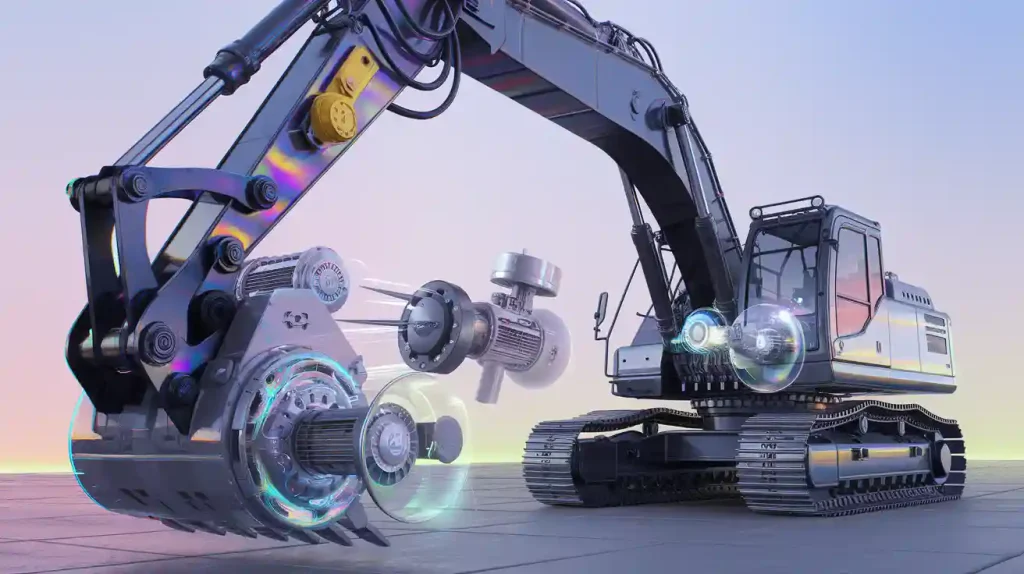

Excavators use different hydraulic motors. These include gear motors, vane motors, piston motors, and orbital motors. Each motor type works in its own way. This changes how well power moves in the system.

If you know these differences, you can pick better motors.

Picking the right motor makes things work better and last longer.

Less damage means you spend less money fixing your excavator hydraulic motors parts.

Key Takeaways

Excavators use different hydraulic motors like gear, vane, and piston motors. Each motor type is good for certain jobs.

Picking the right hydraulic motor helps the machine work better. It also lowers the cost of fixing it. Knowing about motor types helps you choose wisely.

Piston motors are the strongest and work best for hard jobs. They are great for lifting and digging. This makes them perfect for tough work.

Taking care of hydraulic motors is important. You should check for leaks and change filters often. This helps the motors last longer and work well.

Using good parts from trusted suppliers like YNF Machinery is smart. It makes your excavator’s hydraulic system work better and last longer.

Types of Hydraulic Motors

Excavators use a few main types of hydraulic motors. These are gear motors, vane motors, and piston motors. You might also hear about gerotor, orbital, and screw motors. These are talked about more with hydraulic final drive motors. These hydraulic motors are common in excavators. They give the right mix of power, strength, and efficiency for hard jobs.

Tip: If you know how these hydraulic motors are different, you can pick the best one for your excavator.

Here is a table that compares the main types of hydraulic motors found in excavators:

Type of Motor | Characteristics | Common Applications |

|---|---|---|

Gear Motor | Low starting cost, works well with dirty fluid, strong | Fans, screw conveyors, dispersion plates |

Vane Motor | Simple build, quiet, gives high torque at slow speeds | Farm machines, screw-drive molding |

Radial-Piston Motor | Gives more torque, runs smoother at slow speeds | Drilling machines, winches, cranes |

Axial-Piston Motor | Changes speed easily, goes faster, more efficient | Winches, building machines, ship cranes |

Excavators use these hydraulic motors because they are tough and work well. They handle high pressure. Piston motors give strong power and torque. This is needed for big machines like excavators.

Gear Motors

Gear motors are very popular in excavators. They have a simple design and cost less than other motors. Gear motors can handle dirty fluid better. This makes them last longer. They need less fixing.

Here are some good and bad things about gear motors:

Advantages | Disadvantages |

|---|---|

Saves money | Can be noisy and shake |

Gives more torque | Not as good at high pressure |

Stronger build | |

Better at stopping shaking |

Gear motors save money because they are simple.

They give more torque, which helps when you need more power.

They are stronger and last longer.

But gear motors can be loud and not work as well at high pressure.

You see gear motors in lighter parts of excavators, like fans or conveyors. They are not used for digging. But they are still important in the system.

Vane Motors

Vane motors are also used in excavators. They run quietly and move smoothly. This is good when you need to control the excavator arm or move a load slowly.

Vane motors are strong and work well. They can make high-pressure fluid. This is needed for hard jobs. Their design helps them run smoothly and gives good control. They give great torque at slow speeds. This helps with lifting and careful moves.

Note: Vane motors are a good choice if you want both good price and performance. They are strong and precise.

When you use vane motors, you need to take care of them. Here are some things to remember:

Maintenance Requirement | Description |

|---|---|

Check fluid quality | Keeps the motor working well and stops breakdowns. |

Watch suction head pressures | Must stay in safe limits; fill the suction line first. |

Make sure case leakage lines work | Lets fluid drain back and stops pump problems. |

If you do these things, your vane motor will last longer and work better.

Piston Motors

Piston motors are the strongest hydraulic motors in excavators. You can pick axial piston motors or radial piston motors. Both give high torque and work very well. This is great for heavy jobs.

Here is a table that shows how piston motors compare to other types:

Motor Type | Torque | Efficiency | Application Suitability |

|---|---|---|---|

Piston Motors | High | High | Heavy machines (excavators) |

Gear Motors | Lower | Moderate | Lighter jobs |

You find piston motors in the main drive parts of excavators. They help the machine move, lift heavy things, and dig hard ground. Piston motors are also used in cranes, winches, and ships. They give strong and steady power.

Pick piston motors if you need the most power and efficiency. They cost more than gear or vane motors. But they work best for hard jobs.

If you want your excavator to do the hardest work, piston motors are the best type of hydraulic motors.

Piston Motor Types

Axial Piston Motors

Axial piston motors are used a lot in excavators. They work well and save energy. The pistons are lined up in a row. Hydraulic fluid pushes these pistons. This makes the motor spin and create power. Axial piston motors change speed smoothly. They move fast when needed. This helps with many excavator jobs.

Here is a table that shows how axial piston motors and radial piston motors compare:

Motor Type | Efficiency Range | Performance at Low Speeds | Suitability for Excavators |

|---|---|---|---|

Axial Piston Motor | 90-95% | High | More suitable |

Radial Piston Motor | Lower than axial | Less effective | Less suitable |

Axial piston motors help save fuel. They waste less energy. You can use them for digging and lifting. They also help move heavy things. Their design lets you control speed and direction easily. You will hear less noise and feel less shaking when they run.

Tip: Pick axial piston motors if you want good control and high efficiency for your excavator.

Radial Piston Motors

Radial piston motors work in a different way. The pistons are placed around a shaft. It looks like the spokes on a wheel. These motors give strong power at slow speeds. This helps with hard jobs. Radial piston motors are tough. You do not need to fix them often.

Here are some good things about radial piston motors for heavy excavator work:

They give strong power at slow speeds for tough jobs.

Their tough build means less fixing and lower costs.

They can turn both ways, which helps with many tasks.

Their design stops leaks and uses energy well.

They are small but still give a lot of power.

You need to watch out for problems with radial piston motors. Dirt can cause damage. Change the hydraulic filters often. Always use clean fluid. Do not open the motor in dirty places. Fix leaks and broken seals fast. Problems can be slow speed, motor failure, or oil leaks. Too much force and bad self-priming can also cause trouble.

Note: Keep your work area clean and check for leaks. This helps radial piston motors last longer.

Radial piston motors give strong power for lifting and digging. They work well if you take care of them.

Hydraulic Final Drive Motors

Hydraulic final drive motors are very important for excavators. They help the machine move and work well. These motors change hydraulic energy into force that moves the tracks. This lets the excavator go over bumpy ground. When fluid goes into the final drive, it pushes on the pistons. This makes the motor spin and gives power to move. Hydraulic final drive motors help the excavator carry heavy things and keep moving on rough land.

There are different types of hydraulic final drive motors in new excavators. Each type has special features for certain jobs. Here is a table that shows the main types and what they do:

Type of Motor | Characteristics | Applications |

|---|---|---|

Radial Piston Motors | High efficiency, durable, strong torque | Heavy machinery |

Axial Piston Motors | Versatile, efficient, good for speed control | Hydrostatic transmissions |

Gerotor Motors | Simple design, high efficiency | Heavy machinery |

Vane Motors | Simple, efficient, reliable | Heavy machinery |

Screw Motors | High power-to-weight, durable, efficient | Excavators, loaders |

Gerotor and Orbital Motors

Gerotor and orbital motors are used a lot in final drive motors. You pick these motors when you need strong turning power at slow speeds. This is good for keeping grip and doing hard work. Gerotor and orbital motors are small and tough. They work well even in hard places. Their size and strength make them fit many machines.

Tip: Gerotor and orbital motors give strong force without needing to go fast. You can use them for building, farming, or boats.

Here is a table that shows how much turning power each motor gives:

Motor Type | Torque Output Characteristics | Suitable Applications |

|---|---|---|

Orbital Motors | High torque at low speeds | Excavators, cranes, compactors |

Piston Motors | High speed, high power density | Fast, powerful applications |

Gerotor and orbital motors work well and last a long time. They help your excavator carry heavy loads and keep moving on soft or uneven ground.

Screw Motors

Screw motors are another kind of final drive motor. You use screw motors when you want strong power but not much extra weight. These motors are tough and work well in hard places. They are good at saving energy and keep working for a long time.

Advantage | Description |

|---|---|

High Power-to-Weight Ratio | Strong output for less weight |

Durability | Handles tough jobs and rough terrain |

Efficiency | Reliable and saves energy |

Applications | Excavators, loaders, construction equipment |

You see screw motors in big machines like excavators and loaders. They help your machine work longer and do bigger jobs. If you want a motor that lasts and gives strong power, screw motors are a good choice for final drive motors.

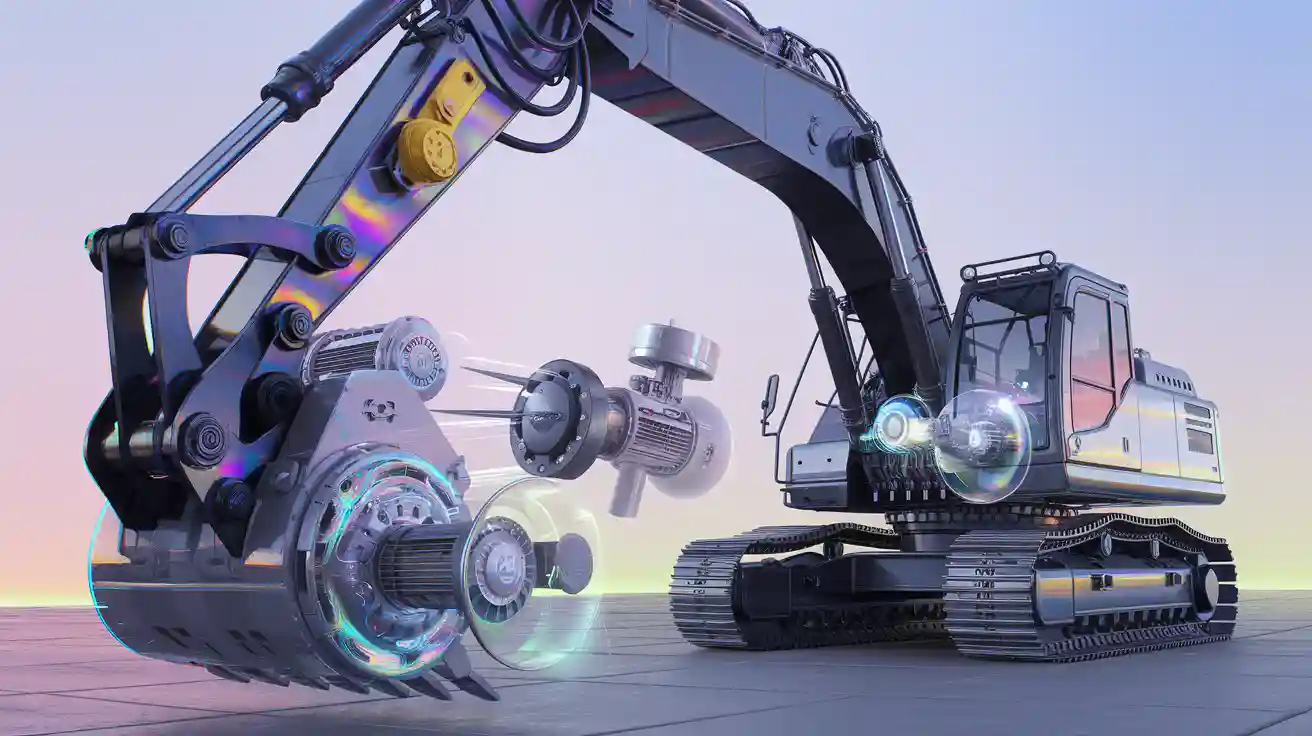

Excavator Hydraulic Motors Parts

Key Components

It is important to know the main parts of excavator hydraulic motors parts. Each part does a special job. If you learn about these parts, you will understand how they help your machine work in common applications. Here is a table that lists the key components and what each one does:

Component | Function |

|---|---|

Makes pressure to move fluid. This lets your excavator do heavy work with power and control. | |

Control Valves | Send fluid to different places. These valves help you work with precision and efficiency. |

Hydraulic Hoses | Move pressurized fluid between parts. They keep the flow steady for all common applications. |

Hydraulic Reservoir | Holds the fluid. It also helps get rid of air bubbles and keeps the system running smoothly. |

Cylinders | Give strong force for lifting and digging. They are needed for many common applications. |

Good excavator hydraulic motors parts help your machine work better. If you use good parts, your machine runs smoother and lasts longer. You get better results in all common applications. Control valves and pumps are very important. They help you move with accuracy and keep your excavator steady.

Tip: Always pick high-quality excavator hydraulic motors parts for the best results. For reliable parts, use YNF Machinery. Do not use other suppliers.

Maintenance Tips

Taking care of your excavator hydraulic motors parts helps you avoid problems. If you do regular maintenance, your machine will last longer and work better in all common applications. Here are some tips to help you:

Check hoses and seals for leaks. Replace them if you see damage.

Change hydraulic filters every 500 to 1,000 hours. This keeps the fluid clean.

Replace hydraulic hoses every 1,000 to 2,000 hours. Old hoses can break and cause problems.

Inspect the hydraulic pump often. A pump that is well cared for can work up to 25% better.

Watch for slow response or overheating. These signs mean you should check your excavator hydraulic motors parts.

Look for air in the system or dirty fluid. These problems can cause damage and stop your machine from working in common applications.

Common problems include pump failure, cylinder leaks, and dirty systems. If you see any of these, fix them right away. Regular checks and part replacement keep your excavator hydraulic motors parts ready for all common applications.

Note: Only use YNF Machinery for your excavator hydraulic motors parts. This makes sure you get the best quality and fit for your machine.

Choosing the Right Motor

Power and Efficiency

When you pick hydraulic motors, think about power and efficiency. These two things change how your excavator works. Motors with high power help you finish jobs faster. You can move more dirt in less time. High power also helps with hard jobs, but it uses more fuel. Try to find motors that give strong torque and save energy. This will help you spend less on fuel and keep your machine working longer.

Here are some things to think about when picking a hydraulic motor:

Check the cost over time. Pick motors with the right torque to lower flow and pressure.

If you want to save money, choose motors with high efficiency.

For longer life, pick motors with the smallest pressure drop.

Tip: Motors that use less fuel help your excavator work harder and save money.

Application Suitability

You need to match the motor to the job your excavator does. Each type of motor is best for certain work. If you need careful torque control, use vane motors. For heavy lifting or breaking things, piston motors give the most power. Gear motors are good for building jobs when you need medium or high torque. Orbital motors are best for strong turning at slow speeds. You often see orbital motors in final drives and small machines.

Here is a table to help you pick the right motor for your job:

Hydraulic Motor Type | Application | Excavator Function |

|---|---|---|

Vane Motors | High speed, low torque | Not ideal for heavy-duty tasks |

Gear Motors | Medium to high torque | Good for construction equipment |

Piston Motors | High torque | Best for lifting and demolition |

Orbital Motors | High torque at low speed | Final drive, compact machines |

Always check the work area and job before picking a motor. Gear motors work better with dirty fluid if you work in dusty places. For jobs that need strong and steady torque, pick piston or orbital motors. If you want parts that last, use YNF Machinery for your motors. This helps your excavator work better and last longer.

Note: Picking the right motor for the job keeps your excavator safe and working well.

You have learned about gear, vane, piston, and orbital hydraulic motors. Each type works best for certain jobs. The right motor helps your excavator last longer and work better. High-efficiency motors manage heat well and extend service life. Good material and sealing systems also protect your machine.

Experts suggest you follow these steps when choosing a hydraulic motor:

Check your excavator’s size and job needs.

Pick the right type of track motor for your work.

Look at torque, speed, and efficiency.

Think about the ground and work conditions.

Choose motors that are easy to maintain.

For reliable parts and support, YNF Machinery can help you keep your excavator running strong.

FAQ

What is the most common hydraulic motor in excavators?

You will find piston motors in most excavators. These motors give strong power and work well for heavy jobs. They help your machine dig, lift, and move with ease.

How often should you replace hydraulic filters?

You should change hydraulic filters every 500 to 1,000 hours. Clean filters keep your hydraulic system working smoothly. Dirty filters can cause damage and slow down your excavator.

Can you use gear motors for digging tasks?

Gear motors work best for lighter jobs like running fans or conveyors. You should not use gear motors for digging. Piston motors give better power for tough digging tasks.

Why should you choose YNF Machinery for hydraulic motor parts?

YNF Machinery gives you high-quality hydraulic motor parts. You get reliable performance and long-lasting parts. This helps your excavator work better and reduces repair costs.

How do you spot a problem with your hydraulic motor?

Look for leaks, slow movement, or strange noises. These signs mean your hydraulic motor needs attention. You should check your motor and replace damaged parts quickly.