Choosing the right crawler excavator undercarriage parts helps your machine work well and stay safe. You need to pick parts that fit your excavator. The parts should also match what your job site needs. Good quality is important because the undercarriage works in hard conditions every day. More than 35% of excavator problems come from undercarriage part issues:

Chassis system failures cause many breakdowns. The kind of part, the materials, and how the operator uses the machine all change how long it lasts. Checking your machine often and looking at aftermarket choices help you use your equipment better.

Key Takeaways

Pick undercarriage parts that match your excavator’s type. Make sure the size and weight are right for better work.

Choose strong materials like steel or good rubber. This helps the parts last longer and break less often.

Check your excavator often and take care of it. This helps you find problems early and makes your parts last longer.

Think about where you will use your machine when picking parts. Make sure the parts can handle the job site’s tough spots.

Buy from trusted suppliers like YNF Machinery. They give you good parts and great help if you need it.

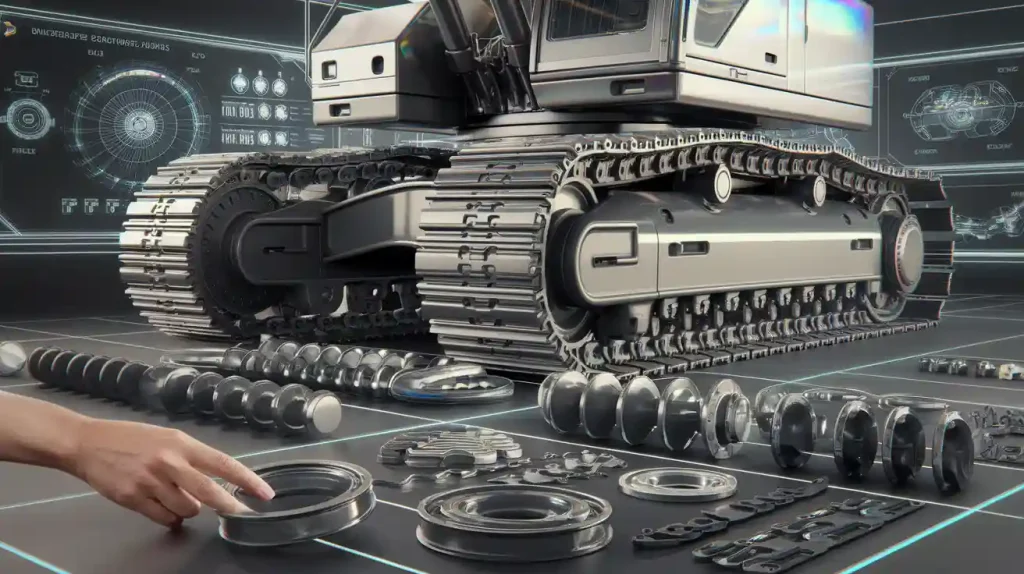

Selection Criteria for Crawler Excavator Undercarriage Parts

Machine Compatibility

You must pick crawler excavator undercarriage parts that fit your machine’s type, size, and weight. Every excavator model needs special undercarriage designs to work best. The size of your excavator decides how big parts like sprockets and rollers should be. The weight of your machine is important because the undercarriage holds it up and takes in shocks while working.

Tip: Always look at your excavator’s manual to find the right part details before you buy new parts.

If parts do not fit right, your machine can become unstable and not last as long. Here is a table that shows common problems:

Compatibility Issue | Description |

|---|---|

Improper Track Tension | Can make the machine unstable and wear out parts too fast. |

Debris and Mud Accumulation | Dirt and mud can break undercarriage parts; cleaning is very important. |

General Wear and Tear | Using the machine a lot wears out parts; check often to find problems early. |

Think about these things too:

Machine specifications: Make sure parts fit your excavator’s make, model, and size.

Operating conditions: Pick parts that work well for your job site, like rocky or muddy places.

Material quality: Choose strong materials so parts last longer.

Brand reputation: Good brands make parts that fit better.

Track shoes, pins, bushings, and bottom rollers wear out the fastest. If you check your machine often, you can find worn parts early and stop bigger problems.

Durability and Quality Undercarriage Parts

Good undercarriage parts help your excavator last longer and break down less. Look for parts made from tough materials like steel or premium rubber. High-strength alloys and composite materials from brands like Komatsu and Caterpillar make parts stronger and help them last longer.

Brand | Material Type | Key Material Properties and Benefits | Durability Improvements |

|---|---|---|---|

Komatsu | Optimized high-strength alloys | Tensile strength 25%-30% higher than regular | Wears out 20% slower; better against wear and breaking |

Caterpillar | Composite materials + high-temp coatings | Rust resistance is about 15% better; lasts longer | Stays strong in heat and does not rust as fast |

You can pick from different material grades:

Economy: Cheaper materials for light work; does not last as long.

Standard: Better materials for normal work; lasts longer than economy parts.

Heavy-duty: Best materials for hard work; lasts the longest and is the toughest.

Premium rubber tracks work better in tough jobs and last longer than regular tracks. Good suppliers follow OEM rules, so parts are less likely to break early. Cheap parts may save money at first, but they wear out fast and cost more later. Good undercarriage parts from trusted sellers help you avoid repairs and keep your excavator working well.

Job Site Requirements

Your job site changes how you pick excavator undercarriage parts. The soil, weather, and type of work all change how fast parts wear out. For example, dozing and pushloading make rollers and idlers wear out faster because the weight moves to the front. Ripping and drawbar work wear out rollers, idlers, and sprockets faster because the weight moves to the back.

Factor | Impact on Undercarriage Components |

|---|---|

Dozing and pushloading | Makes rollers and idlers wear out faster from front weight. |

Ripping and drawbar | Wears out rollers, idlers, and sprockets faster from back weight. |

Loading | Moving weight can make rollers wear out sooner. |

Excavating | Parts on the digging side wear out quicker. |

How you use the machine also matters. Working uphill wears out the back undercarriage parts more. Working on hillsides wears out the parts on the lower side. Doing too much crown work and vee ditching wears out inside and outside undercarriage parts. Try not to drive in reverse too fast, load from the side, turn the same way a lot, or spin in place. These things make parts wear out faster and do not last as long.

Note: Doing regular maintenance and picking the right parts for your work helps you save money and avoid repairs. Cat undercarriage and cat heavy duty undercarriage parts are made for hard jobs and last longer in tough places.

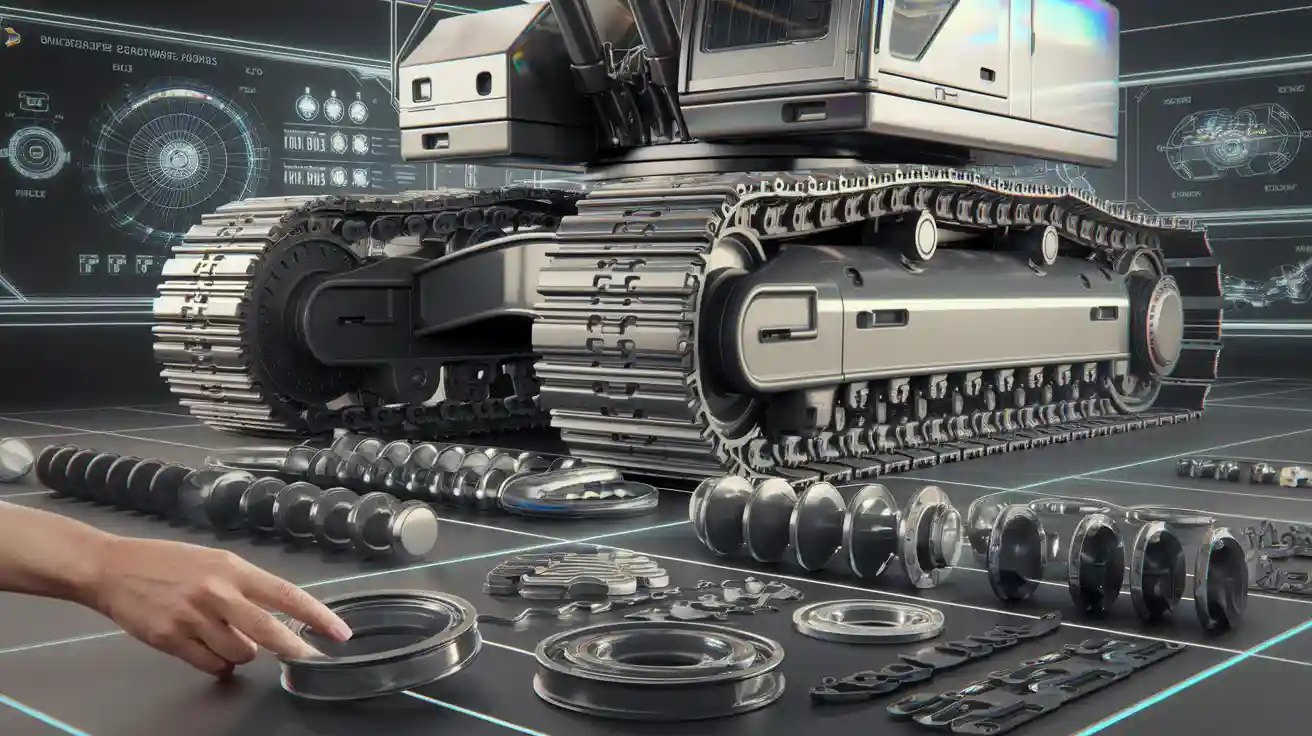

Essential Excavator Undercarriage Parts

When you want your excavator to work at its best, you need to know the main undercarriage parts. Each part has a special job that helps your machine move, dig, and last longer.

Track Adjusters

Track adjusters keep the right tension in your tracks. When you keep the tension correct, you lower friction and help your excavator use less fuel. This also keeps your machine stable and safe. If you check and adjust the track often, you can stop parts from wearing out too fast.

Regular care for track adjusters means your undercarriage will last longer and work better.

Track Rollers

Track rollers help your tracks move smoothly over the ground. They carry the weight of your excavator and keep the tracks in place. If you see leaks or uneven wear, you should replace the rollers. Worn rollers can make your machine shake and lower its performance.

Sprockets

Sprockets connect with the track chains and help move the tracks. Good sprockets spread out the load and stop one spot from wearing out too fast. The right sprocket design gives your excavator strong power and helps the undercarriage last longer.

Core Function | Description |

|---|---|

Power Transmission | Turns engine power into movement for the tracks. |

Load Bearing | Handles heavy loads and keeps the machine steady. |

Wear Distribution | Spreads out wear for longer sprocket life. |

Compatibility | Must match the track pitch to avoid skipping or breaking. |

Idler Wheels

Idler wheels keep the track straight and tight. They help stop the track from slipping off and lower wear on other parts. If the track gets too loose, it can fall off or wear out faster. Idler wheels also take in shocks from rough ground.

Track Pads

Track pads touch the ground and give your excavator grip. You can pick from steel, rubber, or polyurethane pads. Rubber pads give you better traction and work well on many surfaces. Polyurethane pads last longer in tough jobs. Steel pads are strong for heavy work but can wear out faster in some soils.

Track Assemblies

Track assemblies include all the parts that make up the moving track system. When you choose assemblies, look at the material, how much weight they can hold, and how easy they are to fix. Good assemblies help your excavator work in many places and last longer.

Final Drives

Final drives give power to the tracks. They let you move and turn your excavator, even in tight spots. Each excavator has two final drives, so you can steer and work on rough ground. Final drives change hydraulic power into movement and help your machine handle heavy loads.

If you keep all these undercarriage parts in good shape, your excavator will have better performance and need fewer repairs.

Undercarriage Part | Average Replacement Interval (Hours) |

|---|---|

Track Shoes | 2,000 to 3,000 |

Rollers | 3,000 to 5,000 |

Idlers | 4,000 to 6,000 |

Sprockets | 3,000 to 4,000 |

Track Chains | 3,000 to 5,000 |

Evaluating Suppliers and Aftermarket Options

Supplier Reputation

You need a supplier you can trust for crawler excavator undercarriage parts. YNF Machinery is known for strong support and good service. Look for suppliers with lots of experience and the right certifications. They should have helped with big projects before. Here is a table that shows what to check when picking a supplier:

Criteria | Description |

|---|---|

Experience and Reputation | More than 10 years in business means they know excavators well. |

Certifications | ISO9001, CE, or OEM approval shows they follow strict rules for quality. |

Production Capacity and Delivery | Good production and fast delivery help you finish your work on time. |

After-Sales and Technical Support | The best suppliers give warranties and help with installation. They answer questions quickly. |

Global Client References | Working on big international jobs means their parts are good and trusted. |

YNF Machinery meets these standards and gives expert help. You get help with installation and fast answers if you have problems. Reliable delivery means you get your parts on time. This keeps your excavator working and stops delays.

Aftermarket vs. OEM Excavator Undercarriage Parts

You can choose between aftermarket and OEM excavator undercarriage parts. OEM parts use set materials and match the factory’s original specs. This means you get steady quality and reliability. Aftermarket parts cost less and can be made faster. Suppliers can change materials to meet what people need. Good aftermarket parts can work as well as OEM parts. OEM parts lower the chance of breakdowns and work well in tough jobs. Aftermarket options can also meet hard standards and save you money.

If you need full track assemblies, both OEM and aftermarket choices offer steel and rubber tracks. OEM assemblies are strong and give good grip. Aftermarket assemblies can be good quality and cost less. Think about your budget, your work, and how much reliability you want.

Warranty and Service

Warranty and after-sales service are important when buying excavator undercarriage parts. YNF Machinery gives flexible warranty terms and great support. Here is a table that compares OEM and aftermarket warranties:

Warranty Type | Duration | Coverage Details | Installation Requirements |

|---|---|---|---|

OEM | 1-2 years or 2000-3000 machine hours | Covers material problems but not normal wear. Needs factory-certified installation and records. | Must be installed by factory-certified technicians. |

Aftermarket | Up to 3 years or 4000 run hours | Covers making mistakes and normal wear. Allows certified third-party installation. | Can be installed by certified technicians. |

Buyers like fast delivery and quick help after buying. You want help for on-site replacement and emergencies. Good customer reviews show YNF Machinery gives quality parts and strong service. Good warranty and quick support help keep your excavator working and lower downtime.

Maintenance Tips for Excavator Undercarriage

Taking care of your excavator is important. You should do regular undercarriage maintenance. Good habits help you avoid big repair bills. They also help your machine last longer in every job.

Inspection

Check your excavator’s undercarriage often. This helps you find problems early. Start each day by cleaning off dirt and debris. Cleaning helps you see damage and keeps the tracks working well. Use these inspection times to help your machine last:

Clean and check the undercarriage every day.

Look at sprockets and idlers every 100 hours.

Do a full undercarriage check every 1,000 hours or once a year.

Check more often if your machine is old or works in tough places.

When you inspect, follow these steps:

Take off all dirt and debris from the undercarriage.

Look for cracks, loose bolts, or bent steel parts.

Check the track for cuts, bends, or missing rubber pads.

Measure track sag with a straight edge between the idlers.

Look at rollers for leaks or damage.

Use calipers to measure pins and bushings.

Write down what you find and compare it to wear charts.

Tip: Look over your machine at the start of every shift. This helps you find problems before they get worse.

Preventive Care

Doing maintenance before problems happen keeps your excavator running. It also helps you avoid downtime. Here are some important things to do for your cat undercarriage and cat heavy duty undercarriage:

Preventive Maintenance Practice | Description |

|---|---|

Daily Inspections | Find problems early and stop expensive repairs. |

Proper Lubrication | Make sure moving parts work well and wear less. |

Cleaning | Take off mud and debris, especially after hard jobs. |

Maintaining Correct Track Tension | Adjust track tension every 10-15 hours to stop uneven wear. |

Keep a record of all maintenance and inspections. This helps you know how long your parts last. It also shows you took good care of your machine. Clean the undercarriage at the end of each workday. This is extra important after working in mud or gravel. Cleaning helps steel and rubber parts last longer.

Regular checks and cleaning help you avoid sudden breakdowns. You save money, keep your excavator ready for work, and protect your machine’s quality.

To help your excavator work well, do these things:

Pick undercarriage parts that fit your excavator and job site.

Get strong parts made from good materials.

Use YNF Machinery for trusted parts and good help.

Check and care for your excavator often so it lasts longer.

Making good choices and taking care of your machine helps it work better and stops long breaks.

FAQ

What signs show that I need to replace undercarriage parts?

You might see cracks or uneven wear. Sometimes bolts get loose. Your excavator may shake or sound strange. If you notice these things, check the undercarriage. Replace any parts that look worn out soon.

How often should I inspect my excavator’s undercarriage?

Check your undercarriage every day. Clean off dirt before you start work. Look for damage each time. Regular checks help you find problems early. This keeps your machine working well.

Can I use aftermarket parts instead of OEM parts?

Yes, you can use good aftermarket parts. Trusted suppliers like YNF Machinery offer quality parts. These parts often cost less than OEM parts. They work well for many jobs.

What is the best way to keep my undercarriage clean?

Use a pressure washer after each job. Wash away mud and debris. Pay close attention to rollers and track pads. Clean parts last longer. This helps your excavator work better.

Why should I choose YNF Machinery for undercarriage parts?

YNF Machinery gives strong and reliable parts. You get expert help and fast delivery. They offer good warranties and help with installation. Many people trust YNF Machinery for their excavators.