Understanding excavator engine parts is essential for keeping your excavation equipment in top condition. Each component, from the pistons to the fuel system, plays a vital role in ensuring smooth operation. Proper maintenance reduces downtime and improves performance, saving you time and money. For example, monitoring the mean time to repair (MTTR) can help you address issues quickly and efficiently. With over 35 years of expertise, YNF Machinery provides high-quality parts, including diesel engine components, to support your maintenance needs. Their reliable products ensure your excavator operates at peak efficiency, even in demanding conditions.

Key Takeaways

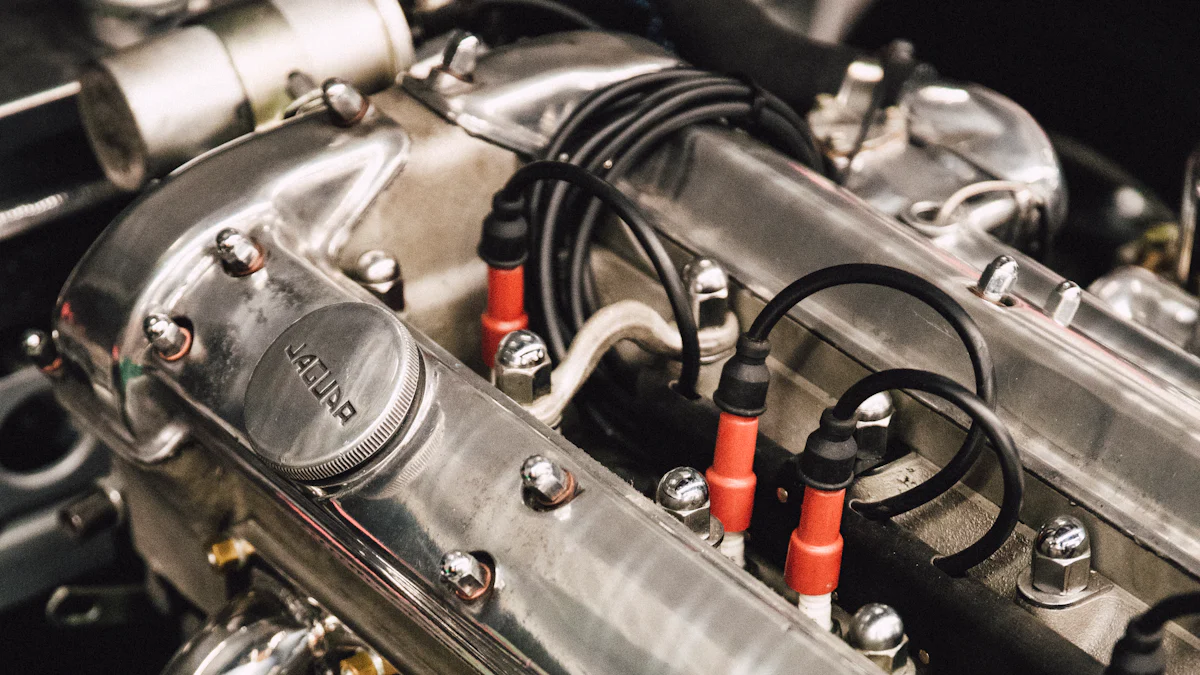

Understanding the main components of an excavator engine, such as pistons, cylinders, crankshaft, and camshaft, is crucial for optimal performance and maintenance.

Regular maintenance, including oil changes and inspections, helps prevent wear and tear on engine parts, reducing downtime and repair costs.

Using high-quality replacement parts from trusted suppliers like YNF Machinery ensures reliability and efficiency in your excavator’s operation.

Monitoring engine performance and addressing issues early can prevent costly repairs and extend the lifespan of your excavator.

Maintaining the cooling, electrical, and fuel systems is essential for the overall efficiency of the engine, preventing overheating and ensuring smooth operation.

Proactive care of injectors and the fuel pump, including using clean fuel and regular cleaning, enhances combustion efficiency and engine power.

Investing in durable components and following maintenance tips can significantly improve your excavator’s performance during demanding tasks.

The Main Parts of an Excavator Engine: Pistons and Cylinders

Functions of Pistons and Cylinders

Pistons and cylinders are among the main parts of an excavator engine. These components work together to drive the combustion process, which powers your excavation equipment. The piston moves up and down within the cylinder, compressing air and fuel to create the energy needed for operation. This process is essential for generating the force required for tasks like digging and lifting.

The pistons and cylinders also play a critical role in converting the energy from combustion into mechanical motion. This motion powers the hydraulic system, enabling the excavator to perform various functions. Without these heavy equipment engine components, the engine would fail to deliver the performance needed for demanding excavation tasks.

Common Issues with Pistons and Cylinders

Over time, pistons and cylinders can experience wear and tear, which affects their efficiency. One common issue is reduced compression, which can lead to a noticeable drop in engine power. You might also notice increased fuel consumption or difficulty starting the engine. These signs often indicate that the pistons or cylinders are no longer functioning optimally.

Damage to these components can occur due to overheating or poor lubrication. Overheating causes the metal to expand, leading to friction and potential damage. Insufficient lubrication increases wear on the moving parts, reducing their lifespan. Regular monitoring can help you identify these issues early and prevent costly repairs.

Maintenance Tips for Pistons and Cylinders

Proper maintenance ensures that pistons and cylinders remain in good condition. Start by performing regular oil changes to keep the engine well-lubricated. Clean oil reduces friction and prevents overheating, extending the life of these critical components. Monitoring engine performance also helps you detect problems before they escalate.

When replacing worn-out parts, choose high-quality options like those offered by YNF Machinery. Their products, such as the Original New engine C18 machinery engine assembly, meet rigorous quality standards. Using reliable components ensures your excavator operates efficiently, even under challenging conditions. Investing in durable parts minimizes downtime and enhances the overall performance of your excavation equipment.

“A well-maintained engine is the heart of efficient excavation operations.” By following these tips, you can keep your excavator running smoothly and avoid unnecessary disruptions.

Important Parts of Excavators: Crankshaft and Camshaft

Functions of the Crankshaft and Camshaft

The crankshaft and camshaft are two of the most important parts of excavators, ensuring the engine operates efficiently. The crankshaft plays a pivotal role by converting the linear motion of the pistons into rotational energy. This rotational energy powers the excavator’s drivetrain, enabling tasks like digging and lifting. Without the crankshaft, the engine would fail to transfer power to the machine’s hydraulic system, which is essential for excavation operations.

The camshaft, on the other hand, controls the timing of the intake and exhaust valves. It ensures that the valves open and close at precise intervals during the combustion cycle. This synchronization allows the engine to maintain optimal performance. By regulating airflow and exhaust, the camshaft directly impacts the engine’s efficiency and power output. Together, these components form the backbone of the engine’s functionality.

“The crankshaft and camshaft work in harmony to transform fuel into mechanical energy, powering your excavator through demanding tasks.”

Common Issues with Crankshaft and Camshaft

Crankshafts and camshafts can encounter several problems over time. Misalignment is a common issue with the crankshaft. This can lead to vibrations, reduced engine efficiency, and even damage to other heavy equipment engine components. Wear and tear on the crankshaft may also result in cracks or fractures, especially under extreme working conditions.

For the camshaft, wear on the lobes is a frequent problem. This wear can disrupt valve timing, causing poor engine performance. Debris within the engine or inadequate lubrication often accelerates this damage. Poor lubrication increases friction, which can lead to overheating and faster degradation of these critical parts.

Recognizing the symptoms of these issues is crucial. Vibrations, unusual noises, or a drop in engine power often indicate crankshaft problems. For camshaft issues, you might notice irregular engine performance or difficulty starting the excavator. Addressing these signs early can prevent costly repairs and downtime.

Maintenance Tips for Crankshaft and Camshaft

Regular maintenance keeps the crankshaft and camshaft in excellent condition. Start by inspecting these components frequently. Look for signs of wear, misalignment, or damage. Early detection helps you address minor issues before they escalate.

Proper lubrication is essential for both components. Use high-quality oil to reduce friction and prevent overheating. Clean oil ensures smooth operation and extends the lifespan of the crankshaft and camshaft. Additionally, keep the engine free of debris to avoid unnecessary wear.

When replacing damaged components, choose reliable options from trusted suppliers like YNF Machinery. Their high-quality products meet rigorous standards, ensuring durability and compatibility with various types of excavators. Investing in dependable replacements minimizes downtime and enhances the overall performance of your excavation equipment.

“Routine inspections and quality replacements are key to maintaining the efficiency of your excavator’s engine.”

By following these maintenance tips, you can ensure the crankshaft and camshaft continue to support your excavator’s demanding tasks. Proper care not only extends the life of these components but also improves the overall efficiency of your machine.

The Electrical System in Excavators: Alternator and Starter Motor

Functions of the Alternator and Starter Motor

The alternator and starter motor are essential components of an excavator’s electrical system. Each plays a unique role in ensuring the engine operates efficiently.

The alternator’s role in powering electrical systems

The alternator generates electricity to power the excavator’s electrical systems. When the engine runs, it drives a belt connected to the alternator’s rotor. This motion converts alternating current (AC) into an electrical charge. The alternator supplies power to critical systems, such as the ignition and fuel injection systems, while simultaneously charging the battery. Without a functioning alternator, the excavator would lose power, affecting its ability to perform tasks like digging or operating the hydraulic system.

“The alternator works in sync with the engine to produce electricity required by other key systems,” explains a Technician at Gregory Poole, emphasizing its importance in maintaining operational efficiency.

The starter motor’s function in engine ignition

The starter motor initiates the engine’s operation. When you turn the ignition key, the starter motor uses power from the battery to crank the engine. This action sets the engine’s moving parts in motion, enabling the combustion process to begin. The starter motor ensures that the excavator is ready for tasks like excavation or lifting heavy loads.

According to a Technician at Chapel Hill Tire, “The starter uses an initial burst of power from the battery to fire up your motor, kickstarting all of your vehicle’s functioning parts.”

Common Issues with Alternator and Starter Motor

Understanding common problems with these components can help you address them before they lead to downtime.

Signs of failure, such as dim lights or starting issues

Dim lights, flickering electrical systems, or difficulty starting the engine often indicate issues with the alternator or starter motor. A failing alternator may not generate enough power to sustain the electrical systems, while a faulty starter motor can prevent the engine from cranking.

Causes of damage, including electrical faults

Electrical faults, such as short circuits or loose connections, can damage the alternator and starter motor. Over time, wear and tear also take a toll on these components. For example, a worn-out alternator belt may slip, reducing its efficiency. Similarly, prolonged use of the starter motor without proper maintenance can lead to overheating or internal damage.

Maintenance Tips for Alternator and Starter Motor

Regular maintenance ensures the longevity and efficiency of these critical components.

Cleaning electrical connections and testing the battery

Inspect and clean the electrical connections regularly. Corrosion or dirt on the terminals can disrupt the flow of electricity, leading to performance issues. Testing the battery ensures it provides adequate power to the starter motor and alternator. A weak battery can strain these components, reducing their lifespan.

Replacing faulty components with YNF Machinery parts

When replacement becomes necessary, choose high-quality parts from trusted suppliers like YNF Machinery. Their products meet rigorous standards, ensuring compatibility with various types of excavators. Reliable replacements minimize downtime and enhance the overall performance of your machine.

“Routine maintenance and quality replacements are key to keeping your excavator’s electrical system in top condition.”

By following these tips, you can maintain the alternator and starter motor effectively. Proper care not only extends their lifespan but also ensures your excavator remains ready for demanding excavation tasks.

The Cooling System: Radiator and Water Pump

Functions of the Radiator and Water Pump

The radiator’s role in heat dissipation

The radiator plays a vital role in maintaining your excavator’s engine temperature. As the engine operates, it generates significant heat, especially during demanding tasks like digging or lifting. The radiator dissipates this heat by transferring it from the coolant to the surrounding air. This process prevents the engine from overheating, ensuring smooth and efficient operation. Without a functioning radiator, the engine’s performance would decline, leading to potential damage and costly repairs.

The radiator’s design includes a network of thin tubes and fins. These components maximize the surface area for heat exchange, allowing the coolant to cool down effectively. By keeping the engine at an optimal temperature, the radiator supports the longevity and reliability of your excavator.

The water pump’s function in circulating coolant

The water pump works hand-in-hand with the radiator to regulate the engine’s temperature. It circulates coolant through the engine block, absorbing heat generated during combustion. The heated coolant then flows to the radiator, where the heat dissipates into the air. This continuous cycle ensures that the engine remains within its ideal operating temperature range.

The water pump’s efficiency directly impacts the cooling system’s performance. A well-functioning pump ensures consistent coolant flow, preventing hotspots within the engine. This consistency is crucial for maintaining the performance of heavy equipment engine components, including the hydraulic system, which relies on stable engine temperatures for optimal functionality.

Common Issues with Radiator and Water Pump

Signs of overheating or leaks

Overheating is one of the most common issues you may encounter with the cooling system. Signs include a rising temperature gauge, steam from the engine compartment, or a noticeable drop in performance. Leaks are another frequent problem. You might notice puddles of coolant under the excavator or a low coolant level in the reservoir. Addressing these signs promptly can prevent further damage to the engine.

Causes of failure, such as blockages or worn seals

Blockages within the radiator or coolant passages can restrict the flow of coolant, leading to overheating. Dirt, debris, or rust often cause these blockages, especially in excavators operating in harsh environments. Worn seals in the water pump can also result in coolant leaks, reducing the system’s efficiency. Regular inspections help you identify these issues early, ensuring the cooling system continues to protect your engine.

Maintenance Tips for Radiator and Water Pump

Flushing the cooling system and inspecting hoses

Flushing the cooling system removes debris, rust, and old coolant that can clog the radiator or damage the water pump. Perform this maintenance task periodically to keep the system clean and efficient. Inspect the hoses for cracks, leaks, or signs of wear. Damaged hoses can disrupt coolant flow, leading to overheating. Replacing worn hoses ensures the cooling system operates smoothly.

Using durable parts from YNF Machinery

When replacing components, choose durable and high-quality parts from trusted suppliers like YNF Machinery. Their products meet rigorous standards, ensuring compatibility with various types of excavators. Reliable parts enhance the cooling system’s performance, reducing downtime and extending the life of your machine. Investing in quality replacements minimizes the risk of future failures, keeping your excavation projects on track.

“A well-maintained cooling system safeguards your excavator’s engine, ensuring reliable performance even in demanding conditions.”

By following these maintenance tips, you can protect your excavator from overheating and extend the lifespan of its critical components. Proper care of the radiator and water pump not only improves efficiency but also reduces the likelihood of costly repairs.

The Fuel System: Injectors and Fuel Pump

Functions of Injectors and the Fuel Pump

How injectors deliver fuel for combustion

Injectors play a crucial role in your excavator’s engine by delivering fuel directly into the combustion chamber. They spray the fuel in a fine mist, ensuring it mixes evenly with air for efficient combustion. This process generates the energy needed to power your excavator during tasks like digging or lifting. Without properly functioning injectors, the engine cannot achieve optimal performance, leading to reduced efficiency and power output.

The fuel pump’s role in maintaining pressure

The fuel pump ensures a steady supply of fuel reaches the injectors at the correct pressure. It draws fuel from the tank and delivers it to the engine, maintaining consistent pressure throughout the system. This pressure is vital for the injectors to function effectively. A reliable fuel pump supports smooth engine operation, enabling your excavator to handle demanding excavation tasks without interruptions.

“The fuel system, powered by the injectors and fuel pump, acts as the lifeline of your excavator’s engine, ensuring consistent performance during heavy-duty operations.”

Common Issues with Injectors and Fuel Pump

Symptoms of clogs or low fuel pressure

Clogged injectors or a failing fuel pump can cause noticeable problems in your excavator. You might experience difficulty starting the engine, uneven idling, or a sudden drop in power during operation. Low fuel pressure often results in poor combustion, leading to increased fuel consumption and reduced efficiency. Recognizing these symptoms early helps you address issues before they escalate.

Causes of damage, such as contaminated fuel

Contaminated fuel is one of the primary causes of damage to the injectors and fuel pump. Dirt, water, or debris in the fuel can clog the injectors, disrupting the spray pattern and reducing combustion efficiency. For the fuel pump, contaminants can cause internal wear, leading to reduced pressure or complete failure. Regularly inspecting and maintaining the fuel system minimizes the risk of damage caused by poor fuel quality.

Maintenance Tips for Injectors and Fuel Pump

Using high-quality fuel and cleaning injectors

Always use high-quality fuel to protect your excavator’s fuel system. Clean fuel reduces the risk of clogs and ensures smooth operation. Periodically clean the injectors to remove any buildup that may affect their performance. Cleaning restores the spray pattern, improving combustion efficiency and engine power. This simple step keeps your excavator running efficiently during excavation tasks.

Replacing worn components with YNF Machinery products

When components like injectors or the fuel pump show signs of wear, replace them promptly. Choose reliable parts from trusted suppliers like YNF Machinery. Their products meet high-quality standards, ensuring compatibility with various types of excavators. Durable replacements minimize downtime and enhance the overall performance of your engine. Investing in quality parts ensures your excavator remains ready for heavy-duty operations.

“Proactive maintenance of the fuel system not only extends the life of your excavator’s engine but also ensures consistent performance during demanding tasks.”

By following these maintenance tips, you can keep the injectors and fuel pump in excellent condition. Proper care of these components ensures your excavator operates efficiently, reducing the likelihood of costly repairs and downtime.

How the Main Components of an Excavator Engine Work Together

Understanding how the main components of an excavator engine collaborate is essential for maintaining its efficiency. Each part plays a specific role, but their combined operation ensures the machine performs demanding tasks like excavation and digging seamlessly.

The Combustion Process

How pistons, cylinders, and the crankshaft collaborate

The combustion process begins with the pistons and cylinders. Pistons compress the air-fuel mixture inside the cylinders, creating the conditions necessary for combustion. This reaction generates energy, which drives the pistons downward. The crankshaft then converts this linear motion into rotational energy. This rotational energy powers the excavator’s hydraulic system, enabling it to perform tasks like lifting and digging.

The collaboration between these components ensures the engine delivers consistent power. Without this synchronization, the excavator would struggle to operate efficiently. Regular maintenance of the pistons, cylinders, and crankshaft is crucial to prevent wear and ensure smooth operation. By keeping these parts in optimal condition, you can maximize the performance of your machine during excavation tasks.

“The engine acts as the heart of the excavator, with its main components working together to generate the power needed for all operations.”

Supporting Systems

The role of cooling, electrical, and fuel systems in engine efficiency

The engine relies on supporting systems to maintain its performance. The cooling system, which includes the radiator and water pump, prevents overheating by regulating the engine’s temperature. This system ensures the engine operates within its ideal range, even during prolonged excavation tasks.

The electrical system, powered by the alternator and starter motor, supports the engine’s ignition and other critical functions. The alternator generates electricity to power the excavator’s systems, while the starter motor initiates the engine’s operation. Without these components, the engine would fail to start or sustain its performance.

The fuel system, consisting of injectors and the fuel pump, ensures the engine receives a steady supply of fuel at the correct pressure. This system plays a vital role in the combustion process, delivering the energy needed for the excavator to perform heavy-duty tasks. Contaminated fuel or clogged injectors can disrupt this process, reducing the engine’s efficiency.

Together, these supporting systems enhance the engine’s reliability and efficiency. Regular inspections and maintenance of these systems help prevent breakdowns and extend the life of your excavator. By understanding their roles, you can ensure your machine remains ready for any excavation challenge.

“The engine’s supporting systems work in harmony to maintain efficiency, ensuring the excavator performs reliably under demanding conditions.”

Regular maintenance of excavator engine parts is essential for keeping your machine in peak condition. By understanding how each engine component functions, you can identify potential issues early and avoid costly repairs. Proactive care ensures your excavator performs efficiently during demanding excavation tasks. Reliable parts, like those from YNF Machinery, provide the durability and quality needed to support your maintenance efforts. Investing in high-quality components not only extends the lifespan of your engine but also minimizes downtime, maximizing productivity on every project.