can you find reliable hydraulic pumps and valves?

You can find strong and reliable hydraulic pumps and valves at YNF Machinery. They offer parts that help your excavator work safely and efficiently.