Understanding how excavator engine parts work is crucial for keeping your machine running smoothly. Each component plays a vital role in delivering power, efficiency, and reliability. When you know the excavator engine parts name and their functions, you can identify issues early and avoid costly repairs. Regular maintenance, such as checking oil levels or replacing filters, ensures optimal performance and extends the engine’s lifespan. As experts emphasize, using genuine parts designed for your machine enhances durability and reduces downtime, allowing your excavator to perform at its best.

Key Takeaways

Understanding the names and functions of excavator engine parts is essential for effective maintenance and early issue identification.

Regular maintenance practices, such as oil changes and air filter replacements, are crucial for extending the lifespan and efficiency of your excavator engine.

Using genuine parts designed for your excavator enhances durability and reduces downtime, ensuring optimal performance.

Monitoring coolant levels and addressing overheating issues promptly can prevent severe engine damage and costly repairs.

Recognizing early signs of engine wear, such as unusual noises or reduced power, allows for timely interventions and maintenance.

Maintaining the synchronization of engine systems—fuel, air intake, cooling, and electrical—is vital for maximizing performance and reliability.

Implementing best practices for troubleshooting common engine issues can significantly improve your excavator’s operational efficiency.

Overview of Excavator Engines

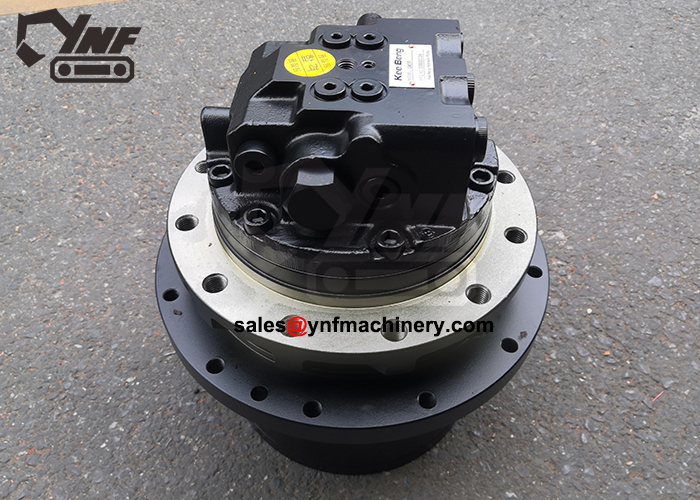

Excavator engines serve as the powerhouse of these heavy-duty machines. They generate the energy required to operate hydraulic systems, move attachments, and perform demanding tasks on construction sites. Most excavators rely on diesel engines due to their durability and ability to deliver high torque. These engines are specifically designed to handle tough conditions while maintaining efficiency and reliability.

The Role of Excavator Engines

The engine plays a central role in powering the entire excavator. It drives the hydraulic pumps, which control the movement of the arm, bucket, and other attachments. Without a properly functioning engine, the excavator cannot perform its essential tasks. The engine also ensures that the machine operates smoothly during long work hours, even under extreme conditions. Regular maintenance, such as oil changes and filter replacements, is critical to keeping the engine in top condition.

“The engine is the heart of an excavator, providing the power necessary for its operation.” This quote highlights the importance of the engine in ensuring the machine’s performance and reliability.

Key Features of Excavator Engines

Modern excavator engines come equipped with advanced features to meet the demands of construction work. These include:

Fuel Efficiency: Diesel engines are designed to maximize fuel usage, reducing operational costs.

High Torque Output: They provide the strength needed to handle heavy loads and challenging terrains.

Emission Standards Compliance: Many engines meet stringent environmental regulations, offering cleaner and more sustainable operation.

Durability: Built to withstand harsh conditions, these engines ensure consistent performance over time.

For example, a four-stroke diesel engine can generate up to 36 KW at 2000 rpm, delivering the power required for heavy-duty tasks. Its robust design ensures that it can handle prolonged use without compromising efficiency.

Why Knowing Excavator Engine Parts Name Matters

Understanding the excavator engine parts name and their functions is essential for effective operation and maintenance. When you know the names of components like pistons, crankshafts, and fuel injectors, you can quickly identify issues and address them before they escalate.

Additionally, recognizing the role of each part allows you to perform routine checks and maintenance tasks more effectively. For instance, monitoring coolant levels and replacing air filters can prevent overheating and improve engine longevity. By staying informed, you can reduce downtime, avoid costly repairs, and keep your excavator running at essential excavator parts performance.

Key Excavator Engine Parts Name and Their Functions

Understanding the core components of an excavator engine helps you maintain its efficiency and reliability. Each part plays a specific role in ensuring the engine operates smoothly. Let’s explore the key excavator engine parts name and their functions.

Core Engine Components

Pistons

Pistons are essential for converting fuel energy into mechanical power. They move up and down inside the cylinder, compressing air and fuel to create combustion. This motion generates the force needed to rotate the crankshaft. When pistons fail, you may notice reduced power, unusual noises, or increased oil consumption. Regular inspections help you detect wear and prevent engine complications.

Crankshaft

The crankshaft transforms the pistons’ reciprocating motion into rotational energy. This energy powers the excavator’s hydraulic systems and other components. The crankshaft includes critical parts like crankpins and counterweights, which ensure balance and smooth operation. Lack of lubrication or engine overload can cause crankshaft damage. Monitoring oil levels and avoiding excessive strain on the engine can extend its lifespan.

Cylinder Block

The cylinder block serves as the foundation of the engine. It houses the pistons, crankshaft, and other internal components. Its robust design withstands high pressure and temperature during operation. Proper maintenance, such as cleaning and checking for cracks, ensures the cylinder block remains durable and functional.

Fuel System Components

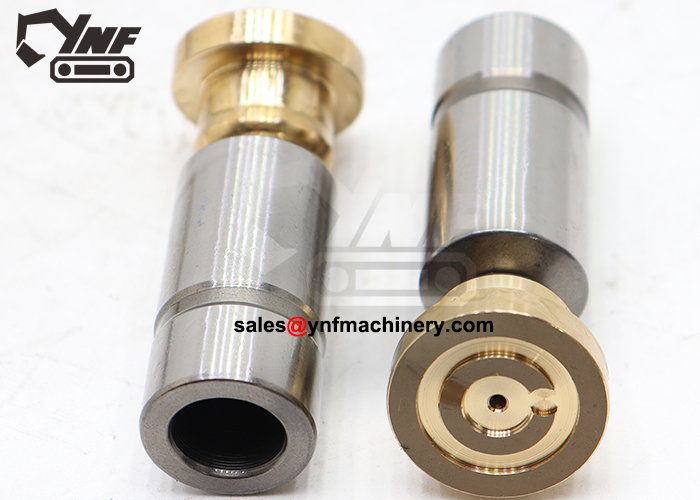

Fuel Injectors

Fuel injectors deliver precise amounts of fuel into the combustion chamber. This ensures efficient combustion and optimal engine performance. Clogged or malfunctioning injectors can lead to poor fuel efficiency and engine misfires. Cleaning or replacing them regularly keeps the fuel system in top condition.

Fuel Pump

The fuel pump supplies fuel from the tank to the injectors under high pressure. It ensures a consistent flow of fuel, which is vital for smooth engine operation. A failing fuel pump can cause starting issues or uneven engine performance. Routine checks help you identify and resolve problems early.

Air Intake and Exhaust System

Turbocharger

The turbocharger increases engine efficiency by forcing more air into the combustion chamber. This boosts power output without increasing fuel consumption. Over time, carbon deposits or wear can reduce its effectiveness. Cleaning the turbocharger and inspecting it for damage ensures consistent performance.

Exhaust Manifold

The exhaust manifold collects exhaust gases from the engine’s cylinders and directs them to the exhaust system. It plays a crucial role in maintaining proper airflow and reducing emissions. Cracks or leaks in the manifold can affect engine efficiency and increase noise levels. Regular inspections help you address these issues promptly.

Cooling System Components

Radiator

The radiator plays a vital role in maintaining the engine’s temperature. It dissipates heat generated during the combustion process, ensuring the engine operates within safe temperature limits. Coolant flows through the radiator, where it releases heat into the surrounding air. A malfunctioning radiator can lead to overheating, which may cause severe engine damage. To keep your radiator functioning effectively, inspect it regularly for leaks, blockages, or corrosion. Cleaning the radiator and ensuring proper coolant levels will help prevent overheating and extend the life of your excavator engine.

Water Pump

The water pump circulates coolant throughout the engine, transferring heat away from critical components. It ensures a steady flow of coolant between the engine and the radiator. A failing water pump can disrupt this flow, leading to overheating and potential engine failure. Common signs of water pump issues include coolant leaks, unusual noises, or engine overheating. Regularly checking the water pump and replacing it when necessary will help maintain the cooling system’s efficiency.

Electrical System Components

Alternator

The alternator generates electrical power to charge the battery and supply energy to the excavator’s electrical systems. It ensures that components like lights, sensors, and control systems function properly. A faulty alternator can cause the battery to drain quickly, leading to starting problems or electrical failures. To avoid these issues, monitor the alternator’s performance and replace it if you notice dimming lights or frequent battery issues. Keeping the alternator in good condition ensures uninterrupted operation of your excavator.

Starter Motor

The starter motor is responsible for initiating the engine’s operation. It uses electrical energy from the battery to crank the engine and start the combustion process. A malfunctioning starter motor can prevent the engine from starting, causing delays in your work. Signs of a failing starter motor include clicking sounds or difficulty starting the engine. Regular maintenance, such as checking connections and ensuring the battery is fully charged, can help prevent starter motor issues.

How Excavator Engine Components Work Together

The Internal Combustion Process

The internal combustion process is the foundation of an excavator engine’s operation. It begins when the engine mixes fuel and air inside the cylinder. The piston compresses this mixture, creating the conditions necessary for combustion. A spark or high pressure ignites the mixture, producing an explosion that forces the piston downward. This motion generates mechanical energy, which powers the crankshaft.

Each component in this process plays a critical role. The pistons convert the energy from combustion into motion. The crankshaft transfers this motion to other systems, such as the hydraulic pump. Fuel injectors ensure the precise delivery of fuel, while the turbocharger increases air intake for more efficient combustion. Without proper synchronization, the engine cannot produce the power needed for heavy-duty tasks.

Maintaining the internal combustion process requires regular care. Cleaning fuel injectors, inspecting pistons, and monitoring the turbocharger’s performance help keep the engine running efficiently. These steps ensure that the combustion process remains smooth and reliable.

Synchronization of Engine Systems

Excavator engines rely on the seamless synchronization of multiple systems to function effectively. The fuel system, air intake, cooling, and electrical components must work together to support the engine’s operation. For example, the fuel pump delivers fuel to the injectors, while the turbocharger supplies air for combustion. The cooling system prevents overheating by circulating coolant through the radiator and water pump.

The electrical system also plays a vital role. The alternator powers essential components, such as sensors and control systems, while the starter motor initiates the engine’s operation. Each system depends on the others to maintain balance and efficiency. If one system fails, it can disrupt the entire engine’s performance.

To ensure proper synchronization, you should follow a consistent maintenance schedule. Inspect the cooling system for leaks or blockages, clean the radiator, and check the water pump for wear. Monitor the alternator and starter motor to avoid electrical issues. By keeping all systems in harmony, you can maximize your excavator’s performance and reduce downtime.

“An excavator engine is a symphony of systems working in unison. Each part must perform its role to achieve peak efficiency.” This quote underscores the importance of synchronization in maintaining engine reliability.

Practical Tips for Maintaining Excavator Engine Efficiency

Maintaining your excavator engine ensures consistent performance and reduces the risk of costly repairs. By following best practices and addressing common issues promptly, you can extend the life of your machine and keep it running efficiently.

Maintenance Best Practices

Regular Oil Changes

Oil lubricates the moving parts of your engine, reducing friction and preventing wear. Over time, oil collects dirt and debris, which can harm engine components. Changing the oil at regular intervals ensures smooth operation and protects critical parts like pistons and the crankshaft. Always use the oil type recommended by the manufacturer to maintain optimal performance.

Cleaning and Replacing Air Filters

Air filters prevent dust and debris from entering the engine. A clogged filter restricts airflow, reducing efficiency and increasing fuel consumption. Inspect the air filter regularly and clean or replace it as needed. This simple step improves combustion and protects the engine from damage caused by contaminants.

Monitoring Coolant Levels

Coolant regulates the engine’s temperature, preventing overheating. Low coolant levels can lead to severe damage, including cracked cylinder blocks or warped components. Check the coolant level frequently and top it off when necessary. Use the correct coolant type to ensure compatibility with your engine’s cooling system.

Troubleshooting Common Engine Issues

Identifying Signs of Engine Wear

Recognizing early signs of wear helps you address problems before they escalate. Look for symptoms like unusual noises, reduced power, or excessive smoke from the exhaust. These could indicate worn pistons, a failing crankshaft, or other internal issues. Regular inspections and maintenance reduce the likelihood of severe damage.

Addressing Fuel System Problems

The fuel system plays a vital role in engine performance. Issues like clogged fuel injectors or a failing fuel pump can cause poor combustion, leading to reduced efficiency. If you notice difficulty starting the engine or uneven performance, inspect the fuel system. Clean the injectors and ensure the fuel pump delivers consistent pressure.

Fixing Overheating Issues

Overheating can severely damage your engine. Common causes include a malfunctioning radiator, a failing water pump, or low coolant levels. If the engine overheats, stop the machine immediately and identify the cause. Check for leaks in the cooling system, clean the radiator, and replace the water pump if necessary. Preventing overheating ensures the longevity of your excavator engine.

“Diesel engines rely on high-pressure compression to ignite fuel, making proper maintenance essential for efficient combustion.” This highlights the importance of keeping all systems in good condition to support the unique operation of diesel engines.

By following these practical tips, you can maintain the efficiency of your excavator engine. Understanding the excavator engine parts name and their functions allows you to perform routine checks effectively and address issues promptly. Consistent care ensures your machine operates at peak performance, minimizing downtime and maximizing productivity.

Understanding excavator engine parts name and their functions equips you with the knowledge to maintain your machine effectively. Each component plays a vital role in ensuring smooth operation and reducing downtime. Regular maintenance, such as oil changes, fuel system inspections, and coolant monitoring, enhances engine performance and extends its lifespan. By addressing issues early and using genuine parts, you can avoid costly repairs and improve productivity. Apply these insights to keep your excavator running efficiently, ensuring reliable performance on every project.