Excavator hydraulic pump parts play a vital role in powering your machine’s hydraulic system. These components convert mechanical energy into hydraulic energy, enabling critical functions like operating the boom and bucket. Understanding these parts helps you maintain your equipment effectively. It also allows you to troubleshoot issues quickly and avoid unnecessary downtime. Familiarity with the hydraulic pump diagram ensures smoother maintenance and enhances your excavator’s performance. By focusing on these essentials, you can keep your machine running efficiently and extend its lifespan.

Key Takeaways

Knowing excavator hydraulic pump parts helps you care for your machine and avoid expensive fixes.

Checking parts like the housing and seals often can stop problems and make your excavator last longer.

Using good replacement parts from reliable sellers keeps your hydraulic system working well and lowers repair needs.

Managing hydraulic fluid is important; check levels often and keep it clean to stop overheating and damage.

Understanding how hydraulic parts work together helps you fix problems fast and reduce delays.

Key Components of Excavator Hydraulic Pump Parts

Hydraulic Pump Housing

The hydraulic pump housing serves as the foundation for the entire pump assembly. It encloses and protects the internal hydraulic pump components, ensuring they operate efficiently. This housing is typically made from durable materials like cast iron or aluminum to withstand high pressures and harsh working conditions. Its design minimizes vibrations and prevents external contaminants from entering the system. A well-maintained housing ensures the excavator hydraulic pump operates smoothly, reducing the likelihood of breakdowns. Regular inspection of the housing can help you identify cracks or wear that might require immediate repair.

Pistons and Cylinder Block

The pistons and cylinder block are critical components of the excavator hydraulic pump. These parts work together to generate the high-pressure fluid flow needed for the excavator hydraulic system. The pistons move within the cylinder block, creating the pressure that drives the hydraulic fluid. The design of these components plays a significant role in the pump’s efficiency. By managing internal leakage and optimizing flow regulation, the pistons and cylinder block ensure reliable performance. Proper alignment and maintenance of these parts are essential to avoid hydraulic repair costs and maintain the excavator’s functionality.

Swash Plate

The swash plate is a key element in regulating the performance of hydraulic pumps. It adjusts the quantity of fluid pumped by altering its angle. This adjustment directly impacts the output of the excavator hydraulic pump.

A larger angle increases the stroke of the pistons, displacing more fluid and boosting output.

A smaller angle allows for precise flow control, which is ideal for tasks requiring accuracy.

Operators can modify the swash plate’s position to control the pressure and flow of hydraulic fluid, enhancing the excavator’s versatility.

Understanding how the swash plate functions can help you optimize the excavator hydraulic system for different applications. Regular checks ensure it remains in good condition, preventing performance issues.

Bearings and Seals

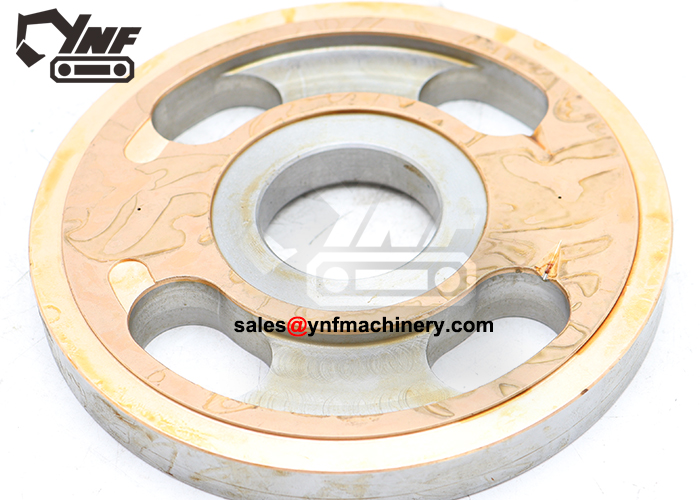

Bearings and seals play a crucial role in the performance of excavator hydraulic pump parts. Bearings support the hydraulic loads and maintain the alignment of moving components. This ensures smooth operation and reduces wear on the hydraulic pump components. Angular contact ball bearings are commonly used in hydraulic pumps. These bearings handle axial loads effectively and promote the longevity of mechanical seals. Often, they are arranged in pairs to manage reversing thrust loads, which enhances their durability in demanding conditions.

Seals, on the other hand, protect the bearings and other internal parts from contamination. Radial shaft seals are particularly effective in retaining lubricants while keeping out dirt and debris. This protection is vital for maintaining the efficiency of the hydraulic system. Without proper seals, contaminants can enter the system, leading to premature wear and costly hydraulic repair. Regular inspection of seals helps you identify potential issues early, ensuring the excavator hydraulic pump operates reliably.

By maintaining the bearings and seals in good condition, you can extend the lifespan of your excavator’s hydraulic pump components. This reduces downtime and minimizes the need for frequent repairs, keeping your hydraulic systems running smoothly.

Control Valves

Control valves are essential for regulating the flow and direction of hydraulic fluid in excavators. These valves ensure precise operation by maintaining system pressure and distributing fluid efficiently. This directly impacts the performance and reliability of the excavator hydraulic pump.

Control valves prevent leaks and pressure build-ups, which could otherwise lead to equipment failure.

They allow you to adjust the hydraulic fluid flow, enabling the excavator to perform various tasks with accuracy.

Properly functioning control valves enhance the overall efficiency of hydraulic systems, reducing energy loss and improving productivity.

Regular maintenance of control valves is critical. Faulty valves can disrupt the hydraulic pump’s performance, leading to reduced efficiency or even system failure. By ensuring these components are in top condition, you can optimize the performance of your excavator and avoid unnecessary hydraulic repair costs.

How Hydraulic Pump Components Work Together in an Excavator

Hydraulic Fluid Flow and Pressure Generation

The excavator hydraulic system relies on a seamless flow of fluid to generate pressure and power its components. This process begins when the hydraulic pump draws fluid from the reservoir. The pump pressurizes the fluid, increasing its energy potential. The pressurized fluid then travels through hydraulic hoses to control valves, which regulate its flow to the hydraulic cylinders or motors. These components convert hydraulic energy back into mechanical energy, enabling the movement of the excavator’s boom, arm, and bucket. Finally, the fluid returns to the reservoir, completing the cycle.

This continuous flow of fluid ensures the excavator hydraulic pump operates efficiently. Regular maintenance of the pump and hoses prevents leaks and ensures consistent pressure. By understanding this process, you can identify potential issues early and avoid costly hydraulic repair.

Role of Hydraulic Pumps in Power Transmission

Hydraulic pumps play a vital role in transmitting power within an excavator. The pump shaft connects directly to the engine, allowing the engine to drive the pump. As the engine rotates the pump shaft, impeller blades move the hydraulic fluid through the system. This process generates the force needed to operate the excavator’s components.

The pressurized fluid flows through control valves, which direct it to specific parts of the excavator. These valves regulate movement, ensuring precise operation. Without properly functioning hydraulic pumps, the excavator would lose its ability to perform essential tasks. Regular inspection of the pump shaft and impeller blades can help maintain system efficiency and prevent downtime.

Integration with Excavator Engine and Hydraulic Cylinder Seal Kits

Integrating hydraulic pumps with the excavator engine and hydraulic cylinder seal kits requires careful attention. Proper power transmission between the engine and pump ensures the system operates smoothly. The hydraulic cylinder seal kits play a crucial role in preventing leaks and maintaining pressure. Degraded seals can lead to fluid loss, reducing the efficiency of the excavator hydraulic system.

Wear and tear on components like the pump shaft and seals can also impact performance. Regular inspection and timely replacement of these parts help maintain the excavator’s functionality. Using high-quality seal kits and hydraulic pump components from trusted suppliers like YNF Machinery ensures durability and reliability.

Common Issues with Excavator Hydraulic Pump Parts

Wear and Tear on Hydraulic Pump Components

Wear and tear is a common issue that affects the performance of excavator hydraulic pump parts. Over time, various factors contribute to the degradation of hydraulic pump components. These include:

Fatigue Wear: Cracking and material loss occur in heavily lubricated parts like bearings and gears.

Cavitation Wear: Collapsing air or oil vapor bubbles erode metal surfaces, leading to damage.

Erosive Wear: Hard particles in hydraulic fluid erode surfaces at high speeds.

Corrosive Wear: Chemical reactions, such as rust or acid formation, damage components.

Abrasive Wear: Hard particles scratch and wear down surfaces.

Adhesive Wear: Materials stick together and separate, causing material loss.

Regular inspection and maintenance can help you identify these issues early. Replacing worn parts promptly ensures the excavator hydraulic pump operates efficiently and avoids costly hydraulic repair.

Overheating and Its Impact on Hydraulic Pumps

Overheating poses a significant risk to hydraulic pumps. Excessive heat increases friction, which accelerates wear and reduces the lifespan of hydraulic pump components. Overheating can also lead to pump failure, which may damage the entire hydraulic system. Debris from a failed pump can contaminate the oil, filters, valves, and actuators, causing widespread issues.

To prevent overheating, monitor the hydraulic system’s temperature and ensure proper cooling mechanisms are in place. Regularly check for signs of excessive heat, such as discoloration or unusual noises. Addressing overheating promptly protects your excavator and maintains its performance.

Contamination in the Hydraulic System

Contamination is another common issue that impacts the efficiency of excavator hydraulic pump parts. Contaminants such as metal particles, silica, rust, and fibers can enter the hydraulic system through various sources:

Hydraulic fluid contamination during production.

Improperly sealed containers or contamination during storage.

These contaminants increase wear, erode surfaces, and may cause catastrophic failures. For example, metal particles can scuff moving parts, especially when hydraulic oil viscosity is too low. To minimize contamination, use clean hydraulic fluid, store it properly, and replace filters regularly. Keeping the system clean ensures the excavator hydraulic pump operates smoothly and reduces the need for frequent repairs.

Maintenance Tips for Excavator Hydraulic Pump Parts

Regular Inspection and Cleaning of Hydraulic Pump Components

Regular inspection and cleaning of your excavator hydraulic pump components are essential for maintaining optimal performance. Follow these steps to ensure thorough maintenance:

Shut down the system and relieve pressure to ensure safety.

Disassemble the pump carefully and inspect each component for wear or damage.

Check for leaks around seals and connections.

Clean all internal parts using a suitable solvent to remove debris and contaminants.

Replace damaged parts with high-quality replacements to avoid further issues.

Change filters according to the manufacturer’s schedule to maintain fluid cleanliness.

Inspect the reservoir for signs of contamination or damage.

By performing these tasks regularly, you can prevent costly hydraulic repair and extend the lifespan of your excavator hydraulic pump.

Using High-Quality Replacement Parts from YNF Machinery

Using high-quality replacement parts ensures your excavator hydraulic pump operates efficiently under demanding conditions. These parts offer several advantages:

They maintain the strength and load capacity of your hydraulic systems.

Their durability reduces the need for frequent repairs, saving you time and money.

Reliable components enhance safety by minimizing the risk of sudden failures.

Although they may cost more initially, they prove cost-effective in the long run by reducing downtime and maintenance expenses.

YNF Machinery provides premium replacement parts designed to meet or exceed industry standards. Investing in these parts ensures your excavator hydraulic pump remains reliable and efficient.

Proper Hydraulic Fluid Management for Excavators

Proper hydraulic fluid management is crucial for the smooth operation of your excavator. Follow these best practices:

Regularly check fluid levels in the reservoir to prevent insufficient lubrication and cooling.

Ensure the fluid remains clean and free from contaminants to avoid wear on internal components.

Monitor the operating temperature of the fluid to prevent overheating and seal failure.

Effective fluid management reduces wear on hydraulic pumps and other components, ensuring your excavator performs at its best. Incorporating preventive maintenance practices like these helps you avoid unnecessary repairs and prolongs the life of your equipment.

Excavator hydraulic pump parts play a vital role in ensuring your machine operates efficiently. Proper maintenance and high-quality components reduce the risk of costly repairs caused by issues like low fluid levels, clogged filters, or leaking seals. Understanding the roles of these components helps you detect potential problems early, preventing downtime and extending the lifespan of your excavator.

YNF Machinery offers reliable solutions to support your equipment. Their products, such as Hydraulic Cylinder Seal Kits, excavator couplings, Excavator Engine Parts, and excavator engine assemblies, ensure durability and optimal performance. By choosing trusted components and maintaining your excavator regularly, you can enhance its reliability and avoid unnecessary expenses.

Tip: Regular inspections and timely replacements are key to keeping your excavator in top condition.

FAQ

1. How often should you inspect hydraulic pump components?

You should inspect hydraulic pump components every 250–500 operating hours. Regular checks help identify wear, leaks, or contamination early. This prevents costly repairs and ensures smooth operation.

2. What are the signs of a failing hydraulic pump?

Common signs include unusual noises, reduced performance, overheating, and fluid leaks. If you notice these, inspect the pump immediately to avoid further damage.

3. Can contaminated hydraulic fluid damage the pump?

Yes, contaminated fluid can cause wear, clog filters, and reduce efficiency. Always use clean hydraulic fluid and replace filters regularly to protect the pump.

4. Why is proper hydraulic fluid management important?

Proper fluid management ensures lubrication, cooling, and efficient power transmission. Neglecting fluid levels or quality can lead to overheating, seal failure, and pump damage.

5. Where can you find high-quality replacement parts?

You can find premium hydraulic pump components at YNF Machinery. Their parts meet industry standards, ensuring durability and reliable performance for your excavator.

Tip: Always follow the manufacturer’s maintenance schedule to keep your hydraulic system in top condition.