Keeping your Nagano mini excavator parts in top shape is essential for smooth operations and fewer breakdowns. Regular maintenance not only boosts performance but also saves you from costly repairs. Did you know preventive care can significantly reduce unexpected downtime?

It minimizes breakdowns.

It improves reliability and performance.

It ensures your equipment runs longer without hiccups.

Ignoring maintenance can lead to serious issues like undercarriage damage or hydraulic system failures. Simple steps, like greasing parts daily or adjusting track tension, can make a big difference. For high-quality parts and expert support, YNF Machinery has your back. They’ve been a trusted name for over 35 years, offering durable solutions to keep your excavator running like new.

Key Takeaways

Taking care of Nagano mini excavator parts stops breakdowns and saves repair money.

Use the manual for clear maintenance steps to keep it working well.

Check worn parts like tracks and hoses often to fix problems early and avoid big costs.

Make a maintenance plan that fits your excavator to make it last longer and work better.

Write down all maintenance to track fixes and help resale value, keeping your excavator in great shape.

Understanding Your Nagano Mini Excavator

Importance of the Operation Manual

Your Nagano mini excavator’s operation manual is more than just a booklet—it’s your go-to guide for keeping your machine in top condition. It provides detailed service recommendations and maintenance schedules, helping you stay on track with essential tasks. Whether it’s daily fluid checks or monthly filter replacements, the manual ensures you know exactly what to do and when to do it.

By following the manual, you can avoid costly repairs and downtime. It emphasizes routine maintenance and operator training, which are key to extending the life of your excavator. If you’re new to operating a mini excavator, the manual also offers tips for safe and efficient use. Think of it as your personal trainer for mastering preventive maintenance.

Key Components of a Mini Excavator

Filters, Belts, and Hydraulic Systems

Filters, belts, and hydraulic systems are the backbone of your mini excavator. Regularly inspecting and replacing filters keeps your machine running smoothly by preventing debris from clogging critical systems. Hydraulic systems, in particular, demand attention. Maintaining proper fluid levels and tracking leaks can save you from expensive repairs. Belts also play a crucial role in power transmission, so keep an eye out for wear and tear.

High-Wear Parts to Monitor

Some parts of your excavator experience more wear than others. Tracks and undercarriage components, for example, take a beating during daily operations. Regular checks improve traction and stability, ensuring your machine performs at its best. Hydraulic hoses and seals are also high-wear items. Inspect them frequently to catch cracks or leaks early. Gentle operation and proper training can further reduce wear and tear, keeping your Nagano mini excavator parts in great shape.

Pro Tip: Schedule quarterly inspections of the hydraulic system and annual checks for the electrical system to stay ahead of potential issues.

Daily and Weekly Mini Excavator Maintenance Tips

Routine Inspections

Checking fluid levels and connections

Routine inspection is the backbone of mini excavator maintenance. Start by checking the oil, coolant, and hydraulic fluid levels daily. Low fluid levels can lead to overheating or system failures. Use a checklist to ensure you don’t miss anything. Look for loose or damaged connections, as these can cause leaks or reduced performance.

Inspect the bucket and other components for cracks or excessive wear. A quick glance at the gauges and controls ensures everything is functioning properly. These small steps can save you from costly repairs down the line.

Inspecting hydraulic hoses and seals

Hydraulic hoses and seals are critical for smooth operation. Look for cracks, leaks, or bulges in the hoses. Damaged seals can lead to oil leaks, which affect the hydraulic system’s efficiency. Catching these issues early prevents breakdowns and keeps your excavator running smoothly.

Tip: Conduct these inspections at the start of every shift to avoid unexpected downtime.

Proper Greasing Practices

Daily greasing of pins and bushings

Greasing pins and bushings daily is essential to prevent wear and tear. Apply one to three shots of grease to each point for optimal results. Over-greasing can damage seals, while under-greasing increases friction, leading to premature failure.

Recommended greasing schedule

Follow the service manual for a detailed greasing schedule. Some components, like the slew bearing and bucket linkages, may require less frequent greasing. Sticking to the recommended schedule ensures all moving parts stay lubricated and functional.

Note: Use high-quality grease to maximize the lifespan of your Nagano mini excavator parts.

Cleaning and Debris Removal

Cleaning air filters weekly

Air filters play a vital role in engine performance. Clean them weekly to prevent dust and debris from clogging the system. You can use the tapping method by gently knocking the filter to remove dirt or the blowing method with compressed air. Always follow the manufacturer’s guidelines to avoid damaging the filter.

Method | Description | Precautions |

|---|---|---|

Tapping method | Remove the filter element and gently tap the end surface to dislodge dust. | Avoid touching the outer surface to prevent damage. |

Blowing method | Use compressed air to blow dust off the filter element. | Do not exceed 0.2 to 0.3 MPa to avoid damaging the filter paper. |

Preventing buildup on key components

Debris buildup on key components like the undercarriage or attachment can reduce efficiency. Clean these areas regularly to maintain performance. A clean machine not only works better but also lasts longer.

Pro Tip: Inspect the attachment for dirt and debris after every use to keep it in top condition.

Key Nagano Mini Excavator Parts to Monitor and Replace

Filters

Air filters: Replacement frequency and process

Air filters are vital for keeping your mini excavator’s engine running efficiently. Over time, they collect dust and debris, which can restrict airflow and reduce performance. You should replace air filters every 250 to 500 hours of operation or as recommended in your manual.

Signs that it’s time to replace your air filter include:

Reduced engine performance

Poor fuel efficiency

Engine misfires

Unusual engine noises

Warning lights

To replace the air filter, follow these steps:

Turn off the engine and let it cool.

Open the air filter housing and remove the old filter.

Clean the housing to remove any trapped dirt.

Insert the new filter and secure the housing.

Regularly replacing air filters ensures your excavator operates at peak efficiency and prevents costly engine repairs.

Hydraulic filters: Signs of wear

Hydraulic filters protect your machine’s hydraulic system by trapping contaminants. Worn-out filters can lead to:

Hydraulic fluid leaks

Reduced power or pressure

Overheating

Inspect hydraulic filters during routine maintenance. If you notice any of these issues, replace the filter immediately to avoid damaging the hydraulic system.

Belts and Hoses

Identifying cracks and fraying

Belts and hoses are essential for transferring power and fluids in your mini excavator. Regular inspections help you spot issues early. Look for:

Cracks or blisters on hydraulic hoses

Fraying, wear, or breakage on belts

Leaks around seals and fittings

Pre-use inspections and semi-annual checks by a certified technician can catch these problems before they escalate. Keeping hoses clean and storing them in the shade also extends their lifespan.

Replacing worn-out components

When you find damaged belts or hoses, replace them immediately. Delaying replacement can lead to system failures and downtime. Always use high-quality spare parts to ensure durability and compatibility with your machine.

Hydraulic Components

Monitoring fluid levels and quality

Hydraulic components are the heart of your mini excavator. Low fluid levels or poor-quality fluid can cause serious issues. Check fluid levels daily and look for signs of contamination, such as discoloration or a burnt smell.

Key indicators of hydraulic component failure include:

Leaks around the system

Unusual noises like knocking or grumbling

Overheating of hydraulic fluid

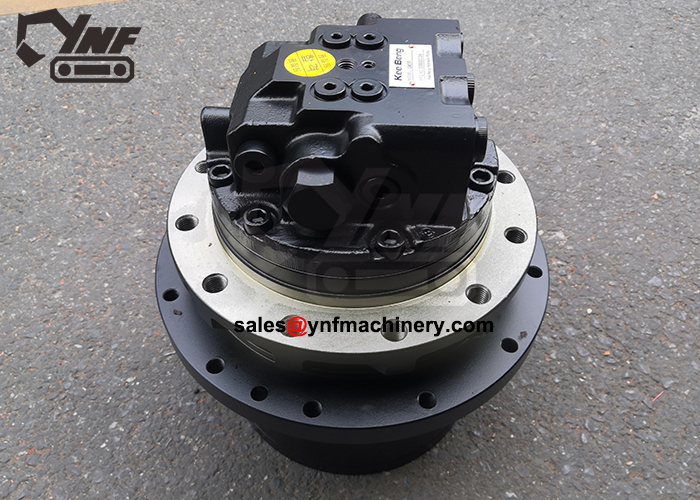

Weak performance in the final drive motor

Addressing these issues promptly keeps your machine running smoothly.

Replacing hydraulic cylinders with YNF Machinery’s Hydraulic Cylinder Seal Kits

If your hydraulic cylinders show signs of wear, like leaks or reduced efficiency, it’s time to replace the seals. YNF Machinery offers high-quality Hydraulic Cylinder Seal Kits designed to prevent oil leaks and restore performance. These kits are made from durable materials and fit a wide range of excavator models. Replacing worn seals with these kits ensures your hydraulic system remains efficient and reliable.

Pro Tip: Always keep a set of spare parts, like seal kits and filters, on hand to minimize downtime during repairs.

Tracks and Undercarriage

Inspecting tracks and sprockets

Your mini excavator’s tracks and sprockets take on a lot of wear during daily operations. Regular inspections help you catch issues early and avoid costly repairs. Start by examining the tracks for damage like exposed cables or missing rubber. These signs indicate the need for immediate attention. Check the sprockets for pointed or hooked teeth, as these are clear indicators of wear.

Pay close attention to track tension. Tracks that are too tight can wear down idlers, rollers, and sprockets faster. On the other hand, loose tracks can sag, causing excessive wear on pins and bushings. A quick adjustment can save you from bigger problems later.

Don’t forget to inspect the track chains for loose bolts, cracks, or bends. Look for oil seepage around idlers and rollers, as this could signal bearing failure. If you notice any of these issues, address them promptly to keep your excavator running smoothly.

Tip: Examine the tracks at the end of each workday. This habit helps you spot problems before they escalate.

Replacing damaged undercarriage parts

When you find damaged undercarriage parts, replacing them quickly is crucial. Start by cleaning the machine thoroughly. Dirt and debris can hide damage, making it harder to spot. Once clean, inspect the track chains, sprockets, idlers, and rollers for wear or cracks.

Evaluate both sides of the undercarriage. Uneven wear might indicate alignment issues or improper operation. If you find damage, decide whether you can replace the parts yourself or need professional help. Always use high-quality spare parts to ensure durability and compatibility with your machine.

Pro Tip: Keep spare parts like sprockets and rollers on hand. This preparation minimizes downtime during repairs and keeps your mini excavator maintenance on track.

By staying proactive with inspections and replacements, you’ll extend the life of your nagano mini excavator parts and maintain peak performance. Preventive maintenance is the key to avoiding unexpected breakdowns and keeping your equipment ready for action.

Professional Maintenance and Advanced Tools

Benefits of Professional Inspections

Professional maintenance offers several advantages that go beyond what you can achieve with routine checks. Bringing in experts ensures your mini excavator stays in top condition. Here’s why professional inspections are worth considering:

Experts can spot issues that might escape an untrained eye.

Inspections ensure your equipment complies with safety and industry standards.

Proper documentation supports OSHA compliance and boosts resale value.

Regular checks enhance safety for your crew and extend your machine’s lifespan.

Professional inspections also use advanced diagnostic tools to identify potential problems early. These tools provide real-time monitoring and predictive maintenance features. They save time and money by allowing targeted repairs before issues escalate. Plus, they’re reliable even in tough construction environments.

Tip: Schedule professional inspections at least twice a year to keep your excavator running smoothly.

Using Telematics for Maintenance

Telematics has revolutionized how you approach preventive maintenance. This technology tracks your excavator’s performance and alerts you when repairs or replacements are needed. It’s like having a personal assistant for your machine!

With telematics, you can:

Monitor machine activity and performance in real time.

Receive alerts for predictive maintenance, reducing unplanned downtime.

Access a detailed history of your excavator to schedule maintenance effectively.

Advanced telematics tools also offer custom dashboards and fault code alerts. These features make troubleshooting faster and more efficient. You can even track key metrics like efficiency and health scores.

Pro Tip: Use telematics to create a maintenance schedule tailored to your machine’s needs. This approach keeps your equipment in peak condition and minimizes unexpected breakdowns.

By combining professional maintenance with telematics, you’ll ensure your mini excavator stays reliable and efficient. These tools and services not only save you time and money but also give you peace of mind knowing your equipment is in expert hands.

Best Practices for Long-Term Preventive Maintenance

Creating a Maintenance Schedule

Importance of preventive maintenance plans

A preventive maintenance strategy is your best defense against unexpected breakdowns. It keeps your excavator running smoothly and reduces downtime expenses. By sticking to a routine maintenance schedule, you can catch small issues before they turn into costly repairs.

Here’s how you can create an effective preventative maintenance program:

Train your operators to spot potential problems early.

Follow the manufacturer’s routine maintenance schedule for service recommendations.

Inspect hydraulic cylinders daily to prevent accidents.

Regularly check the attachment for wear and tear to avoid costly repairs.

Preventive maintenance plans save time and money while improving machine performance. They also ensure your equipment stays reliable for years to come.

Customizing schedules for your excavator

Every excavator has unique needs. To customize your preventive maintenance strategy, consider your machine’s workload and environment. For example:

Check and add fluids every 10 hours.

Examine tracks weekly for proper tension.

Change engine oil and filters every 500 hours.

Replace radiator coolant every 2,000 hours.

By tailoring your schedule, you’ll address your machine’s specific needs and maximize its lifespan.

Keeping Maintenance Records

Tracking repairs and replacements

Keeping detailed records is essential for a preventative maintenance program. Document every repair, replacement, and inspection. This helps you track service history and identify recurring issues.

Benefits of a detailed service log

A well-maintained log offers several benefits:

It provides proof of maintenance for warranty claims.

It supports resale value by showing proper care.

It helps you plan future maintenance tasks effectively.

With accurate records, you’ll stay organized and avoid missing critical maintenance tasks.

Proper Storage of Mini Excavators

Protecting from harsh weather

Storing your excavator properly protects it from harsh weather and extends its life. Before storage, clean the machine to remove dirt and debris. Use hydraulic fluids suitable for cold temperatures and depressurize the hydraulic system.

Inspect the battery for damage and clean the terminals. Check the tires or tracks for wear and adjust tension if needed. Block openings to prevent rodents from nesting inside.

Long-term storage tips

For long-term storage, follow these steps:

Conduct a final inspection to address any exposed areas.

Cover the machine to shield it from rain and snow.

Start the engine occasionally to keep it in good condition.

Proper storage prevents unnecessary wear and ensures your excavator is ready to work when you need it.

Consistent maintenance is the secret to keeping your Nagano mini excavator parts in excellent condition. It reduces downtime, prevents costly repairs, and ensures your machine performs at its best. Preventive maintenance offers several benefits: it enhances reliability, lowers the risk of breakdowns, and extends your mini excavator’s lifespan.

When it’s time to replace parts, YNF Machinery has you covered. From durable excavator engine parts to reliable hydraulic cylinder seal kits and couplings, they provide everything you need to keep your excavator running smoothly. Start adopting preventive maintenance today and see the difference it makes for your equipment’s performance and longevity.

FAQ

How often should you inspect your Nagano mini excavator?

You should inspect your excavator daily before starting work. Check fluid levels, hoses, tracks, and other critical components. Weekly inspections can focus on deeper cleaning and maintenance tasks like air filter cleaning or greasing.

What’s the best way to store your excavator during winter?

Clean the machine thoroughly and cover it to protect it from snow and rain. Use cold-weather hydraulic fluids and block openings to keep rodents out. Start the engine occasionally to keep it in good condition.

How do you know when to replace hydraulic filters?

Look for signs like reduced power, overheating, or hydraulic fluid leaks. If you notice these issues or reach the recommended service hours in your manual, replace the filter immediately.

Can you use aftermarket parts for your Nagano mini excavator?

Yes, but make sure they meet or exceed OEM standards. YNF Machinery offers high-quality aftermarket parts that are durable and compatible with various excavator models.

Why is greasing pins and bushings so important?

Greasing reduces friction and prevents wear. Without it, parts can fail prematurely, leading to costly repairs. Stick to a daily greasing routine for the best results.

Pro Tip: Always keep spare filters, belts, and seal kits on hand to minimize downtime during repairs.