You must pick a hydraulic pump that fits your John Deere excavator hydraulic pump specifications. The pump should match the size, power, flow rate, and pressure. This helps your machine work better and last longer. If you use a pump with a bigger flow rate, it can make your John Deere excavator more efficient. A variable speed power source can help save energy by up to 10%. Always look at the manufacturer number and model or SKU. This ensures the pump is right for your John Deere excavator. Choosing carefully helps your machine work well and use less energy.

Specification | Efficiency Improvement |

|---|---|

Output Flow Rate | Bigger flow rates make machines work better |

Power Source Type | Variable speed source helps save energy |

Energy Consumption | Less energy used when not working hard |

Key Takeaways

Pick a hydraulic pump that fits your John Deere excavator. This helps it work well and last longer.

Take care of the pump often and use the right hydraulic oil. This can lower repair costs and make the pump last longer.

Always look at the pump’s flow rate, pressure, and power before you buy it. If these do not match, it can cause leaks and bad performance.

Buy pumps from trusted sellers like YNF Machinery. This helps you avoid bad products that might cause accidents.

Check your hydraulic pump often to find problems early. This keeps your excavator working well.

Why Pump Selection Matters

Performance Impact

Choosing the right hydraulic pump helps your John Deere excavator work well. The correct pump lets your machine move easily and lift heavy things. If the pump matches your excavator, it can last longer. Pumps that are taken care of can last 10 to 20 years. Some pumps in big machines work for 5,000 to 10,000 hours if you care for them. You need to check the pump’s flow rate, pressure, and power so it fits your machine.

If you pick the wrong pump or use the wrong hydraulic oil, you might pay more for repairs. Using regular hydraulic oils can hurt the pump and make it break. Many companies spend more money fixing pumps because of this. If you use the right oil and pump, you can cut repair costs by half and help your john deere excavator hydraulic pump last longer. Doing regular checks, like looking at oil and cleaning parts, helps your machine work for more years.

Tip: Always follow the maintenance plan for your hydraulic pump. This stops early damage and saves money on repairs.

Safety Factors

Safety is important when working with hydraulic pumps. If you put in the wrong pump or skip checks, accidents can happen. High-pressure fluid can leak from broken hoses and hurt people. Sometimes, fluid can go through the skin and cause bad injuries. Fires and explosions can happen if hydraulic oil sprays on hot parts.

Safety Risk | Description |

|---|---|

Fire and explosion risks | Hydraulic oil can catch fire if it touches hot parts and cause fires or explosions. |

Fluid injection hazards | High-pressure fluid can leak and cause serious injuries if it gets into the skin. |

General maintenance issues | Not taking care of the pump can lead to dangerous problems, like fires or broken safety systems. |

You should look at hoses often and never touch hoses with pressure to find leaks. Clean parts and use the right pump to keep your john deere excavator hydraulic pump safe and working well.

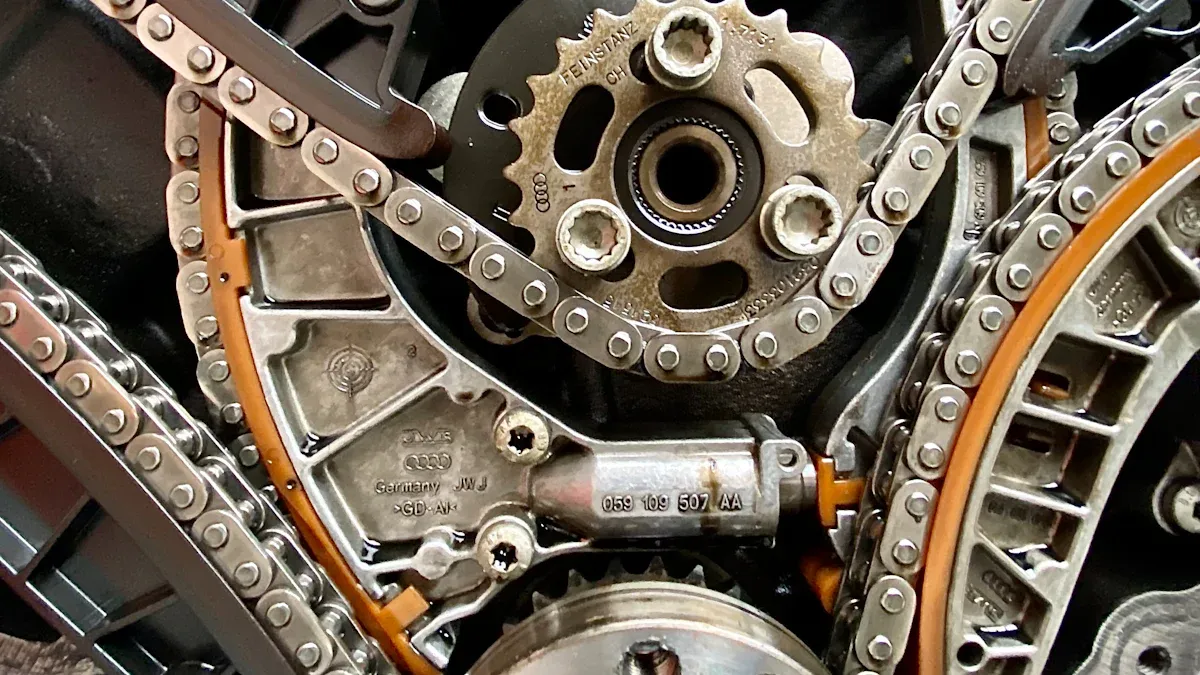

Types of Hydraulic Pumps

When picking a hydraulic pump for your John Deere excavator, you should know the main types. Each type works best for certain jobs and machine sizes. John Deere uses gear pumps, piston pumps, and vane pumps in their machines. Gear pumps and piston pumps are used the most. Gear pumps are good for smaller machines because they are strong and cost less money. Piston pumps are better for bigger excavators. They can handle more pressure and work more efficiently.

Gear Pumps

Gear pumps move hydraulic fluid by turning gears. You usually see these pumps in smaller John Deere excavators. They are simple to take care of and last a long time. Many people pick gear pumps because they are cheap and easy to put in. But, they can be loud and do not work well with thick fluids. They also do not work in a wide range of jobs.

Advantages | Disadvantages |

|---|---|

Easy maintenance | Narrow operating range |

Smooth flow output | High noise |

High durability | Sensitivity to liquid contamination |

Flexible flow adjustment | Potential inefficiency with high viscosity liquids |

Suitable for harsh environments |

Gear pumps are strong and last a long time. They do not need much care and cost less than other pumps.

After a while, gear pumps can get noisy and lose some power.

Piston Pumps

Piston pumps use pistons to move fluid. You see these pumps in bigger John Deere excavators. They can handle high pressure and work very well—up to 95% efficiency. Piston pumps help your john deere excavator hydraulic pump do tough jobs. These pumps cost more and are harder to fix. They can break faster if you do not take care of them.

Piston pumps are strong and work well.

They cost more and are harder to fix than gear pumps.

Vane Pumps

Vane pumps use sliding vanes to move fluid. You find these pumps in some John Deere excavators, mostly for jobs that need steady flow. Vane pumps are not as common as gear or piston pumps, but they give a good mix of price and efficiency.

Hydraulic Cylinders:

Move the boom and arm in and out

Control the bucket for digging and loading

Turn the top part of the machine

Hydraulic Motors:

Move the tracks

Turn attachments

Note: Newer John Deere models, like the 85 P-Tier, have stronger pump torque and higher flow. These changes help you dig better and make your machine work harder.

Choosing a John Deere Excavator Hydraulic Pump

Compatibility

You need to make sure the hydraulic pump fits your John Deere excavator. Compatibility means the pump matches your machine’s model and works with its systems. Each John Deere excavator model has its own needs. Check the part number and manufacturer number. These numbers help you pick the right pump. Pumps made for John Deere excavators use strong materials. They meet or go beyond OEM standards. This helps the pump do tough jobs and keeps hydraulic flow steady.

Match the pump to your John Deere excavator model.

Check the part number and manufacturer number.

Use pumps made for John Deere machines.

Look for pumps that meet or beat OEM specifications.

Pick strong pumps for hard work.

To avoid problems, always use the correct type and specifications for your john deere excavator hydraulic pump. Keep the right hydraulic fluid in your system. Follow a regular maintenance plan.

Specifications

You must look at the pump’s specifications before you buy. The main things to check are flow rate, pressure, and power. Each John Deere excavator model needs different things. For example, the John Deere 350 needs a pump with a maximum flow rate of 106 gallons per minute (gpm) and a maximum operating pressure of 4,400 psi. The John Deere 245 P-Tier needs a total flow of 162 gpm and a bucket pressure of 4,970 psi.

Model | Maximum Flow Rate (gpm) | Maximum Operating Pressure (psi) |

|---|---|---|

John Deere 350 | 106 | 4,400 |

John Deere 245 P-Tier | 162 | 4,970 (bucket) / 5,510 (boost) |

You should also check the size of your excavator and the type of work you do. Some jobs need more power or higher flow rates. Always compare the pump’s numbers to your machine’s needs. If you use the wrong pump, you might see leaks, slow response, or strange noises. Operators often notice these problems when the pump does not match the machine.

Checklist

Use this checklist to help you choose the right john deere excavator hydraulic pump:

Find your excavator’s model and year.

Get the manufacturer number and model/SKU of your pump.

Check the part number of the coupler.

Review the needed flow rate and pressure for your model.

Make sure the pump meets or beats OEM specifications.

Pick a pump made from strong materials.

Confirm the pump fits your job (digging, lifting, etc.).

Ask about warranty coverage and what is not covered.

Buy from a trusted supplier like YNF Machinery.

Tip: Regular checks and watching hydraulic fluid levels help your pump last longer and work better.

Mistakes to Avoid

Many people make mistakes when picking a hydraulic pump. You can avoid these problems by following some easy rules:

Do not ignore compatibility. Always match the pump to your excavator’s model.

Do not buy from unknown suppliers. Bad pumps can break and cause accidents.

Do not focus only on price. Cheap pumps may cost more in repairs and lost time.

Do not forget to check the pump’s specifications. Wrong flow rate or pressure can hurt your machine.

Do not skip regular maintenance. This helps you find problems early.

If you want your john deere excavator hydraulic pump to work well and last a long time, pick a pump that fits your machine and your job. YNF Machinery offers pumps that meet these needs and give good performance for John Deere excavators.

You can pick the right john deere excavator hydraulic pump by following some easy steps. First, make sure the pump’s specifications fit your machine. Then, check if the pump matches by using the manufacturer number and model. You can ask suppliers like YNF Machinery for help. They have many pumps and keep parts ready. Experts can help you choose the best pump for your excavator. You can also learn more by taking classes or watching online videos about pumps. Doing these things helps your excavator work safely and well. You can feel sure about your choice and keep your machine working strong.

Suppliers have many hydraulic pump choices for you.

Experts can help you pick the right pump for your machine.

Parts specialists help you avoid long waits by having parts ready.

Training includes classes for operators and online lessons.

Tip: Always talk to experts and use trusted suppliers to get the best results for your john deere excavator hydraulic pump.

FAQ

What information do you need before buying a hydraulic pump?

You need your excavator’s model, year, and the manufacturer number. Check the pump’s flow rate and pressure. This helps you pick the right pump for your machine.

How often should you check your hydraulic pump?

You should inspect your hydraulic pump every month. Look for leaks, strange noises, or slow movement. Regular checks help you find problems early.

Can you install a hydraulic pump by yourself?

You can install a hydraulic pump if you have experience. If you feel unsure, ask a professional for help. This keeps your machine safe.

Where can you buy a reliable hydraulic pump for your John Deere excavator?

You can buy a reliable hydraulic pump from YNF Machinery. They offer pumps that fit John Deere excavators and meet high standards.

Tip: Always ask for warranty details before you buy a hydraulic pump.

What signs show your hydraulic pump needs replacement?

You may notice slow digging, weak lifting, or loud noises. Leaks and overheating also mean your pump needs replacement. Replace it soon to avoid damage.