You need to do regular maintenance to keep your excavator main hydraulic pump working well. If you skip regular maintenance, the pump can get too hot. The seals can break, and fixing it can cost a lot of money. Some common problems are dirty hydraulic fluid, air bubbles, and blocked heat exchangers. If you do not do regular maintenance, you might have to pay more for emergency repairs. Your machine might stop working, and there could be safety problems. Experts say if you do not spend one dollar on maintenance now, you may have to spend four to seven dollars later.

Key Takeaways

Taking care of your excavator’s hydraulic pump saves money. Check fluid levels every day. Look for leaks often. This helps your machine work well.

Use the right hydraulic fluid from your manual. This keeps the pump safe from damage. It stops the pump from getting too hot. Your machine works better this way.

Watch for signs the pump is failing. Listen for weird sounds. Notice if the machine moves slowly. Fix problems quickly to avoid bigger trouble.

Stick to a good maintenance plan. Do daily checks and regular inspections. This finds problems early. It keeps your excavator working great.

Fix small problems on expensive pumps instead of replacing them. This saves you money. It helps your equipment last longer.

Excavator Main Hydraulic Pump Overview

Pump Function

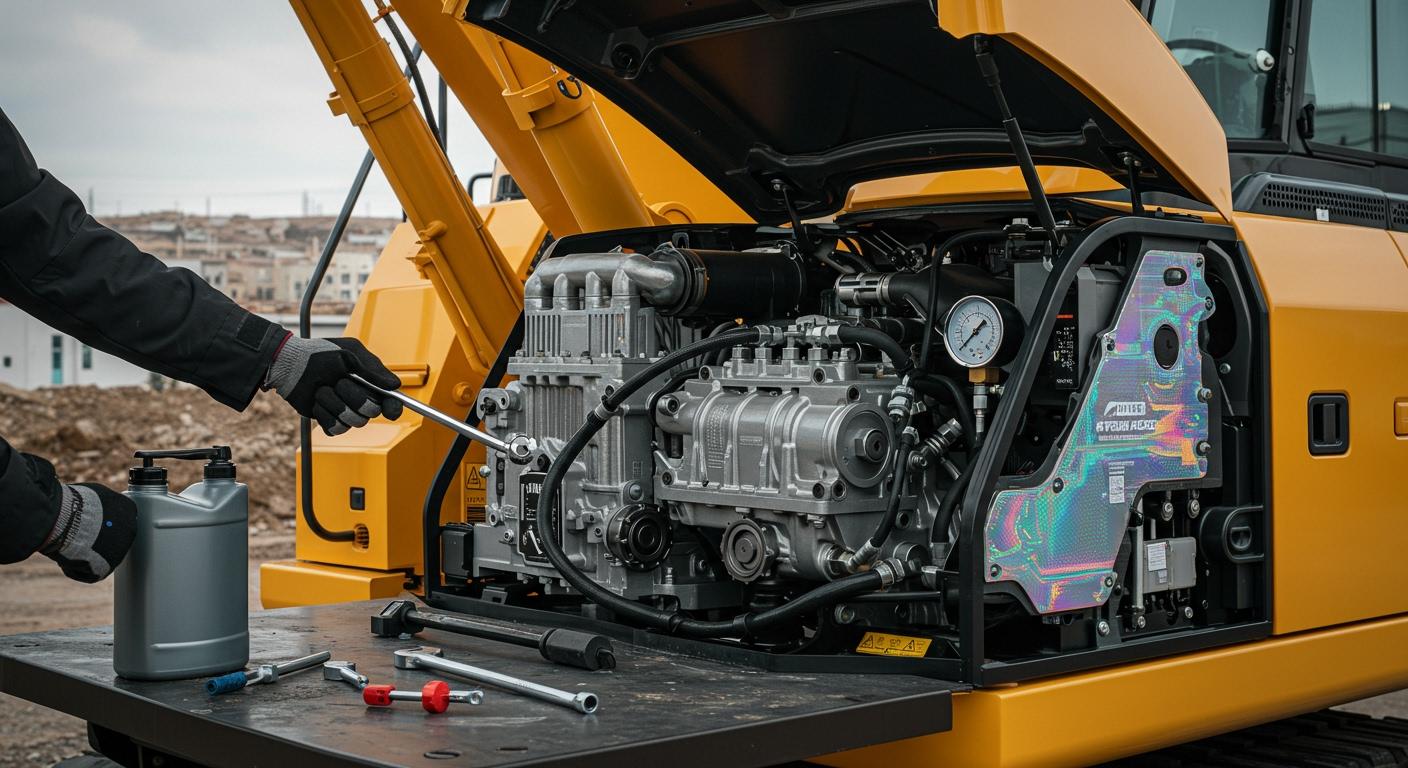

The excavator hydraulic pump helps your machine move. It changes engine power into hydraulic energy. This energy lets you control the machine’s parts. The pump pushes hydraulic fluid through the system. You need strong pressure to lift heavy things. The pump gives this power.

Changes engine power into hydraulic energy

Moves hydraulic fluid through the system

Helps run machine attachments

Makes high pressure for lifting heavy things

Gives power for digging

Lets you move materials

Helps you make careful movements

The pump has parts like the pump body, pistons, and seals. You should check these parts often. If you see leaks or damage, fix them fast. Change filters and fluids when needed to keep things clean. Watch the system pressure to keep it working well.

Tip: Taking care of pump parts often helps you avoid big repair bills and stops.

Excavators use different kinds of pumps. Gear pumps are quiet and work well. Vane pumps run smoothly and handle high pressure. Piston pumps last a long time and work hard. Each pump type needs special care and reacts to dirt in its own way.

Importance in Excavator Performance

The main hydraulic pump is very important for your excavator. It turns engine power into hydraulic flow and pressure. This is needed for the machine to work well. The pump’s strength and how well it works affect your machine’s job.

Component | Description |

|---|---|

Main Hydraulic Pump | Changes engine power into hydraulic flow and pressure for good work. |

Efficiency | Affects how well the whole hydraulic system works. |

You need the hydraulic system for smooth and careful moves. Digging and lifting need power and accuracy. The pump makes this happen. If you take care of the pump, your excavator will work better and last longer.

Hydraulic Pump Maintenance Essentials

Daily Maintenance Tasks

You should check your excavator’s hydraulic pump every day. These checks help you find problems early. This can stop expensive repairs. Start by looking at fluid levels. Check hydraulic oil, engine oil, and coolant. Add more fluid if it is low. Use the right fluid for your machine.

Use this table to help with daily checks:

Task | Description |

|---|---|

Visual Leak Detection | Look at cylinders, hoses, and fittings for leaks. |

Hydraulic Fluid Level Check | Check fluid level with engine on and bucket pulled in. |

Fluid Quality Assessment | Look at fluid color and thickness for dirt or problems. |

Operational Response Testing | Test all hydraulic parts for smooth moves and correct speed. |

Clean the pump area often to keep dirt away. Check for leaks every day. Look for signs of damage or fluid loss on hoses, seals, and valves. If you see a leak, fix it right away. This stops more damage.

Tip: Finding leaks and dirty fluid early saves money and keeps your excavator working well.

Scheduled Inspections

Regular inspections help your hydraulic pump last longer. Follow the maker’s rules for how often to check. Do daily, weekly, and monthly checks. This helps you find problems before they get worse.

Frequency | Inspection Focus |

|---|---|

Daily | Check fluid levels, leaks, and safety gear. |

Weekly | Check the hydraulic system and grease moving parts. |

Monthly | Look at the pump, engine, and electrical systems. |

Each time, look at hoses, seals, and valves. Watch for wear, leaks, or damage. Bad seals can cause leaks inside and lower pressure. Regular checks help stop surprise breakdowns and costly repairs.

Maintenance tips: Follow the maker’s service plan. Change your schedule if your work area is tough.

Fluid and Filter Changes

Changing fluid and filters is very important. Check your machine’s manual for when to change hydraulic fluid. Most makers say to change fluid every 1,000 to 2,000 hours. If you work in rough places, change it more often.

Change filters as the maker says and for your work area.

In dusty or wet places, change filters more often.

Check filters often; change them if they are dirty or blocked.

Use hydraulic oils that stay thick, fight rust, and protect parts.

Make sure the oil matches your excavator pump’s needs.

Guideline | Description |

|---|---|

Viscosity | Hydraulic oils must stay thick from -20°C to +80°C and protect against heat and breakdown. |

Additives | Oils need rust fighters, heat helpers, water blockers, foam stoppers, and part protectors. |

Seal Conditioning | Special seal helpers keep seals soft and stop leaks. They must work with different seal types. |

Anti-Wear Properties | Oils must protect against wear and heat for high-pressure jobs. |

Tips: Always use hydraulic fluid with a boiling point much higher than water. Make sure it works with your pump.

YNF Machinery sells good hydraulic pump parts, kits, and fluids for your excavator. Their products meet maker rules and help you do the right maintenance for long life.

Leak Detection

Finding leaks is very important for pump care. You can use different ways to find leaks:

Use UV dye to find leaks you cannot see.

Test for leaks by checking all connections under pressure.

Leak detectors help find leaks you cannot see by looking.

Ultrasonic tools work well for high-pressure leaks.

Use a flow meter to measure how much fluid is lost.

Tip: Finding leaks early stops repairs and keeps your pump working well.

Check for leaks often and fix them fast. This keeps your hydraulic system safe and helps your pump last longer. If you need new parts or help, YNF Machinery has good solutions for your hydraulic pump care.

Common Excavator Hydraulic Pump Problems

Symptoms of Failure

You should look for signs that your hydraulic pump is not working right. If you see these signs early, you can stop bigger problems. Many people notice these signs before the pump breaks. Here are some things you might see:

You might hear strange sounds like grinding or whining. These sounds can mean the pump is wearing out inside.

The excavator arms or bucket may move slower than normal. This can mean the pump is not making enough pressure.

The engine might use more fuel than before. If the pump is having trouble, the engine works harder and burns more fuel.

The hydraulic system can get too hot. If this happens, the pump may not work as well.

You might see fluid leaking near the pump seals. This often means some parts are worn out.

The machine may shake more than usual when you use it. Extra shaking can mean something is wrong inside the pump.

Warning lights may turn on if the pressure or temperature is not right.

Tip: If you see any of these signs, stop and check your machine right away.

Troubleshooting Steps

Finding pump problems early can save you money. Try these steps to find and fix common issues:

If there is low or no pressure, check the fluid level first. Look at the filters to see if they are blocked. Check for leaks in hoses and around the pump. Make sure the power supply is working.

If the system is getting too hot, check the fluid temperature. Look at the cooler to see if it is blocked. Make sure the pump is the right size for your machine. Check the flow control settings.

If you hear odd noises or feel shaking, look for loose parts. Check for cavitation. Make sure the pump is put in the right way. Look at the fluid to see if it is clean.

If you lose power or the machine is weak, check inside the pump for damage. Look for leaks in the lines. Check other parts of the system. Make sure everything matches the maker’s rules.

Here is a table that shows some common problems, what causes them, and how to fix them:

Problem | Causes | Repairs |

|---|---|---|

Slow Hydraulic Response | Contaminated Fluid, Worn Pump | Replace fluid/filters, test/replace pump |

Hydraulic Cylinder Leaks | Worn Seals, Damaged Rod | Replace seals, repair/replace rod |

Hydraulic System Failures | Low Fluid, Damaged Hoses | Top up fluid, inspect hoses/seals |

If you need good parts or help, YNF Machinery has solutions for your hydraulic pump.

Repair or Replace

When to Repair

You can fix your excavator’s main hydraulic pump if the damage is small. If you see worn seals or bearings, a repair might help the pump work better. Newer pumps with only small problems are good for repair. Fixing these issues early saves you time and money. Expensive pumps like Rexroth or Parker are often worth fixing. These pumps cost a lot to buy new.

Think about these things before you repair:

Criteria | Explanation |

|---|---|

Age of the Pump | Newer pumps with small wear are good to repair. |

Extent of Damage | Small leaks or worn bearings can be fixed. |

Timing for Repair | Fast repairs help when you need your machine soon. |

Cost of Repair vs Replacement | Repairs usually cost less for big or pricey pumps. |

If you decide to repair, always use good parts. YNF Machinery has strong pump kits and parts that meet the rules.

When to Replace

Sometimes, you must get a new pump. If the pump has a cracked case or bent shaft, fixing it will not work. If the pump is old or fixing it costs 60% of a new one, it is better to buy a new pump. You should also replace the pump if you need your machine working fast and a new pump is quicker.

Here are some signs you need a new pump:

Leaks that do not stop after you fix them

Strange knocking or banging sounds from the pump

Hydraulic fluid gets hotter than 81°C

The final drive motor is weak

Here is a simple chart to help you choose:

Option | Condition for Choice | Cost Implication |

|---|---|---|

Replace | Big damage, need machine fast | Fixing costs 60% of a new pump. |

Repair | Small problems, big or expensive pump | Usually saves more money |

Picking the right choice keeps your excavator working well. If you need help, YNF Machinery can give you the right pump or repair kit.

Maximizing Excavator Hydraulic Pump Lifespan

Preventive Maintenance Tips

You can make your excavator hydraulic pump last longer. Follow a strict maintenance plan. Most pumps work for 5,000 to 10,000 hours if you care for them. Regular checks help you find problems early. Check oil levels often. Test hydraulic fluids for dirt. Always use the oil the maker suggests for your yanmar excavator hydraulic pump. Change old seals, O-rings, and gaskets to keep pressure steady. This helps stop leaks. Change filters when monitors show dirt. Good hydraulic fluid protects inside parts. It also shows why maintenance is important.

Tip: Test hydraulic fluid in a lab often. This helps you find problems early and saves money.

Listen for strange sounds or shaking from your yanmar excavator hydraulic pump. Watch for high temperatures. Keep the cooling system working well. These steps help you stop breakdowns. They also help your machine work longer. YNF Machinery gives you good parts and fluids for your maintenance.

Best Operation Practices

You can use smart ways to help your yanmar excavator hydraulic pump last longer. Use clean and correct hydraulic fluid. This stops early wear. Watch pressure and temperature to stop overheating and fluid problems. Keep filters and seals clean and working. This blocks dirt and stops leaks. Teach workers how to use the pump right. This lowers stress on the hydraulic pump.

Here are steps you should follow:

Check for leaks and broken hoses every day.

Warm up the hydraulic system before hard work, especially when it is cold.

Check and fix the oil cooling system often.

Evidence Point | Description |

|---|---|

Excessive Heat Damage | Too much heat can hurt pump parts and make oil bad. |

Temperature Monitoring | Use a gauge to watch pump heat and stop overheating. |

Cooling System Maintenance | Keep the cooling system working to stop pump problems. |

If you do these things, your excavator will work well. You can fix problems before they cost a lot. Good care helps save fuel and lowers costs. YNF Machinery has the right parts and fluids for your yanmar excavator hydraulic pump. They help you do good maintenance.

You can help your excavator work well by taking care of it. Check the machine often to keep it safe and strong. Look at the hydraulic fluid levels a lot. Use fluid that is clean and right for your machine. Look for leaks every time you check. Change filters when you need to. Watch the system pressure so it stays normal. Listen for strange sounds when the machine runs.

If you check for problems often, you can fix them early. Keeping things clean helps stop breakdowns. Write down what you do for your machine. Using good parts from YNF Machinery keeps your pump safe. This helps your pump last longer and saves money.

FAQ

How often should you check the hydraulic pump on your excavator?

You should check your hydraulic pump every day before you start work. Regular checks help you find leaks, low fluid, or damage early. This keeps your excavator running well and safe.

What hydraulic fluid should you use for your excavator pump?

Always use the hydraulic fluid listed in your machine’s manual. The right fluid protects your pump from wear and heat. YNF Machinery offers high-quality fluids that meet most manufacturer standards.

What are the signs that your hydraulic pump needs service?

Look for slow movement, strange noises, leaks, or overheating. If you see any of these signs, stop and inspect your pump. Early service can prevent bigger problems.

Can you repair a leaking hydraulic pump seal yourself?

You can replace simple seals if you have the right tools and parts. For best results, use seal kits from YNF Machinery. If you are unsure, ask a professional for help.

Where can you buy reliable parts for your excavator hydraulic pump?

You can get strong and reliable hydraulic pump parts from YNF Machinery. They offer kits, seals, and fluids that fit many excavator brands. Their products help you keep your machine in top shape.