Valve Plate Description

The YNF16654 Valve Plate for MFC200 SG12 is a critical internal component in axial piston hydraulic pumps, responsible for maintaining controlled fluid transfer and pressure distribution. Made from hardened alloy steel, this valve plate is precision-ground to ensure perfect surface flatness and durability during high-load cycles. Engineered for professional use in excavators and construction equipment, it meets or exceeds OEM standards. This product is a preferred item for B2B customers dealing with pump overhaul services, parts trading, and equipment maintenance fleets. Enhance your hydraulic performance by replacing worn valve plates with YNF’s high-quality solution.

Valve Plate Technical Sheet

| Parameter |

Specification |

| Model |

MFC200 SG12 |

| YNF Part Number |

YNF16654 |

| Part Type |

Valve Plate / Flat Plate |

| Application |

Hydraulic Piston Pump Component |

| Material |

Hardened Alloy Steel |

| Processing |

CNC Machined, Surface Ground |

| Surface Treatment |

Anti-wear, corrosion-resistant coating |

| Compatibility |

MFC200 SG12 hydraulic systems |

| Origin |

China |

| MOQ |

1 Piece |

| Shipment |

By Sea, Air, Express |

| Payment Terms |

T/T, Western Union, L/C |

Valve Plate Applications

| Sector |

Application Usage |

| Hydraulic Repair Shops |

Pump rebuilding and internal wear component swap |

| Excavator Maintenance |

Pressure control and fluid redirection systems |

| Spare Parts Distributors |

Stock for construction equipment pump service |

| Heavy Machinery OEM |

Internal use in pump assemblies and reman units |

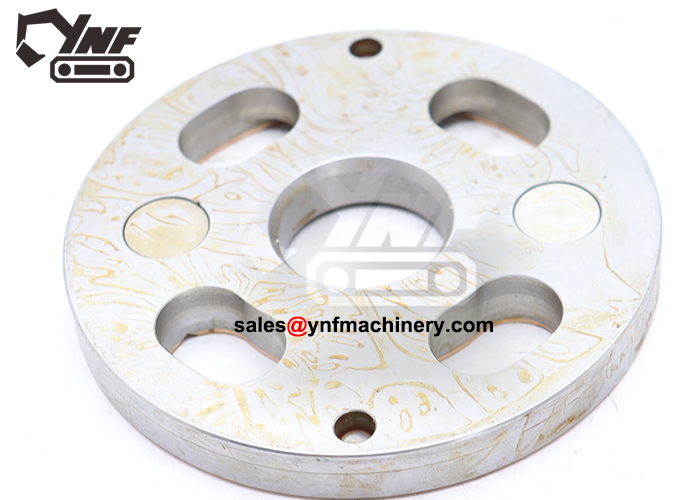

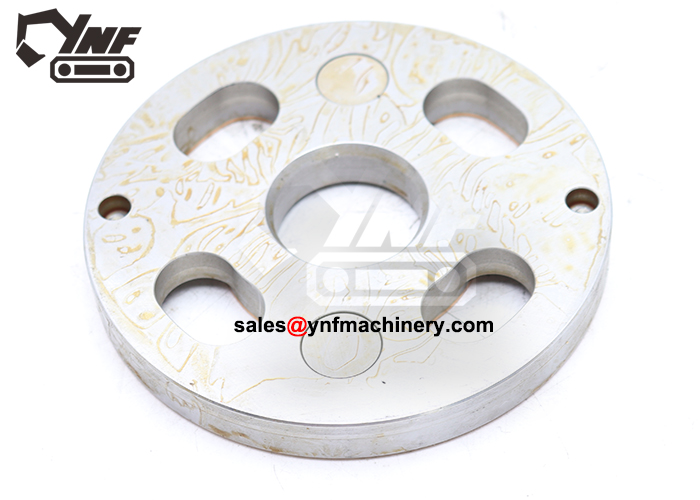

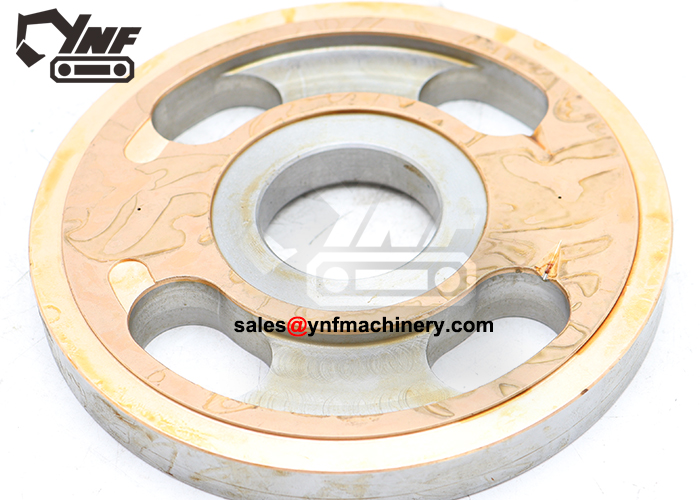

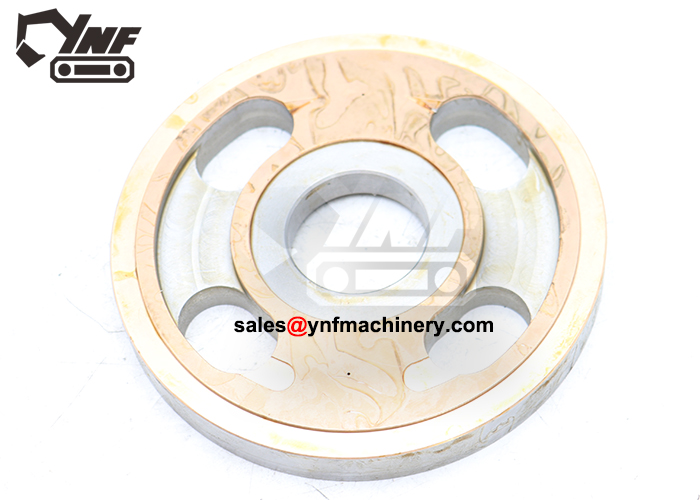

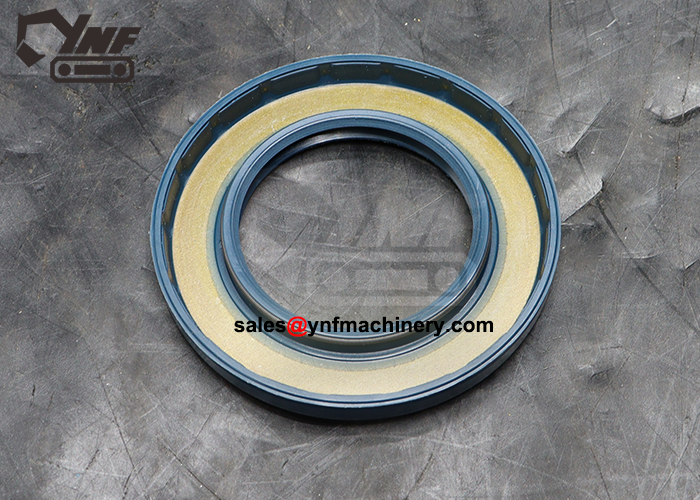

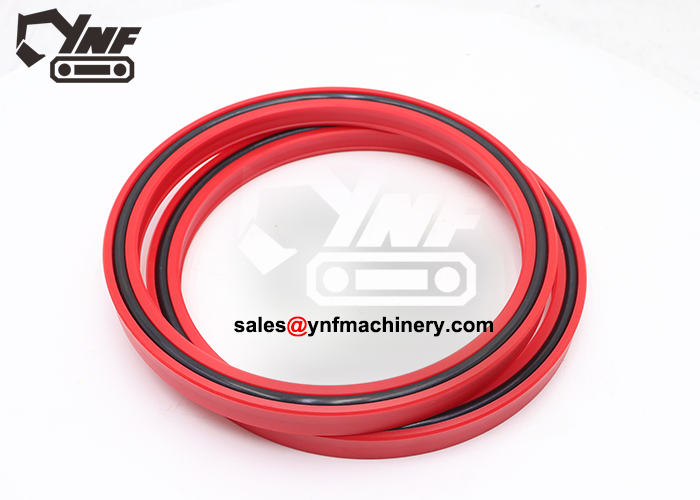

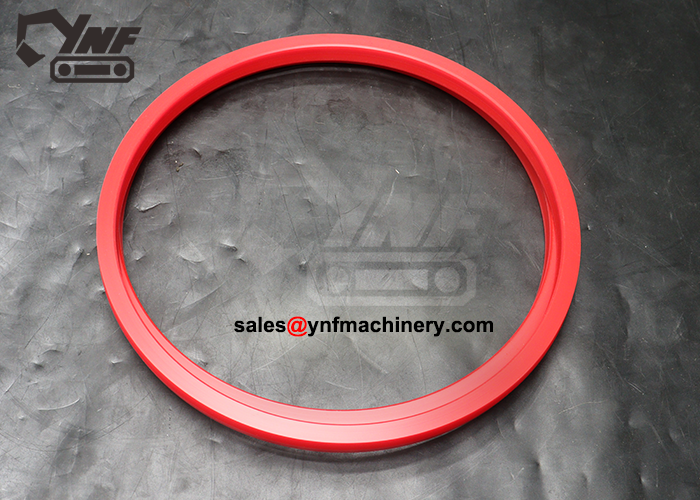

MFC200 SG12 Valve Plate Detail Display

FAQs

-

Q: Is this valve plate a direct replacement for the OEM MFC200 SG12 plate?

A: Yes, it matches OEM specifications for size, material, and machining.

-

Q: How is the durability in high-load applications?

A: It’s manufactured from hardened steel and tested under full-load simulations.

Related Products

-

MFC200 piston pump cylinder block

-

Valve plate for MFC135 SG09 hydraulic pump

-

Hydraulic piston pump repair kits

Industry Knowledge

Valve plates are one of the first wear points in piston pump assemblies. Replacing them proactively prevents cavitation damage and improves fluid efficiency—critical for contractors and fleet operators aiming for uptime reliability.