The excavator hydraulic system drives the power and precision behind your machine’s operations. It relies on several components working together seamlessly. The hydraulic pump generates the force needed to move the system. Control valves direct this force to specific parts of the excavator. Hydraulic cylinders convert fluid pressure into motion, enabling tasks like lifting and digging. Clean hydraulic fluid ensures smooth operation, while durable hoses and fittings maintain pressure flow. Filters protect the system by removing contaminants. Without proper care, fluid contamination can cause up to 75% of hydraulic system failures. Understanding these elements helps you keep your excavator running efficiently.

Key Takeaways

The hydraulic pump is the heart of the excavator system, converting mechanical energy into hydraulic pressure essential for operation.

Control valves are crucial for directing hydraulic fluid, ensuring precise movement and enhancing the machine’s responsiveness.

Hydraulic cylinders provide the necessary force for lifting and digging, making regular inspection and maintenance vital for optimal performance.

Using the correct hydraulic fluid is essential; it lubricates, cools, and protects the system, preventing costly failures.

High-quality hoses and fittings are necessary to maintain pressure and prevent leaks, ensuring the system operates efficiently and safely.

Regular filter maintenance is key to keeping hydraulic fluid clean, which protects components and extends the system’s lifespan.

Prioritizing maintenance and care for your hydraulic system not only enhances performance but also ensures reliability on the job site.

Hydraulic Pump

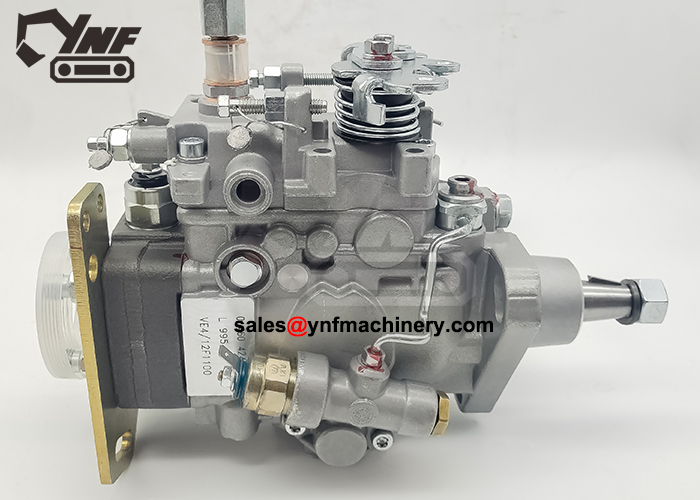

The hydraulic pump serves as the heart of the excavator hydraulic system. It transforms mechanical energy from the excavator’s engine into hydraulic pressure, which powers the entire system. This pressure drives the hydraulic fluid through the system, enabling the excavator to perform tasks like digging, lifting, and moving materials. Without the hydraulic pump, the system would lack the force needed to operate effectively.

Role of the Hydraulic Pump

The hydraulic pump plays a vital role in ensuring the smooth operation of your excavator. It generates the hydraulic pressure required to move fluid through the system. This fluid powers the hydraulic pumps and cylinders, which control the movement of the boom, arm, and bucket. The pump’s efficiency directly impacts the machine’s performance. A well-functioning pump ensures precise control and consistent power delivery, allowing you to handle heavy-duty tasks with ease.

“Hydraulic pumps convert mechanical energy into hydraulic energy, providing the force needed for excavators to perform with precision and power.”

Regular maintenance of the pump is essential. Neglecting it can lead to reduced efficiency, overheating, or even system failure. Always monitor the pump’s performance and address any issues promptly to avoid costly repairs.

Types of Hydraulic Pumps

Excavators use different types of hydraulic pumps, each designed for specific applications. Understanding these types helps you choose the right pump for your machine:

Gear Pumps: These pumps are simple and cost-effective. They are ideal for low-pressure applications and provide steady flow rates. However, they may not be as efficient as other types in high-pressure scenarios.

Vane Pumps: Known for their quiet operation, vane pumps offer moderate efficiency and are suitable for medium-pressure tasks. They are commonly used in applications where noise reduction is a priority.

Piston Pumps: These pumps excel in high-pressure environments. They deliver superior performance and efficiency, making them ideal for demanding tasks. Piston pumps are often used in heavy-duty excavators due to their ability to handle variable flow rates.

Each type of pump has its advantages and limitations. For instance, gear pumps are affordable but less efficient, while piston pumps provide high performance at a higher cost. Selecting the right pump depends on your excavator’s requirements and the nature of the tasks you perform.

Control Valves

Control valves are essential to the excavator hydraulic system. They act as the system’s command center, directing hydraulic fluid to specific components. By regulating the flow, pressure, and direction of the fluid, control valves ensure that your excavator operates with precision and efficiency. Without them, the hydraulic system would lack the coordination needed to perform tasks like digging, lifting, or moving materials.

Function of Control Valves

Control valves manage the movement of hydraulic fluid within the system. They determine where the fluid flows, how much pressure it exerts, and the speed at which it moves. This control allows you to operate the boom, arm, and bucket with accuracy. For example, when you move the joystick, the control valves adjust the fluid flow to the corresponding hydraulic cylinder, enabling the desired motion.

“Hydraulic control valves direct the pump’s output to machine actuators, converting fluid power back into mechanical power.”

Modern control valves often include advanced features like two-stage compensators. These features protect the system from pressure surges, ensuring smooth operation and extending the lifespan of components. By maintaining consistent fluid flow, control valves help prevent system inefficiencies and potential damage.

Importance of Control Valves

The importance of control valves lies in their ability to optimize the performance of your excavator hydraulic system. They ensure that each component receives the right amount of hydraulic fluid at the right time. This precision enhances the machine’s responsiveness and power, allowing you to handle heavy-duty tasks with ease.

Control valves also contribute to the safety and reliability of your excavator. By regulating pressure and flow, they prevent overloading and reduce the risk of component failure. Properly functioning control valves minimize downtime and maintenance costs, keeping your excavator productive on the job site.

Regular inspection and maintenance of control valves are crucial. Dirt, debris, or wear can affect their performance, leading to inefficiencies or malfunctions. Cleaning and replacing worn parts will help maintain the valves’ effectiveness and ensure the overall health of your hydraulic system.

Hydraulic Cylinders

Hydraulic cylinders are vital components of the excavator hydraulic system. They convert hydraulic cylinders fluid pressure into linear motion, enabling your excavator to perform essential tasks like lifting, digging, and pushing. Without these cylinders, the machine would lack the force and precision needed for heavy-duty operations.

Purpose of Hydraulic Cylinders

Hydraulic cylinders serve as the muscle of your excavator. They push, pull, and lift loads with remarkable power and accuracy. These cylinders allow you to control the movement of the boom, arm, and bucket, ensuring that your excavator can handle a variety of tasks efficiently. Whether you are digging trenches, moving debris, or loading materials, hydraulic cylinders provide the strength and stability required for the job.

“Hydraulic cylinders enable excavators to perform a wide range of tasks with power, precision, and efficiency.”

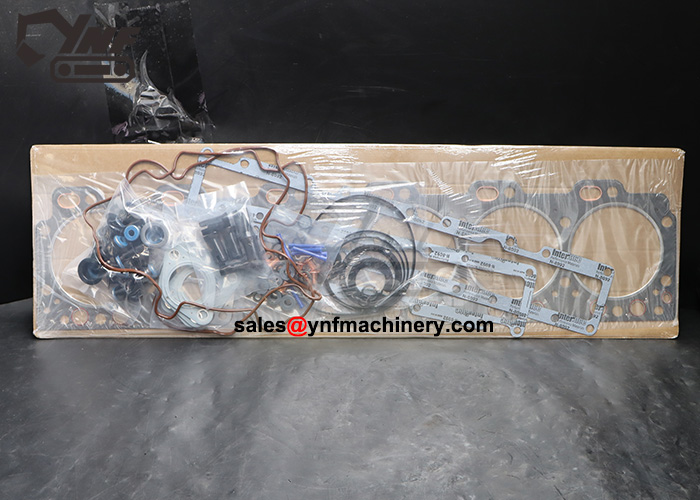

Properly functioning cylinders ensure smooth and reliable operations, reducing downtime and enhancing productivity. Regular maintenance, such as inspecting seals and checking for leaks, helps keep these components in top condition.

Types of Hydraulic Cylinders

Hydraulic cylinders come in different types, each designed to meet specific operational needs. Understanding these types helps you choose the right cylinder for your excavator:

Single-Acting Cylinders: These cylinders use hydraulic pressure to move in one direction, with a spring or external force returning them to their original position. They are ideal for applications requiring simple, unidirectional motion.

Double-Acting Cylinders: These cylinders use hydraulic pressure to move in both directions, providing greater control and versatility. They are commonly used in excavators for tasks that require precise and repetitive movements.

Telescopic Cylinders: These cylinders consist of multiple nested tubes, allowing for extended reach. They are perfect for applications where space is limited but a long stroke is necessary, such as lifting or dumping materials.

Tie-Rod Cylinders: These cylinders feature rods that hold the end caps in place, making them easy to assemble and disassemble. They are suitable for medium-pressure applications and are often used in smaller excavators.

Welded Cylinders: These cylinders have a compact design with welded end caps, offering durability and strength. They are ideal for high-pressure tasks and are commonly found in heavy-duty excavators.

Each type of hydraulic cylinder has unique advantages. For example, single-acting cylinders are simple and cost-effective, while double-acting cylinders provide enhanced control. Selecting the appropriate type depends on your excavator’s requirements and the nature of your projects.

Regular inspection and proper maintenance of hydraulic cylinders are essential. Dirt, debris, or wear can compromise their performance, leading to inefficiencies or failures. By understanding the purpose and types of hydraulic cylinders, you can ensure that your excavator hydraulic system operates at its best.

Hydraulic Fluid

Hydraulic fluid plays a critical role in the excavator hydraulic system. It serves as the lifeblood of the system, transmitting power while ensuring smooth and efficient operation. Without it, the hydraulic components would fail to function, rendering your excavator inoperable. The fluid not only transfers energy but also lubricates moving parts, reduces wear, and dissipates heat generated during operation. Its performance directly impacts the efficiency and longevity of your machine. hydraulic fluid

Role of Hydraulic Fluid

Hydraulic fluid enables the conversion of mechanical energy into hydraulic energy, powering the excavator’s movements. It flows through the system, delivering the necessary force to hydraulic cylinders, motors, and other components. This force allows your excavator to lift heavy loads, dig trenches, and perform other demanding tasks with precision.

“Hydraulic fluid ensures seamless energy transfer, lubrication, and cooling, making it indispensable for the efficient operation of hydraulic systems.”

The fluid also acts as a coolant, preventing overheating by absorbing and dissipating heat. Additionally, it protects the system from corrosion and contamination. Clean hydraulic fluid minimizes the risk of component failure, ensuring that your excavator operates reliably under tough conditions. Regularly monitoring the fluid’s condition helps maintain its effectiveness and prevents costly repairs.

Importance of Using the Correct Fluid

Using the correct hydraulic fluid is essential for maintaining the performance and durability of your excavator hydraulic system. Different fluids have unique properties, such as viscosity, thermal stability, and anti-wear additives. These characteristics influence how well the fluid performs under various operating conditions. correct hydraulic fluid

Viscosity: The fluid’s thickness affects its ability to flow through the system. A fluid with the wrong viscosity can lead to power losses, sluggish response, or excessive wear on components.

Thermal Stability: High-quality hydraulic fluids resist breakdown at elevated temperatures, ensuring consistent performance during prolonged use.

Anti-Wear Additives: These additives reduce friction and wear, extending the lifespan of critical components like pumps and valves.

Studies highlight that poor-quality or incorrect hydraulic fluid can result in reduced responsiveness, power transmission losses, and even system failure.

Selecting the right fluid prevents issues like overheating, contamination, and premature wear. Always refer to your excavator’s manual for the recommended fluid type. Regularly check fluid levels and replace the fluid as needed to maintain optimal system performance. Neglecting this can compromise the efficiency of your excavator and lead to expensive downtime.

Hoses and Fittings

Hydraulic hoses and fittings form the backbone of the excavator hydraulic system. They ensure the seamless transfer of hydraulic fluid between components, enabling your excavator to perform heavy-duty tasks with precision. These parts must withstand high pressure and harsh conditions, making their quality and maintenance critical for the system’s efficiency and safety.

Function of Hoses and Fittings

Hoses and fittings serve as the conduits that carry hydraulic fluid throughout the system. The hoses transport the fluid under high pressure, while the fittings connect the hoses to other components like pumps, valves, and cylinders. Together, they create a closed-loop system that powers the excavator’s movements.

“Hydraulic hoses and fittings are essential for maintaining the flow of hydraulic fluid, ensuring the system operates efficiently and safely.”

The flexibility of hydraulic hoses allows them to adapt to the excavator’s movements without compromising the flow of fluid. Fittings, on the other hand, provide secure connections that prevent leaks and maintain consistent pressure. Without properly functioning hoses and fittings, the hydraulic system would fail to deliver the power needed for tasks like digging, lifting, or moving materials.

Importance of Quality Hoses and Fittings

Investing in high-quality hoses and fittings is essential for the long-term performance of your excavator hydraulic system. Poor-quality components can lead to leaks, pressure drops, and even system failure. Regular inspection and maintenance help you identify wear and tear early, preventing costly repairs and downtime.

Durability: High-quality hoses and fittings resist wear, corrosion, and extreme temperatures, ensuring reliable performance under tough conditions.

Safety: Secure connections reduce the risk of leaks, which can cause accidents or damage to the system.

Efficiency: Properly functioning hoses and fittings maintain consistent pressure, optimizing the system’s power and responsiveness.

“Selecting the right hydraulic hose fittings is crucial to maintain the efficiency and safety of the hydraulic system.”

Regularly check for signs of damage, such as cracks, bulges, or leaks. Replace worn-out hoses and fittings promptly to avoid compromising the system’s performance. By prioritizing quality and maintenance, you can extend the lifespan of your excavator and ensure it operates at peak efficiency.

Filters

Filters play a vital role in maintaining the efficiency and longevity of your excavator hydraulic system. filters play a vital role They act as the system’s defense mechanism, removing contaminants and ensuring that hydraulic fluid remains clean. Without filters, dirt, debris, and other impurities could circulate through the system, causing damage to critical components like pumps, valves, and cylinders.

Role of Filters in the Hydraulic System

Filters protect the hydraulic system by trapping foreign particles before they can enter sensitive components. These particles, if left unchecked, can cause wear and tear, reduce efficiency, and lead to costly repairs. By keeping the hydraulic fluid clean, filters help maintain smooth operation and extend the lifespan of the system.

“The efficiency and longevity of hydraulic systems heavily rely on one crucial aspect: cleanliness.”

High-quality filters ensure that the hydraulic fluid is effectively decontaminated before it circulates through the system. high-quality filters ensure This process prevents blockages, reduces friction, and minimizes the risk of overheating. Regularly inspecting and replacing filters is essential to prevent contamination and maintain optimal performance.

Benefits of Regular Filter Maintenance

Regular filter maintenance offers several benefits that directly impact the performance and durability of your excavator hydraulic system:

Prevention of Component Damage: Clean filters prevent contaminants from reaching sensitive parts, reducing the risk of damage and ensuring smooth operation.

Extended System Lifespan: Properly maintained filters reduce wear and tear, helping your hydraulic system last longer.

Improved Efficiency: Clean hydraulic fluid flows more smoothly, optimizing the system’s power and responsiveness.

Cost Savings: Preventing contamination and damage reduces the need for expensive repairs and minimizes downtime.

“Keeping a hydraulic system clear of damaging impurities requires cleansing the system regularly.”

To maximize these benefits, check your filters frequently and replace them before the manufacturer’s recommended date. Neglecting this step can lead to fluid contamination, which accounts for a significant percentage of hydraulic system failures. Always use high-quality filters to ensure the best protection for your system.

The excavator hydraulic system relies on its key components to deliver power and precision for demanding tasks. Each part, from the hydraulic pump to the filters, plays a vital role in ensuring smooth operation and efficiency. Regular maintenance is essential to keep these components functioning at their best. By inspecting hoses, replacing filters, and using the correct hydraulic fluid, you can prevent costly repairs and extend your machine’s lifespan. Prioritizing care for your hydraulic system not only enhances performance but also ensures reliability on every job site.