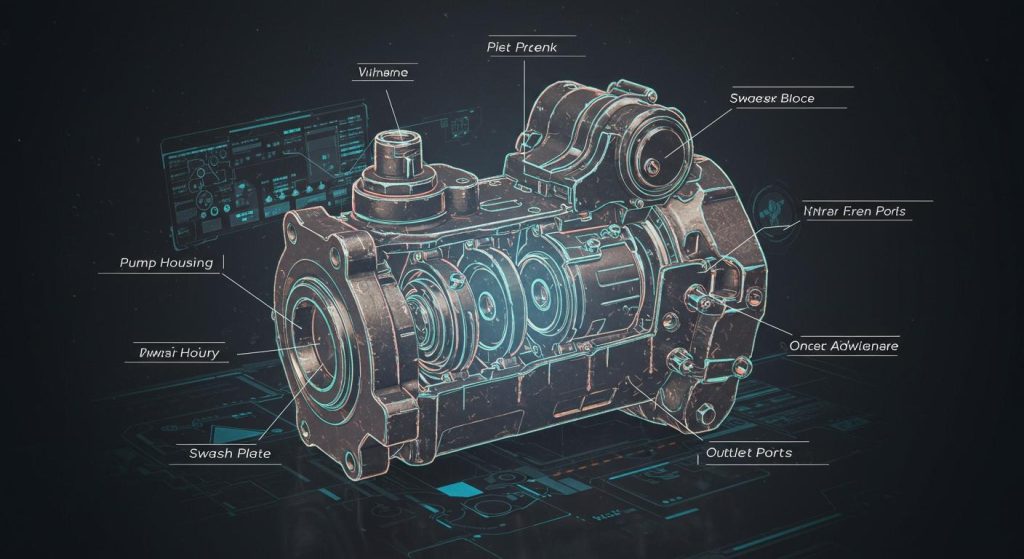

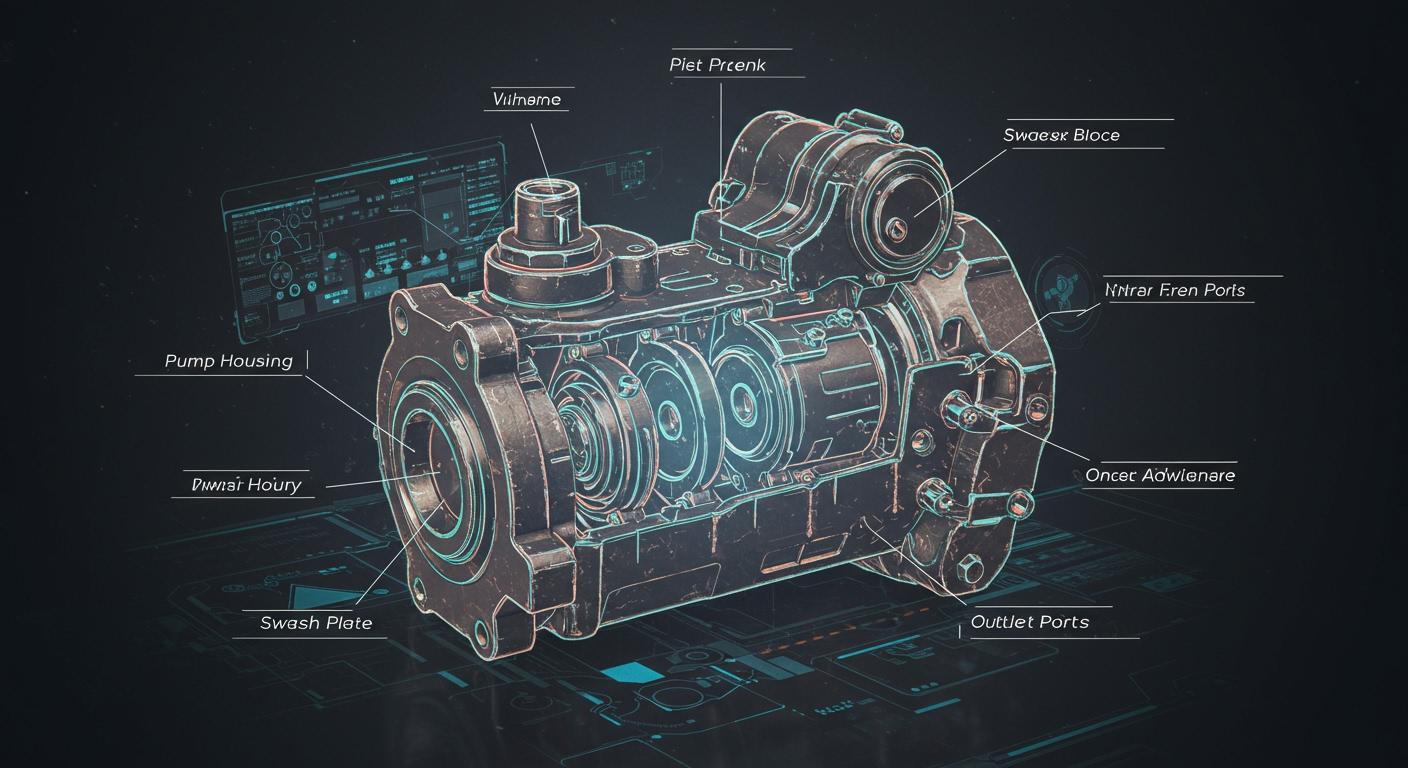

You use many important excavator hydraulic pump parts name in an excavator hydraulic pump. These parts include the valve plate, cylinder block, ball guide, retainer plate, piston, drive shaft, oil reservoir, and safety release valve. If you know each excavator hydraulic pump part’s name, you can find problems early. This helps your machine work well.

Component | Impact on Maintenance Efficiency |

|---|---|

Hydraulic Pump | Main part; needed for system to work and for quick checks. |

Hydraulic Cylinder | Needed to keep pressure; checking often stops breakdowns. |

Oil Tank | Good hydraulic oil helps the system; change oil often. |

Valve | Makes sure oil flows right; fixing it stops problems. |

Filter | Change filter often to stop dirt; this helps the system last longer. |

You do better maintenance if you know what sealings do and keep impeller blades working well. Every part has its own job, and you will see how they work in the next parts.

Key Takeaways

Learn the main parts of an excavator hydraulic pump, such as the valve plate and cylinder block. This helps you find problems early and keeps your machine working well.

It is important to do regular maintenance. Check fluid levels every day. Change filters every 500 hours. This stops breakdowns and makes your pump last longer.

Use good parts from trusted suppliers like YNF Machinery. Quality parts help prevent failures and save money on running costs.

Know how each part works with the others. This helps you fix problems and keep your excavator working well.

Keep a log for maintenance to track checks and repairs. This helps you see patterns and plan future maintenance better.

Excavator Hydraulic Pump Parts Name

When you know the excavator hydraulic pump parts name, you see how each part works together. These parts help power your machine. Here are the main parts you should learn about:

Valve Plate

The valve plate controls how hydraulic fluid moves in the pump. You find it in the center of the pump. Most valve plates use strong alloy steel. The surface gets special treatment to make it very hard, with a hardness of HV900 or more.

The shape of the valve plate slots is important. Triangular slots help control pressure better. They also react well when conditions change. This design helps the pump work smoothly and efficiently.

Cylinder Block

The cylinder block holds the pistons. It spins with the drive shaft. This part makes chambers for the hydraulic fluid to move. The cylinder block must be strong to handle high pressure. It is a key part of the excavator hydraulic pump.

Ball Guide

The ball guide keeps the pistons lined up as they move. You need it so pistons follow the right path. The ball guide lowers friction. It helps the pump last longer. It supports smooth operation of the excavator hydraulic pump parts name.

Retainer Plate

The retainer plate holds the piston shoes in place. It keeps them lined up with the bearing plate. This is important for stable operation. It helps transfer force well, even at high speed or pressure.

Material | Specifications |

|---|---|

Cast/Ductile iron | Good for strength and durability |

Steel | Has high tensile strength |

Bronze | Resists corrosion well |

These materials are used for retainer plates in high-pressure pumps. The right material helps the retainer plate handle tough jobs.

Piston

The piston moves back and forth inside the cylinder block. It pushes hydraulic fluid through the system. Most pistons last about 10,000 hours, or around 14 months.

Piston design changes how much fluid the pump moves. You can adjust the swash plate angle to change the piston stroke. A bigger angle gives more fluid. A smaller angle gives better control. This helps you match pump performance to your needs and save energy.

Drive Shaft

The drive shaft connects the pump to the engine or motor. It must be strong to transfer power and keep the pump working. Makers use alloy steel, steel, and stainless steel for drive shafts. These materials are strong and resist wear.

If the splines on the drive shaft wear out, you lose power. Worn splines can stop the pump from working. This causes machine downtime.

Oil Reservoir

The oil reservoir stores hydraulic fluid for the pump. You should size the reservoir for your system type. For open circuit systems, use 3–5 times the pump flow rate per minute, plus a 10% air cushion. For mobile machines, use 1.5–2 times the pump flow rate.

A good reservoir helps control fluid temperature. It lets heat escape and works with heat exchangers. This keeps the oil at the right temperature. It stops problems like pump cavitation and keeps your excavator hydraulic pump parts name working well.

Safety Release Valve

The safety release valve protects your hydraulic system from too much pressure. You should check this valve every 3–6 months in normal conditions. If you use your excavator in tough jobs or harsh places, check it more often.

Inspection Frequency | Conditions |

|---|---|

Every 3–6 months | Standard |

More often | High-demand systems or harsh conditions |

Knowing each excavator hydraulic pump parts name helps you spot problems early. It helps you take care of the components of an excavator hydraulic pump. When you understand these parts, you keep your machine safe and working well.

Components of an Excavator Hydraulic Pump

Knowing how each part works helps you keep your excavator working well. The main parts of a hydraulic pump fit into three groups. These are rotating parts, stationary parts, and supporting parts. Each group has a special job in the pump.

Rotating Parts

Rotating parts change mechanical energy into hydraulic energy. These parts move inside the pump and push hydraulic fluid.

The drive shaft turns and makes the cylinder block spin.

The cylinder block spins and holds the pistons.

Pistons move back and forth to pull in and push out hydraulic fluid.

The ball guide keeps the pistons moving the right way.

When the pump works, these parts go through two main steps:

Intake: The pump makes low pressure and pulls fluid inside.

Discharge: The pump squeezes the fluid and sends it out at high pressure.

You should look for damage on these parts. Some common problems are:

Type of Wear | Description |

|---|---|

Cavitation | Air bubbles make small holes on surfaces. |

Abrasive Wear | Not enough oil causes scratches and damage. |

Fatigue Wear | Moving over and over makes cracks and breaks. |

Adhesive Wear | Heat from rubbing makes metal stick and break. |

Erosive Wear | Hard bits wear away surfaces and cause leaks. |

Corrosive Wear | Bad oil causes chemical damage and loss of material. |

Stationary Parts

Stationary parts do not move, but they keep the pump sealed and safe.

Valve plates control where the hydraulic fluid goes.

Retainer plates keep pistons in the right place.

Seals and flanges stop leaks and keep pressure steady.

Seal Type | Function |

|---|---|

Static Seals | Hold tight under high pressure with no movement. |

Flange Seals | Seal between pump parts to stop leaks. |

These parts help the pump keep its shape and stop fluid from leaking out.

Supporting Parts

Supporting parts help the pump last longer and work better.

The oil reservoir holds and cools the hydraulic fluid.

The safety release valve keeps the system safe from too much pressure.

Aspect | Explanation |

|---|---|

High-Quality Materials | Strong materials help parts last through hard work. |

Reduced Breakdowns | Good supporting parts mean fewer problems and more work time. |

Easier Maintenance | Well-made parts make repairs and checks faster and easier. |

You should check and change worn-out supporting parts often. If you skip maintenance, you might have big repairs and lose time. When you know about these groups, you can keep your excavator hydraulic pump working its best.

Hydraulic Pump Excavator Parts Function

Energy Conversion

When you use an excavator, energy changes form. The hydraulic pump gets power from the engine. It turns this power into hydraulic energy. The drive shaft spins when the engine is on. This spinning makes the cylinder block turn. Pistons inside move back and forth. They push hydraulic fluid through the pump. The valve plate sends the fluid where it needs to go.

The pump turns spinning motion into fluid pressure. This pressure makes the excavator work.

Powering Excavator Systems

Hydraulic energy travels in hoses and valves. You use this energy to move the arm, boom, and bucket. When you pull a lever, the pump sends fluid under pressure to the cylinders. The fluid pushes the piston inside each cylinder. The arm goes up, the boom moves, and the bucket curls.

The retainer plate keeps pistons steady for smooth work.

The ball guide helps pistons move the right way.

The safety release valve stops too much pressure.

Each part helps the machine move strong and smooth.

System Efficiency

Good pumps help you save time and money. If all parts work well, the pump uses less energy and stays cooler. The oil reservoir keeps the fluid cool and clean. Good seals stop leaks and keep pressure up.

Part | How It Improves Efficiency |

|---|---|

Valve Plate | Controls fluid flow |

Cylinder Block | Handles high pressure |

Piston | Moves fluid quickly |

Oil Reservoir | Keeps fluid at right temperature |

Check each part often to keep things working well. Clean oil and strong seals help your excavator last longer. If you want good parts, you can pick YNF Machinery. Their parts help your pump stay strong and work well.

Good pumps make digging, lifting, and loading easier every day. 🛠️

Excavator Hydraulic Pump System Maintenance

Common Issues

If you do not check the hydraulic pump parts often, you can have problems. Some issues happen a lot with the excavator hydraulic pump system.

Fluid leaks can show up near seals or connections.

The hydraulic pump excavator parts can get too hot.

Air in the system can make loud noises.

Cavitation can hurt hydraulic pump parts.

Parts like pistons and valve plates can wear out.

Dirty oil or debris can cause contamination.

If you see less power, hear odd sounds, or spot leaks, check the hydraulic pump excavator parts right away. Finding problems early helps you avoid bigger repairs.

Maintenance Tips

You keep your excavator hydraulic pump system working well by doing regular maintenance. Use this table to help you plan your checks:

Maintenance Task | Recommended Interval |

|---|---|

Check fluid levels | Daily |

Replace filters | Every 500 hours |

Change oil | Every 2,000 operating hours |

Check hydraulic oil level | Every 8 to 10 hours of work |

Look at hydraulic pump parts for wear, cracks, or leaks. Clean the oil reservoir and change filters when needed. Always use clean hydraulic fluid to protect the hydraulic pump excavator parts. If you need new hydraulic pump parts, YNF Machinery has good choices for your excavator hydraulic pump system.

Tip: Keep a maintenance log. Write down every check and repair. This helps you see patterns and plan future service.

Longevity Practices

You help your hydraulic pump excavator parts last longer by using smart habits.

Do regular check-ups and maintenance on all hydraulic pump parts.

Teach operators how to use the excavator hydraulic pump system the right way.

Use approved repairers to fix hydraulic pump parts.

Clean your equipment often to stop rust and wear.

Look at hydraulic pump parts for leaks or damage.

Change your maintenance plan if your work environment changes.

Training operators and keeping good records helps you find problems early. You protect your excavator hydraulic pump system from breaking down and save money over time. If you pick YNF Machinery for hydraulic pump parts, you get strong and long-lasting key components.

Knowing about each excavator hydraulic pump part helps you find problems early. This keeps your machine working well. You can save money and stop big repairs if you do regular maintenance.

If you check the hydraulic fluid and pump parts often, your machine works better.

Good parts from YNF Machinery help your machine break down less and cost less to run.

Taking care of your machine lets you find most warning signs early and stops big problems.

Look after your hydraulic pump system. Your excavator will work better and last longer.

FAQ

What does an excavator hydraulic pump do?

You use an excavator hydraulic pump to move hydraulic fluid. This pump creates pressure. The pressure powers the arm, boom, and bucket. You control the excavator with levers. The pump sends fluid to the right place for each movement.

How often should you check the hydraulic pump diagram?

You should check the hydraulic pump diagram every time you do maintenance. The diagram helps you find each part. You spot problems faster. You keep your excavator safe and working well.

Why does the oil reservoir matter in an excavator hydraulic pump?

The oil reservoir stores hydraulic fluid. You need clean fluid for the pump to work well. The reservoir helps control temperature. It stops the pump from overheating. You protect the excavator hydraulic pump parts from damage.

What signs show hydraulic pump problems in an excavator?

You may see leaks, hear loud noises, or notice weak movement. The pump may get hot. You should check the hydraulic pump diagram and look for worn parts. Early checks help you avoid big repairs.

Where can you buy reliable excavator hydraulic pump parts?

You can buy reliable excavator hydraulic pump parts from YNF Machinery. They offer strong and long-lasting parts. You keep your excavator working well with their products.