Excavator Solenoid Valves

Excavator solenoid valves are important parts of the hydraulic system. They work like switches, managing how hydraulic fluid moves in the machine. This helps the excavator dig or lift things accurately. The valves respond to electric signals to control movements smoothly. This makes the machine work better and use less energy.

How Excavator Solenoid Valves Work

Working Principle of Solenoid Valves

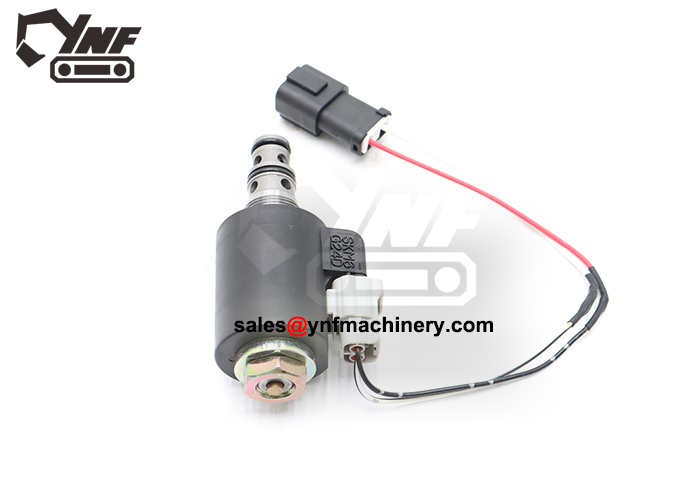

A solenoid valve works like a switch to control fluid flow. It uses electricity and magnetism to function. Here’s how it works step by step:

- Electricity flows through the solenoid coil, creating a magnetic field.

- The magnetic field pulls a part inside the valve called the plunger.

- The plunger moves to open or close the valve, controlling fluid flow.

- When the electricity stops, the magnetic field disappears, and a spring pushes the plunger back.

Each part of the valve has an important job. The solenoid coil makes the magnetic force, and the spring resets the valve when the electricity stops. This system helps the valve control fluid flow effectively.

Role of Electromagnetic Force in Hydraulic Systems

Electromagnetic force powers solenoid valves. When electricity energizes the solenoid coil, it creates this force. The force moves the plunger to open or close the valve, controlling fluid flow.

In hydraulic systems, this force allows quick and accurate actions. For example, when you move a lever in an excavator, the valve reacts fast. It sends fluid to the right part, helping the machine work smoothly. Whether lifting heavy loads or doing precise tasks, the valve responds instantly.

Electromagnetic force also saves energy. The valve only works when needed, reducing energy waste. This makes the excavator more efficient.

Integration in Excavator Hydraulic Systems

Solenoid valves are part of an excavator’s hydraulic system. They connect electrical controls to hydraulic parts. When you use the excavator, signals from the control panel activate the valves. The valves then send fluid to parts like the boom, arm, or bucket.

This setup has many advantages:

- Energy Efficiency: Valves save energy by letting fluid flow only when needed.

- Control Flexibility: They help manage fluid flow rates for better performance.

- Fast Response: Quick actions make the hydraulic system work efficiently.

For example, modern excavators use digital systems with solenoid valves for precise control. These valves make switching between tasks smooth, whether digging or lifting. Their role shows how important they are for accuracy and efficiency.

Types of Excavator Solenoid Valves

Excavators use two main solenoid valve types: direct acting and indirect acting. Direct acting valves work without needing extra pressure. When powered, the solenoid coil moves the plunger to open or close the valve. These valves are great for low-pressure systems or when fast actions are needed.

Indirect acting valves use system pressure to help them work. The solenoid coil activates a small pilot mechanism, which then controls the main valve. These valves handle higher pressures and larger fluid flows, making them perfect for heavy-duty tasks. Picking the right valve depends on your excavator’s hydraulic needs.

Direct Acting vs. Indirect Acting Solenoid Valves

Solenoid valves also differ in how they work when not powered. Normally open valves let fluid flow when turned off. These are used in systems needing constant flow unless stopped by electricity. For example, auxiliary systems often use normally open valves.

Normally closed valves stop fluid flow when turned off. These are common in excavators because they give better control. When powered, they open to send fluid to parts like the boom or bucket. This design helps with precise and efficient operations.

Normally Open vs. Normally Closed Solenoid Valves

Excavators use solenoid valves for many jobs. Direct acting valves are good for smaller hydraulic parts. Indirect acting valves handle high-pressure systems for heavy lifting. Normally open valves are best for secondary systems needing constant fluid flow. Normally closed valves are used for precise tasks like moving buckets or blades.

Other machines like bulldozers and cranes also use solenoid valves. Bulldozers use them to adjust blades accurately. Cranes rely on them for smooth load handling. These examples show how useful solenoid valves are in hydraulic systems.

Applications of Different Types in Excavators

Excavator Solenoid Valves Sorted by Brands

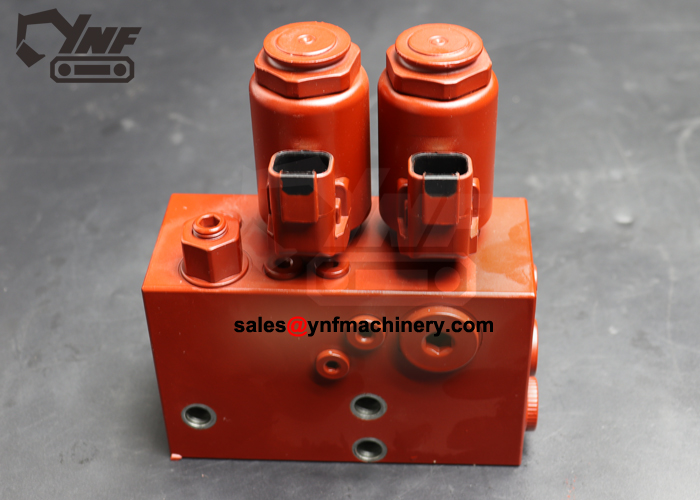

YNF01411

121-1491 Soleoid Valve KWE5K-31G24DA30

YNF01562

4I5674 4I-5674

YNF01854 YNF13063

111-9916 225-4558 for Caterpillar E320BCD E325B

YNF02644

121-1490

YNF15952

349295A1 Solenoid Valve

YNF01358 YNF02294

4288337 EX100-3 EX200-2 EX200-3

YNF01359

PC Valve 4288336

YNF01596

9101532 9102068 Differential Pressure Sensor DP Sensor

YNF01863

4254647 9218370 4299959 Valve 4254647 9218370 4299959 AT158394 AT154742

YNF02352

XJBN-00382

YNF02660

K3V112 HD700-7 HD800-7

YNF02661

K3V112 HD800-7

YNF00187

YN35V00048F1 KDREDE5K-31-40C50-213-0213

YNF00592

SK-6E YB35V00006F1 KWE5K-31G24YA50-303 SK-8 YN35V00051F1 KWE5K-31G24YB50

YNF00822

YN35V00021F1 KWE5K-30G24YA40

YNF01567

KAWASAKI PUMP SK200-2

YNF00893

SD1244-C-1005 203-60-62171 PC100 PC120 203-60-62161 203-60-62170 4D95

YNF01926

YNF01926 702-21-55901 702-21-57400 702-21-55600 702-21-5680

YNF01927

Hydraulic Polit Valve Solenoid 702-21-57500

YNF01949

561-15-47210 17A-15-17271

KDRDE5K-20-40C04-109

YNF00242

VALVE FOR KIT LZP0179 SKC5P-14A-104 4302

YNF02869

LL001140 SH210-5 SH200-5

YNF03798

KDRDE5K-20 40C13 LJ00684 Valve

YNF03584

SV09-T3917S-V 24V

YNF15292

PVD-15B-32BCP Solenoid Valve Set

YNF15759

HLPPRV06A 24V valve genuine

YNF15844

SD1233-C-1001 Valve Solenoid 24V

Key Specifications of Hydraulic Solenoid Valves

Flow Rate and Response Time

Flow rate and response time are key for smooth operation. Most hydraulic solenoid valves move 4.5 to 6 gallons per minute (17 to 22.7 liters per minute). This keeps fluid flowing steadily in the system.

Response time shows how fast the valve reacts to signals. Most valves respond in 50 to 100 milliseconds. This quick reaction helps the excavator do tasks like digging or lifting without delay.

When choosing a valve, look at flow rate and response time. These features affect how well the valve supports your excavator. A valve with the right flow rate and fast response ensures smooth and efficient operation.

Voltage and Compatibility

Hydraulic solenoid valves need specific voltage to work well. They usually require at least 85% of their rated voltage at 72°F (20°C). Matching the valve’s voltage with your excavator’s system is very important. If the voltage doesn’t match, the valve might not work or could get damaged.

Always check the valve’s voltage rating before buying it. This ensures it fits your system properly. For example, if your excavator uses a 24V system, pick a valve made for 24V. Correct voltage matching improves how the valve works and makes it last longer.

Pressure Range and Performance

Hydraulic solenoid valves are built to handle certain pressure levels. Most can manage up to 3600 PSI (250 BAR). This lets them work well in tough conditions. The pressure range affects how well the valve controls fluid flow.

Valves are tested to ensure they work under pressure. For example, industrial valves go through strength and sealing tests to prevent leaks. These tests make sure the valve works reliably, even in hard situations. Choose a valve that matches your system’s pressure needs to avoid problems.

| Valve Type | Testing Method Description |

|---|---|

| Industrial Valves | Strength tests happen after repairs; sealing tests are done before use. |

| Globe/Throttle | Valves are tested on racks; fluid is added to check for leaks. |

| Gate | Sealing tests increase pressure to find leaks at seals. |

| Ball | Tightness tests check for leaks at packing and gaskets when half-open. |

Temperature and Environmental Tolerance

Hydraulic solenoid valves need to work well in all conditions. Temperature and environment can change how they perform. When picking a valve, think about its ability to handle heat, cold, and tough surroundings.

Temperature Range

Most solenoid valves work between -4°F (-20°C) and 176°F (80°C). Some advanced models can handle even more extreme temperatures.

Tip: If your excavator works in very hot or cold places, choose valves with wider temperature ranges. This helps them work smoothly in harsh weather.

Environmental Challenges

Excavators often face dirt, dust, and water. These can harm hydraulic parts. Valves with good seals block out harmful materials. This keeps them working longer.

Look for these features:

- Water Resistance: IP65-rated valves or higher can handle water exposure.

- Dust Protection: Sealed valves stop dirt from getting inside.

- Corrosion Resistance: Stainless steel or brass prevents rusting.

Choosing the Right Valve

Match the valve to your excavator’s environment. For example, near saltwater, use anti-corrosion valves. In dusty areas, pick valves with strong seals.

| Condition | Recommended Feature |

|---|---|

| Extreme Cold | Handles very low temperatures |

| High Heat | Made with heat-resistant parts |

| Wet Environments | Water-resistant design |

| Dusty Areas | Strong sealing to block dirt |

Choosing the right valve for the conditions ensures it works well and lasts longer.

Material and Build Quality of Solenoid Valves

Common Housing Materials

The material used for a solenoid valve’s housing is very important. It affects how strong and long-lasting the valve is. Different materials work better for different jobs. For example, stainless steel resists chemicals and lasts a long time. This makes it great for tough tasks. Brass is strong and handles high heat well. PVC is good for areas with corrosive substances like seawater.

| Material | Advantages | Disadvantages |

|---|---|---|

| PVC | Works well with seawater, acids, and bases. | Cannot handle some hydrocarbons. Lower pressure limits than brass. |

| Brass | Strong, durable, and handles high heat. | Not good for salt water, acids, or chlorides. |

| Nickel-plated brass | Better resistance to heat, pressure, and wear. | Scratches can cause rust. |

| Stainless steel | Resists chemicals and wears out slowly. | Not good with hydrochloric acids or chlorides. |

| Nylon | Light and resists many chemicals. | Handles less heat and pressure compared to metals. |

When picking a solenoid valve, match the material to your system. This helps it work better and last longer.

Importance of Sealing Materials

Seals in solenoid valves stop leaks and keep dirt out. Good seals help the valve work well, even in tough conditions.

Common seal materials include rubber, silicone, and PTFE (Teflon). Rubber is flexible and works in normal heat. Silicone handles higher temperatures. PTFE resists chemicals very well. Pick the right seal based on your system’s heat, pressure, and fluid type.

Tip: Check seals often to avoid leaks and make them last longer.

Resistance to Wear and Corrosion

Solenoid valves can wear out or rust because of fluids and the environment. To make them last, companies test them in different ways. These tests check how well the valves resist damage and rust.

| Testing Method | Description |

|---|---|

| Environmental Testing | Tests how valves handle extreme heat and humidity. |

| Salt Spray Testing | Checks how coatings protect against rust. |

| Vibration Testing | Tests if valves can handle shaking and still work well. |

| Metallographic Testing | Looks at material quality and coatings to ensure strength. |

| Tribology Testing | Measures wear on valve parts and changes in surface texture. |

Choose valves with materials that resist rust and wear. Stainless steel and nickel-plated brass are great for tough conditions. These features keep the valve working well for a long time.

Hydraulic Solenoid Valve Selection Criteria

Picking the Right Valve for Your Excavator

To choose the best hydraulic solenoid valve, start by knowing your excavator’s needs. Excavators come in different sizes and have unique hydraulic systems. Smaller excavators may need small valves with low pressure limits. Bigger machines need strong valves for high-pressure tasks.

Check if the valve matches your excavator’s hydraulic control system. This ensures everything works smoothly. For example, if your excavator uses a 24V system, pick a valve made for 24V. Using the wrong valve can cause problems or damage the system.

Modern excavators often use smart technology like IoT. Smart valves let you track performance in real time. This helps keep the machine efficient and reduces downtime. Choosing the right valve for your excavator improves performance and makes the system last longer.

Hydraulic solenoid valves must work well in tough conditions. These include extreme temperatures, pressure changes, and exposure to dirt or water. Pick a valve that can handle these challenges.

- Temperature Range: Valves should work in both hot and cold weather. For example, a valve that works from -4°F to 176°F performs well in any climate.

- Pressure Strength: High-pressure systems need valves tested for strength. Many industrial valves can handle up to 3600 PSI, perfect for heavy-duty jobs.

- Environmental Protection: Sealed valves block dust and water, making them last longer in harsh places.

The tasks your excavator does also affect valve choice. Quick response times are important for precise jobs like digging or lifting. Most solenoid valves react in milliseconds, making them great for fast and accurate work. They also save energy, using less power than other valve types.

Tip: Always pick a valve that meets or beats your system’s needs. This keeps your excavator reliable and avoids breakdowns.

Handling Tough Conditions and Performance Needs

Trustworthy Brands and Certifications

The brand of the valve matters a lot. Good brands focus on quality and follow industry rules. This ensures their hydraulic solenoid valves work well. Look for brands with a history of making strong and efficient valves.

Certifications show the manufacturer cares about quality. For example, ISO certifications mean the valves meet global safety and performance standards. Companies that offer help with installation and repairs add extra value.

Studies show over 70% of buyers choose valves based on durability. Brands with eco-friendly practices and smart tech stand out in the market. By picking a trusted brand, you get high-quality valves and good customer support, improving your excavator’s performance.

| Selection Factor | Key Insights |

|---|---|

| Durability | Over 70% of buyers value durability when choosing valves. |

| Eco-Friendly Practices | Companies with green sourcing are more competitive. |

| Smart Technology | Buyers prefer valves with IoT features for real-time tracking. |

| Price vs. Value | About 65% of buyers compare price with the valve’s benefits. |

| Customer Support | Good after-sales service builds trust and loyalty. |

By considering these points, you can pick a hydraulic solenoid valve that fits your excavator perfectly.

Maintenance and Troubleshooting of Solenoid Valves

Inspection and Cleaning Procedures

Regular checks and cleaning keep your solenoid valve working well. Look for dirt, rust, or damage on the valve. Focus on seals and housing, as they collect debris. Use a soft brush or air to clean the outside. For inside cleaning, disconnect the valve and flush it with a safe cleaner. Always follow the maker’s instructions to avoid damage.

Tip: Check valves every three months in dusty or wet areas. This stops dirt buildup that can hurt performance.

Preventive checks are also important. Experts suggest testing air-operated valves often to catch problems early. Field tests and planning fixes can save time and cut repair costs.

Addressing Common Issues

Solenoid valves may have problems during use. Fixing these quickly keeps your excavator running well:

- Overheating: Look for blockages or low voltage, which often cause this.

- Shorting: Check for water-based coolants causing short circuits. Replace bad wires fast.

- High Voltages: Watch voltage levels to avoid rare burnouts.

- Mechanical Damage: Find out what caused the damage before replacing the valve.

A Gartner Group study found 50% of plant repairs were unneeded. Predictive maintenance helps find which valves need fixing, saving time and money.

Replacing Worn-Out Components

Replace worn parts quickly to stop more damage. Find the problem part, like the plunger, seals, or coil. Use only parts that match the valve to keep it working well. Follow these steps to replace parts:

- Disconnect the valve from the system.

- Carefully remove the broken part.

- Put in the new part securely.

- Test the valve to ensure it works before reconnecting.

Note: If unsure, check the manual or ask a technician for help.

Switching to predictive maintenance improves efficiency. Services like Vinson’s Valve Diagnostic Services or Proconex give detailed reports and plans, helping avoid extra repairs.

Tips for Making Valves Last Longer

Taking care of your solenoid valves helps them work better and last longer. Follow these simple tips to keep them in good shape:

1. Check and Clean Regularly

Look at your valves often to find problems early. Watch for dirt, leaks, or worn-out parts. Use a soft brush or air to clean the outside. Regular care stops small issues from becoming big repairs.

Tip: If your excavator works in dusty or wet places, check every three months.

2. Use the Right Fluids

Always pick hydraulic fluids recommended by the valve maker. Wrong fluids can harm seals and parts inside. Check the fluid type before adding it to your system.

3. Don’t Overwork the Valves

Keep valves within their pressure and temperature limits. Overworking them can cause overheating or damage. Watch system settings to avoid going over these limits.

4. Replace Broken Parts Quickly

Change worn seals, coils, or plungers as soon as you see damage. Waiting too long can break the valve and cause delays. Use original parts to keep everything working well.

5. Protect from Dirt and Water

Keep valves safe from dirt, water, and harmful chemicals. Pick valves with strong seals or made from materials like stainless steel or brass.

| Condition | How to Protect |

|---|---|

| Wet Areas | Pick water-resistant valves |

| Dusty Locations | Use valves with sealed designs |

| Corrosive Fluids | Choose corrosion-proof materials |

6. Check Voltage Levels

Make sure your excavator gives the right voltage to the valves. Low or changing voltage can hurt the solenoid coil and lower performance.

Alert: If your valve needs 24V, check the power supply matches.

By following these steps, your solenoid valves will last longer and work better. Taking care of them saves money and keeps your excavator running smoothly.

Applications of Solenoid Valves in Excavators

Controlling Hydraulic Cylinders and Actuators

Solenoid valves help control hydraulic cylinders and actuators in excavators. They act like switches, guiding fluid to move parts like the boom, arm, and bucket. When you use the excavator, the valve sends fluid to the right cylinder for smooth motion.

- They lift and lower the boom.

- They extend and retract the arm.

- They tilt the bucket for digging or dumping.

This control makes tasks easier, like lifting heavy loads or digging trenches. Solenoid valves ensure movements are accurate and save energy.

Use in Auxiliary Systems

Solenoid valves are also important for auxiliary systems. These systems handle extra tasks that support the excavator’s main work. For example, they control tools like breakers, grapples, or augers. The valves send the right amount of fluid to these tools for smooth operation.

Auxiliary systems often use normally open valves to keep fluid flowing. This setup helps attachments work without stopping. Adding solenoid valves to auxiliary systems makes the excavator more versatile for different jobs.

Precision Tasks in Excavator Operations

Solenoid valves are great for precise tasks needing accuracy and quick response. They are perfect for jobs requiring fine control. For example, when scooping or dumping material, solenoid valves make movements exact.

| Metric | Value |

|---|---|

| Opening Time | 21 ms |

| Closing Time | 12 ms |

| Maximum Flow Rate | 225 L/min |

| Driving Power | < 1.2 W |

| Positioning Accuracy | ± 0.15 mm |

These numbers show how solenoid valves improve precision. They respond fast and position accurately, reducing mistakes. Whether on a construction site or in mining, solenoid valves help your excavator work its best.

Excavator solenoid valves help hydraulic systems work smoothly. They allow accurate control, helping the excavator do jobs well and quickly. Picking the right valve and taking care of it often can stop expensive repairs and make it last longer.

Solenoid valve technology is improving fast. New trends like smarter designs and easier setups make valves better and more useful. Green materials and energy-saving features are also becoming popular, supporting global eco-friendly goals. Choosing good solenoid valves boosts your excavator’s performance and supports a cleaner, smarter future.

FAQ

A solenoid valve controls how hydraulic fluid moves. It works like a switch, sending fluid to parts like the boom or bucket. This helps the excavator move accurately and work efficiently.

Watch for slow actions, leaks, or strange sounds. If the valve can’t control fluid flow well, it’s time to change it.

Yes, most solenoid valves work from -4°F (-20°C) to 176°F (80°C). For tougher conditions, pick valves made for extreme temperatures.

Check them every three months if your excavator works in dusty or wet areas. Regular checks stop dirt buildup and keep them working well.

No, not all valves work with every machine. Make sure the valve’s voltage, pressure, and material match your excavator’s hydraulic system.