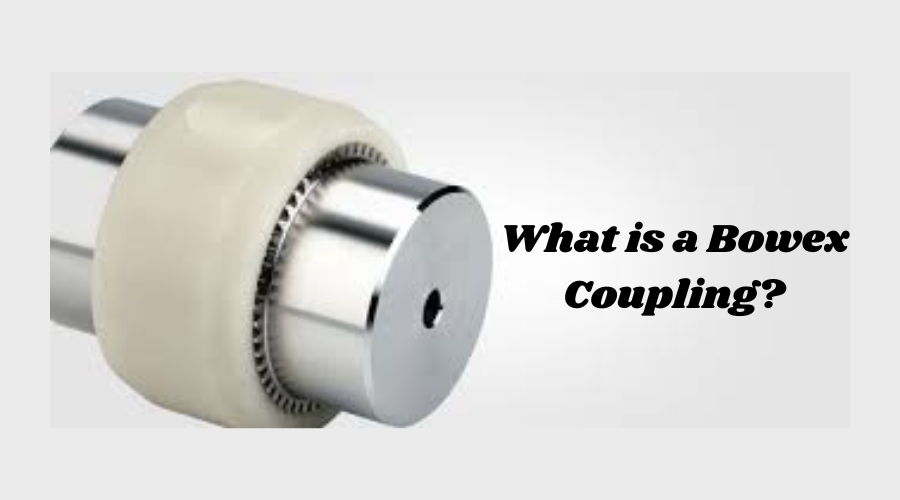

Each component of heavy machinery, especially excavators, requires smooth functionality and durability. One component is the Bowex coupling, essential to optimizing an excavator’s productivity, output, and durability. Bowex couplings are constructive equipment used to attach and drive machines together using different technologies.

Understanding Bowex Couplings

Bowex coupling is a flexible coupling used in mechanical systems requiring strength and flexibility. It joins to shafts and can accommodate minor offset and damp vibrations and shocks. It is more applicable when laden with heavy loads since it minimizes several other machine parts.

How Does a Bowex Coupling Work?

Bowex couplings contain a curved tooth profile, which makes it flexible, but at the same time, there is a strong joining between two shafts. This curvature assists in counterbalancing a slight shift of the shaft, which is expected in heavy equipment due to the normal vibration and varying loads. The coupling’s teeth are flexible, and the coupling has a hub that can absorb shock and reduce the amount of wear and tear the rest of the machine is exposed to vibrations.

Types of Bowex Couplings

As mentioned above, Bowex couplings come in different types to suit the intended users. The three main types include:

- Standard Bowex Couplings: These are commonly employed in various equipment applications requiring a dependable connection, but reasonable flexibility is not an essential characteristic.

- Bowex Curved Tooth Gear Couplings: Of the two, the taper bushings are famous for their ability to absorb shock and vibrations and are suitable for applications that experience drastic load changes, like excavators.

- Bowex Elastic Couplings: These are specifically useful for applications that, due to their design, need an extra level of elasticity.

Each has its benefits, and the kind of machine it has to go in mostly depends on that.

Why Are Bowex Couplings Necessary for Excavators?

Bowex coupling in excavators is crucial because it increases the machines’ power, reliability, and safety. Since the excavators are used under harsh conditions. Here’s why Bowex couplings are particularly beneficial in these machines:

- Shock Absorption: Excavators often face challenges like carrying capacity and rough working surfaces. Bowex couplings cushion these shocks so that essential components such as the engine and hydraulic system are not adversely affected.

- Flexibility: Unlike other excavators where minor misalignments are, in most cases, the order of the day, Bowex couplings are designed to accommodate such misalignments in a way that improves the machine’s performance.

- Extended Equipment Life: Bowex couplings benefit the excavator’s overall performance by absorbing stress and distributing it so that specific areas of the excavator do not experience as much wear and tear. This increases the machine’s life or ‘useful life,’ which means fewer repairs and overhauls, fewer spares needed, and less money spent on them.

Benefits of Bowex Couplings in Excavators

Bowex couplings provide several key advantages, making them an ideal choice for heavy machinery like excavators:

- Reduced Vibration and Noise: Bowex couplings minimize vibration. They also help the equipment operate more softly.

- Improved Efficiency: Bowex couplings thus minimize sleeve contact and, therefore, keep wear and tear to a minimum where the powertrain of the excavator is concerned.

- Ease of Maintenance: Bowex couplings often require less maintenance because they have fewer wear points, reducing downtime and associated costs.

Choose the Right Bowex Coupling for Your Excavator

- Load Capacity: Ensure that the coupling can handle the maximum load in your excavator at any time.

- Environmental Conditions: Higher working life and corrosion protection are required for coupling in extreme climatic conditions.

- Maintenance Needs: Some Bowex couplings are made for low maintenance, and this might be advantageous because excavator applications require a couple to be in service for an extended time.

Helpful Maintenance Tips for Bowex Couplings

Even though Bowex couplings are relatively maintenance-friendly, there are a couple of things that you can do to increase the couplings’ service life. Essential maintenance tips include:

- Inspect for Wear: Wear on the teeth or the coupling hub will invariably affect its performance, which must be checked frequently.

- Check Alignment: Coupling misalignment should not be tolerated because it can place high stress on the coupling, and regular alignment should be conducted.

- Lubricate if Needed: Bowex couplings vary in the degree to which they require lubrication; some models require it periodically.

When does the Excavator’s Bowex Coupling Need Replacement?

Understanding when to change the Bowex coupling is critical to achieving the best performance out of an excavator.

- Excessive Vibration: If the excavator vibrates more than usual, there is a problem with the coupling – it is either worn out or misaligned.

- Unusual Noise: If one hears any grinding or squeaking sounds, one can probably see that the coupling has worn down or damaged teeth.

- Reduced Efficiency: Ex effigies, an ill-fitted coupling is the root cause of reduced efficiency of an excavator in terms of fuel consumption and productivity, among others.

Conclusion

Bowex couplings are of immense importance to excavators’ overall efficiency and longevity. Hence, they enable excavators to solve complex challenges without exposing them to fast physical wear and tear. One has to determine how big your machine is and, therefore, approach a specialist supplier to get the correct coupling. Bowex coupling improves smoothness, low noise levels, increased excavator work efficiency, and low repair and replacement costs when installed correctly.