Selecting the proper machine for your project plays a vital role in achieving success. The right equipment ensures efficiency, reduces costs, and minimizes delays. When it comes to an excavator JCB, understanding your project’s demands becomes essential. You need to evaluate factors like terrain, tasks, and material handling. But how do you choose the right excavator that fits your needs? By focusing on size, capabilities, and job site requirements, you can make an informed decision that maximizes productivity and ensures smooth operations.

Key Takeaways

Understand the different types of JCB excavators—mini, mid-size, and large—to choose the right one for your project’s scale and requirements.

Evaluate key specifications like operating weight, engine power, and bucket capacity to ensure the excavator meets your specific job demands.

Consider the terrain and site conditions when selecting an excavator to ensure optimal performance and stability.

Decide whether to rent or buy based on your project’s duration and budget; renting offers flexibility, while buying provides long-term availability.

Implement regular maintenance and operator training to enhance excavator performance and reduce operational costs.

Leverage modern technology, such as telematics, to monitor performance and schedule predictive maintenance for your excavator.

Partner with reliable suppliers like YNF Machinery for high-quality parts and support to keep your excavator running efficiently.

Excavator JCB Types and Sizes: A Comprehensive Excavator Size Guide

Choosing the right excavator for your project begins with understanding the various categories and sizes available. Each type of excavator serves specific purposes, making it essential to match the machine to your project’s requirements. This excavator size guide will help you navigate the options and make an informed decision.

Overview of JCB Excavator Categories

Mini excavators: Compact and versatile for small-scale projects.

Mini excavators are ideal for projects requiring precision in tight spaces. Their compact design allows you to maneuver easily in urban areas or confined job sites. These machines excel in tasks like landscaping, trenching, and small-scale construction. JCB Compact Excavators, for instance, feature heavy-duty H-frames and sealed track components, ensuring durability and stability. Their low center of gravity enhances safety, while advanced hydraulic systems provide smooth operation. If your project involves light digging or material handling, mini excavators offer the perfect balance of power and portability.

Mid-size excavators: Balancing power and maneuverability for medium projects.

Mid-size excavators strike a balance between strength and flexibility. They handle medium-scale construction tasks, such as roadwork, foundation digging, and utility installation. These machines deliver more power than compact excavators while maintaining ease of operation. The JCB 100C-1 Excavator, for example, combines strong digging capabilities with extended reach. Its efficient hydraulics and user-friendly design ensure you can complete tasks effectively. Mid-size excavators are versatile enough to adapt to a variety of job site conditions.

Large excavators: Heavy-duty machines for large-scale construction and mining.

Large excavators are built for demanding tasks that require maximum power and capacity. These machines excel in large-scale construction, mining, and heavy lifting. Their robust engines and high bucket capacities allow you to move significant amounts of material quickly. Large excavators also offer impressive digging depths and reach, making them suitable for deep excavation projects. If your project involves extensive earthmoving or demolition, a large excavator provides the strength and efficiency you need.

Key Specifications to Consider

Operating weight and size.

The operating weight and size of an excavator determine its stability and suitability for specific tasks. Mini excavators weigh less and are easier to transport, while larger models provide greater stability for heavy-duty operations. Consider the scale of your project and the space available on-site when selecting the right size.

Engine power and fuel efficiency.

Engine power directly impacts an excavator’s performance. Machines with higher horsepower handle tougher tasks but may consume more fuel. Look for models with efficient engines that balance power and fuel consumption. For example, JCB excavators feature advanced engine technology to optimize performance and reduce operating costs.

Bucket capacity and digging depth.

Bucket capacity affects how much material you can move in one cycle, while digging depth determines how deep you can excavate. Mini excavators typically have smaller buckets and shallower digging depths, making them suitable for light tasks. Larger excavators offer greater capacities and depths, ideal for heavy-duty projects. Evaluate your project’s material handling and excavation needs to choose the right specifications.

By understanding the types of excavators and their key specifications, you can select a machine that aligns with your project’s demands. This excavator size comparison ensures you maximize efficiency and productivity on the job site.

Matching Excavator Features to Your Project Needs

Selecting the right excavator for your project involves more than just understanding the types and sizes of excavators. You must evaluate your specific job requirements, choose suitable attachments, and consider practical factors that impact efficiency and cost-effectiveness. This section will guide you through these critical aspects.

Assessing Your Project Requirements

Understanding your project’s unique demands is the first step in choosing excavators that align with your goals. Here are the key factors to evaluate:

Type of terrain and site conditions.

The terrain and site conditions play a significant role in determining the type of excavator you need. For rocky or uneven ground, you may require a machine with strong hydraulic systems and durable tracks. On softer terrains, lighter excavators with rubber tracks can prevent damage to the surface while maintaining stability.

Project scale and duration.

The scale and duration of your project influence the size and capacity of the excavator. For short-term, small-scale tasks, mini excavators are ideal due to their compact size and ease of transport. For larger, long-term projects, mid-size or large excavators provide the power and efficiency needed to handle heavy workloads.

Specific tasks (e.g., digging, lifting, demolition).

Different tasks require specific features and capabilities. If your project involves digging and lifting capabilities, focus on models with high bucket capacities and extended reach. For demolition tasks, opt for excavators equipped with reinforced booms and hydraulic breakers. Matching the machine’s capabilities to your job requirements ensures optimal performance.

Choosing the Right Attachments

Attachments enhance the versatility of your excavator, allowing it to perform a wide range of tasks. Selecting the right attachments can significantly improve efficiency and productivity.

Buckets for digging and trenching.

Buckets are essential for most excavation tasks. Standard buckets handle general digging and material handling, while trenching buckets are designed for creating narrow trenches. Choose a bucket size that matches your project’s material volume and digging depth.

Hydraulic breakers for demolition.

Hydraulic breakers are powerful tools for breaking through concrete, rocks, and other hard materials. They are indispensable for demolition projects and heavy-duty construction tasks. Ensure the breaker is compatible with your excavator’s hydraulic system for seamless operation.

Augers for drilling and boring.

Augers are ideal for projects requiring precise drilling or boring, such as installing fence posts or utility poles. These attachments come in various sizes to accommodate different hole diameters and depths. Select an auger that meets your project’s specifications for efficient results.

Practical Considerations

Beyond job requirements and attachments, practical factors can influence your choice of excavator. Addressing these considerations ensures smooth operations and minimizes unexpected challenges.

Transportation and site access.

The size and weight of the excavator affect its transportability and accessibility. Mini excavators are easier to transport and maneuver in tight spaces, making them suitable for urban projects. Larger machines may require specialized transport equipment and ample space for operation.

Maintenance and servicing needs.

Regular maintenance is crucial for keeping your excavator in top condition. Consider models with accessible components and user-friendly designs that simplify servicing. Reliable support from manufacturers or suppliers, like YNF Machinery, ensures you have access to quality parts and assistance when needed.

By carefully assessing your project requirements, selecting the right attachments, and addressing practical considerations, you can choose a right-sized excavator that meets your needs. This approach ensures efficiency, reduces downtime, and maximizes the value of your investment.

Should You Rent or Buy a JCB Excavator?

Deciding whether to rent or buy an excavator is a critical choice that depends on your project’s needs and financial considerations. Both options offer unique advantages, and understanding these can help you make the best decision for your situation.

Factors to Consider When Renting

Renting an excavator provides flexibility and convenience, especially for short-term or one-time projects. Here are the key factors to evaluate:

Short-term projects with limited budgets.

If your project has a tight budget or a short duration, renting becomes a practical solution. You avoid the high upfront costs of purchasing equipment, which allows you to allocate funds to other essential areas of your project. For example, if you need an excavator for a few weeks to complete a landscaping task, renting ensures you get the machine you need without a long-term financial commitment.

Access to the latest models without long-term commitment.

Renting gives you access to the newest excavator models equipped with advanced features. This is particularly beneficial if your project requires specific capabilities or if you want to test different models before making a purchase. Additionally, you don’t have to worry about maintenance or storage costs, as rental companies typically handle these aspects.

“Renting is suitable for temporary jobs, while buying ensures 24/7 availability of equipment without scheduling constraints.” – Insights from contractors.

Benefits of Buying

Buying an excavator is a long-term investment that offers control and cost savings for frequent or extended use. Consider these benefits:

Cost savings for frequent or long-term use.

If you frequently use an excavator or have ongoing projects, purchasing becomes more cost-effective over time. The initial investment may seem high, but it eliminates recurring rental fees. For instance, contractors working on multiple construction sites often find that owning equipment reduces overall expenses.

Full control over equipment availability and usage.

Owning an excavator ensures you have access to the machine whenever you need it. You don’t have to rely on rental availability or deal with scheduling conflicts. This level of control is crucial for projects with tight deadlines or unpredictable timelines. Additionally, owning equipment allows you to customize it with attachments that suit your specific needs.

Financial and Operational Considerations

When deciding to rent or buy an excavator, you must weigh the financial and operational implications carefully.

Upfront costs vs. recurring rental fees.

Purchasing requires a significant upfront investment, but it eliminates the ongoing costs associated with renting. On the other hand, renting spreads out expenses over time, making it easier to manage cash flow for short-term projects. Evaluate your budget and project timeline to determine which option aligns with your financial goals.

Depreciation and resale value.

Excavators, like any machinery, depreciate over time. However, owning equipment allows you to recover some of the initial cost through resale. If you maintain the machine well, its resale value can offset a portion of your investment. Renting, while avoiding depreciation, doesn’t offer this potential return.

By considering these factors, you can make an informed decision when choosing excavators for your projects. Whether you decide to rent or buy an excavator JCB, the key is to align your choice with your project’s requirements and financial strategy.

Tips for Optimizing Excavator Performance and Cost-Effectiveness

Maximizing the efficiency and lifespan of your excavator requires a proactive approach. By focusing on regular maintenance, operator training, and leveraging modern technology, you can ensure optimal performance while reducing costs. These strategies not only enhance productivity but also contribute to operator comfort and safety.

Regular Maintenance and Inspections

Routine maintenance is the backbone of keeping your excavator in top condition. It prevents unexpected breakdowns and ensures smooth operations.

Checking fluid levels and filters.

You should regularly check the fluid levels, including engine oil, hydraulic fluid, and coolant. Low fluid levels can lead to overheating or reduced performance. Replace filters as needed to maintain clean systems and prevent contaminants from damaging internal components. This simple step significantly improves fuel efficiency and emissions control.

Inspecting tracks, tires, and hydraulic systems.

Inspect the tracks or tires for wear and tear. Damaged tracks can reduce stability and maneuverability, especially on uneven terrain. Examine the hydraulic systems for leaks or pressure inconsistencies. Addressing these issues early minimizes downtime and extends the machine’s lifespan.

“Maintenance training is essential for keeping machines running efficiently, preventing breakdowns, reducing downtime, and increasing operational efficiency.”

Operator Training and Best Practices

A well-trained operator plays a crucial role in optimizing excavator performance. Proper handling reduces wear and tear, ensuring the machine operates at its best.

Ensuring proper handling to avoid wear and tear.

Operators should follow manufacturer guidelines for operating the excavator. Avoid overloading the bucket or using the machine for tasks beyond its capacity. Gentle handling of controls prevents unnecessary strain on hydraulic systems and other components.

Maximizing fuel efficiency through smart operation.

Encourage operators to adopt fuel-saving techniques, such as idling less and using the appropriate power mode for each task. Efficient operation not only reduces fuel consumption but also lowers emissions, aligning with environmental standards.

Leveraging Technology

Modern technology offers valuable tools for optimizing excavator performance. By integrating advanced systems, you can monitor and maintain your equipment more effectively.

Using telematics for performance monitoring.

Telematics systems provide real-time data on your excavator’s performance. You can track fuel usage, engine hours, and maintenance schedules. This information helps you identify inefficiencies and address them promptly, ensuring consistent productivity.

Scheduling predictive maintenance to reduce downtime.

Predictive maintenance uses data analytics to forecast potential issues before they occur. By scheduling repairs in advance, you avoid unexpected breakdowns and costly delays. This approach keeps your excavator running smoothly and extends its operational life.

By implementing these strategies, you can achieve the goal of optimizing excavator performance while maintaining cost-effectiveness. Regular maintenance, skilled operators, and advanced technology work together to enhance efficiency, reduce expenses, and ensure operator comfort and safety.

Why YNF Machinery is Your Partner for Proper Machine Selection

Choosing the right partner for your excavator parts ensures your machinery operates efficiently and reliably. YNF Machinery stands out as a trusted provider, offering high-quality components, competitive pricing, and exceptional support. Here’s why YNF Machinery is the ideal choice for your excavator needs.

High-Quality Excavator Parts for Every Need

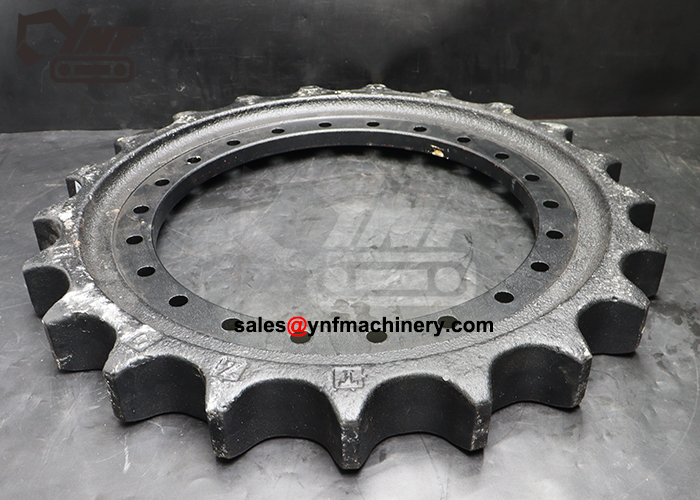

Components for over 26 excavator brands, ensuring compatibility.

YNF Machinery provides a wide range of excavator parts compatible with over 26 leading brands. Whether you need couplings, hydraulic components, or rubber mounts, you’ll find parts designed to fit seamlessly with your equipment. This compatibility ensures your excavator performs at its best without unnecessary modifications or adjustments.

Rigorous quality inspections for reliable performance.

Every part from YNF Machinery undergoes strict quality inspections. These checks ensure durability and reliability, even in demanding conditions. For example, Bowex couplings supplied by YNF Machinery excel in reducing vibration and handling misalignment, making them essential for smooth power transmission. By prioritizing quality, YNF Machinery helps you extend the lifespan of your machinery and reduce maintenance costs.

“Quality components are essential for long-lasting and efficient construction and heavy machinery equipment.”

Competitive Pricing and Comprehensive Support

Low minimum order quantities for stocking essential parts.

YNF Machinery offers low minimum order quantities, making it easier for you to stock up on essential parts without overextending your budget. This flexibility benefits contractors, equipment rental companies, and excavator owners who need reliable parts on hand for quick replacements.

Documentation and logistics assistance for a smooth purchasing experience.

Navigating international purchases can be challenging, but YNF Machinery simplifies the process. The company provides comprehensive documentation and logistics support, ensuring your orders arrive on time and without complications. This level of service minimizes delays and keeps your projects running smoothly.

Trusted by Excavator Owners and Contractors Worldwide

Over 35 years of experience in the global market.

With over three decades of experience, YNF Machinery has built a reputation for excellence. The company’s deep understanding of the excavation industry allows it to meet the unique needs of clients worldwide. This expertise ensures you receive parts that meet high standards and perform reliably.

A reputation for reliability and customer satisfaction.

YNF Machinery’s commitment to customer satisfaction sets it apart. Clients trust the company for its consistent quality, competitive pricing, and responsive support. By choosing YNF Machinery, you join a global network of satisfied excavator owners and contractors who rely on the company to keep their operations running efficiently.

“By focusing on quality over cost alone, you can invest in components that will extend the life of your machinery, reduce maintenance costs, and ensure safety in your operations.”

When you partner with YNF Machinery, you gain access to high-quality parts, expert support, and a proven track record of reliability. Equip your excavator with components that enhance performance and durability, and experience the difference a trusted supplier can make.

Choosing the right-sized excavator is essential for achieving project success. You need to understand excavator types and sizes, match features to your job requirements, and decide whether to rent or buy based on your needs. Optimizing performance through maintenance and training ensures long-term efficiency. YNF Machinery provides reliable support for your excavator needs, offering high-quality parts and expert assistance. Explore their offerings to find solutions tailored to your job requirements. Contact their team today to ensure your projects run smoothly with the right-sized excavator.