Choosing the right excavator undercarriage for sale in 2026 is crucial. It impacts how efficiently your machine operates, its durability, and your overall expenses. You need to select an undercarriage that matches your equipment and job site conditions to prevent early wear and costly repairs.

-

An undercarriage accounts for about 20% of a new machine’s price and up to 50% of maintenance costs.

-

Job site conditions such as mud, rock, or rough terrain influence which track type is best suited for you.

-

Regular maintenance, including cleaning and adjusting track tension, helps extend the life of your excavator undercarriage.

When looking for an excavator undercarriage for sale, focus on quality and compatibility to maximize your investment.

Key Takeaways

-

Pick an undercarriage that matches your excavator’s weight. Make sure it works well with the ground at your job site. This helps your machine work better and last longer.

-

Choose the right track type for your job. Use rubber tracks for soft or city areas. Use steel tracks for rough or heavy work. This keeps your machine and the ground safe.

-

Clean and check your undercarriage parts often. Look at the tracks, rollers, and bolts. This helps you find problems early and stop big repairs.

-

Use good quality parts for your machine. Try new materials and smart sensors if you can. This makes your machine stronger, saves time, and costs less.

-

Do not just look at the price when you buy. Think about the total cost, warranty, and support. This helps you get the best deal and keeps your machine working well.

Machine & Terrain

Equipment Type

To pick the right excavator undercarriage, you need to know your machine’s type and weight. Every excavator model needs a certain undercarriage to work well. The undercarriage must fit your machine’s weight so it stays steady and lasts longer. Bigger excavators need wider tracks and stronger parts. This helps spread out the weight and lets the machine lift more. It also stops the undercarriage from wearing out too soon.

The table below shows different excavator types in 2026 and what undercarriage they need:

|

Excavator Type |

Undercarriage Type |

Key Features and Applications |

|---|---|---|

|

Wheeled Excavators |

Wheels |

Move fast on roads, good for cities, need outriggers for balance |

|

Mini and Small Excavators |

Tracks (mostly) |

Small, easy to move, great for tight spots and gardens |

|

Crawler Excavators |

Tracks |

Strong grip and balance, best for tough jobs and rough ground |

|

Special/Customized |

Tracks or Wheels |

Made for special places, can be changed for certain jobs |

Wheeled excavators use strong tires. They move quickly on roads and are easy to turn. But they sit higher up and need outriggers or a dozer blade to stay steady on bumpy ground. Their undercarriage is simple and easy to fix, but they do not grip well on soft or sloped ground. Tracked excavators, like mini and crawler types, grip the ground better and stay steady. This makes them good for hard jobs and rough places.

Tip: Always check your machine’s weight and what you will use it for before picking an undercarriage. This helps your machine work better and saves money on repairs.

Job Site Conditions

The ground at your job site is very important when choosing an undercarriage. You should think about the soil, how wet it is, and other things around you. This helps your machine work well and last longer.

-

Agriculture Fields (Wet Soil): Rubber tracks are best here. They do not press down the dirt too much, keep crops safe, and grip well in mud.

-

Urban and Compact Sites: Rubber tracks are good because they do not hurt roads or make much noise. They also help the machine move fast and turn easily.

-

Heavy Construction & Mining: Steel tracks are best for these jobs. They are strong, hold heavy loads, and grip well on rocks and gravel.

-

Forestry: Pick undercarriage parts that do not rust and can handle bumps and water.

-

Specialized Terrains (Snow, Landscaping): Some jobs need special tracks, like quiet rubber tracks or small frames, to solve tough problems.

The table below compares steel and rubber tracks on different ground types:

|

Terrain Type |

Steel Tracks |

Rubber Tracks |

|---|---|---|

|

Mud |

Great grip, do not slip much |

Good, but wear out faster |

|

Sand |

Spread weight well |

Easy to turn and move |

|

Rock |

Very strong, best for rough ground |

Wear out quickly |

|

Urban/Paved |

Can hurt roads, loud |

Quiet, keeps roads safe |

|

Snow/Ice |

Heavy, grips well |

Bends, but not as much grip |

Rubber tracks come in many shapes, like block, straight bar, and zig-zag. You can pick the best one for your job. Block tread works well on gravel and grass. Zig-zag tread helps keep mud and snow from sticking.

Wheeled excavators need special undercarriage parts. Their wheels help them move fast on roads, but you must use outriggers to keep them steady when digging. They are good for cities and finished ground, but do not work well on soft or bumpy ground because they press down harder and do not grip as well.

Note: Always pick an undercarriage that fits both your machine and the ground. This gives you better grip, balance, and helps your machine last longer.

Excavator Undercarriage Parts

Understanding excavator undercarriage parts helps you make smart choices for your machine. Each part plays a key role in stability, movement, and optimal performance. When you know how these parts work together, you can boost both performance and longevity.

Track Options

You have several track options for your excavator undercarriage. The right choice depends on your job site and the type of work you do. Here are the main types you will find in 2026:

-

Rubber Tracks: These tracks use steel-reinforced rubber. They move smoothly and quietly, making them perfect for urban areas and landscaping. Rubber tracks cause less ground damage and offer a comfortable ride. However, they wear out faster on sharp rocks or rough terrain.

-

Steel Tracks: Steel tracks give you high durability and strong traction. They work best on rocky, muddy, or uneven ground. Steel tracks last longer in harsh conditions but can damage paved surfaces and make more noise.

-

Hybrid Tracks: Hybrid tracks combine steel and rubber. They use steel belts for strength and have replaceable rubber pads. This design gives you the toughness of steel and the gentle touch of rubber. Hybrid tracks work well on mixed terrain and help protect delicate surfaces.

Track tread patterns also affect how your excavator undercarriage parts perform. You can choose from straight bar, C-pattern, zig-zag, multi-bar, or block tread. Each pattern suits a different ground type. For example, zig-zag treads grip well in mud, while block treads last longer on paved roads.

|

Track Pattern |

Description & Advantages |

Best Used For |

|---|---|---|

|

Turf |

Smooth, protects grass and irrigation systems |

Landscaping, Parks, Gardens |

|

TDF Super |

Extra rubber, strong grip for wet or rough terrain |

Hills, Mud, Snow, Demolition |

|

Zig-Zag |

Prevents slipping on muddy slopes |

Mud, Clay, Sloped Terrain, Snow |

|

Terrapin |

Durable shell, reduces vibration |

Rocky Terrain, Construction, Landscaping |

|

C-Pattern |

Smooth ride, good traction on many surfaces |

Clay, Mud, Asphalt, Off-road |

|

Staggered Block |

Durable, multi-purpose for hard surfaces |

Asphalt, Concrete, Street Paving |

Track width and track shoes matter, too. Wider tracks spread the weight of your machine, giving you better stability and less ground pressure. Narrow tracks help you move in tight spaces but may wear out faster. Track shoes dig into the ground and pull the excavator forward. The number and shape of grousers (the raised bars on each shoe) affect grip and wear. Triple grousers balance traction and ground protection, making them a popular choice for most jobs. Single or double grousers give more grip on steep slopes but can wear out the undercarriage faster.

Tip: Always match your track shoes and tread pattern to your job site. This helps you get optimal performance and reduces wear on your excavator undercarriage parts.

Rollers, Idlers, Sprockets

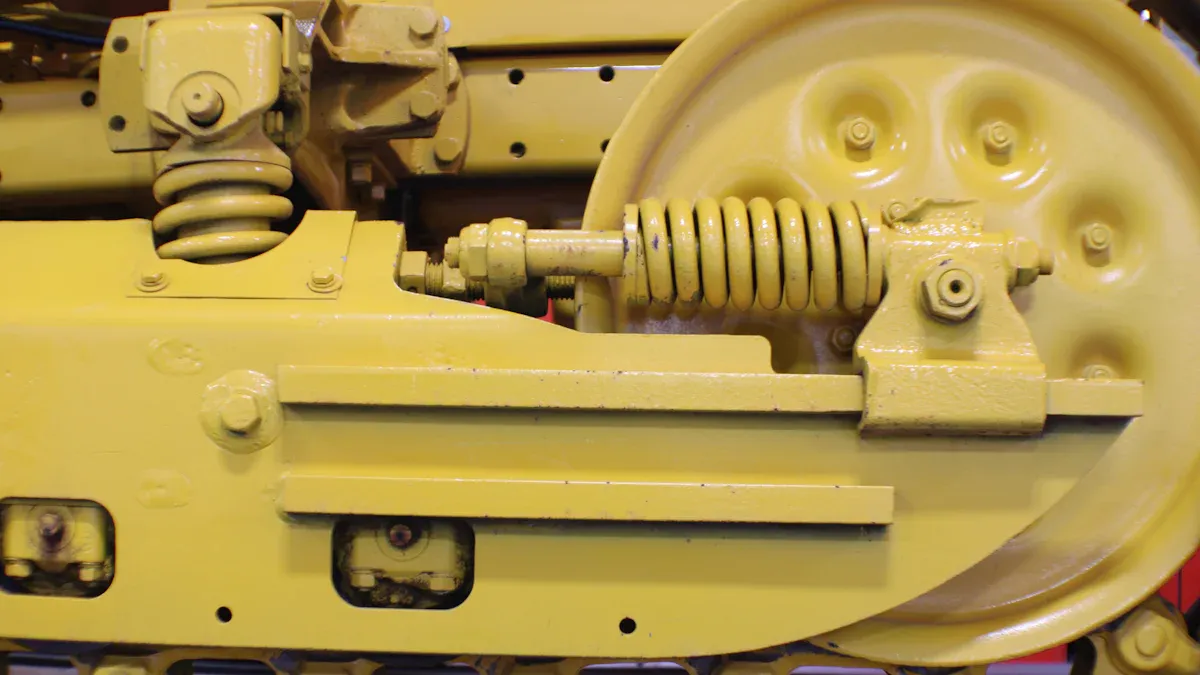

Rollers, idlers, and sprockets are the backbone of your excavator undercarriage parts. Each one supports movement, stability, and optimal performance.

-

Rollers: These metal wheels support your machine’s weight and guide the tracks. Bottom rollers carry the load, while top rollers keep the tracks tight. Rollers also absorb shocks from rough ground, which protects other undercarriage parts and improves operator comfort.

-

Idlers: Idlers are large wheels at the ends of the track frame. They guide the tracks and keep them aligned. Idlers also help maintain the right tension, so your tracks do not slip or derail.

-

Sprockets: Sprockets look like large gears. They engage with the track chains and move the tracks forward or backward. Sprockets must fit well with the track shoes and chains to prevent slipping and ensure smooth power transfer.

Here is a quick overview of the main excavator undercarriage parts and their roles:

-

Excavator Tracks: Move the machine and provide traction.

-

Track Frame: Holds the tracks and connects them to the machine.

-

Track Pad: Reduces noise and vibration, improves grip.

-

Track Chains: Flexible links that allow the tracks to move.

-

Track Shoes: Plates that dig into the ground and pull the excavator.

-

Track Bolts: Hold the track shoes together.

-

Rock Guards: Protect the undercarriage from debris.

-

Sprockets: Drive the tracks by engaging with the chains.

-

Rollers: Guide and support the tracks.

-

Idlers: Keep the tracks aligned and maintain tension.

High-quality excavator undercarriage parts make a big difference. Parts made from high-strength steel alloys resist wear and absorb shocks. Precision machining and heat treatment give you better fit and strength. Sealed and lubricated designs keep out dirt and reduce friction, which extends the life of your rollers, idlers, and sprockets. When you use quality parts, you get more stability, better grip, and less downtime. This means your excavator undercarriage lasts longer and costs less to maintain.

Note: Investing in top-quality excavator undercarriage parts pays off. You get longer service life, fewer breakdowns, and lower total cost of ownership. Always check that your parts match OEM standards for the best results.

Routine checks and proper care help you spot problems early. Look for oil leaks, worn track shoes, or loose bolts. Keep your undercarriage clean and adjust track tension as needed. These steps help you get the most out of your excavator undercarriage parts and keep your machine running strong.

Maintenance & Inspection

Wear & Lifespan

You can make your excavator undercarriage last longer with good care. Most undercarriages work for 4,000 to 6,000 hours if you use them right. If you skip maintenance or work in tough places, they may only last 3,000 hours. If you take care of your machine and use strong parts, it can last over 6,000 hours. Clean the undercarriage every day. Check the track chains for stretching. Change out old parts early. This helps you avoid big repairs and keeps your machine working.

Look for signs that parts are wearing out. These signs are loose or missing bolts, track chains that do not look even, and rollers or idlers that look worn. If you see oil leaking or hear strange sounds, check the undercarriage right away. Finding problems early stops bigger issues and keeps your machine working well.

|

Component |

Inspection Frequency / Guidance |

|---|---|

|

Track Shoes |

Look at them every day; check bolts each week; review monthly |

|

Rollers |

Check often for uneven wear and grease spots |

|

Idlers |

Check often for wear and if they are straight |

|

Track Chains |

Check often for movement and worn pins or bushings |

Maintenance Tips

You can help your machine work better and last longer by following these tips:

-

Clean off dirt and rocks from the undercarriage after every shift.

-

Look at track chains, shoes, rollers, and idlers for damage or uneven wear.

-

Adjust the track tension as the maker says and for your job site.

-

Change out worn parts, like track chains, before they break other things.

-

Do not make sharp turns or spin in place to keep stress off the undercarriage.

-

Dig the right way to protect the drive parts.

-

Write down what you check and fix, and do regular checks.

Tip: Cleaning and checking the undercarriage and track chains every day stops breakdowns and helps save fuel by keeping off extra dirt.

Taking care of your undercarriage helps it last longer and work better. When you do these things, you lower the chance of breakdowns and keep your machine running well. Checking track chains and other parts often helps your machine last and saves you money on repairs.

Upgrading Excavator Undercarriage Parts

New Materials & Tech

In 2026, you have more choices for upgrading excavator undercarriage parts. Makers use new materials that are lighter and stronger. These help your machine last longer and use less fuel. Some materials are recycled or made from plants. This makes your equipment better for the environment and helps parts last longer. Some companies use 3D printing to make custom parts that fit just right.

-

Lighter materials make the engine work less.

-

Stronger metals and composites stop damage from rocks.

-

Eco-friendly tracks made with recycled rubber help you follow rules.

You will also find more smart sensors in undercarriage parts. These sensors watch heat, pressure, and wear as you work. When you upgrade, you get parts that last longer and break less often. This means you spend less on repairs and your machine works longer.

Upgrading excavator undercarriage parts with new materials and technology makes your machine work better, last longer, and cost less to run.

Smart Features

Smart features are now important in undercarriage systems. Sensors and software collect data about your machine every day. You can get alerts on your phone or computer if something is wrong. This helps you fix problems before your machine breaks down.

-

Real-time monitoring helps you find problems early.

-

Predictive maintenance means you fix things only when needed.

-

Automated checklists and digital work orders save time.

These smart systems help you stop surprise breakdowns and keep your machine working. Many people save up to 25% on repairs and make their machines work 30% better. When you upgrade excavator undercarriage parts with smart features, your job site is safer and your business makes more money.

Excavator Undercarriage for Sale & Cost

Purchase Tips

When you shop for an excavator undercarriage for sale, you want to make a smart choice for your machine and wallet. First, check the quality of important parts like track chains, rollers, idlers, sprockets, and track shoes. These parts help your machine move well and last longer. Good undercarriage parts help you avoid breakdowns and save fuel.

Here are some tips to help you pick the right excavator undercarriage for sale:

-

Look at product details, what materials are used, and how the parts are made. Forged parts usually last longer than cast ones.

-

Read reviews from real users and talk to technicians for advice. This helps you know what works best on job sites.

-

Choose suppliers who give good after-sales support, like clear warranty, help with installation, and tips for maintenance.

-

Make sure the undercarriage fits your machine’s make, model, and year.

-

Check used parts for damage, cracks, or leaks. Ask for the part’s history and any maintenance records.

-

Do not just buy the most expensive part. The best excavator undercarriage for sale is the one that fits your job.

Tip: Digital tools like telematics and wear sensors help you watch part health and plan repairs before problems happen.

Total Cost of Ownership

You should think about more than just the price when you buy an excavator undercarriage for sale. The total cost of ownership means how long the parts last, how much care they need, and how easy they are to fix. For example, internal drive sprockets and open undercarriage designs can lower repair costs and help parts last longer. Rubber tracks with strong support help stop derailments, which saves you money and time.

A good warranty protects you from extra repair bills. Some brands, like Caterpillar, give a 12-month warranty and even cover other parts if something fails. This kind of warranty helps you worry less and control costs. Aftermarket parts may have less warranty, so you might take more risk if something breaks.

|

Factor |

Upfront Cost |

Long-Term Value |

|---|---|---|

|

High-Quality Parts |

Higher |

Lower maintenance, longer life |

|

Limited Warranty |

Lower |

Higher risk, more repairs |

|

Digital Monitoring |

Higher |

Fewer breakdowns, better planning |

When you pick the right excavator undercarriage for sale, your machine works better, needs fewer repairs, and is worth more if you sell it. Always think about both the first price and the long-term savings and support.

Picking the right excavator undercarriage means you need to match the track type, width, and shoe size to your machine and the jobsite. Here’s what you should do:

-

Look at the ground and pick tracks that fit your job.

-

Teach operators how to use the machine the right way to stop parts from wearing out fast.

-

Check and take care of your undercarriage often.

New technology, like better materials and smart tools, can help you save money and keep your machine working longer.

Talk to experts or suppliers for advice, help with checking your machine, and service choices that help you get the most out of your money.

FAQ

What is the most important factor when choosing an excavator undercarriage?

You need to pick an undercarriage that matches your machine’s weight and the ground at your job site. This helps your machine stay steady, last longer, and work better.

How often should you inspect your excavator undercarriage?

Check your undercarriage every day. Look for loose bolts, worn parts, or dirt. Finding problems early helps you avoid big repair bills.

Can you use rubber tracks on rocky terrain?

Rubber tracks do not last long on rocks. Steel tracks are better for rocky or rough ground. Rubber tracks are best for soft or paved areas.

How do smart sensors help with undercarriage maintenance?

Smart sensors watch for wear, heat, and pressure. They send alerts to your phone or computer right away. This lets you fix things before your machine breaks down.

Should you buy OEM or aftermarket undercarriage parts?

-

OEM parts fit your machine well and usually last longer.

-

Aftermarket parts can be cheaper but may not be as good.

-

Always read reviews and check warranties before buying.