You want your excavator to work well and last long. The right excavator swing gear parts are very important. If you pick parts that fit your machine, you avoid problems. Trusted suppliers give you better parts. This helps you stop fitment issues and early failures. Good swing gear parts keep your excavator safe and steady. They help during hard jobs. Precision-engineered swing motor parts also help a lot. They lower downtime and save on maintenance costs. When you pick the right swing motor and excavator parts, your machine stays strong. You also avoid costly repairs.

Key Takeaways

Always pick swing gear parts that fit your excavator’s model and job needs. This helps stop damage and keeps your machine working.

Use high-quality parts, and try to get OEM for important pieces. This makes sure your parts last long and work well.

Check and take care of your swing motor and swing gear parts often. This helps you find problems early and keeps your machine running.

Choose suppliers who have good reviews and give strong warranties and technical help. This keeps your money safe.

Think about both cost and quality. Buying good parts saves money because you fix less and your excavator lasts longer.

Excavator Swing Gear Parts

Function and Importance

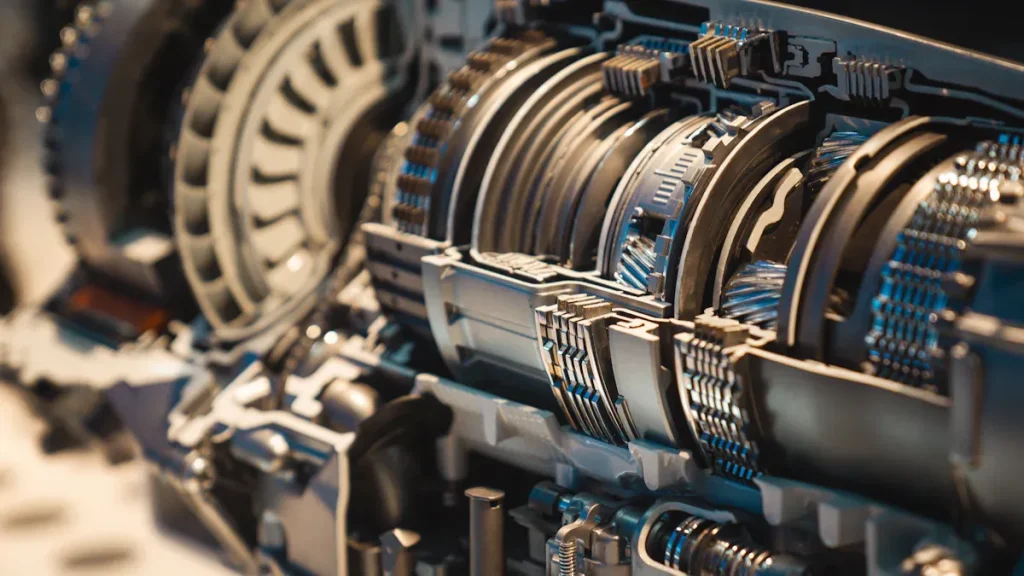

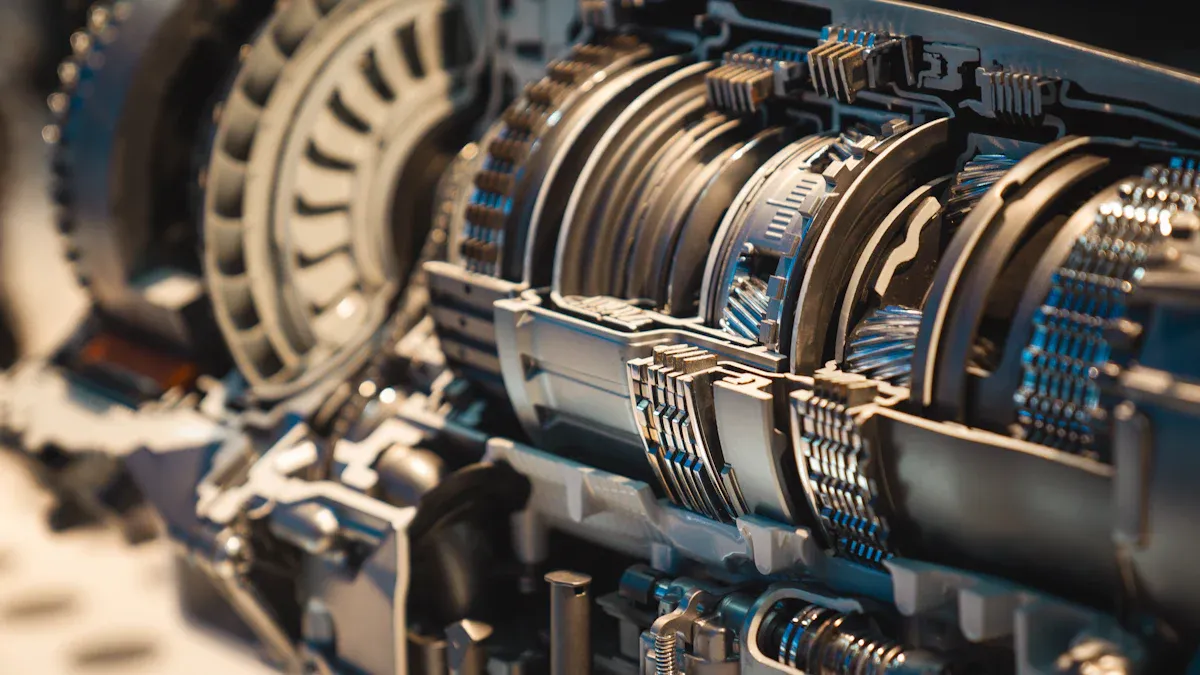

Excavator swing gear parts help your machine move and work safely. You find these parts in the upper structure of the excavator. The main parts include the slewing ring and the swing drive. The slewing ring sits between the upper and lower parts of the excavator. It lets the upper structure rotate a full 360 degrees. This rotation helps you dig, lift, and move materials without moving the whole machine.

The slewing ring uses inner and outer rings with rolling elements like balls or rollers. These parts move smoothly with little friction. The design spreads out heavy loads from digging or lifting. This keeps your excavator stable and safe. Some slewing rings have built-in gears. These gears let the swing motor turn the upper structure with power and control. The swing drive works with the swing motor to give you the right speed and torque for each job.

Tip: A strong slewing ring and swing drive keep your excavator steady, even when you handle heavy loads or work on rough ground.

You need the swing motor to power the rotation. The swing motor connects to the swing drive and slewing ring. It gives the force needed for smooth and fast movement. When all these excavator swing gear parts work together, your machine stays efficient and safe. You avoid sudden stops or jerky movements. This helps you finish jobs faster and keeps your excavator in good shape.

Compatibility Factors

You must verify compatibility before you buy new excavator swing gear parts. Each excavator model has its own needs. The swing motor, swing drive, and slewing ring must match your machine’s size and power. If you use the wrong parts, you risk damage and downtime.

Part numbers help you find the right match. Every swing motor, drive gear, and slewing ring has a unique part number. These numbers link to specific excavator models. For example, a swing motor for a Case Excavator 880 will not fit a CX130. When you verify compatibility using part numbers, you make sure the parts fit and work well.

Operational needs also matter. Your excavator may need parts that handle heavy loads or work in tough conditions. The swing motor must give enough torque for your jobs. The swing drive and slewing ring must support the weight and stress of daily use. Suppliers often help you choose parts that meet or beat the original equipment standards. They use catalogs and expert advice to guide you.

Note: Always check your machine’s manual and part numbers. Ask your supplier to verify compatibility with your excavator’s model and job needs.

A good supplier offers a wide range of excavator swing gear parts. They can find parts for many brands and models. This helps you keep your excavator running with less downtime. When you pick the right swing motor, swing drive, and slewing ring, you protect your investment and keep your machine working hard.

Quality and Durability

OEM vs Aftermarket

When you pick swing motor parts, you have two choices. You can buy OEM parts or aftermarket parts. OEM parts are made by the original company. They fit your machine well and meet high standards. Aftermarket parts are made by other companies. These parts usually cost less, but their quality is not always the same.

Here is a quick comparison to help you choose:

Factor | OEM Parts | Aftermarket Parts | Recommendation |

|---|---|---|---|

Cost | Higher price (40–80% more than aftermarket); lower long-term cost due to reliability | Lower initial cost; wide price range from budget to premium brands | Use aftermarket for budget-limited jobs; OEM for critical parts |

Consistent, manufacturer-approved; longer lifespan under heavy use | Quality varies; premium brands approach OEM quality; low-cost brands risky | Use OEM for hydraulics/engine; aftermarket for non-critical parts | |

Compatibility | Guaranteed fit with no modifications needed; ideal for electronics/sensors | May require adjustments; premium brands offer OEM-equivalent parts | Use OEM for precision components; aftermarket for older machines with discontinued OEM parts |

Lead Time | Longer delays depending on OEM stock; risk of supply chain disruptions | Faster shipping; widely stocked; good for urgent repairs | Use aftermarket for emergency fixes; OEM for scheduled maintenance |

Warranty | 1–2 years OEM warranty; required for new machine warranties | Varies by supplier; some offer limited warranty (e.g., Amoparts 6 months) | Warranty-sensitive buyers prefer OEM; out-of-warranty machines can use certified aftermarket |

OEM parts give you confidence. They last longer and fit just right. You do not have to worry about leaks or parts wearing out too soon. Aftermarket swing motor parts can save you money. But you should check the brand and read reviews first. Some cheap aftermarket parts break quickly and can hurt your excavator. If you use your machine for hard work or need it to be very reliable, OEM parts are best. For older machines or easy jobs, good aftermarket parts can help you save money and still work well.

Tip: Try to balance cost and quality. Use OEM parts for swing motor and swing motor parts in important systems. Pick trusted aftermarket brands for smaller repairs.

Material and Build

The material and build of swing motor parts matter a lot. Good parts use strong materials like treated steel or special metals. These materials fight rust and damage. When you choose swing motor parts made from tough materials, your excavator lasts longer.

Good parts last longer and break less often.

Strong materials like galvanized steel keep swing motor parts safe, even in wet or dirty places.

Well-made parts fit right and work smoothly.

Checking and cleaning your parts often helps you find problems early and keep your excavator running.

Even weight spread in swing gear parts is important too. When your swing motor and slewing ring share the load, your excavator moves better. This lowers friction and wear. Your machine uses less power and needs fewer repairs. You spend less time fixing things and more time working.

Note: Always pick swing motor parts with easy-to-reach lubrication points. This makes it easier to take care of your excavator and helps it last longer.

Heavy Load and Harsh Conditions

Excavators often work in rough places. You need swing motor parts that can handle heavy loads and bad weather. Good parts use strong designs and tough materials to stay safe.

Powder-coated galvanized steel stops rust and damage from rain or mud.

Thick frames and beams help your excavator stay steady when lifting heavy things.

Strong bolts and coated chains keep swing motor parts working, even after long use.

Good design spreads the weight, so no part wears out too fast.

When you use swing motor parts made for tough jobs, your excavator stays safe and works well. You avoid sudden breakdowns and big repair bills. Good anchoring and even weight spread also help your machine do big jobs without tipping or shaking.

Alert: If you work in bad weather or lift heavy things a lot, always pick swing motor parts made for those jobs. This keeps your excavator safe and protects your team.

It is smart to balance cost and quality. Saving money on swing motor parts can lead to quick failures. This means more downtime and higher repair costs. Spending more on good parts helps in the long run. Your excavator works better, lasts longer, and needs fewer repairs.

Swing Motor and Swing Motor Parts

Performance Checks

You want your excavator to work at its best every day. Regular checks on your swing motor and swing motor parts help you avoid big problems. Start by looking for leaks around the swing motor. Worn seals or damaged swing motor parts can cause leaks. Replace faulty swing motor parts or use genuine seal kits to rebuild the swing motor. Check the hydraulic fluid often. Use only approved fluids for your excavator and follow the service schedule. Clean fluid keeps your swing motor and swing motor parts running smoothly.

Test the swing control valve with a pressure gauge. If you find clogs or leaks, replace the swing motor parts right away. Inspect the swing gear and bearings for any signs of wear or damage. Lubricate these swing motor parts with the right grease. Stick to the service intervals for your excavator. Most experts suggest checking the swing motor and swing motor parts every 250 to 500 hours or at least every three months.

Tip: Train your operators to use the swing motor and swing motor parts correctly. Good habits protect your excavator and help swing motor parts last longer.

Always watch the load and terrain. Heavy loads or rough ground put extra stress on the swing motor and swing motor parts. Use only genuine swing motor parts for your excavator to keep everything working well.

Signs of Wear

You need to spot trouble early to keep your excavator safe. Worn swing motor parts can cause big problems. Look for these signs:

Excessive wear on swing motor parts from constant use or friction.

Reduced performance from your swing motor, such as less power or slower movement.

Increased noise or vibration when the swing motor runs.

Visible damage like cracks, breaks, or bent swing motor parts.

If you see any of these signs, replace the swing motor parts right away. Regular checks help you find problems before they get worse. Proactive care keeps your excavator running and protects your swing motor and swing motor parts from sudden failure.

Alert: Never ignore strange sounds or shaking from your swing motor. Quick action saves your excavator from costly repairs.

Swing Drive and Slewing Ring

Torque and Speed Specs

You need to know the right torque and speed for your excavator’s swing motor. Torque is the force that helps your machine turn heavy loads. Speed tells you how fast the upper part of your excavator can rotate. If you choose a swing motor with the wrong torque, your machine may struggle to move or stop too quickly. Too much speed can make your excavator hard to control. Too little speed can slow down your work.

Manufacturers give you torque and speed specs for each swing motor. You should always check these numbers before you buy new parts. Look in your machine’s manual or ask your supplier for help. The swing drive works with the swing motor to deliver the right balance of power and control. When you match the swing motor specs to your job, you keep your excavator safe and efficient.

Tip: Always use the swing motor that matches your excavator’s weight and job needs. This helps you avoid damage and keeps your machine working longer.

Maintenance Tips

You can make your swing motor and slewing ring last longer with good care. Follow these steps to keep your machine in top shape:

Lubricate the slewing ring often. Check the grease for metal grit. Grit can mean early wear or damage.

Clean the area around the slewing ring and swing motor. Dirt and debris can cause extra strain and lower efficiency.

Inspect the slewing ring and swing motor area often. Look for signs of leaks, cracks, or loose bolts.

Check fluid levels and quality. Low or dirty fluids can cause big problems for your swing motor.

Feel and look at the fluids. If you find debris or metal shavings, fix the problem right away.

Alert: If you hear strange noises or feel shaking from the swing motor, stop and check your machine. Early action can prevent bigger repairs.

Regular care helps your swing motor, swing drive, and slewing ring work better and last longer. You save money and avoid downtime by catching problems early.

Supplier Selection

Reputation and Support

You want your excavator to work well every day. Picking the right supplier for swing motor parts is important. Find suppliers with a good history. Companies that work with big brands like Komatsu, Caterpillar, Volvo, and Hitachi often give better help. These suppliers know how to match swing motor parts to your machine. They help you avoid mistakes and keep your excavator running.

A good supplier gives more than just swing motor parts. You also get help after you buy and technical support. This help keeps your swing motor working longer and helps you fix problems fast. Here are some ways good support helps you:

You get real swing motor parts that fit and last longer.

Maintenance and repair plans can save you money over time.

Services that find problems early help stop breakdowns.

Special tools help you track your swing motor and swing motor parts.

Remanufacturing can make your swing motor work like new.

You should talk to parts experts before you buy. They can answer questions about swing motor parts and help you choose the right ones. Good support means you spend less time fixing your excavator and more time working.

Warranty and Red Flags

You need to check the warranty before buying swing motor parts. Good suppliers give clear warranty rules for every part. This protects your money and gives you peace of mind. The table below shows what to expect from each part type:

Part Type | Warranty Terms |

|---|---|

OEM Parts | Clear warranty; rules depend on part and brand; you must keep service records. |

Aftermarket Parts | Warranty changes by maker; quality and coverage can be different. |

Refurbished Parts | Short warranty; you pay for repairs after it ends. |

Salvaged Parts | Little or no warranty; lowest price but highest risk. |

Look for suppliers with many years in business and good reviews. Ask about their warranty and help after you buy. Watch out for bad signs like unclear warranty, poor answers, or no technical support. These signs mean you may not get help if your swing motor or swing motor parts break.

Tip: It is smart to balance cost and quality. Pick oem parts for important swing motor repairs. Good suppliers help you get the best value for your excavator.

To keep your excavator working well, check if parts fit by looking at mounting surfaces and checking part numbers. Pick high-quality parts to stop wear, leaks, and help your machine last longer. Choose suppliers who know a lot and can help you pick the right swing gear parts for your excavator. Check your excavator often and use the right grease to find problems early and stop expensive repairs. Look at your swing gear parts and how you care for them often to make your machine more reliable and save money over time.

FAQ

What happens if you use the wrong swing gear part?

If you use the wrong part, your excavator may not work right. You could see poor rotation, extra wear, or even damage. Always check part numbers and machine manuals before you buy.

How often should you inspect swing gear parts?

You should inspect swing gear parts every 250 to 500 hours of use. Look for leaks, noise, or loose bolts. Regular checks help you catch problems early and keep your machine safe.

Can you mix OEM and aftermarket swing gear parts?

You can mix them, but you must check for fit and quality. Some aftermarket parts may not match OEM standards. Ask your supplier for advice before you mix parts.

What are signs that swing gear parts need replacing?

You hear grinding or loud noises.

The excavator shakes during rotation.

You see leaks or cracks.

Tip: Replace worn parts quickly to avoid bigger repairs.

How do you choose a trusted supplier for swing gear parts?

Look for suppliers with good reviews and experience with big brands. Ask about their warranty and support. A trusted supplier helps you find the right parts and gives you help after your purchase.