A hydraulic pump coupling links the engine to the hydraulic pump in your machine. You need this part because it moves power smoothly and keeps equipment safe from harm. If you use a good coupling, your machine works better. Fast attachment changes save time and help your equipment last longer. YNF Machinery gives strong hydraulic pump couplings for excavators and other big machines. Picking the right coupling helps your machine work well and stop less often.

Key Takeaways

A hydraulic pump coupling links the engine to the hydraulic pump. It helps power move smoothly and keeps your machine safe from harm.

Picking the right coupling type, like flexible or rigid, is very important. It helps your machine work well and last longer.

Check your coupling often for wear, like odd sounds or more shaking. This can help you avoid expensive fixes.

Using good couplings from trusted brands like YNF Machinery helps your machine work better. It also means less time when your machine is not working.

Follow easy steps to change a bad coupling. This helps your equipment keep running well and smoothly.

Hydraulic Pump Coupling Basics

What Is a Hydraulic Pump Coupling

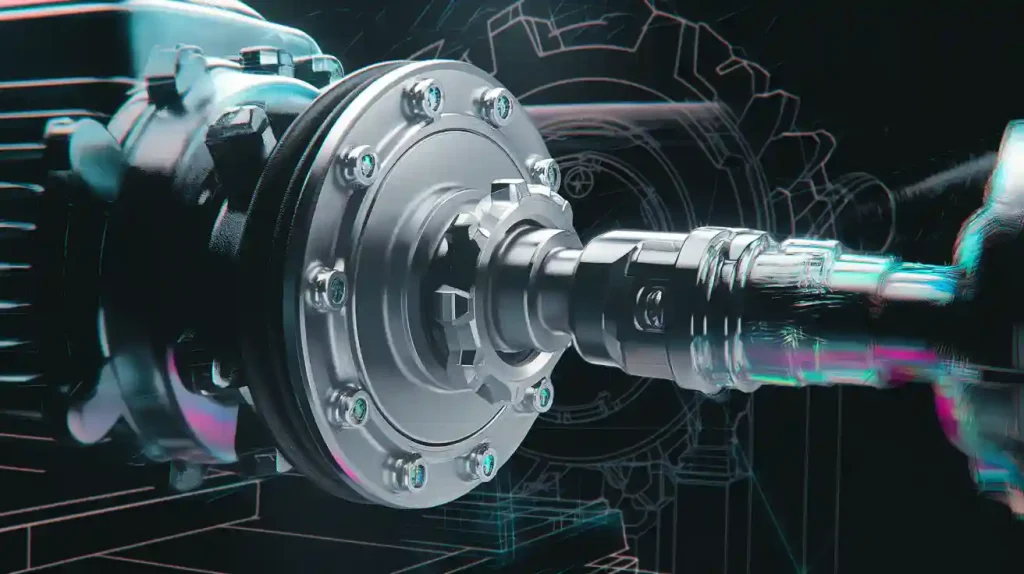

A hydraulic pump coupling connects the engine or motor to the hydraulic pump in big machines. This part helps move power from the engine to the pump. It makes sure your machine works well and does not break easily. Picking the right coupling keeps your equipment safe and helps it last longer.

Hydraulic pump couplings come in many types and use strong materials. You can find flexible couplings, rigid couplings, and magnetic couplings. Each type is made for a special job or machine. Look at the table below to see some common types and what they do:

Type | Description |

|---|---|

Flexible | Uses rubber or elastomer to absorb shock and vibration. |

Torsionally-rigid flexible | Handles misalignment but stays firm under torque. |

Rigid | Connects shafts directly with no flexibility. |

Magnetic | Transfers power without physical contact. |

Hydrodynamic | Uses fluid for smooth power transmission. |

YNF Machinery sells strong hydraulic pump couplings for excavators and other heavy machines. Their CF-A Couplings use SVR 3L hybrid rubber. This rubber lasts a long time and does not wear out fast. You can trust these couplings to work well in tough jobs like construction or mining.

Tip: Always check the type and material of the coupling before you buy. This helps you pick the right part for your machine and your work.

How a Pump Coupling Works

A pump coupling joins two shafts. One shaft comes from the engine. The other shaft comes from the hydraulic pump. When the engine turns, the coupling moves this power to the pump. This makes the hydraulic system work. It moves the arms, buckets, or other parts of your machine.

You need a coupling that can handle vibration and misalignment. Flexible couplings from YNF Machinery absorb shocks and lower noise. This helps your machine run smoothly and stops sudden breakdowns.

Here are the main steps for how a hydraulic pump coupling works:

The engine or motor makes rotational force.

The coupling links the engine shaft to the pump shaft.

The coupling sends power, even if the shafts are not lined up perfectly.

The pump gets the force and powers the hydraulic system.

Good pump couplings use strong materials so they last longer. YNF Machinery makes couplings for tough places. You can use them in construction, mining, or factories.

There are many types of couplings in industrial machines. The table below shows some common types and where they are used:

Coupling Type | Description | Applications |

|---|---|---|

Mechanical Couplings | Screw-to-connect designs for precise transmission in heavy-duty machinery. | Rigid connections in heavy-duty systems. |

Hydraulic Jaw Couplings | Flexible elements absorb shock and dampen vibrations. | High torque applications with significant movement. |

Diaphragm Couplings | Uses a flexible diaphragm for torque transmission. | High-speed or high-precision applications. |

Fluid Couplings | Transmits torque using hydraulic fluid for smooth startup. | Automotive and heavy-duty applications. |

Magnetic Couplings | Uses magnetic fields to transmit energy without contact. | Clean environments like food and pharmaceutical. |

YNF Machinery has many pump couplings, like CF-A Couplings and excavator couplings. You can find products for many brands and models. Their couplings help your machine work well and stop less often.

Note: If you want your equipment to last longer and work better, use a hydraulic pump coupling from a trusted company like YNF Machinery.

Coupling Features and Benefits

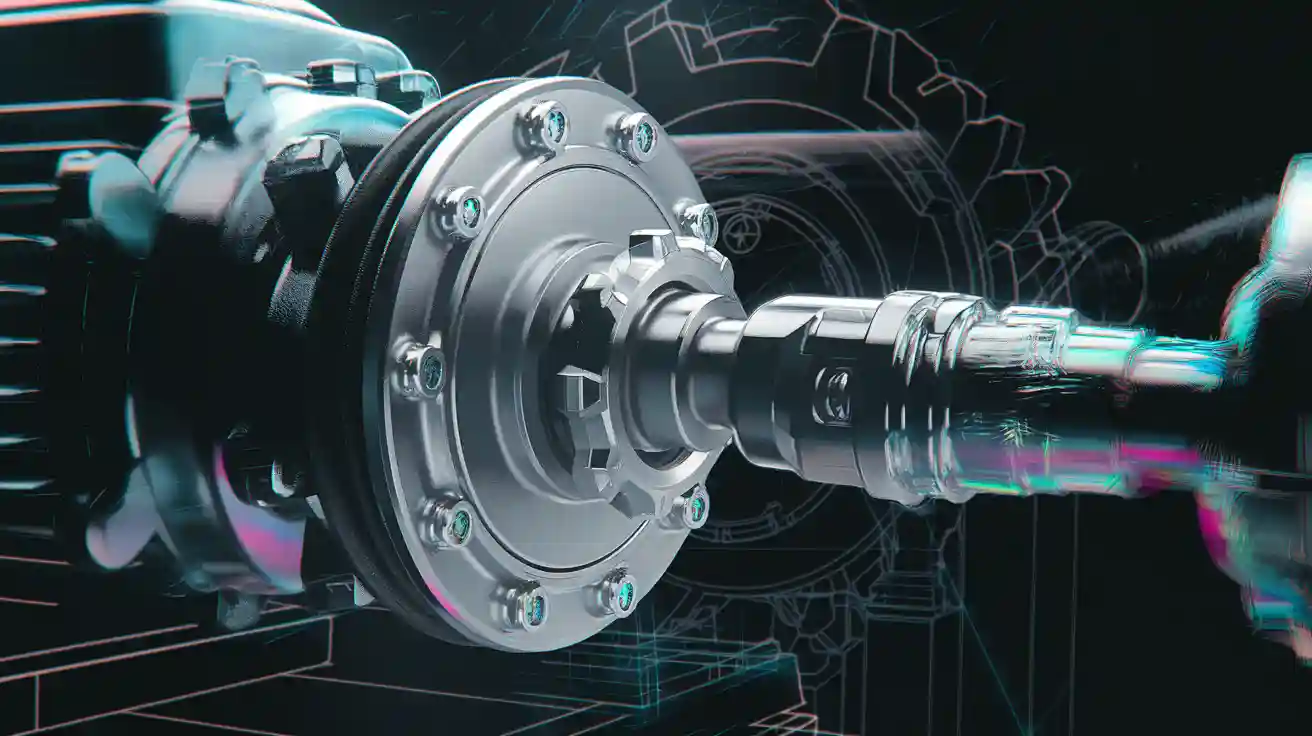

Vibration Dampening

You want your machine to work quietly and smoothly. A good coupling helps by cutting down on vibration. When a coupling uses elastic materials, it soaks up shocks and keeps things steady. This matters because too much vibration can break parts and make your machine loud.

Vibration-dampening couplings, like those from YNF Machinery, use special rubber to block vibration. This makes the assembly’s natural frequency lower. If the coupling’s natural frequency is less than the pump’s, vibration does not spread. Your machine runs quieter and the pump works better.

Here are some ways these couplings help your machine: They fix small shaft misalignments. They guard sensitive parts from vibration issues. They help you save money by stopping extra wear.

Rubber couplings cut noise by blocking vibration and machine shaking.

Heat-resistant rubber and strong build also help keep things quiet.

Tip: If your machine is loud or shakes, check the coupling. A good coupling can fix these problems and help your machine last longer.

Equipment Protection

Your equipment deals with stress every day. A strong coupling keeps it safe from harm. When you use a coupling that soaks up vibration and shock, you lower the chance of broken parts and early damage.

The table below shows how couplings keep your equipment safe:

Function | Description |

|---|---|

Corrects Misalignment | Couplings take care of different misalignments, lowering stress on parts. |

Absorbs Vibrations and Shock | Couplings act as shock stoppers, making things stable and last longer. |

A coupling from YNF Machinery protects your hydraulic pump and engine. It fixes misalignment and soaks up vibration. This keeps your machine running and helps you avoid stopping work.

The LS30P01072F1 Hydraulic Pump Coupling uses tough rubber and metal.

It soaks up shocks and stands up to oil, rust, and wear.

You get strong torque and steady work in hard places.

Note: Using the right coupling saves you money and time. You avoid lots of repairs and keep your machine working well.

YNF Machinery Coupling Advantages

YNF Machinery gives you couplings with special features. The CF-A Coupling uses SVR 3L hybrid rubber. This rubber is very pure and has steady quality. It meets world standards and works in many jobs.

Feature | Description |

|---|---|

High-grade purity | Less dirt means a clear, bright, and even look. |

Quality Stability | Steady Mooney viscosity, so it works well in factories. |

Good Plasticity and Elasticity | Fits the needs for top tires, belts, hoses, and more. |

International Standard Compliance | Made under ISO/TCVN rules, meeting world factory needs. |

Wide Applications | Used in top tire making, rubber goods, gaskets, cables, and belts. |

YNF Machinery couplings are flexible and tough. PU and Hytrl materials soak up shocks and stay bendy for a long time. These couplings stretch and bounce back, which helps stop wear in fast machines. Hytrl does not get stiff, even after lots of use.

YNF Machinery couplings handle strong torque and hard jobs.

They last longer and need less fixing.

You get steady pump work and fewer stops.

If you want your machine to work well and last, pick a coupling from YNF Machinery. Their products give you the best safety and value.

Applications of Pump Couplings

Excavators and Heavy Machinery

You can see hydraulic pump couplings at work on job sites. They connect the engine to the hydraulic pump in machines. This helps your excavator or loader work without problems. The right coupling lets your machine dig, lift, and move heavy things.

In mining and building, new pump designs and smart fluid use help machines work better. Here are some ways couplings make work easier:

New designs control flow and pressure for better work.

Sensors check the system all the time to stop sudden problems.

Motors that save energy and heat recovery systems use less power.

Systems change pressure and flow to fit the job for best results.

A good coupling helps your machine last longer and finish jobs on time.

Industrial Uses

Hydraulic pump couplings do more than help big machines. You find them in many places, like farms and ships. Each coupling type is made for a special job. The table below shows where you might see different couplings used:

Coupling Type | Application Examples |

|---|---|

Elastomeric Couplings | Farm watering systems, boat engines |

Universal Couplings | Machines that move and need to adjust often |

Fluid Couplings | Turbines, factory pumps, belts, and mining |

You can see couplings are important in many machines, not just excavators.

YNF Machinery Product Applications

YNF Machinery makes couplings for many machines and jobs. You can use their parts in building, mining, farming, and factories. YNF Machinery makes each coupling to fit many brands and models. Their products handle hard work, lower vibration, and move power well. If you need something special, YNF Machinery can make a coupling just for your machine.

YNF Machinery sells to people all over the world. You get strong parts that keep your machines working well. When you pick YNF Machinery, you help your machine work better and protect your money.

How to Replace a Pump Coupling

Signs of Coupling Failure

You should watch for signs that your hydraulic pump coupling might fail soon. These signs help you stop big problems and keep your machine working well. Look for these common problems:

Your machine does not work as well. It feels slow.

You lose power slowly or all at once. Jobs get harder.

The pump moves slower than before. It is not fast.

The machine moves in a jumpy or weird way. Fluid flow is not steady.

You hear strange sounds. Listen for grinding or screeching.

The machine shakes too much. Vibration is higher than normal.

Check your machine often to find these problems early. If you see any of these signs, you should get ready to change the pump coupling soon.

Replacement Steps

You can change a pump coupling by following some easy steps. Get all the tools you need before you start:

Calipers to measure sizes

Dial indicator to check if things line up

Infrared thermometer to check heat

Stethoscope or electronic tool to listen for noise

Torque wrench to tighten bolts

Wrenches and sockets

Safety gloves and goggles

New coupling from YNF Machinery

Hydraulic fluid

Here are the steps to change a pump coupling:

Turn off the machine and unplug it.

Take off the old coupling with wrenches and sockets.

Use calipers to measure the shafts and check the size.

Use a dial indicator to make sure things line up.

Put on the new coupling and tighten bolts with a torque wrench.

Add hydraulic fluid if you need more.

Test the machine to see if it works smoothly.

Check couplings often, especially if you use your machine a lot. Change the pump coupling if you see damage, hear odd sounds, or feel more shaking.

Choosing the Right Coupling from YNF Machinery

YNF Machinery helps you pick the best hydraulic pump coupling for your machine. Their team answers quickly and gives you both regular and custom choices. You do not have to wait long because YNF Machinery has many products ready.

You can ask YNF Machinery for help with sizing, putting in, and picking products. Their experts make sure you get the right part for your machine.

Hydraulic pump couplings make your machine work well and last longer. If you pick strong couplings from YNF Machinery, your equipment stays safe. Checking couplings often and changing them on time stops leaks and big problems.

You can help your machine by watching temperature, pressure, flow, and vibration. Fixing issues fast and using clean fluid keeps your machine working and saves time. Always look at couplings and change them when needed to keep your machine safe.

FAQ

How do you know which hydraulic pump coupling fits your machine?

You check the model number, shaft size, and spline count. You can ask YNF Machinery for help. They will guide you to the right coupling for your equipment.

What signs show your coupling needs replacement?

You hear strange noises, feel more vibration, or see slow machine movement. These signs mean you should check and replace the coupling soon.

Can you install a hydraulic pump coupling by yourself?

You can install it if you have basic tools and follow safety steps. YNF Machinery provides guides and support to help you with installation.

Why should you choose YNF Machinery for couplings?

YNF Machinery offers high-quality couplings, fast service, and expert advice. You get reliable parts that help your machine work better and last longer.

How often should you check your hydraulic pump coupling?

You should inspect the coupling every few months or after heavy use. Regular checks help you catch problems early and keep your machine running smoothly.