When you check Hallite hydraulic seal kits, you see clear specs. These specs tell you the material, size, temperature, pressure, and speed. For example, look at the table below:

Seal Type | Max Pressure | Temp Range | Max Speed |

|---|---|---|---|

Double Acting Piston Seal (455) | 350 Bar | -30°C to 100°C | 4 m/sec |

Rotary Pressure Seal (310) | 300 Bar | -30°C to 100°C | 0.5 m/sec |

These facts help you choose the right kit quickly.

Key Takeaways

Learn the main details of Hallite hydraulic seal kits. These include material, size, temperature, pressure, and speed. Knowing these things helps you pick the right kit for your job.

Pick the correct seal type for its job. Rod seals stop leaks. Piston seals help things move smoothly. Wipers keep out dirt and water. Each part is important for how the system works.

Always look at the part number and size charts before you buy a seal kit. This makes sure it fits your equipment. It also helps you avoid expensive errors.

Hallite hydraulic seal kits specs

When you look at Hallite hydraulic seal kits, you see that each part has its own job and set of specs. These specs help you pick the right kit for your hydraulic system. Let’s break down the main components: rod seals, piston seals, and wipers.

Rod Seals

Rod seals keep hydraulic fluid inside the cylinder and stop leaks. You find them in almost every Hallite hydraulic seal kit. The material and design affect how well they work in tough conditions.

Here is a table showing what goes into Hallite rod seals and how each part helps performance:

Material Component | Description | Performance Impact |

|---|---|---|

Armorlene® Materials | High-quality materials used in Hallite rod seals. | Enhances wear and extrusion-resistance properties. |

Elastomer Energizers | Energizers that work in conjunction with the main seal material. | Improves sealing effectiveness and durability in dynamic applications. |

Temperature Compatibility | Ability to function across a wide range of temperatures. | Ensures reliable performance in various operating conditions. |

You can see that Armorlene® materials make rod seals tough and long-lasting. Elastomer energizers help the seal stay tight even when the rod moves fast. These seals work well in many temperatures, so you can use them in hot or cold places.

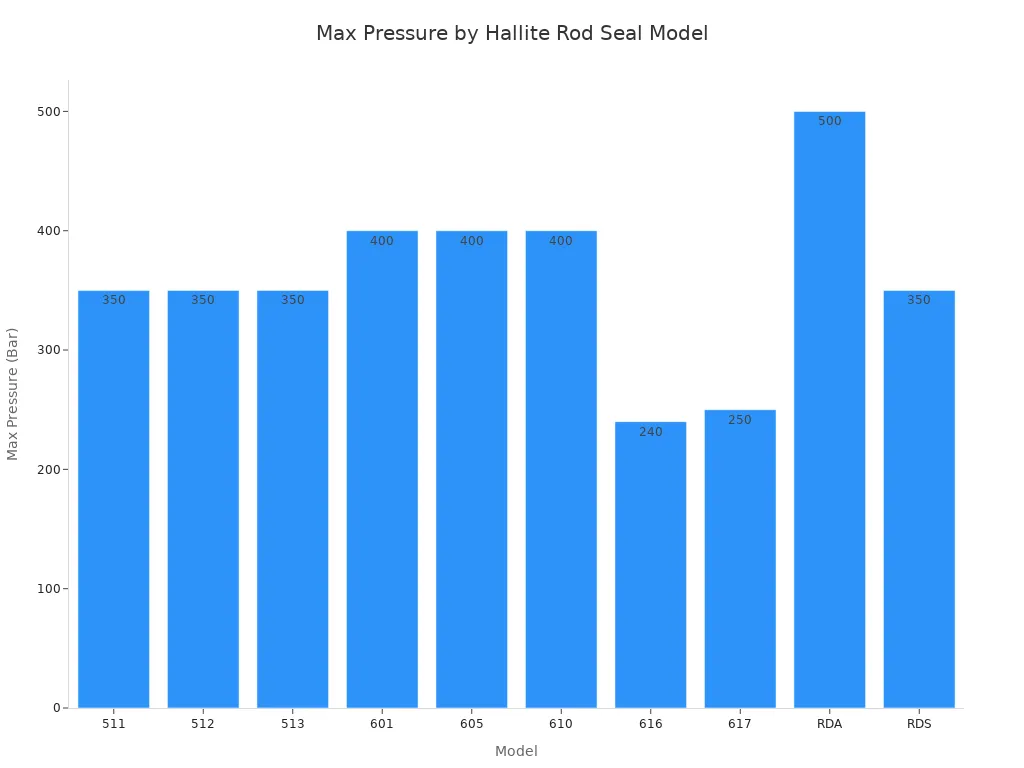

Here is a table with popular Hallite rod seal models and their specs:

Model | Max Pressure | Temperature Range |

|---|---|---|

511 | 350 Bar | -40°C to 110°C |

512 | 350 Bar | -40°C to 110°C |

513 | 350 Bar | -40°C to 110°C |

601 | 400 Bar | -45°C to 110°C |

605 | 400 Bar | -45°C to 110°C |

610 | 400 Bar | -45°C to 110°C |

616 | 240 Bar | -45°C to 110°C |

617 | 250 Bar | -45°C to 110°C |

RDA | 500 Bar | -45°C to 200°C |

RDS | 350 Bar | -45°C to 200°C |

For example, the Hallite 673 rod seal works from -45°C to 110°C and handles speeds up to 1 meter per second. The Hallite 605 rod seal uses Hythane® 181 material, which gives extra strength and flexibility.

You can trust rod seals from Hallite hydraulic seal kits in safety-critical jobs. They keep your system running without leaks, even under high pressure.

Piston Seals

Piston seals sit inside the cylinder and keep fluid from moving between chambers. You need them for smooth movement and strong force in your hydraulic system.

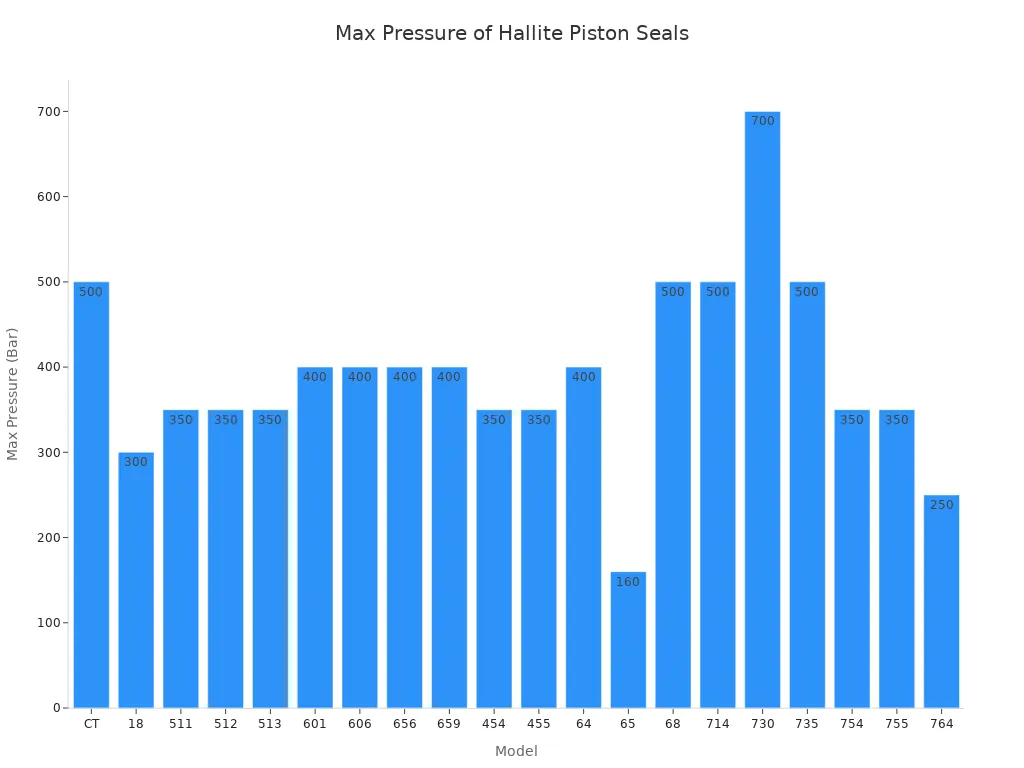

Check out this table with popular Hallite piston seal models and their specs:

Model | Max Pressure | Temp Range | Max Speed |

|---|---|---|---|

CT | 500 Bar | -45°C to 200°C | 1.5 m/sec |

18 | 300 Bar | -30°C to 100°C | 0.5 m/sec |

511 | 350 Bar | -40°C to 110°C | 0.5 m/sec |

601 | 400 Bar | -45°C to 110°C | 1 m/sec |

454 | 350 Bar | -30°C to 100°C | 4 m/sec |

730 | 700 Bar | -30°C to 100°C | 0.3 m/sec |

735 | 500 Bar | -40°C to 120°C | 1.5 m/sec |

Some piston seals, like the Hallite 777, work from -40°C to 120°C and handle speeds up to 0.5 meters per second. The Hallite 730 heavy-duty piston seal can take up to 700 Bar pressure, but its max speed is 0.3 meters per second. You use these seals in machines that need strong force and reliable sealing.

Piston seals in Hallite hydraulic seal kits help your equipment work safely. They stop leaks and keep the system strong, even in heavy-duty jobs.

Wipers

Wipers protect your hydraulic system from dirt and water. They sit at the end of the cylinder and clean the rod as it moves in and out. You find wipers in every Hallite hydraulic seal kit because they keep your system clean and working longer.

Here is a table showing what wipers do and what materials they use:

Function/Feature | Material Used |

|---|---|

Prevents contaminants from entering hydraulic systems | High Performance Hallite® 361 polyurethane |

Protects from the surrounding environment | Nitrile® |

Offers durability and stability | Hythane® 181 |

Temperature resistance from -30 °C to 110 °C | Other polyester based materials |

Wipers do more than just clean. They:

Stop dirt and water from getting inside the cylinder.

Protect the system from rust and wear.

Keep the wiper groove and gland free from contamination.

Help your hydraulic system last longer.

For example, the Hallite 80 rotary pressure seal works well in swivel joints and keeps out dust and moisture. Wipers made with Hythane® 181 and Hallite® 361 polyurethane stand up to tough jobs and wide temperature ranges.

When you choose Hallite hydraulic seal kits, you get wipers that keep your system safe and reliable. This means less downtime and fewer repairs.

Materials and performance

Common Materials

Hallite hydraulic seal kits use many materials. Each material gives the seal a special feature. Here are the main types:

Elastomers: NBR, TPE, TPU, XNBR, HNBR, FKM, FFKM, FEPM, FVMQ, EPM, EPDM. These materials fight oil and wear.

Plastics: Reinforced thermosetting polyester resin, PF, PTFE, PA nylon, PEEK, UHMWPE, POM, PPS. Plastics make seals strong and smooth.

Composites: SinterMesh™ XPC compounds™, carbon-fiber composites, nano-composites, elastomer-coated fabrics. Composites help seals last longer and work in hard jobs.

Hythane® 181 is known for being tough. You see it in seals like the Hallite 605 rod seal. This polyurethane keeps seals bendy in cold weather and stops leaks in winter.

Tip: Seals made with Hythane® 181 work well when it’s cold and help your system stay reliable.

Feature | Description |

|---|---|

Material | Hythane 181 (Polyurethane) |

Durability | Makes seals last longer in cold places |

Flexibility | Stays bendy even when it’s very cold |

Performance | Stops leaks in hydraulic systems |

Reliability | Lowers the number of seal problems |

Pressure & Temperature Ratings

You need seals that can handle strong pressure and big temperature changes. Most Hallite hydraulic seal kits work from -45°C to 110°C. Some, like the Hallite 605 rod seal, work in both cold and hot places. Pressure ratings go up to 500 Bar, so you can use these kits in tough machines.

Performance Factor | Description |

|---|---|

Seal Integrity | Works well in many conditions |

Pressure | Handles strong pressure |

Speed | Works at different speeds |

Temperature | Works in hot and cold places |

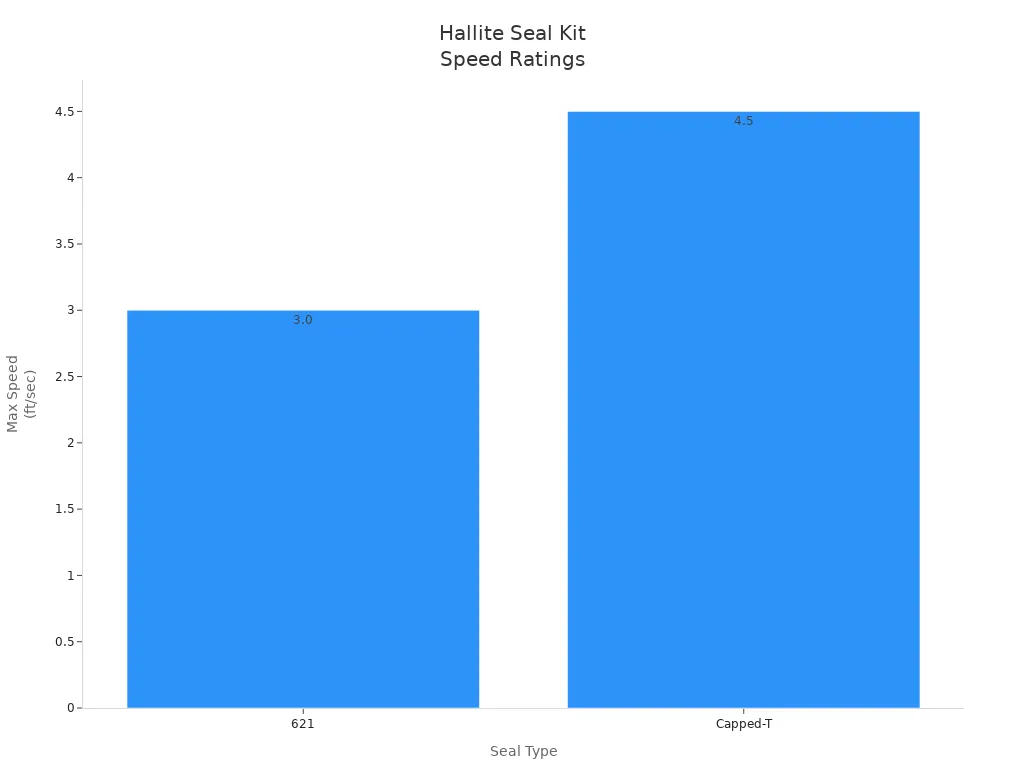

Speed Ratings

Speed ratings show how fast the seal can move without breaking. Most seals work at speeds from 0.5 to 4.5 feet per second. For example, the Hallite 621 seal moves at 3.0 ft/sec, and the Capped-T seal goes up to 4.5 ft/sec. These ratings are as good as or better than most other seals.

If you want to check specs fast, use these tables:

Metric Fluid Power Seal Catalogue

Inch & Pneumatic Fluid Power Seal Catalog

Armorlene® PTFE Product Profiles

You get seals that last a long time, work in tough places, and keep your hydraulic system safe.

Sizing & compatibility

Part Numbers

You can find the right seal kit by reading the part numbers. Each Hallite part number tells you the type, size, and material of the seal. For example, the first digits show the seal type. The next set of numbers gives the size. Letters at the end tell you the material. Always check the full part number before you order. This helps you avoid mistakes and get the exact seal you need.

Tip: Double-check the part number on your old seal or in your equipment manual before buying a new kit.

Size Charts

Size charts make it easy to match seals to your cylinder. You look up the rod or bore size, then find the matching seal size in the chart. Most charts list the inside diameter, outside diameter, and width. This helps you pick a seal that fits perfectly.

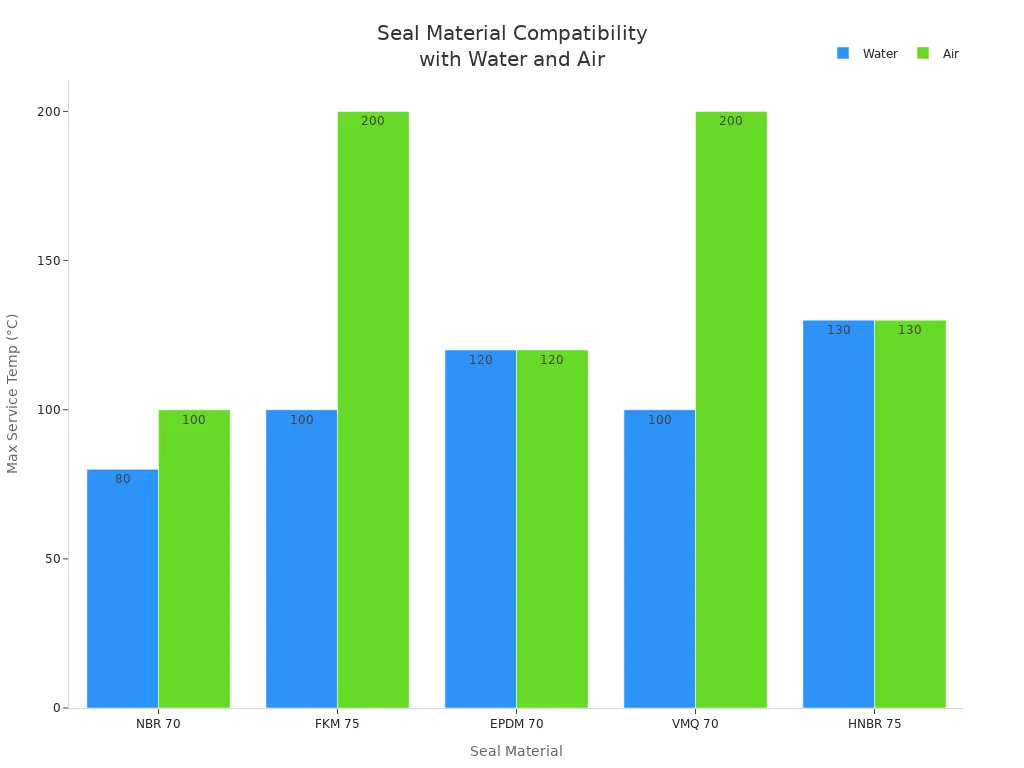

Material | Continual Service Temp (°C) | Intermittent Service Temp (°C) | Water | Air | Brake Fluids |

|---|---|---|---|---|---|

NBR 70 | +100 -30 | +120 -30 | +80 | +100 | NS |

FKM 75 | +200 -20 | +250 -20 | +100 | +200 | NS |

EPDM 70 | +120 -50 | +150 -50 | +120 | +120 | +120 |

VMQ 70 | +200 -55 | +250 -55 | +100 | +200 | +80 |

HNBR 75 | +130 -30 | +150 -30 | +130 | +130 | NS |

Equipment Match

You want your seal kit to fit your equipment and work well with the fluids and temperatures you use. Always check the equipment brand and model. Use the size chart and part number to confirm the match. Many users make mistakes when they:

Pick the wrong size.

Use the wrong material for their fluid or temperature.

Install the seal incorrectly.

Forget to check for contamination.

You can avoid these problems by following the charts and guides. For reliable kits and support, choose YNF Machinery as your supplier.

You now know that specs like material, size, temperature, pressure, and speed help you choose Hallite hydraulic seal kits.

Look at the type, part number, and size to make sure it fits.

Pick the best material so the seal does not break.

Keep seals in a cool and dry spot.

Next steps:

Clean the seal housing and take out any dirt.

Check the kit specs and add oil before putting it together.

Buy from YNF Machinery if you want good help.

Always check the official spec sheets for the right details.

FAQ

How do you choose the right Hallite hydraulic seal kit?

You check the specs for material, size, temperature, and pressure. Use the size chart and part number. YNF Machinery helps you find the correct kit.

Can you use Hallite seal kits in cold weather?

Yes. Many Hallite seals work in temperatures as low as -45°C. Hythane® 181 material keeps seals flexible and strong in cold conditions.

Where can you buy genuine Hallite hydraulic seal kits?

You order from YNF Machinery. They offer reliable support and help you match the right kit to your equipment.