Excavator hydraulic pump pressure usually stays between 2,000 and 2,500 psi during normal operation. Some models reach higher values for demanding tasks. You can see the differences in the table below:

Excavator Size | Maximum Pressure (PSI) | Boost Pressure (PSI) |

|---|---|---|

1-ton machines | 3,130 – 3,555 | N/A |

Larger models | Up to 4,980 | 5,260 (for 10-15 seconds) |

Keeping the right pressure helps your excavator work smoothly and safely. If pressure drops or rises, you may notice slower movement, trouble with work cycles, or even damage to hydraulic parts.

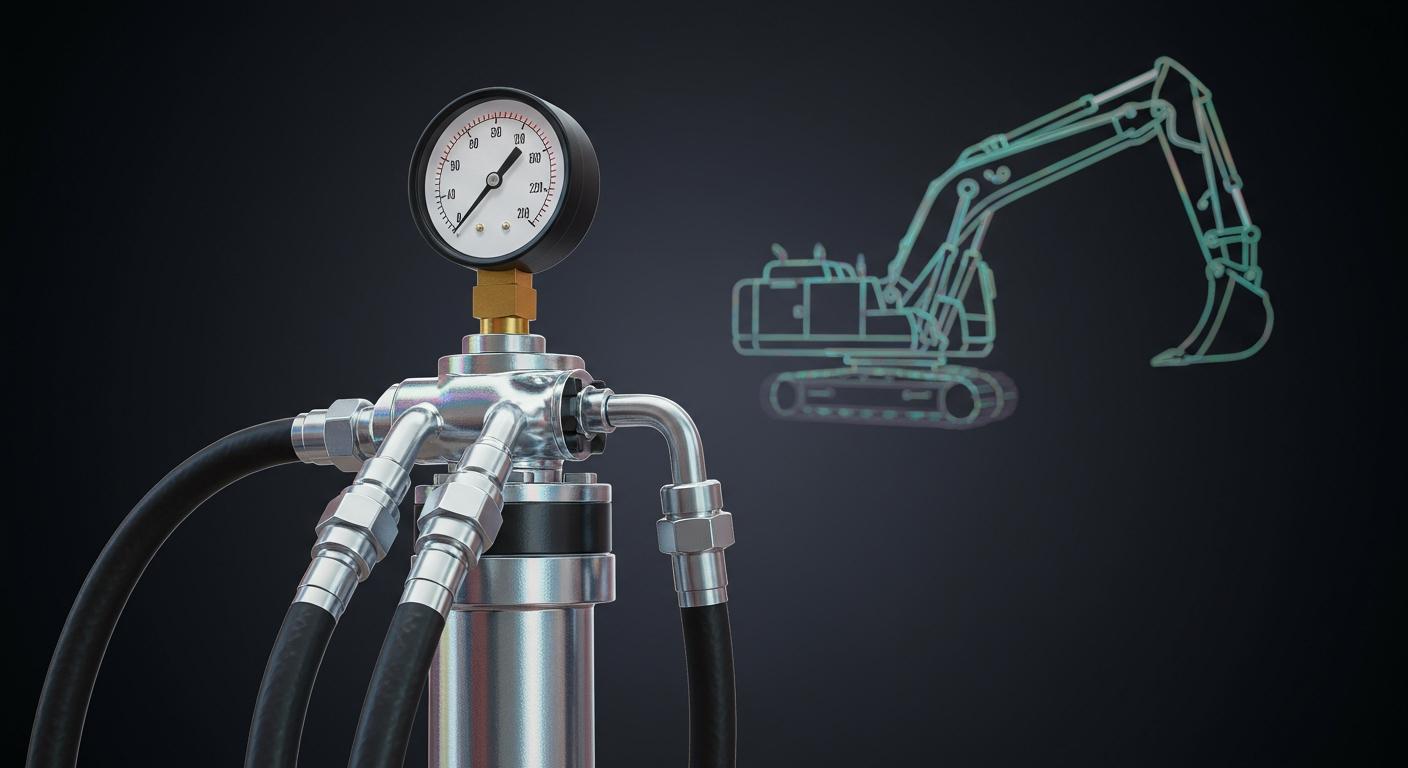

Tip: To check if your pump pressure is correct, follow these steps:

Check connections for leaks.

Attach a gauge to the pressure port.

Warm up the system.

Find the regulating valve.

Adjust pressure as needed.

Test all functions.

Check connections again.

Key Takeaways

Excavator hydraulic pumps usually work between 2,000 and 2,500 psi. Keeping this pressure helps the machine run well and stops damage.

Check your hydraulic pump pressure often with a gauge. Use clear steps to get correct readings and find problems early.

Look for signs of bad pressure, like weird sounds or slow moves. These signs mean there could be a problem that needs quick fixing.

Keep hydraulic fluid clean and change it every 2,000 to 4,000 hours. This keeps the machine working well and helps it last longer.

Watch the oil temperature carefully. If it gets too hot, the fluid gets thin and can leak. Try to keep it under 80°C to stay safe.

Excavator Hydraulic Pump Pressure Range

Standard Operating Pressure

It is important to know the usual pressure for excavator hydraulic pumps. Most excavators work at 2,000 to 2,500 psi for normal jobs. This pressure helps the machine move smoothly and dig well. The flow rate, measured in gallons per minute, changes how fast your excavator reacts. Small excavators often use gear pumps. Bigger machines use piston pumps instead. You can look at the table below to see the differences:

Excavator Type | Hydraulic Pump Type | Pressure Range (PSI) |

|---|---|---|

Compact Excavators | Gear Pumps | 3,130 – 4,980 (up to 5,260 with boost) |

Large Excavators | Piston Pumps | Higher than 4,980 |

The working pressure depends on your machine’s size and setup. Always check your manual to find the right numbers.

Maximum and Boost Pressure

Some jobs need more power. Your excavator hydraulic pump pressure can go up to 4,980 psi. Some strong models use boost pressure for a short time. Boost pressure can reach 5,260 psi or 380 bar. Boost pressure helps lift heavy things or break hard ground. Only use boost pressure for a few seconds. Using it too long can hurt the hydraulic system.

Note: High heat can change your excavator hydraulic pump pressure. When oil gets hot, it becomes thinner. This can cause leaks and make the system less efficient. Oil can also wear out faster. Seals may break if the temperature goes above 80°C. Watch the temperature to keep your system safe.

Pilot Pressure

Pilot pressure helps control your excavator. Most systems, like the VOLVO 200 Excavator, use pilot pressure between 400 and 500 psi. This lower pressure lets you move the arms and bucket carefully. The pilot pump sends flow to different parts, so you can work safely and smoothly. Pilot pressure also controls bigger valves. This makes it easier to handle high-pressure flows. You get better control of your machine. This means there is less chance of something breaking.

Pilot valves use pilot pressure so a small control can manage bigger flows. This setup is important for excavators. You need good control for digging, lifting, and moving things.

Importance of Correct Pressure

Performance Impact

It is important to keep the right pressure in your excavator hydraulic pump. If the pressure gets too low, your excavator loses power. Lifting heavy things becomes harder. The machine may not dig deep or move fast. Low pressure makes each movement take longer. This means you might have more downtime. You could also pay more for repairs. If the flow rate is too low, actuators do not get enough power. Your work will slow down.

High pressure can cause problems too. The hydraulic system can get too hot. The flow rate may change quickly. You might see leaks or hear odd sounds. These signs show the system is stressed. Keeping the pressure in the right range helps avoid these problems. Your excavator will run better.

Tip: Always look at the pressure gauge before you start. If the numbers are not normal, stop and check the system.

Safety and Longevity

Having the right pressure keeps you safe. It also helps your excavator last longer. High pressure can break parts inside the hydraulic system. You might see damage, parts coming apart, or less oil between parts. O-rings and hoses can burst. This can cause sudden breakdowns. If fluid leaks, it can blow out or even hurt you. Fluid injection injuries are very dangerous.

Check hoses often. Never touch pressurized hoses to find leaks. Always let out the pressure before fixing anything. If the system gets too hot or loses pressure, shut it down fast. This helps stop accidents.

Keeping the right pressure stops overheating. It also lowers wear on hydraulic parts. You avoid too much strain on the pump and other parts. This helps them last longer. Regular checks and good settings protect your excavator. Your machine will be ready for work.

Checking Excavator Hydraulic Pump Pressure

Tools Needed

To check excavator hydraulic pump pressure, you need the right tools. You should have a pressure gauge that connects to the test ports on your machine. Many digital hydraulic pressure test kits are available. For example, you can use a kit that measures up to 10,000 psi. These kits help you check both the pump and pilot pressure. Always compare your readings with the numbers in your manual.

Pressure gauge or digital test kit

Test couplings and hoses

Wrenches and safety gloves

Tip: You can find reliable hydraulic pump testing tools and replacement parts at YNF Machinery. They offer equipment that fits most excavators and helps you keep your hydraulic system in top shape.

Testing Steps

You need to follow a step-by-step process to get accurate results. Start by making sure the hydraulic oil temperature is about 131°F (55°C). This helps you get a true reading. Next, check for cylinder drift. Measure the boom cylinder from pin to pin, then wait three minutes with the engine off. Record any changes. After that, test the cylinder cycle times. Set the engine speed to maximum, then time how long it takes to extend and retract the bucket. You should also measure travel cycle times by marking a distance and timing the machine as it moves.

Warm up the hydraulic oil to the correct temperature.

Measure and record the boom cylinder length.

Wait three minutes with the engine off, then check for drift.

Set the engine to full speed and time the bucket’s movement.

Mark a distance and time the excavator as it travels.

Reading Results

When you finish testing, look at your pressure readings. Compare them to the manufacturer’s recommended working pressure. If the numbers are too low, your flow rate may drop, and the machine could lose power. If the numbers are too high, the hydraulic system may overheat or leak. Pressure testing helps you spot problems early. You can see if the flow rate matches what your excavator needs. This keeps your excavator hydraulic pump pressure in the safe range and helps your machine last longer.

Note: Always record your results and check them against the manual. If you see big changes, fix the problem before using the machine again.

Abnormal Pressure Issues

Causes

Many things can make the pressure in your excavator go wrong. Old pump parts often cause low pressure. Leaks in the hydraulic fluid also lower pressure and slow the flow. Dirty or blocked filters stop fluid from moving easily. This makes the pump work harder. Air in the system can cause cavitation. Cavitation makes loud noises and hurts parts. Overheating happens if oil is low, dirty, or the cooling system is blocked. Using oil with the wrong thickness or putting too much weight on the machine can also cause problems.

Worn pump parts

Hydraulic fluid leaks

Blocked or dirty filters

Air in the system (cavitation)

Overheating from low oil or blocked cooling

Tip: Check your excavator every 1,000 hours to find problems early.

Symptoms

You can find abnormal pressure problems by looking for certain signs. Listen for grinding, whining, or knocking sounds near the pump. These sounds often mean parts are worn or there is cavitation. If the arms or bucket move slower than normal, the pump may not give enough flow. If the engine uses more fuel, it may be working too hard. Overheating in the hydraulic system is another clue. Look for leaks around seals or hoses. You might feel more shaking when you use the machine. Some excavators show warning lights if the pressure is not right.

Strange noises from the pump

Slower arms or bucket movement

More fuel used

Overheating

Leaks you can see

More shaking

Warning lights on the dashboard

Troubleshooting

You can fix pressure problems by following simple steps. First, check the hydraulic fluid level and add more if needed. Look at all filters for dirt or clogs and change them if needed. Check hoses and connections for leaks. Look at the hydraulic pump for damage or wear. Make sure the engine gives enough power. Check the fluid temperature to keep it safe. Clean the hydraulic cooler if it is blocked. Make sure the pump fits your system. Listen for odd sounds or feel for shaking, and tighten or change loose parts. If you think there is cavitation, get rid of air and fix leaks. Check all hydraulic lines for blockages. Last, make sure the pump’s speed and flow match what the manual says.

Note: Always check your results with the manual. If you need new parts or testing tools, YNF Machinery has good choices for most excavators.

You help your excavator work well by keeping the right hydraulic pump pressure. Checking the pressure often lets you find problems early. This also keeps the flow rate steady. Try these tips to get good results:

Change hydraulic fluid every 2,000–4,000 hours.

Watch oil temperature so it does not get too hot.

Test fluid often and change it if it is dirty.

Look for leaks and clean safety valves.

Taking care of your machine and fixing problems fast keeps it safe. This helps you avoid losing time and money. Always check the flow rate and use your manual for changes. YNF Machinery has good parts to help you with maintenance.

FAQ

What happens if your excavator hydraulic pump pressure is too low?

Low pressure makes your excavator slow and weak. You may notice poor digging or lifting. The machine might not finish tasks on time. Always check for leaks or worn parts if you see these signs.

How often should you check hydraulic pump pressure?

You should check the pressure every 1,000 hours of use or if you notice performance changes. Regular checks help you find problems early and keep your excavator running well.

Can you adjust the hydraulic pump pressure yourself?

Yes, you can adjust the pressure if you have the right tools and follow the manual. Always warm up the system first. If you feel unsure, ask a trained technician for help.

What tools do you need to test hydraulic pump pressure?

You need a pressure gauge, test hoses, and safety gloves. A digital test kit works best for most excavators. YNF Machinery offers reliable testing tools for your needs.

Why does hydraulic oil temperature matter?

High oil temperature can thin the fluid and cause leaks. Hot oil wears out seals and parts faster. You should keep the oil below 80°C to protect your hydraulic system.