You need the right excavator undercarriage parts to keep your machine working well. The correct undercarriage gives your excavator strength and helps you avoid expensive repairs. When you match the parts to your excavator, you make it work better and faster. Strong parts last longer and mean less time fixing your machine. If you pick undercarriage parts that fit your job, your excavator works its best every day.

Key Takeaways

-

Pick undercarriage parts that fit your excavator’s size and weight. Make sure the parts match your machine’s model. This helps keep your machine safe and working longer.

-

Pick tracks and track shoes that work with your job site’s ground. Think about how hard your machine will work. This helps your machine work better and last longer.

-

Use good parts from brands people trust. This makes your machine stronger and helps it grip better. It also saves money on repairs later.

-

Clean and check your undercarriage every day. This helps you find problems early. It keeps your machine working well.

-

Ask a professional for help if you need it. This stops big mistakes and helps your excavator work its best.

Machine Requirements

Size & Weight

First, check your excavator’s size and weight. Every machine is built differently. The undercarriage parts must fit these details. If you use the wrong parts, your equipment can get damaged. Heavy excavators need strong and tough undercarriage parts. Lighter machines can use smaller and lighter parts. When you match the size and weight, your excavator works safely and lasts longer.

Tip: The wrong size can make the chain jump or the track move off. It can also cause uneven wear. These problems mean more repairs and less time working.

Model Compatibility

Each excavator model has its own needs. You should check your machine’s make and model before buying new undercarriage parts. Parts are made to fit certain models, so even small changes matter. If you use the wrong parts, your machine might shake, not line up, or even break down. Always pick parts that fit your model to keep your excavator working well.

-

Match parts to your excavator’s make, model, and size.

-

Pick parts made for your machine’s work area.

-

Make sure track adjusters and tensioning systems fit your model.

Manufacturer Specs

Manufacturers give you special instructions for each excavator. You should follow these to help your machine work its best. Look for parts made from strong materials like forged or cast steel. Sealed bearings and oil-filled seals keep dirt and water out. Good brands like Caterpillar, Komatsu, and Volvo give you warranties and help if you need it. These things protect your machine and help you work more.

|

Manufacturer Spec |

Why It Matters |

|---|---|

|

Material Quality |

Makes parts last longer |

|

Sealed Bearings |

Stops dirt and water |

|

Proper Fit |

Lowers wear and breakdowns |

|

Warranty |

Gives help and coverage |

If you follow the manufacturer’s rules, you avoid big mistakes and keep your excavator undercarriage parts working well.

Terrain & Workload

Excavator Tracks for Ground Types

You need to pick tracks that match the ground at your job site. Different ground types can make undercarriage parts wear out faster. Hard sand or gravel can quickly wear down bushings, track shoes, chains, and rollers. Mud or wet ground can get stuck between parts. This causes more rubbing and makes parts wear out faster. Rocky ground can move your excavator’s weight around. This makes some undercarriage parts wear out quicker than others.

Here is a simple guide to help you pick the right tracks for your ground:

|

Track Type |

Recommended Ground Conditions |

Best For |

Pros |

Cons |

|---|---|---|---|---|

|

Rubber Tracks |

Soft ground, urban environments |

Landscaping, residential projects |

Gentle on surfaces, good maneuverability |

Less stable on rough terrain |

|

Steel Tracks |

Rugged, rocky, uneven terrain |

Mining, demolition, heavy-duty tasks |

Durable, stable, high traction |

Can damage soft surfaces, less maneuverable in tight spaces |

You can choose from different tread patterns for your tracks. C-pattern treads work well in dirt and mud. Multi-bar lug treads help on wet and flat hard ground. Zig zag treads are good for muddy slopes and clay. H-pattern treads lower shaking and work on rock, concrete, and mud. Hex pattern treads are best for turf and gravel but not for very wet ground. Non-marking tracks are good for concrete and driveways.

Tip: Always look for signs of wear after working on tough ground. Mud or sand can hide damage to your track chains and track shoes.

Work Intensity

How hard you use your excavator changes how fast parts wear out. Heavy jobs, like digging in rocky ground, put more stress on tracks, chains, and track shoes. Light work on soft ground wears parts out slower. If you use your machine for tough jobs every day, you need heavy duty tracks or heavy duty xl tracks. These have stronger links and special pin-locking designs for hard work.

|

Track Category |

Recommended Usage and Terrain |

Key Features |

|---|---|---|

|

General Duty |

Low to moderate impact jobs |

Cost-effective, suitable for lighter workloads |

|

Heavy Duty |

Tough jobs, demanding ground conditions |

Built for heavy construction and demolition |

|

Heavy Duty XL |

Extreme applications, rough terrain, frequent travel |

Stronger links, special pin-locking design |

You should always check your undercarriage for wear, especially after hard work. Look at your track chains, track shoes, and rollers. Clean out dirt and rocks to keep your tracks working well.

Track Shoe Selection

Picking the right track shoes helps your machine work better and last longer. On soft ground, like mud or sand, use wider track shoes. These help your excavator float and lower ground pressure. On hard or rough ground, narrow track shoes give better grip and dig into the soil. More grousers on your track shoes help with grip and lower shaking. This can make your tracks last longer.

|

Aspect |

Soft Terrain Recommendations |

Abrasive/Hard Terrain Recommendations |

|---|---|---|

|

Shoe Width |

Use wider shoes for better flotation and lower ground pressure |

Use narrower shoes for better soil penetration and grip |

|

Grouser Number |

Fewer grousers may be sufficient depending on application |

More grousers recommended for better ground contact, reduced vibration, and longer track life |

|

Track Tension |

Slightly looser tension to prevent accelerated wear and de-tracking |

Proper tension critical; too tight or loose accelerates wear |

|

Track Type |

Rubber tracks recommended for smaller excavators on soft/sensitive surfaces due to buoyancy and minimal ground disturbance |

Steel tracks preferred for durability in abrasive conditions |

Note: If you use wide track shoes on hard ground, pins, bushings, and rollers can wear out faster. Always adjust your track tension for the ground. Loose tracks can slip off. Tight tracks can wear out chains and track shoes.

You should check your track shoes, track chains, and undercarriage after each job. Take out packed mud or gravel to stop extra wear. Follow your manufacturer’s maintenance plan to keep your excavator working well.

Quality & Brands

Excavator Undercarriage Parts Quality

You want your excavator to last and work hard. Using high-quality undercarriage parts helps a lot. Heavy-duty undercarriage parts are made from strong steel alloys. These parts can handle heavy loads and rough ground. They are tested to make sure they last longer and stay strong. Standard parts do not use the same strong materials. They also may not fit as well. This makes them wear out faster and can hurt your machine’s performance.

-

Heavy-duty undercarriage parts fit better and help your track and chains last longer.

-

Precision manufacturing lets your excavator move smoothly and keeps track chains in place.

-

You get more traction and better control, even on tough ground.

Tip: If you use your excavator every day or in tough places, pick heavy-duty undercarriage parts for the best results.

Trusted Brands

Picking a good brand for your undercarriage is important. The best brands check their parts carefully and give strong support. Here are some of the most trusted names:

-

Caterpillar (Cat): Known for tough undercarriage parts and a strong dealer network.

-

Komatsu: Makes long-lasting parts that fit many excavators.

-

John Deere: Offers reliable undercarriage products and great customer service.

These brands design their tracks, chains, and other parts for the best performance and traction. You can trust their parts to keep your excavator working well.

Warranty & Support

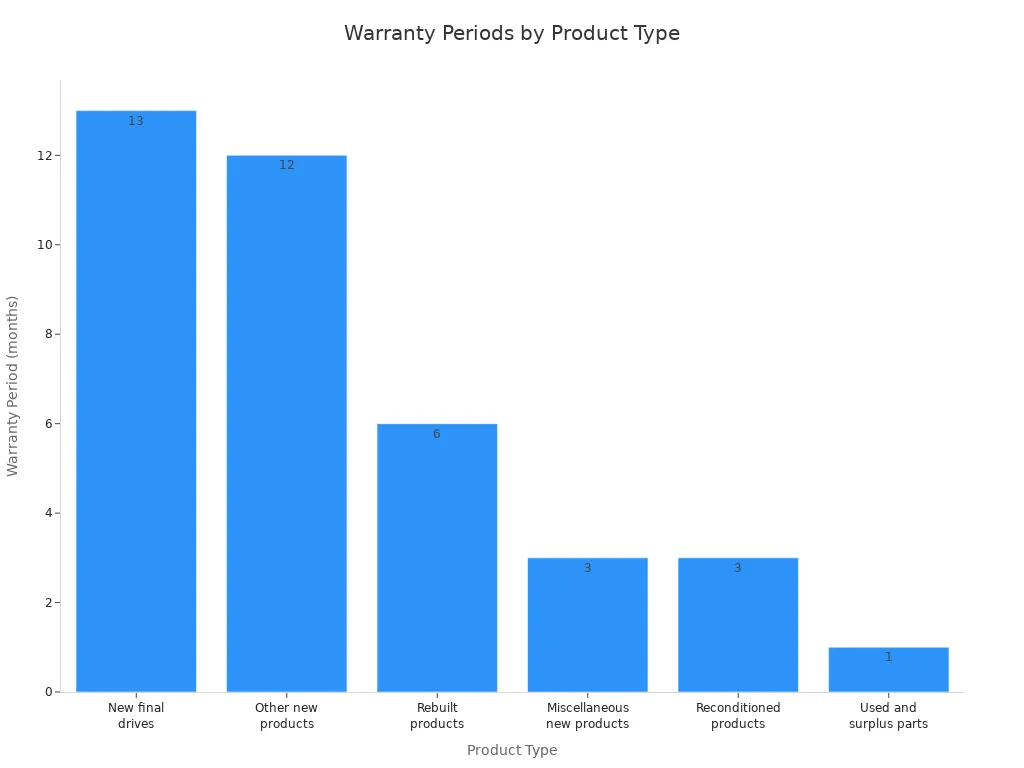

A good warranty and support help protect your money when you buy excavator undercarriage parts. Top brands give strong warranties and extra support plans. Most new parts have a 12-month warranty. Some final drives have 13 months. Rebuilt or used parts have shorter coverage.

|

Product Type |

Warranty Period |

|---|---|

|

New final drives |

13 months |

|

Other new products |

12 months |

|

Rebuilt products |

6 months |

|

Used and surplus parts |

30 days |

You also get help from dealer networks and fast parts delivery. Some brands have extra plans that pay for repairs, rental costs, and even transport. These services help you avoid downtime and save money.

Note: OEM parts usually have better warranties and last longer than aftermarket parts. Always check the warranty before you buy.

Maintenance & Service

Undercarriage Accessibility

Pick undercarriage parts that are easy to work on. Some undercarriage systems have open spaces. This lets you reach bolts, rollers, and track shoes fast. You do not need to take off other parts. This saves time and lowers repair bills. If you can clean and check your undercarriage quickly, you find problems early. Daily cleaning gets rid of dirt and rocks. These things can make parts wear out faster. Use a shovel or pressure washer to clean your undercarriage. This is very important after working in mud or gravel.

|

Maintenance Routine |

Description and Purpose |

|---|---|

|

Take off dirt, rocks, and plants after each shift. This stops debris from building up and wearing parts out early. |

|

|

Visual Inspection |

Look for worn track shoes, loose bolts, and broken parts. This helps you find problems before they get worse. |

|

Track Tension Checks |

Check and fix track sag (20-30mm is best). This stops early wear and keeps tracks from slipping off. |

Tip: If you can reach your undercarriage easily, you can do maintenance the right way and your machine will last longer.

Parts Availability

You must make sure you can always get replacement parts. If you cannot find the right parts fast, your excavator may not work. This wastes time and costs more money. Keep common undercarriage parts, like track shoes and rollers, in stock. This helps you avoid waiting for parts. Many dealers have these parts ready to ship fast. If you plan ahead and keep spare parts, you can fix problems right away and keep working.

-

Make a list of important undercarriage parts for your machine.

-

Order new track parts before you run out.

-

Work with suppliers who ship fast and offer local pickup.

Dealer Support

Good dealer support helps you take care of your undercarriage. Dealers give expert service and help you plan regular checks. They know which parts fit your machine and send them quickly. Many dealers, like Cat, have Customer Value Agreements. These plans give you real parts, expert help, and set times for maintenance. Dealers help you use the right fluids and filters. They check your undercarriage and help you follow a schedule. This means less downtime and your excavator stays in good shape.

Good dealer support means you get the right parts fast and repairs are quick. You wait less and save money. You also avoid big repairs by doing maintenance with your dealer’s help.

Upgrading Excavator Undercarriage Parts

Cost vs. Value

When you want to upgrade your excavator undercarriage parts, you may see that high-quality parts cost more than standard ones. The price for the best parts can look high at first, but it is important to think about what you get in the long run. High-quality undercarriage parts last longer and help your machine work better. You will spend less time fixing your excavator and more time using it.

-

High-quality parts help your excavator grip the ground and stay steady.

-

Strong parts mean you do not have to replace them as often.

-

Good undercarriage parts let your excavator work well even in hard places.

Remember: Spending more now can help you save money later because you will have fewer repairs and less downtime.

Long-Term Savings

You can save money over time if you pick the best undercarriage parts and take care of them. When you buy strong parts, your excavator breaks down less and you do not have to pay for big repairs as often. Cleaning and checking your undercarriage helps you find problems early. This stops small problems from getting worse.

-

Good parts help your excavator last longer.

-

Checking your machine often helps you find problems before they get bad.

-

Changing worn parts on time keeps your excavator safe and working well.

It is smart to think about how much you spend over time, not just the first price. You get more for your money when your excavator works longer and needs fewer fixes.

Professional Help

Sometimes you need an expert when you upgrade your excavator undercarriage parts. If you see uneven wear, broken track pins, or oil leaks, a professional can tell you what to change. Experts know which parts fit your machine and job site. They also check track tension and make sure everything is right.

Common times to call an expert are:

-

Your undercarriage breaks often or you see damage.

-

You work on rough ground and need special tracks.

-

You need help with checks or fixing your machine.

-

You need to adjust track tension or change chains and sprockets.

Tip: Getting help from a professional makes your machine safer and work better. You get more out of your money and avoid big mistakes.

Choosing the right excavator undercarriage parts helps you get the best from your machine. Follow these steps:

-

Check your terrain and workload to pick strong, suitable parts.

-

Match parts to your excavator’s size and weight.

-

Pick high-quality components from trusted brands.

-

Make sure parts fit well and are easy to maintain.

-

Inspect and service your undercarriage often.

-

Quality parts, regular maintenance, and smart investment choices keep your excavator running longer.

If you feel unsure, ask a dealer or expert for help. This ensures your machine stays reliable and efficient.

FAQ

What signs show that I need to replace my excavator undercarriage parts?

You might see the tracks wearing out unevenly. Sometimes bolts get loose or you hear odd sounds. If your machine shakes or slips, check the undercarriage. Waiting too long with worn parts can make things worse.

Can I mix different brands of undercarriage parts on my excavator?

It is best to use parts from the same brand or ones your maker says are okay. Mixing brands can make parts not fit right and wear out faster. Always make sure new parts work with your machine before you put them on.

How often should I inspect my excavator’s undercarriage?

Check your undercarriage every day before you start working. Look for dirt, loose bolts, or worn track shoes. Checking often helps you find problems early and keeps your machine working longer.

What is the best way to clean my excavator undercarriage?

-

Use a pressure washer or shovel to get rid of mud and rocks.

-

Clean after every job, especially if you work in wet or muddy places.

-

Keeping your undercarriage clean stops early wear and damage.