You know your 17d excavator needs important 17d excavator parts. The engine, hydraulics, undercarriage, and electrical systems work hard. Regular care keeps these 17d excavator parts working well. Fixing problems early stops them from getting worse. John Deere manuals and apps show you what to do. If you stay ahead, you save money and time at work.

Key Takeaways

It is very important to take care of your 17D excavator parts. Check engine parts like air and fuel filters often. This helps stop breakdowns from happening.

The hydraulic system also needs good care. Change hydraulic filters every 1,000 hours. Change the oil every 2,000 to 3,000 hours. This helps you avoid expensive repairs.

Look at the undercarriage often. If tracks and rollers are worn, you will feel more shaking. This can also make repairs cost more.

Always use real John Deere parts when you need new ones. They fit better and last longer. This saves you money over time.

Keep a log of all maintenance. Write down every check and repair. This helps you stay organized and find problems early.

Essential 17d excavator parts

Engine Components

Your 17D excavator does tough jobs every day. The engine is very important for your machine. You need to keep it in good shape so it does not break down. Some engine parts you should know are air filters, fuel filters, belts, and spark plugs. If you do not take care of these parts, your excavator might lose power or run badly. You should look for leaks, weird sounds, or smoke. If you hear grinding or rattling, stop and check the engine right away. Checking your engine often helps you find problems before they get worse.

Tip: Clean or change air and fuel filters often. Dirty filters make your engine work harder and use more fuel.

Hydraulic System Parts

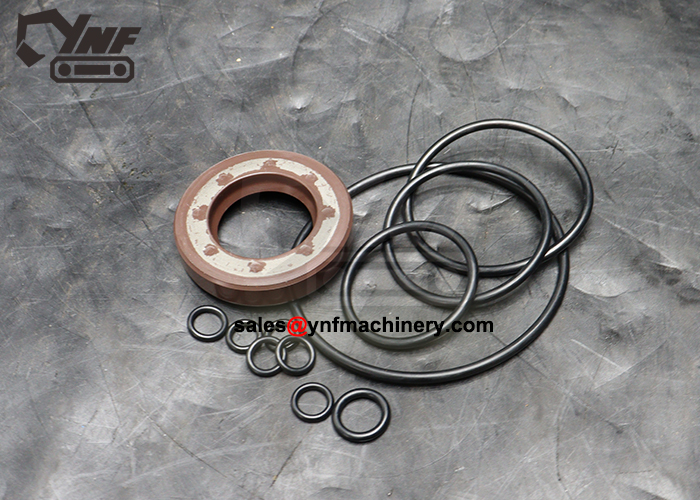

The hydraulic system helps your excavator lift, dig, and move things. To keep your machine working well, you need to care for these parts. Hydraulic pumps, hoses, cylinders, and valves are very important. Leaks or slow movement can happen when hydraulic system parts get old or worn out. Low oil, old seals, or a bad pump can make the system overheat or act strangely.

Here’s a quick guide for replacing hydraulic system parts:

Part | Recommended Replacement Interval |

|---|---|

Hydraulic filters | Every 1,000 hours |

Hydraulic oil | Every 2,000-3,000 hours |

Change hydraulic filters every 1,000 hours.

Change hydraulic oil every 2,000-3,000 hours.

If you follow these times, you can avoid expensive repairs and keep your 17d excavator parts working well.

Undercarriage Parts

The undercarriage holds up your excavator and helps it move. Tracks, rollers, sprockets, and idlers all work together. If you let these parts get too old, your machine will shake more and not work as well. Old undercarriage parts can make pumps and motors wear out faster. You might have to pay a lot for repairs.

Impact of Undercarriage Wear | Description |

|---|---|

Increased Vibration Levels | A worn undercarriage makes the machine shake more and not work as well. |

Reduced Service Life | Worn parts make pumps and motors not last as long. |

Higher Repair Costs | Fixing the undercarriage can cost half of all repairs for the machine. |

Taking care of your undercarriage can lower costs.

If one part breaks, other parts can wear out faster and cost more to fix.

Checking and fixing your undercarriage often helps your machine work better and saves money.

If you check your undercarriage often, you can find problems early. You save money and help your 17d excavator parts last longer.

Maintenance Tips

Engine Care

You want your 17D excavator to start strong every day. Start by checking the oil level before you turn the key. Low oil can damage your engine fast. Look at the air filter and clean it if you see dust or dirt. A clogged filter makes your engine work harder and burn more fuel. Listen for odd sounds when the engine runs. Knocking or rattling means you should stop and check for loose parts. Change the fuel filter on schedule to keep dirt out of the engine. If you see smoke or smell fuel, fix the problem right away.

Tip: Keep a small notebook in your cab. Write down when you change oil, filters, or notice anything strange. This helps you spot problems early.

Hydraulic Maintenance

Hydraulic parts do the heavy lifting. You need to keep the system clean and full of oil. Check hoses and fittings for leaks every week. Even a small drip can turn into a big mess. Wipe off dirt and mud from the cylinders. Dirt can scratch the seals and cause leaks. Change the hydraulic filter and oil as the manual says. If you hear whining or see slow movement, check the oil level first. Air in the system can make the machine act strange. Bleed the system if you see bubbles in the oil.

Always use the right hydraulic oil for your machine.

Store extra oil in a clean, dry place.

Track and Undercarriage Care

Your undercarriage takes a beating every day. If you want your 17d excavator parts to last, you need to check the tracks and rollers often. Here are some common causes of undercarriage trouble:

Rough terrain can crack or damage the tracks.

Water and moisture cause rust and weaken metal parts.

Mud that sticks to the undercarriage holds moisture and leads to seal problems.

Pushing your machine too hard or working on steep slopes puts stress on the undercarriage.

Collisions with rocks or other objects can bend or break parts.

Clean the undercarriage after each job. Remove mud and rocks with a shovel or pressure washer. Look for loose bolts or missing parts. Tighten anything that feels loose. If you see a crack or broken part, fix it before you use the machine again.

Electrical and Controls

Battery and Wiring

Your 17D excavator depends on a strong battery and good wiring. If your battery gets weak, your machine might not start. Loose or corroded cables can cause power loss. You should check the battery terminals for rust or white powder. Clean them with a wire brush if you see buildup. Make sure the cables fit tight. If you spot cracks or swelling on the battery, replace it soon.

Wiring problems can sneak up on you. Look for frayed wires or broken insulation. Tape up small spots, but replace wires that look really bad. If you see flickering lights or warning beeps, check the wiring first. Sometimes, a small fix can stop a big problem.

Here are some of the most common electrical issues you might face:

Electrical Issue | Description |

|---|---|

Circuit Failure | Poor contact, short circuit, or open circuit. Key parts need inspection. |

Motor Failure | Abnormal operation or hard starting. Check power supply and motor winding. |

Sensor Failure | Unstable operation and less accuracy. Check sensor power and signal output. |

Machine acts strange. Check the circuit system and control unit. | |

Aging Electrical Circuits | Old wires can fail. Inspect and replace damaged circuits. |

Tip: Keep a small toolkit with fuses, tape, and a multimeter in your cab. Quick fixes can save your workday.

Control Panel Checks

You use the control panel every time you run your excavator. If something feels off, you should check it right away. Here’s a simple routine to keep your controls in top shape:

Visual Inspection: Look at the boom, arm, and bucket for cracks or damage. Check hydraulic hoses for leaks. Make sure the undercarriage looks good.

Operational System Inspection: Fill the fuel tank. Check oil and fluid levels. Inspect filters to make sure they are clean.

Operational Function Test: Start the engine. Watch the dashboard lights and gauges. Test the brakes and safety systems.

If you follow these steps, you can catch problems before they stop your work. A quick check each day keeps your 17D running smooth and safe.

Attachments and Wear Items

Buckets and Teeth

Buckets and teeth do the hard work on your 17D excavator. You dig, scoop, and move heavy materials every day. Over time, these parts wear down. You might notice the bucket edge looks thin or the teeth look dull. When this happens, your machine will not dig as well. You may even see the bucket struggle to break through tough soil.

You can spot worn teeth if they look rounded or chipped. Sometimes, you will see cracks along the bucket edge. If you ignore these signs, you risk breaking the bucket or damaging the arm. Replacing worn teeth and bucket edges helps you keep digging strong and fast.

Tip: Check your bucket and teeth after each job. Clean off dirt and rocks. This helps you spot damage early and keeps your machine working longer.

Here are a few signs you need to replace your bucket teeth:

Teeth look shorter than normal.

You see cracks or chips.

The bucket edge feels sharp or thin.

Pins and Bushings

Pins and bushings help your excavator move smoothly. They connect the bucket, arm, and boom. When these parts wear out, you will feel extra movement or hear clunking sounds. If you let them get too loose, you can damage other parts of your machine.

Look for these signs that mean you need to replace pins and bushings right away:

You notice too much play between the pin and bushing.

You can twist the bushing by hand.

You see a lot of dust or dirt building up around the joint.

If you spot any of these problems, stop and fix them before you keep working. Worn pins and bushings can lead to bigger repairs if you wait too long.

Note: YNF Machinery offers reliable pins, bushings, and other wear parts for your 17D excavator. Choosing quality parts helps you avoid downtime and keeps your machine running strong.

Sourcing Parts in 2025

Genuine vs Aftermarket

When you need new parts for your 17D excavator, you face a choice. Should you buy genuine John Deere parts or go with aftermarket options? Genuine parts come straight from John Deere. They fit your machine perfectly and last a long time. You get peace of mind because these parts meet the highest standards. If you want your excavator to run like new, genuine parts are a safe bet.

Aftermarket parts cost less. Some work well, but others may not fit right or last as long. You might save money at first, but you could face more repairs later. If you use your 17D every day, genuine parts help you avoid downtime and big repair bills.

Tip: Always check your warranty before you buy. Some warranties only cover repairs if you use genuine parts.

Where to Buy

You want to find a trusted place to buy your 17D excavator parts. In 2025, many owners look online for fast shipping and good prices. You can find engine assemblies, seal kits, and more from reputable sources.

You can also talk to your local John Deere dealer. They help you find the right part and answer your questions. If you order online, double-check the part number before you buy. This step saves you time and keeps your 17D running strong.

Note: Always keep your machine’s serial number handy. It helps you get the exact part you need.

Maintenance Tools & Resources

Manuals and Guides

You want your 17D excavator to work well and stay safe. The best way is to use the right manuals and guides. The John Deere 17D service manual, repair manual, and operator’s manual give you easy steps for every job. These guides show you how to check fluids, change filters, and fix simple problems. You can trust these books because they come from the people who made your machine.

When you use official manuals, you work safer and make fewer mistakes. You learn how to keep your excavator steady and spot problems early. Here are some safety tips you will find in these manuals:

Safety Tips | Description |

|---|---|

Ballasting Equipment | Learn how to add weight to your equipment so it stays steady and safe. |

Pre-Operation Checklist | Use the checklist to find problems before you start the machine. |

Workshop manuals help with hard repairs too. They have clear pictures and diagrams. You can see where each part goes and how to put things back. Even if you are new to fixing machines, these guides make it easier and help you not mess up.

Tip: Keep your manuals in the cab or toolbox. You will always have help when you need it.

Mobile Apps

You can make taking care of your machine even easier with mobile apps. The Equipment Mobile App helps you track service dates, order parts, and fix problems from your phone. You get reminders for oil changes and filter swaps. If you see a warning light, the app helps you know what it means.

You can also use the app to find part numbers and repair guides. Good pictures and easy steps help you fix things fast. With the right app, you spend less time guessing and more time working.

Note: Using digital tools keeps your 17D excavator working well and helps you avoid big problems.

Routine Checklist

Daily Tasks

You want your 17D excavator to start strong every day. A quick daily check keeps your machine safe and ready for work. Here’s a simple list you can follow:

Check the engine oil and coolant levels.

Look at the hydraulic oil sight glass.

Inspect the tracks for rocks, mud, or damage.

Walk around your machine. Spot leaks, loose bolts, or missing parts.

Clean the cab windows and mirrors for a clear view.

Test the lights, horn, and backup alarm.

Make sure the control panel shows no warning lights.

Tip: Take five minutes each morning for these checks. You can catch small problems before they stop your work.

Weekly and Monthly Tasks

Some jobs need a little more time, but they help your 17D last longer. Set a reminder for these weekly and monthly tasks:

Weekly:

Grease all pivot points and joints.

Clean the air filter or replace it if dirty.

Inspect the battery terminals for corrosion.

Check the bucket, teeth, and pins for wear.

Monthly:

Inspect hydraulic hoses for cracks or leaks.

Tighten loose bolts on the undercarriage.

Check the condition of belts and replace if worn.

Review the operator’s manual for any special tasks.

Task | How Often |

|---|---|

Grease joints | Weekly |

Inspect hoses | Monthly |

Clean air filter | Weekly |

Check belts | Monthly |

Record-Keeping

Good records help you remember what you checked and fixed. You can use a notebook, a spreadsheet, or a mobile app. Write down the date, what you checked, and any repairs you made. If you spot a problem, note it right away.

Keeping track of your work helps you plan ahead. You can order parts from YNF Machinery before you need them. This way, your 17D excavator stays ready for every job.

You want your 17D excavator to work well every day. Watch the engine parts, hydraulics, and undercarriage. John Deere manuals and apps give you simple steps and reminders. Do maintenance often so you find problems early. This helps you save money.

Need good parts? YNF Machinery can help you.

Start now, and your machine will stay strong and dependable in 2025 and later!

FAQ

How often should you replace the hydraulic oil on a 17D excavator?

You should change the hydraulic oil every 2,000 to 3,000 hours. Always check your manual for the exact time. Clean oil keeps your machine running strong.

What signs show that your undercarriage needs repair?

Look for extra shaking, loud noises, or uneven tracks. If you see cracks or missing bolts, fix them soon. These signs mean your undercarriage needs attention.

Can you use aftermarket parts for your 17D excavator?

You can use aftermarket parts, but genuine parts fit better and last longer. If you want fewer problems, choose quality parts from YNF Machinery.

Where can you find reliable 17D excavator parts?

You can order reliable 17D excavator parts from YNF Machinery. They offer strong parts that help your machine work better and last longer.