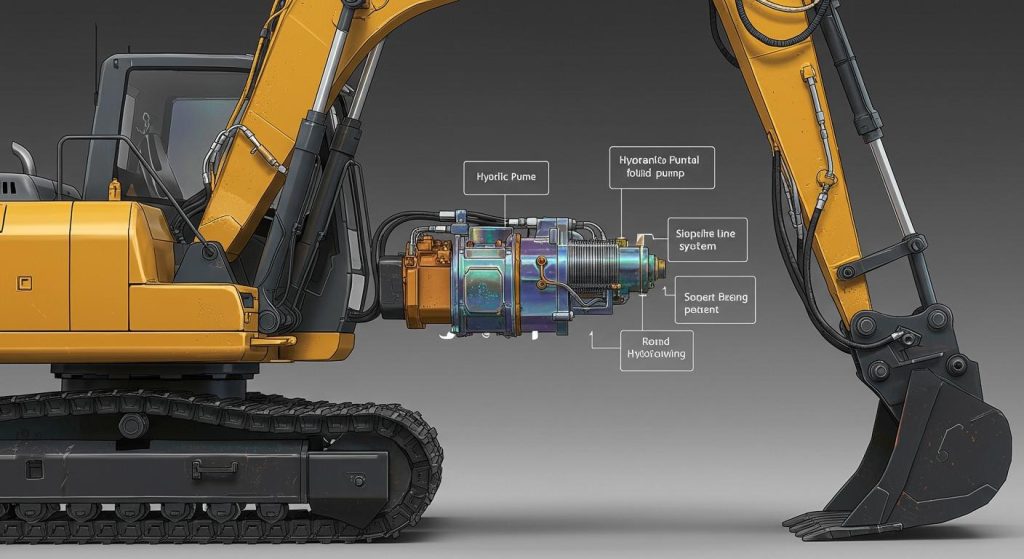

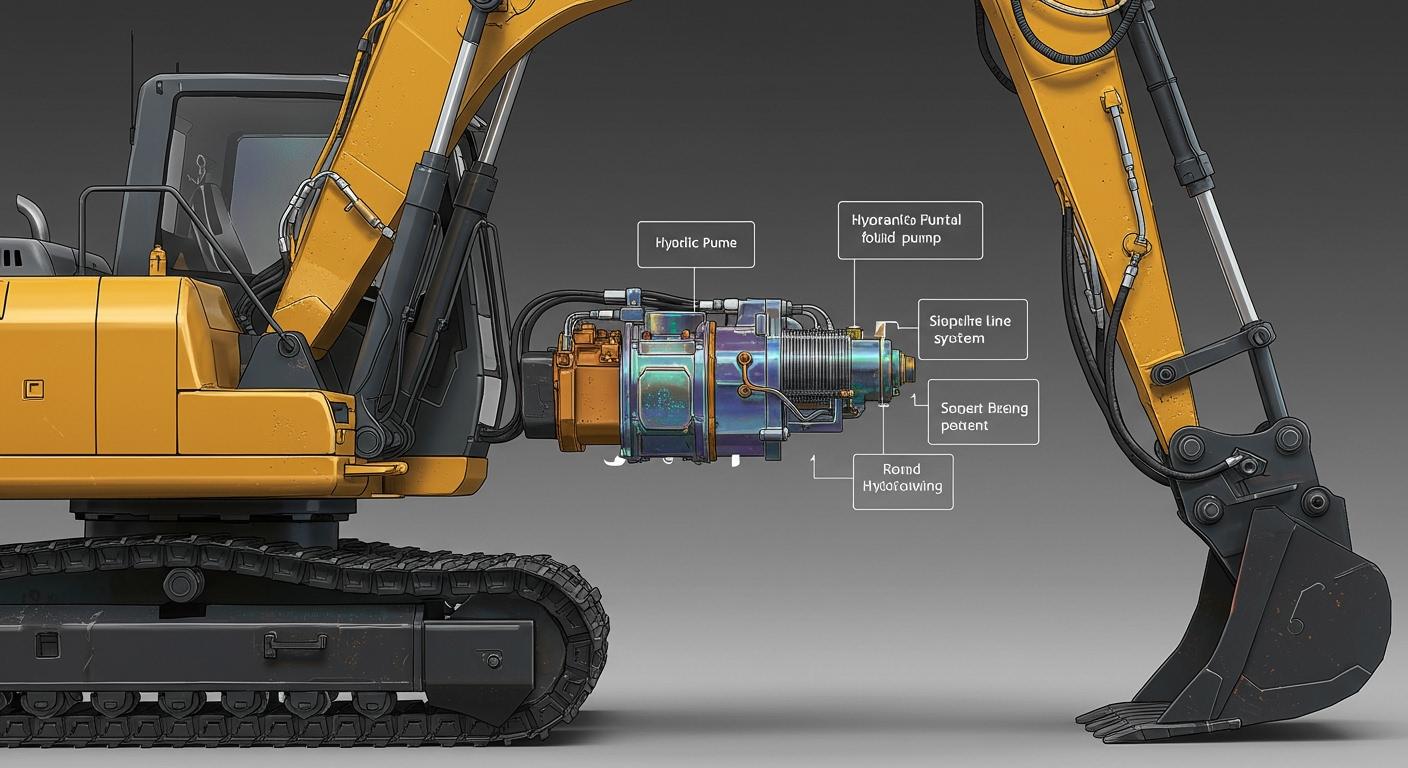

You use the excavator machine hydraulic pump each time you run the machine. This key part gets energy from the engine and changes it into hydraulic energy. That energy makes the excavator’s arm and bucket work. The excavator machine hydraulic pump keeps oil moving in the system, so you can dig, lift, and move things with ease.

The excavator machine hydraulic pump moves fluid, so the machine can work.

The engine gives power to the hydraulic pump, which pushes the fluid for strong and smooth movement.

Pressurized fluid from the excavator machine hydraulic pump helps move heavy parts of the excavator with control.

Key Takeaways

The hydraulic pump changes engine power into hydraulic energy. This lets the excavator dig, lift, and move well.

Picking the right hydraulic pump, like variable displacement, saves energy. It also helps the excavator work better by making flow rates just right.

Check the hydraulic pump and fluid levels often. This stops breakdowns and keeps your excavator working smoothly.

Knowing how pressure and flow change performance helps you use your excavator better. It also helps you get more work done.

Using clean hydraulic fluid and good filters is very important. It keeps the pump working longer and stops expensive repairs.

Excavator Machine Hydraulic Pump Role

Converts Engine Power to Hydraulic Energy

You need the excavator machine hydraulic pump every time you use your excavator. The pump gets energy from the engine and turns it into hydraulic energy. This change gives power to the whole hydraulic system. When you start the engine, the pump moves fluid through the system. This lets you control the boom, stick, and bucket easily.

Excavators use two main hydraulic pump types: variable displacement and fixed displacement. Each type changes how well the pump uses energy.

Key Point | Variable Displacement | Fixed Displacement |

|---|---|---|

Flow | Adjustable | Constant |

Efficiency | High | Moderate |

Control | Precise | Simple |

Applications | Versatile | Specific |

Cost | Higher | Lower |

Maintenance | Complex | Simple |

Power Use | Optimized | Fixed |

Flexibility | High | Low |

Variable displacement pumps change flow rates when needed. This means you only use the energy you need. It helps save energy and makes the system work better. You can save up to 75% of energy during the boom’s work cycle. Electric power use drops by 76.1% when the boom moves. About 82.7% of possible energy can be used again. This makes your excavator work better and saves money.

Tip: Pick the right hydraulic pump for your excavator. This helps you save energy and makes your machine work better.

YNF Machinery sells strong excavator machine hydraulic pumps. Their pumps help your hydraulic system work well. They make sure energy changes smoothly and your pump lasts a long time.

Powers Digging and Lifting

The excavator machine hydraulic pump gives you the power to dig and lift. When you use the controls, the pump sends pressurized fluid to the cylinders. This fluid moves the pistons. The pistons move the boom, stick, and bucket. You can dig holes, lift heavy things, and move parts exactly because of the pump’s power.

The hydraulic pump changes engine energy into hydraulic energy. This makes digging and lifting possible.

Hydraulic systems let you move excavator parts smoothly and exactly.

The system turns engine energy into force. This powers the excavator’s movement.

Hydraulic fluid pressure moves pistons. This lets the boom, stick, and bucket do their jobs.

When you dig, resistance goes up. The pump increases pressure in the boom’s small chamber. When you lift a full bucket, pressure moves to the big chambers in the stick and bucket. This change in pressure helps you do different jobs easily.

A good excavator machine hydraulic pump keeps your system working well. Pumps made from strong materials last longer and work better. If you take care of your pump and use good filters, you lower damage. YNF Machinery has tough hydraulic pumps. These pumps help your excavator last longer and work better.

Excavator Hydraulics System

Hydraulic Fluid Flow

You control your excavator’s power by moving hydraulic fluid. The hydraulic pump starts by pulling fluid from the reservoir. It then pushes the fluid under pressure. This fluid travels through hoses and valves to different parts. Hydraulic flow lets you move the boom, stick, and bucket exactly. The pump type changes how much fluid moves. Gear pumps and piston pumps are often used in excavators.

Pump Type | Flow Rate (GPM) |

|---|---|

Gear Pumps | 15-25 |

Piston Pumps | 30-44 |

Faster hydraulic flow means parts move quicker. Control valves send fluid to the right cylinders. This makes sure each part works when needed. The pump, hoses, valves, and cylinders all work together. They help your excavator hydraulics run well.

The hydraulic pump pulls fluid from the reservoir and adds pressure.

It sends the pressurized fluid to different excavator parts.

The main control valve manages where the fluid goes, so you can move parts easily.

Pressure Creation and Control

Pressure is what gives excavator hydraulics their strength. The hydraulic pump pushes fluid into the system with force. Valves help control this pressure. They keep your machine safe and working well. Relief valves stop too much pressure from building up. They let out extra pressure to protect the excavator. There are different types of relief valves in excavators.

Relief Valve Type | Function |

|---|---|

Main Relief Valve | Sets the highest pressure; stops damage from too much pressure; lets out extra pressure. |

Secondary Relief Valve | Sets its own pressure limit; acts as backup; stops local overpressure. |

Pilot Relief Valve | Controls pilot pressure; keeps things steady; protects solenoid valves. |

Travel Relief Valve | Stops pressure from getting too high; protects the travel motor. |

Swing Relief Valve | Lets out extra pressure if the swing stops fast; protects the swing motor. |

Load-holding Relief Valve | Stops parts from moving by accident; keeps pressure steady in circuits. |

Pressure helps you lift heavy things and dig hard ground. The pump and valves work together to control pressure. This keeps your excavator hydraulics safe and strong.

Movement of Arms and Attachments

Excavator hydraulics let you move the arms and tools. The hydraulic pump sends pressurized fluid to the cylinders. Control valves guide the fluid to the right spot. When fluid goes into a cylinder, it pushes the piston. This moves the boom, stick, or bucket. The system gives you smooth and exact movement.

The boom circuit uses cylinders, hoses, and a control valve for up and down movement. You can dig, lift, and move things easily. How fast you move depends on hydraulic flow. More flow means the arms and bucket move faster. Pressure gives the power to do tough jobs.

Factor | Role in Excavator Operation |

|---|---|

Pressure | Gives the excavator more force for heavy work. |

Flow | Makes the arms and bucket move faster when higher. |

You need the pump, valves, hoses, and cylinders to work together. This gives you good control. YNF Machinery has strong hydraulic pumps. These pumps help your excavator hydraulics work their best.

Pump Interaction with System Parts

Suction and Pressure Process

You control your excavator’s power by steps inside the hydraulic pump. First, oil suction happens. The pump shaft turns and makes negative pressure. This opens the oil suction valve. Hydraulic oil comes from the tank. Next, the swash plate turns and pushes the plunger. The plunger goes into the cylinder. This makes the cavity smaller and raises hydraulic pressure. Pressurized oil moves through the main oil circuit. It goes to the boom and stick cylinders. If pressure gets too high, the overload valve opens. Extra oil goes back to the tank. This keeps your excavator safe.

Oil suction: The pump shaft turns. Negative pressure pulls oil from the tank.

Pressurization: The swash plate pushes the plunger. The cavity gets smaller and pressure goes up.

Delivery: Pressurized oil moves to the boom and stick cylinders.

Pressure relief: The overload valve opens if pressure is too high. Oil returns to the tank.

Tip: Check your hydraulic fluid and system pressure often. This stops overheating and helps your excavator work well.

Cylinder and Piston Movement

The hydraulic pump helps move the cylinder and piston. When you use the controls, the pump changes mechanical energy into hydraulic pressure. The piston moves up and down and pumps oil. As the piston moves, it makes a vacuum. This lets hydraulic oil enter the pump chamber. When the piston goes up, it pressurizes the oil. If pressure is higher than the outlet spring, oil goes through the main control valve into the cylinder.

Higher flow rates make the piston move faster. This helps you finish jobs quickly.

Lower flow rates slow the piston down. You get more control for careful work.

Thick hydraulic fluid can make the pump work harder and respond slower.

Thin fluid may make things faster but can cause leaks and poor lubrication.

Longer stroke lengths mean the piston takes more time to travel.

Shorter stroke lengths let the piston move quicker.

Note: YNF Machinery has pumps for smooth cylinder and piston movement. Their pumps help you get good performance and better control.

Impact on Performance

How your hydraulic pump works with other parts affects performance. Good hydraulic flow makes your machine work better and last longer. More hydraulic flow means faster cycles. Better hydraulic flow can make your excavator work up to 20% better. Using two sources for the pump saves energy. Changing engine speed and bucket cut depth can make you 30% more productive. It also lowers greenhouse gas emissions by 24%. Your excavator can move 62% more spoil per hour for each liter of fuel.

Aspect | Effect on Performance |

|---|---|

Flow Rate | More flow can move fluid better. Too much flow can lower pressure. |

Pressure | More pressure gives more power. Too much pressure can break parts. |

Issue | Description | Solution |

|---|---|---|

Fluid Contamination | Dirty fluid hurts pump life and performance. | Check fluid, use good filters, seal system. |

Leakage | Leaks waste fluid and lower efficiency. | Check for leaks, change seals, tighten parts. |

Cavitation | Air bubbles can break pump parts. | Use clean fluid, keep levels and pressure right. |

Overheating | Too much friction and bad cooling cause damage. | Watch temperature, lubricate, don’t overload. |

Noise and Vibration | Bad alignment or worn parts cause problems. | Check for wear, change bearings, mount right. |

Loss of Pressure | Leaks or bad parts lower performance. | Check for leaks, check seals, set pump right. |

Callout: Better pump-system integration, like using hydraulic dredge pumps, gives better performance and reliability. Fewer moving parts mean less breakdown and lower costs.

You need the hydraulic pump to make your excavator strong and accurate for digging and lifting. If you understand how the pump works, you can find problems early and keep your machine working well.

Checking the pump often and using clean fluid helps it last longer.

New pumps with digital controls help save fuel and work better.

YNF Machinery gives you good options to help you take care of your excavator and make it work even better.

FAQ

How often should you check the hydraulic pump on your excavator?

Check the hydraulic pump every time before you use it. Look for leaks or strange sounds. Make sure the fluid level is not low. Regular checks help stop breakdowns. They keep your excavator safe and working well.

What signs show your excavator hydraulic pump needs repair?

Look for slow arm movement or loud sounds. Watch for leaking fluid from the pump. If your excavator feels weak or loses power, the pump may need fixing. Fix problems fast to stop bigger issues.

Can you use any hydraulic pump for your excavator?

You must use a pump that fits your excavator’s size and system. The wrong pump can hurt your machine or make it work badly. YNF Machinery has pumps made for many excavator models.

How does clean hydraulic fluid help your excavator?

Clean hydraulic fluid helps the pump and system work well. Dirty fluid can cause damage, leaks, or overheating. Change fluid and filters often to keep your excavator safe.